Dtc P0717 Turbine Speed Sensor Circuit No Signal

DESCRIPTION

MONITOR DESCRIPTION

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

WIRING DIAGRAM

INSPECTION PROCEDURE

INSPECT SPEED SENSOR INSTALLATION

INSPECT SPEED SENSOR (NT)

CHECK HARNESS AND CONNECTOR (SPEED SENSOR - ECM)

DTC P0717 Turbine Speed Sensor Circuit No Signal |

DESCRIPTION

This sensor detects the rotation speed of the input turbine. By comparing the input turbine speed signal (NT) with the output shaft speed, the ECM detects the shift timing of the gears and appropriately controls the engine torque and hydraulic pressure according to various conditions. Thus, providing smooth gear shift.DTC No.

| DTC Detection Condition

| Trouble Area

|

P0717

| ECM detects conditions (a), (b) and (c) continuously for 5 sec. or more: (1-trip detection logic)

(a) Vehicle speed: 50 km/h (31 mph) or more

(b) Park/neutral position switch (STAR, R and L) is OFF

(c) Speed sensor (NT): less than 300 rpm

| - Open or short in transmission revolution sensor NT (speed sensor NT) circuit

- Transmission revolution sensor NT (speed sensor NT)

- ECM

- Automatic transaxle assembly

|

MONITOR DESCRIPTION

The input speed sensor detects the transmission input shaft speed. The ECM determines the gear shift timing based on a comparison of the input speed sensor (input shaft speed) with the output speed sensor (output shaft speed).When the output shaft speed is higher than the expected value and the input shaft speed is 300 rpm or less while running with the shift in the D position, the ECM will conclude that there is malfunction of the input turbine speed sensor (NT). The ECM will illuminate the MIL.

MONITOR STRATEGY

Related DTCs

| P0717: Turbine speed sensor/Verify pulse input

|

Required sensors/Components

| Transmission revolution sensor (Speed sensor (NT))

|

Frequency of operation

| Continuous

|

Duration

| 5 seconds

|

MIL operation

| Immediate

|

Sequence of operation

| None

|

TYPICAL ENABLING CONDITIONS

The monitor runs whenever the following DTCs are not present.

| P0500 (VSS)

P0748 - P0798 (Trans solenoid (range))

|

Shift change

| After shift change is completed and before starting next shift change operation

|

ECM selected gear

| 2nd, 3rd or 4th

|

Output shaft revolution

| 1000 rpm or more

|

Park/neutral position switch

| OFF

|

R switch

| OFF

|

L switch

| OFF

|

Transmission range switch fail

| Not detected

|

Battery voltage

| 8 V or more

|

Ignition switch

| ON

|

Starter

| OFF

|

Engine

| Running

|

TYPICAL MALFUNCTION THRESHOLDS

Turbine speed sensor revolution

(Speed sensor (NT))

| Less than 300 rpm

|

COMPONENT OPERATING RANGE

Transmission revolution sensor (speed sensor (NT))

| Input turbine speed is equal to engine speed when lock-up ON

|

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Perform the universal trip to clear permanent DTCs (COROLLA_ZRE142 RM000000W770S5X.html).

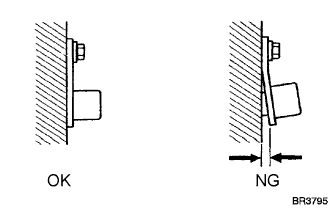

| 1.INSPECT SPEED SENSOR INSTALLATION |

Check the speed sensor installation.

- OK:

- The installation bolt is tightened properly and there is no clearance between the sensor and transaxle case.

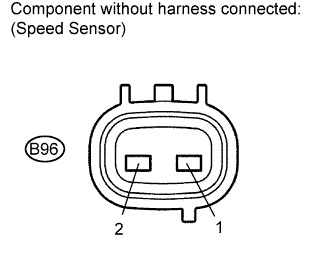

| 2.INSPECT SPEED SENSOR (NT) |

Disconnect the speed sensor connector from the transaxle.

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

1 - 2

| 20°C (68°F)

| 560 to 680 Ω

|

| 3.CHECK HARNESS AND CONNECTOR (SPEED SENSOR - ECM) |

Connect the speed sensor connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

B31-122 (NT+) - B31-100 (NT-)

| 20°C (68°F)

| 560 to 680 Ω

|

Measure the resistance according to the value(s) in the table below.

- Standard resistance (Check for short):

Tester Connection

| Condition

| Specified Condition

|

B31-122 (NT+) - Body ground

| Always

| 10 kΩ or higher

|

B31-100 (NT-) - Body ground

| Always

| ↑

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|