Entry And Start System Room Oscillator Does Not Recognize Key

DESCRIPTION

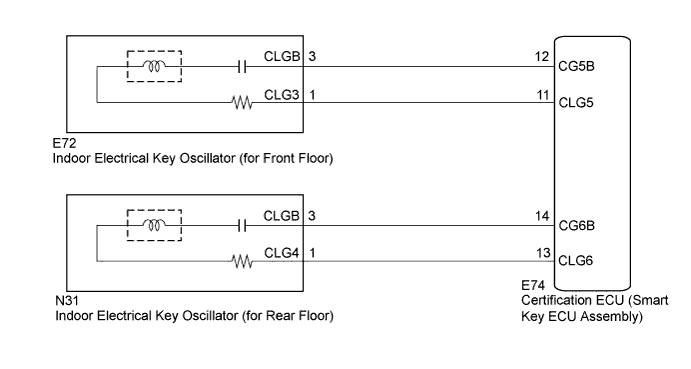

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK ENTRY AND START SYSTEM (ENTRY FUNCTION)

CHECK ENTRY AND START SYSTEM (START FUNCTION)

CHECK WAVE ENVIRONMENT

PERFORM KEY DIAGNOSTIC MODE INSPECTION

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU - INDOOR ELECTRICAL KEY OSCILLATOR)

INSPECT INDOOR ELECTRICAL KEY OSCILLATOR (for Front Floor)

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU - INDOOR ELECTRICAL KEY OSCILLATOR)

INSPECT INDOOR ELECTRICAL KEY OSCILLATOR (for Rear Floor)

ENTRY AND START SYSTEM - Room Oscillator does not Recognize Key |

DESCRIPTION

If the room oscillator does not recognize a key, either of the following may be the cause: 1) communication between the indoor electrical key oscillator (for front floor) and electrical key transmitter cannot be performed; or 2) communication between the indoor electrical key oscillator (for rear floor) and electrical key transmitter cannot be performed.

WIRING DIAGRAM

INSPECTION PROCEDURE

- CAUTION:

- The entry and start system (for entry function) uses a multiplex communication system (LIN communication system) and CAN communication system. Inspect the communication function by following How to Proceed with Troubleshooting (CAMRY_ACV40 RM000000XU707QX.html). Troubleshoot the entry and start system (for entry function) after confirming that the communication system is functioning properly.

- When using the intelligent tester to troubleshoot: Connect the intelligent tester to the vehicle while the engine switch is off, and turn a courtesy light switch on and off at 1.5-second intervals until communication between the tester and vehicle begins.

| 1.CHECK ENTRY AND START SYSTEM (ENTRY FUNCTION) |

Check that entry lock and unlock functions can be operated at each door (CAMRY_ACV40 RM000002U9W010X.html).

- OK:

- Entry lock and unlock functions operate normally.

| 2.CHECK ENTRY AND START SYSTEM (START FUNCTION) |

Remove the battery of the electrical key transmitter (CAMRY_ACV40 RM000001P7R01SX.html).

With the brake pedal depressed, touch the engine switch while facing the logo side of the key to the engine switch.

When operating the engine switch, check whether the power source mode changes.

- OK:

- Power source mode changes.

- HINT:

- When the key cannot be verified even though it is within the specified range, the engine start check can be performed by removing the transmitter battery from the key and holding the transmitter close to the engine switch.

- When performing the check, if the power source mode changes, there is a problem with key certification inside the cabin.

Install the battery to the electrical key transmitter (CAMRY_ACV40 RM000001P7P01OX.html).

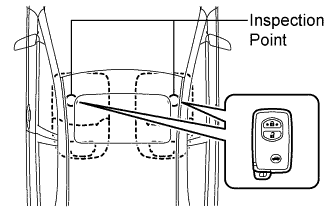

Bring the electrical key transmitter near the indoor electrical key oscillator (for front floor), and perform an engine start check.

- NOTICE:

- If the key is brought within 0.2 m (0.656 ft.) of the indoor electrical key oscillator (for front floor), communication is not possible.

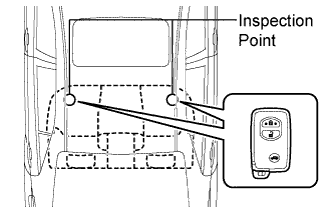

Bring the electrical key transmitter near the indoor electrical key oscillator (for rear floor), and perform an engine start check.

- NOTICE:

- If the key is brought within 0.2 m (0.656 ft.) of the indoor electrical key oscillator (for rear floor), communication is not possible.

- HINT:

- When the electrical key transmitter is brought near the indoor electrical key oscillator, the possibility of wave interference decreases, and it can be determined if wave interference is causing the problem symptom.

- If the operation check is normal, the possibility of wave interference is high. Also, added vehicle components may cause wave interference. If installed, remove them and perform the operation check.

