DESCRIPTION

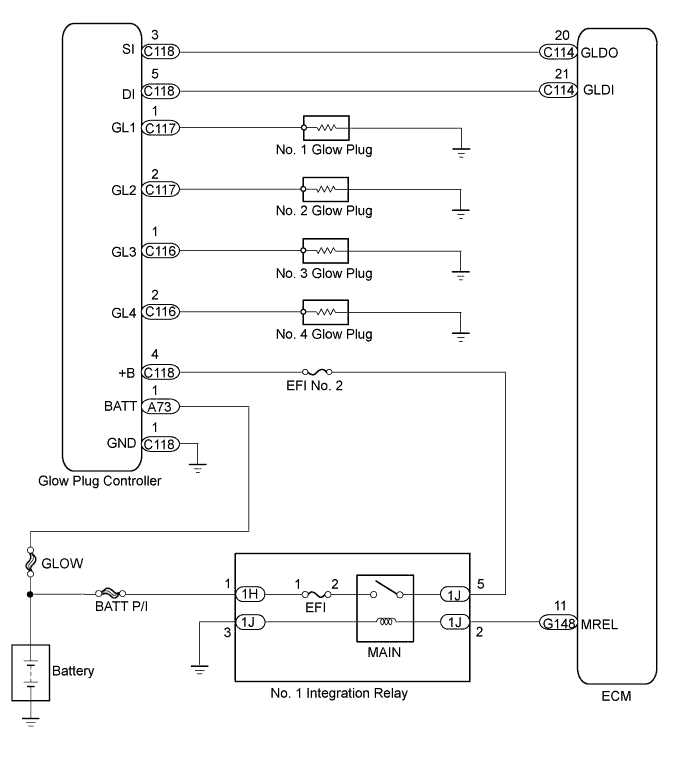

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK DTC OUTPUT

CHECK GLOW PLUG CONTROLLER (POWER SOURCE CIRCUIT)

CHECK HARNESS AND CONNECTOR (GLOW PLUG CONTROLLER - BODY GROUND)

CHECK HARNESS AND CONNECTOR (GLOW PLUG CONTROLLER - ECM)

CHECK HARNESS AND CONNECTOR (GLOW PLUG CONTROLLER - NO. 1 INTEGRATION RELAY)

CHECK CHARGING SYSTEM

REPAIR OR REPLACE HARNESS OR CONNECTOR

REPLACE GLOW PLUG CONTROLLER

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

REPLACE ECM

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

REPLACE GLOW PLUG CONTROLLER

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

DTC P052F Glow Plug Control Module System Voltage |

DTC P0683 Glow Plug Control Module to PCM Communication Circuit |

DESCRIPTION

The glow system consists of the glow plug controller, glow plugs and ECM. The glow plug controller turns on the glow plug of each cylinder according to the duty command signal from the ECM in order to maintain optimal engine temperatures. The glow plugs can be controlled according to the engine coolant temperature at engine start by using duty signals. This helps induce ignition under low temperatures and prevent rough idle after starting the engine.The glow plugs are turned on during PM forced regeneration in order to prevent the engine speed from rising due to an increase in fuel injection volume used to increase the exhaust gas temperature. The glow plug controller contains a self-diagnosis function. When the glow plug controller detects an internal malfunction, it sends a signal indicating the malfunction to the ECM. When the ECM receives this signal, it illuminates the MIL and stores a DTC.P052FDTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

Enter check mode

| The glow plug controller recognizes the battery voltage as being 18.4 V or higher 3 times or more when the glow plugs are on (2 trip detection logic).

| Glow plug controller

|

P0683DTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

Enter check mode

| When the glow plugs are on, the ECM detects that there is no output from the glow plug control unit for 3 seconds even though the ECM outputs an SI signal ("ON" command signal) (1 trip detection logic).

| - Open or short circuit in ground wire

- Open or short circuit in battery wire

- Open in SI wire

- SI wire short circuit to ground or battery

- Open in DI wire

- DI wire short circuit to ground or battery

- Low battery voltage

- Glow plug controller

- ECM

|

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses of circuits related to this system before performing the following inspection procedure.

- After replacing the ECM, the new ECM needs registration (HILUX_TGN26 RM0000012XK070X.html) and initialization (HILUX_TGN26 RM000000TIN057X.html).

- After replacing the fuel supply pump assembly, the ECM needs initialization (HILUX_TGN26 RM000000TIN057X.html).

