Dtc P0087 Fuel Rail / System Pressure - Too Low

DESCRIPTION

MONITOR DESCRIPTION

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

WIRING DIAGRAM

INSPECTION PROCEDURE

READ VALUE USING INTELLIGENT TESTER (FUEL PRESS)

CHECK IF DTC OUTPUT RECURS

CHECK HARNESS AND CONNECTOR (FUEL PRESSURE SENSOR - ECM)

DTC P0087 Fuel Rail / System Pressure - Too Low |

DTC P0190 Fuel Rail Pressure Sensor Circuit |

DTC P0192 Fuel Rail Pressure Sensor Circuit Low Input |

DTC P0193 Fuel Rail Pressure Sensor Circuit High Input |

DESCRIPTION

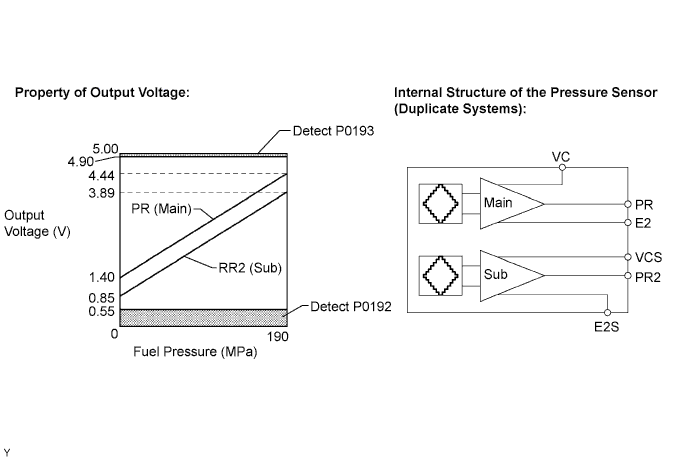

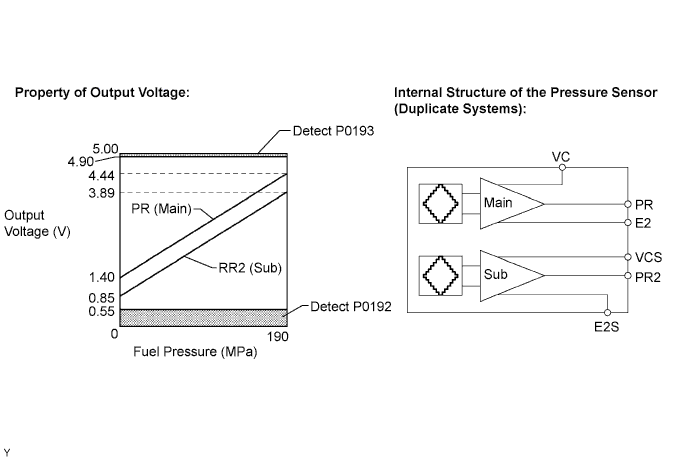

The ECM monitors the internal fuel pressure of the common rail using the fuel pressure sensor, and controls the suction control valve to regulate the internal pressure to the target pressure. The pressure sensor is a semiconductor that varies electrical resistance when pressure is applied to its silicon chip. This sensor outputs the voltage in proportion to the internal fuel pressure. The sensor has been designed as a duplicate circuit, and its main (PR) circuit is used under normal conditions. Even if either of the sensor circuits fail, the other normal circuit will be used to monitor the internal fuel pressure.

DTC No.

| DTC Detection Condition

| Trouble Area

|

P0087

| Fuel pressure sensor output voltage stays at fixed value

(1 trip detection logic)

| - Open or short in fuel pressure sensor circuit

- Fuel pressure sensor

- ECM

|

P0190

| Fuel pressure sensor output voltage is 0.55 V or less, or 4.9 V or more for 0.5 seconds

(1 trip detection logic)

| - Open or short in fuel pressure sensor circuit

- Fuel pressure sensor

- ECM

|

P0192

| Fuel pressure sensor output voltage is 0.55 V or less for 0.5 seconds

(1 trip detection logic)

| - Open or short in fuel pressure sensor circuit

- Fuel pressure sensor

- ECM

|

P0193

| Fuel pressure sensor output voltage is 4.9 V or more for 0.5 seconds

(1 trip detection logic)

| - Open or short in fuel pressure sensor circuit

- Fuel pressure sensor

- ECM

|

- HINT:

- For more information on the fuel pressure sensor and common rail system, refer to the system description (Toyota Fortuner RM0000012WW024X.html).

- When DTC P0087, P0190, P0192 and/or P0193 is set, check the internal fuel pressure of the common rail by entering the following menus on the intelligent tester: Powertrain / Engine and ECT / Data List / Fuel Press.

- Reference:

Engine Speed

| Fuel Pressure

|

Idling

| Approximately 28000 to 40000 kPa

|

3,000 rpm (No engine load)

| Approximately 30000 to 60000 kPa

|

MONITOR DESCRIPTION

- P0087 (Fuel pressure sensor output stays at fixed value):

Under normal conditions, the internal fuel pressure of the common rail usually fluctuates 1000 to 2000 kPa (10 to 20 kgf/cm2, 145 to 290 psi) even when the driving conditions are constant. The internal fuel pressure is approximately 28000 to 40000 kPa (285 to 408 kgf/cm2, 4060 to 5801 psi) when idling, and it increases to approximately 30000 to 60000 kPa (306 to 612 kgf/cm2, 4351 to 8700 psi) when running the engine at 3,000 rpm. This DTC is set if there is no fluctuation of the fuel pressure.