- OK:

- The engine starts.

| OK |

|

|

|

| AFFECTED BY WAVE INTERFERENCE |

|

| 4.PERFORM KEY DIAGNOSTIC MODE INSPECTION |

Diagnostic mode inspection (indoor electrical key oscillator (for front floor))

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG).

Turn the intelligent tester on.

Enter the following menus: Body / Entry & Start / Utility / Key Communication Check / Overhead + Front Room.

When the electrical key transmitter is placed on the driver seat or front passenger seat cushion, check that the wireless door lock buzzer sounds.

- HINT:

- Place the key on the driver or front passenger seat cushion.

- If the buzzer sounds, it can be determined that the indoor electrical key oscillators are operating normally.

Diagnostic mode inspection (indoor electrical key oscillator (for rear floor))

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG).

Turn the intelligent tester on.

Enter the following menus: Body / Entry & Start / Utility / Key Communication Check / Overhead + Rear Room.

When the electrical key transmitter is placed on the rear seat cushion, check that the wireless door lock buzzer sounds.

- HINT:

- Place the key on the driver or front passenger seat cushion.

- If the buzzer sounds, it can be determined that the indoor electrical key oscillators are operating normally.

- Result:

Result

| Proceed to

|

Front operation check is fail

| A

|

Front and rear operation checks are normal or fail

| B

|

Rear operation check is fail

| C

|

| | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

|

| |

|

| 5.CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU - INDOOR ELECTRICAL KEY OSCILLATOR) |

Disconnect the certification ECU (smart key ECU assembly) connector.

Disconnect the indoor electrical key oscillator (for front floor) connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

E74-11 (CLG5) - E72-1 (CLG3)

| Always

| Below 1 Ω

|

E74-12 (CG5B) - E72-3 (CLGB)

| Always

| Below 1 Ω

|

E74-11 (CLG5) - Body ground

| Always

| 10 kΩ or higher

|

E74-12 (CG5B) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

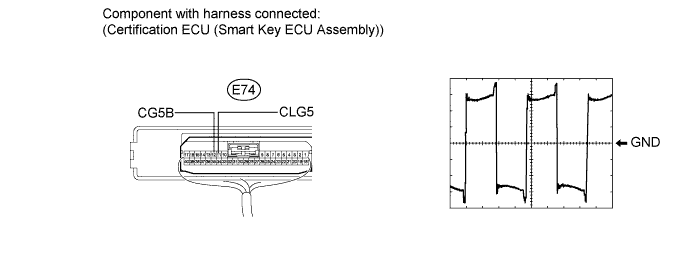

| 6.INSPECT INDOOR ELECTRICAL KEY OSCILLATOR (for Front Floor) |

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Tool Setting

| Switch Condition

| Specified Condition

|

E74-11 (CLG5) - E74-12 (CG5B)

| 2 V/DIV, 2 μs/DIV. (Reference)

| Engine switch on (IG)

| Pulse generation

|

| | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

|

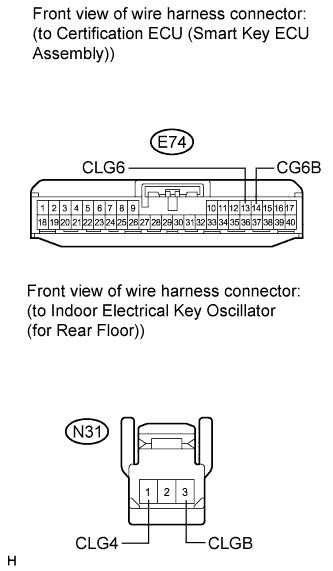

| 7.CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU - INDOOR ELECTRICAL KEY OSCILLATOR) |

Disconnect the certification ECU (smart key ECU assembly) connector.

Disconnect the indoor electrical key oscillator (for rear floor) connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

E74-13 (CLG6) - N31-1 (CLG4)

| Always

| Below 1 Ω

|

E74-14 (CG6B) - N31-3 (CLGB)

| Always

| Below 1 Ω

|

E74-13 (CLG6) - Body ground

| Always

| 10 kΩ or higher

|

E74-14 (CG6B) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

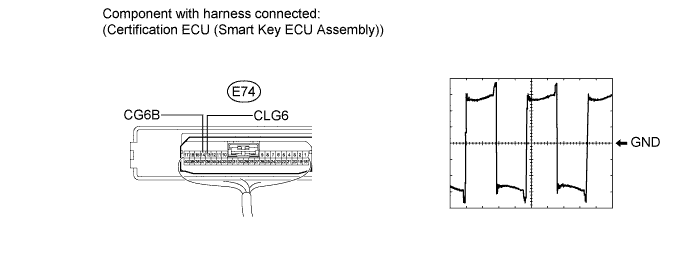

| 8.INSPECT INDOOR ELECTRICAL KEY OSCILLATOR (for Rear Floor) |

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Tool Setting

| Switch Condition

| Specified Condition

|

E74-13 (CLG6) - E74-14 (CG6B)

| 2 V/DIV, 2 μs/DIV. (Reference)

| Engine switch on (IG)

| Pulse generation

|

| | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

|