- After replacing an injector assembly, the ECM needs registration (HILUX_TGN26 RM0000012XK070X.html).

- HINT:

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON and turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTCs.

ResultResult

| Proceed to

|

P0683 is output

| A

|

P052F is output

| B

|

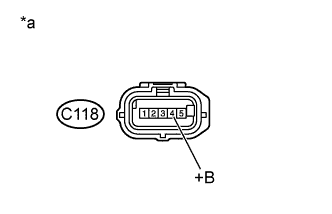

| 2.CHECK GLOW PLUG CONTROLLER (POWER SOURCE CIRCUIT) |

Disconnect the glow plug controller connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

C118-4 (+B) - Body ground

| Ignition switch ON

| 11 to 14 V

|

C118-4 (+B) - Body ground

| Ignition switch off

| Below 0.5 V

|

Text in Illustration*a

| Front view of wire harness connector

(to Glow Plug Controller)

|

Reconnect the glow plug controller connector.

| 3.CHECK HARNESS AND CONNECTOR (GLOW PLUG CONTROLLER - BODY GROUND) |

Disconnect the glow plug controller connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

C118-1 (GND) - Body ground

| Always

| Below 1 Ω

|

Reconnect the glow plug controller connector.

| 4.CHECK HARNESS AND CONNECTOR (GLOW PLUG CONTROLLER - ECM) |

Disconnect the glow plug controller connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

C118-3 (SI) - C114-20 (GLDO)

| Always

| Below 1 Ω

|

C118-5 (DI) - C114-21 (GLDI)

| Always

| Below 1 Ω

|

C118-3 (SI) or C114-20 (GLDO) - Body ground

| Always

| 10 kΩ or higher

|

C118-5 (DI) or C114-21 (GLDI) - Body ground

| Always

| 10 kΩ or higher

|

Reconnect the glow plug controller connector.

Reconnect the ECM connector.

| 5.CHECK HARNESS AND CONNECTOR (GLOW PLUG CONTROLLER - NO. 1 INTEGRATION RELAY) |

Disconnect the glow plug controller connector.

Remove the No. 1 integration relay from the engine room relay block and junction block assembly.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

C118-4 (+B) - 1J-5

| Always

| Below 1 Ω

|

C118-4 (+B) or 1J-5 - Body ground

| Always

| 10 kΩ or higher

|

Reconnect the glow plug controller connector.

Reinstall the No. 1 integration relay

Check the charging system and perform repairs as necessary (HILUX_TGN26 RM0000013Y001IX.html).

| 7.REPAIR OR REPLACE HARNESS OR CONNECTOR |

Repair or replace the harness or connector.

| 8.REPLACE GLOW PLUG CONTROLLER |

Replace the glow plug controller (HILUX_TGN26 RM000000JIT00UX.html).

| 9.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Connect the intelligent tester to the DLC3.

Clear the DTCs (HILUX_TGN26 RM000000PDK11ZX.html).

Turn the ignition switch off for 30 seconds or more.

Turn the ignition switch to ON.

Turn the tester on.

Using the intelligent tester, switch the ECM from normal mode to check mode (HILUX_TGN26 RM000000PDL0O2X.html).

Confirm that the DTC is not output again.

- HINT:

- Check for DTCs in check mode.

Replace the ECM (HILUX_TGN26 RM0000013Z001HX.html).

| 11.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Connect the intelligent tester to the DLC3.

Clear the DTCs (HILUX_TGN26 RM000000PDK11ZX.html).

Turn the ignition switch off for 30 seconds or more.

Turn the ignition switch to ON.

Turn the tester on.

Using the intelligent tester, switch the ECM from normal mode to check mode (HILUX_TGN26 RM000000PDL0O2X.html).

Confirm that the DTC is not output again.

- HINT:

- Check for DTCs in check mode.

| 12.REPLACE GLOW PLUG CONTROLLER |

Replace the glow plug controller (HILUX_TGN26 RM000004LIW00IX.html)

| 13.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Connect the intelligent tester to the DLC3.

Clear the DTCs (HILUX_TGN26 RM000000PDK11ZX.html).

Turn the ignition switch off for 30 seconds or more.

Turn the ignition switch to ON.

Turn the tester on.

Using the intelligent tester, switch the ECM from normal mode to check mode (HILUX_TGN26 RM000000PDL0O2X.html).

Confirm that the DTC is not output again.

- HINT:

- Check for DTCs in check mode.