Automatic Transmission Assembly (For 1Gr-Fe) -- Installation |

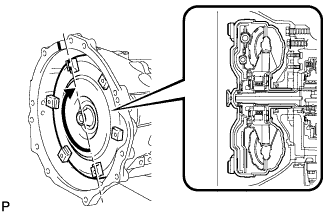

| 1. INSPECT TORQUE CONVERTER ASSEMBLY |

|

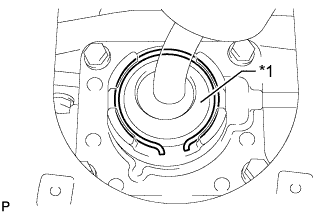

Inspect the 1-way clutch.

Install SST to the inner race of the 1-way clutch.

- SST

- 09350-32014(09351-32020)

Press on the serrations of the starter with a finger and rotate it.

Check if it rotates smoothly when turned clockwise and locks when turned counterclockwise.

If the results are not as specified, clean the converter and recheck the 1-way clutch. If the results still are not as specified, replace the torque converter clutch assembly.Text in Illustration

Free

Lock

Determine the condition of the torque converter clutch.

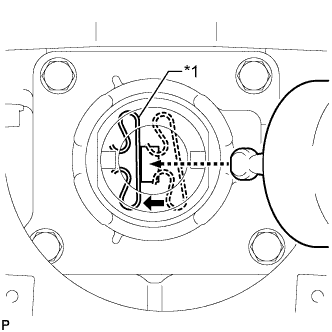

Text in Illustration *1 Sample showing maximum allowable amount of powder in ATF Check that the following conditions are met:

- During the stall test or when the shift lever is in N, metallic sounds are not emitted from the torque converter clutch.

- The 1-way clutch turns in one direction and locks in the other direction.

- The amount of powder in the ATF is not more than the sample shown in the illustration.

- HINT:

- The sample illustration shows approximately 0.025 liters (0.026 US qts, 0.022 Imp. qts) of ATF taken from a removed torque converter clutch.

- During the stall test or when the shift lever is in N, metallic sounds are not emitted from the torque converter clutch.

|

Replace the ATF in the torque converter clutch.

AT If the ATF is discolored and/or has a foul odor, stir the ATF in the torque converter clutch thoroughly and drain the ATF with the torque converter facing upward.

Prevent deformation of the torque converter clutch and damage to the oil pump gear.

Text in Illustration *a Correct *b Incorrect *c Bottom is damaged When any marks due to interference are found on the end of the bolt for the torque converter clutch and on the bottom of the bolt hole, replace the bolt and torque converter clutch.

All of the bolts should be the same length.

Make sure no spring washers are missing.

|

| 2. INSTALL TORQUE CONVERTER ASSEMBLY |

Attach the splines of the input shaft and turbine runner.

|

Attach the splines of the stator shaft and stator while turning the torque converter assembly.

- HINT:

- If the stator shaft splines are difficult to engage with the stator splines, move the torque converter back approximately 10 mm (0.393 in.) and engage the splines while rotating the torque converter assembly.

|

Turn the torque converter to engage the key of the oil pump drive gear with the slot on the torque converter assembly.

|

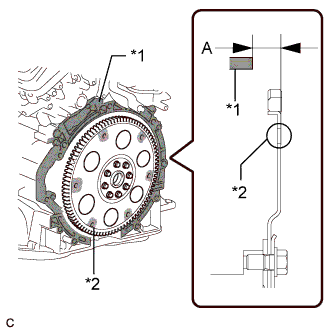

Using a vernier caliper and straightedge, measure dimension A between the transmission contact surface of the engine and the torque converter contact surface of the drive plate.

Text in Illustration *1 Engine Surface *2 Drive Plate Surface - NOTICE:

- Make sure to deduct the thickness of the straightedge.

|

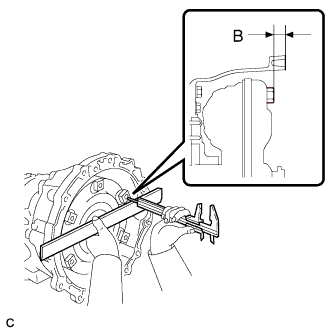

Using a vernier caliper and straightedge, measure dimension B shown in the illustration and check that dimension B is more than dimension A, which was measured in the previous step.

- Standard:

- B = A + 1.00 mm (0.0394 in.) or more

- NOTICE:

- Make sure to deduct the thickness of the straightedge.

- If the transaxle is installed to the engine with the torque converter not sufficiently inserted, the torque converter may be damaged.

|

| 3. INSTALL TRANSFER ASSEMBLY |

Install the transfer to the transmission.

Install the clamp and 8 bolts.

- Torque:

- 24 N*m{244 kgf*cm, 17 ft.*lbf}

| 4. INSTALL AUTOMATIC TRANSMISSION ASSEMBLY |

|

Apply clutch spline grease to the surface of the crankshaft that contacts the torque converter clutch centerpiece.

- Clutch spline grease:

- Toyota Genuine Clutch Spline Grease or equivalent

- Maximum grease amount:

- Approximately 1.0 g (0.0353 oz)

Text in Illustration *1 Torque Converter Centerpiece *2 Crankshaft

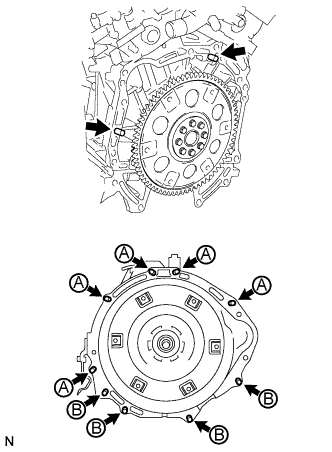

Install the transmission to the engine with the 9 bolts.