If this DTC is set, the ECM enters fail-safe mode and limits engine power. The fail-safe mode continues until the ignition switch is turned OFF.

- P0190, P0192 and P0193 (Open or short in fuel pressure sensor circuit):

These DTCs are set if the fuel pressure sensor output voltage is out of the standard range and an open or short malfunction of the sensor circuit has occurred.

If these DTCs are set, the ECM enters fail-safe mode and limits the engine power. The fail-safe mode continues until the ignition switch is turned OFF.

MONITOR STRATEGY

P0087:Required Sensors

| Fuel pressure sensor

|

Frequency of operation

| Continuous

|

Duration

| 1 second

|

MIL operation

| 1 driving cycle

|

P0190:Required Sensors

| Fuel pressure sensor

|

Frequency of operation

| Continuous

|

Duration

| 0.5 seconds

|

MIL operation

| 1 driving cycle

|

P0192:Required Sensors

| Fuel pressure sensor

|

Frequency of operation

| Continuous

|

Duration

| 0.5 seconds

|

MIL operation

| 1 driving cycle

|

P0193:Required Sensors

| Fuel pressure sensor

|

Frequency of operation

| Continuous

|

Duration

| 0.5 seconds

|

MIL operation

| 1 driving cycle

|

TYPICAL ENABLING CONDITIONS

P0087:Item

| Specification

| Specification

|

Minimum

| Maximum

|

Engine speed

| 500 rpm

| -

|

Battery voltage

| 8 V

| -

|

Fuel volume

| 5 mm3

| -

|

The monitor will not run if the fuel pressure sensor circuit (P0190, P0192 and P0193) is malfunctioning.

|

TYPICAL MALFUNCTION THRESHOLDS

P0087:Detection Criteria

| Threshold

|

Changing value of fuel pressure

| Virtually no fluctuation

|

P0190:Detection Criteria

| Threshold

|

Fuel pressure sensor output voltage

| Less than 0.55 V or more than 4.9 V

|

P0192:Detection Criteria

| Threshold

|

Fuel pressure sensor output voltage

| Less than 0.55 V

|

P0193:Detection Criteria

| Threshold

|

Fuel pressure sensor output voltage

| More than 4.9 V

|

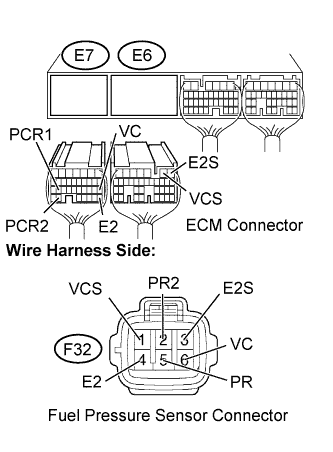

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- After replacing the ECM, the new ECM needs registration (Toyota Fortuner RM0000012XK04BX.html) and initialization (Toyota Fortuner RM000000TIN04NX.html).

- HINT:

- After completing repairs, check that P0087, P0190, P0192 and/or P0193 is not set again.

- If different DTCs related to different systems that have terminal E2 as the ground terminal are output simultaneously, terminal E2 may have an open circuit.

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

| 1.READ VALUE USING INTELLIGENT TESTER (FUEL PRESS) |

Connect the intelligent tester to the DLC3.

Start the engine and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / Fuel Press.

Read the values.

- OK:

- The internal fuel pressure of the common rail is within the specification below.

- Result:

Engine Speed

| Fuel Pressure

|

Idling

| Approximately 28000 to 40000 kPa

|

3,000 rpm (No engine load)

| Approximately 30000 to 60000 kPa

|

| 2.CHECK IF DTC OUTPUT RECURS |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON (IG) and turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Clear the DTC(s).

Let the engine idle for 60 seconds, and then repeat quick engine RPM accelerations (to 2,500 rpm) for 30 seconds.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTC(s).

- Result:

Display (DTC Output)

| Proceed to

|

P0087, P0190, P0192 and/or P0193

| A

|

No output

| B

|

| 3.CHECK HARNESS AND CONNECTOR (FUEL PRESSURE SENSOR - ECM) |

Disconnect the E6 and E7 ECM connector.

Disconnect the F32 fuel pressure sensor connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance (Check for open):

Tester Connection

| Specified Condition

|

PCR1 (E7-26) - PR (F32-5)

| Below 1 Ω

|

PCR2 (E7-33) - PR2 (F32-2)

| Below 1 Ω

|

VCS (E6-2) - VCS (F32-1)

| Below 1 Ω

|

VC (E7-18) - VC (F32-6)

| Below 1 Ω

|

E2 (E7-28) - E2 (F32-4)

| Below 1 Ω

|

E2S (E6-1) - E2S (F32-3)

| Below 1 Ω

|

- Standard resistance (Check for short):

Tester Connection

| Specified Condition

|

PCR1 (E7-26) or PR (F32-5) - Body ground

| 10 kΩ or higher

|

PCR2 (E7-33) or PR2 (F32-2) - Body ground

| 10 kΩ or higher

|

VCS (E6-2) or VCS (F32-1) - Body ground

| 10 kΩ or higher

|

VC (E7-18) or VC (F32-6) - Body ground

| 10 kΩ or higher

|

E2 (E7-28) or E2 (F32-4) - Body ground

| 10 kΩ or higher

|

E2S (E6-1) or E2S (F32-3) - Body ground

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|