Dtc P0627 Fuel Pump Control Circuit / Open

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

INSPECT FUEL SUPPLY PUMP ASSEMBLY (SUCTION CONTROL VALVE)

CHECK HARNESS AND CONNECTOR (SUCTION CONTROL VALVE - ECM)

CHECK WHETHER DTC OUTPUT RECURS

REPLACE FUEL SUPPLY PUMP ASSEMBLY (SUCTION CONTROL VALVE)

BLEED AIR FROM FUEL SYSTEM

PERFORM FUEL SUPPLY PUMP INITIALIZATION

REPLACE ECM

REPAIR OR REPLACE HARNESS OR CONNECTOR

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

DTC P0627 Fuel Pump Control Circuit / Open |

DESCRIPTION

P0627DTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

Idling for 1 second

| Even though the CPU (command area inside the ECU) is outputting the suction control valve operation duty, the output monitor signal is absent for 0.5 seconds (1 trip detection logic).

| - Open or short in suction control valve circuit

- Suction control valve (fuel supply pump assembly)

- ECM

|

Related Data ListDTC No.

| Data List

|

P0627

| Fuel Press

Target Common Rail Pressure

|

- HINT:

- For more information on the fuel supply pump assembly (suction control valve) and common rail system, refer to System Description (HILUX_TGN26 RM000000XSN01WX.html).

- When DTC P0627 is stored, check the internal fuel pressure of the common rail by entering the following menus on the intelligent tester: Powertrain / Engine and ECT / Data List / Fuel Press.

Under a stable operating condition such as idling, Fuel Press is within 5000 kPa of Target Common Rail Pressure.

WIRING DIAGRAM

Refer to DTC P0088 (HILUX_TGN26 RM000001884067X_06.html).

INSPECTION PROCEDURE

- NOTICE:

- After replacing the ECM, the new ECM needs registration (HILUX_TGN26 RM0000012XK05BX.html) and initialization (HILUX_TGN26 RM000000TIN04CX.html).

- After replacing the fuel supply pump assembly, the ECM needs initialization (HILUX_TGN26 RM000000TIN04CX.html).

- HINT:

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

| 1.INSPECT FUEL SUPPLY PUMP ASSEMBLY (SUCTION CONTROL VALVE) |

Disconnect the suction control valve connector.

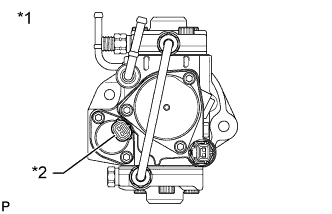

Text in Illustration*1

| Fuel Supply Pump Assembly

|

*2

| Suction Control Valve

|

Measure the resistance of the suction control valve.

- OK:

- No open or short circuit malfunction.

| 2.CHECK HARNESS AND CONNECTOR (SUCTION CONTROL VALVE - ECM) |

Disconnect the suction control valve connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

C5-1 - C22-2 (PCV+)

| Always

| Below 1 Ω

|

C5-2 - C22-1 (PCV-)

| Always

| Below 1 Ω

|

C5-1 or C22-2 (PCV+) - Body ground

| Always

| 10 kΩ or higher

|

C5-2 or C22-1 (PCV-) - Body ground

| Always

| 10 kΩ or higher

|

Reconnect the suction control valve connector.

Reconnect the ECM connector.

| 3.CHECK WHETHER DTC OUTPUT RECURS |

Connect the intelligent tester to the DLC3

Turn the ignition switch to ON and turn the tester on.

Clear the DTCs (HILUX_TGN26 RM000000PDK0XBX.html).

Start the engine and idle it for 1 second or more.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTCs.

ResultResult

| Proceed to

|

No DTC is output

| A

|

P0627 is output

| B

|

| 4.REPLACE FUEL SUPPLY PUMP ASSEMBLY (SUCTION CONTROL VALVE) |

Replace the fuel supply pump assembly (HILUX_TGN26 RM0000014FO01RX.html).

| 5.BLEED AIR FROM FUEL SYSTEM |

Bleed the air from the fuel system (HILUX_TGN26 RM000002SY8025X_01_0002.html).

| 6.PERFORM FUEL SUPPLY PUMP INITIALIZATION |

Perform fuel supply pump initialization (HILUX_TGN26 RM000000TIN04CX.html).

Replace the ECM (HILUX_TGN26 RM0000013Z001IX.html).

| 8.REPAIR OR REPLACE HARNESS OR CONNECTOR |

Repair or replace the harness or connector.

| 9.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Connect the intelligent tester to the DLC3.

Clear the DTCs (HILUX_TGN26 RM000000PDK0XBX.html).

Turn the ignition switch off for 30 seconds or more.

Start the engine and idle it for 1 second or more.

Confirm that the DTC is not output again.