- Torque:

- for bolt A:

- 71 N*m{724 kgf*cm, 52 ft.*lbf}

- for bolt B:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

- NOTICE:

- Confirm that the 2 knock pins are installed to the surface of the engine block before installing the transmission.

|

| 5. INSTALL DRIVE PLATE AND TORQUE CONVERTER SETTING BOLT |

Turn the crankshaft to gain access to the installation locations of the 6 torque converter clutch setting bolts and install each bolt through the hole of the flywheel while holding the crankshaft pulley bolt with a wrench.

- Torque:

- 48 N*m{489 kgf*cm, 35 ft.*lbf}

- NOTICE:

- Install the black colored bolt first, and then the silver colored 5 bolts.

| 6. INSTALL STARTER ASSEMBLY |

| 7. CONNECT WIRE HARNESS |

Connect the 8 connectors and attach the 7 clamps.

Connect the ground cable with the nut.

- Torque:

- 5.5 N*m{56 kgf*cm, 49 in.*lbf}

| 8. INSTALL REAR NO. 1 ENGINE MOUNTING INSULATOR |

Install the engine mounting insulator to the transmission with the 4 bolts.

- Torque:

- 47 N*m{479 kgf*cm, 35 ft.*lbf}

| 9. INSTALL NO. 3 FRAME CROSSMEMBER SUB-ASSEMBLY |

Connect the ends of the No. 3 frame crossmember to the vehicle with the 4 bolts and 4 nuts.

- Torque:

- 50 N*m{510 kgf*cm, 37 ft.*lbf}

Install the No. 3 frame crossmember to the rear No. 1 engine mounting insulator with the 4 set bolts.

- Torque:

- 17 N*m{173 kgf*cm, 13 ft.*lbf}

| 10. INSTALL NO. 1 TRANSMISSION CONTROL CABLE BRACKET |

Install the control cable bracket with the 2 bolts.

- Torque:

- 14 N*m{143 kgf*cm, 10 ft.*lbf}

| 11. INSTALL TRANSMISSION CONTROL CABLE ASSEMBLY |

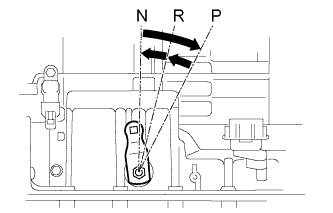

Move the shift lever to N.

Turn the control shaft lever clockwise until it stops, and then turn it counterclockwise 2 notches to set it to the N position.

|

Connect the transmission control cable to the transmission control cable bracket with a new clip, and then connect the cable end to the control shaft lever with the nut.

- Torque:

- 14 N*m{143 kgf*cm, 10 ft.*lbf}

| 12. INSTALL OIL COOLER TUBE |

Loosely install the tip of the inlet oil cooler tube to the automatic transmission by hand.

Loosely install the tip of the outlet oil cooler tube to the automatic transmission by hand.

Install the 2 clamps with the 2 bolts.

- Torque:

- 5.0 N*m{50 kgf*cm, 43 in.*lbf}

Using a union nut wrench, tighten the inlet and outlet oil cooler tubes.

- Torque:

- 34 N*m{346 kgf*cm, 25 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (HILUX_TGN26 RM000004QR1006X.html).

| 13. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY |

| 14. INSTALL PROPELLER SHAFT ASSEMBLY |

| 15. INSTALL FRONT PROPELLER SHAFT ASSEMBLY |

| 16. INSTALL EXHAUST PIPE |

| 17. INSTALL TRANSFER HIGH AND LOW SHIFT LEVER ASSEMBLY |

While pushing the select return spring to the left with the end of the transfer high and low shift lever, insert the end of the shift lever into the shift fork.

Text in Illustration *1 Select Return Spring

|

While holding down the shift lever cap, install the snap ring to install the transfer high and low shift lever.

Text in Illustration *1 Shift Lever Cap

|

Return the transfer front drive shift boot to its original position.

| 18. INSTALL SHIFT LEVER BOOT ASSEMBLY |

Install the shift lever boot with the 4 screws.

| 19. INSTALL CONSOLE BOX ASSEMBLY |

| 20. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- NOTICE:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected (HILUX_TGN26 RM000004QR3009X.html).

| 21. ADD TRANSFER OIL |

Add transfer oil until the oil level is within 5 mm (0.196 in.) from the bottom of the transmission filler plug opening.

Install a new gasket to the filler plug, and then install the plug.

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

- NOTICE:

- When adding transfer oil, make sure the vehicle is level.

- An excessively large or small amount of oil may cause problems.

- After adding oil, drive the vehicle and recheck the oil level.

Inspect for transfer oil leaks.

| 22. ADD AUTOMATIC TRANSMISSION FLUID |

| 23. INSPECT SHIFT LEVER POSITION |

When moving the shift lever from P to R with the ignition switch ON and the brake pedal depressed, make sure that the shift lever moves smoothly and correctly into position.

Start the engine and make sure that the vehicle moves forward after moving the shift lever from N to D, and moves rearward after shifting to the R.

If the results are not as specified, inspect the park/neutral position switch and check the shift lever.

| 24. CHECK FOR EXHAUST GAS LEAKS |

| 25. INSTALL NO. 3 ENGINE UNDER COVER |

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

| 26. INSTALL NO. 2 ENGINE UNDER COVER |

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

| 27. INSTALL NO. 1 ENGINE UNDER COVER |

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}