Air Conditioning System Low Pressure Sensor Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK REFRIGERANT PRESSURE

CHECK HARNESS AND CONNECTOR (AIR CONDITIONING AMPLIFIER - LOW PRESSURE SENSOR)

INSPECT LOW PRESSURE SENSOR

AIR CONDITIONING SYSTEM - Low Pressure Sensor Circuit |

DESCRIPTION

The low pressure sensor reduces the capacity of the compressor when the compressor is operating at high speed. This sensor monitors the pressure on the low pressure side at terminal CUT+ and sends a signal to terminal PSW of the A/C amplifier, which increases the accuracy of compressor control.

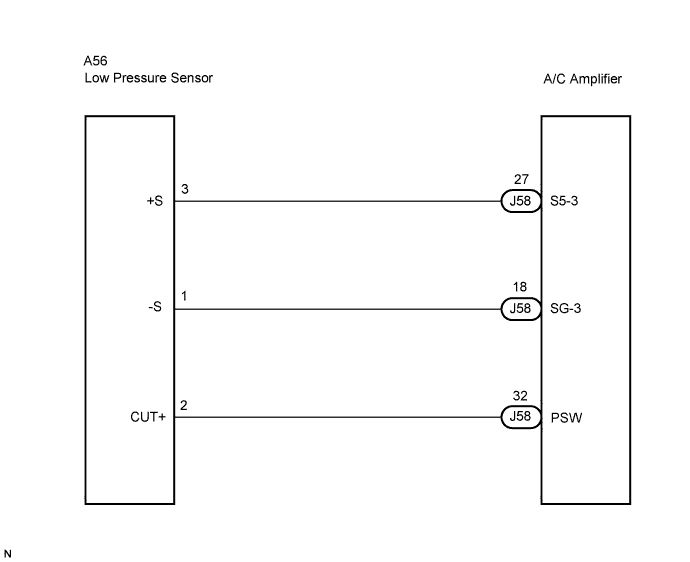

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.CHECK REFRIGERANT PRESSURE |

|

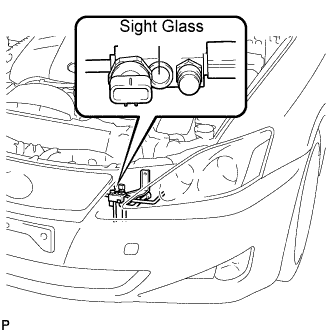

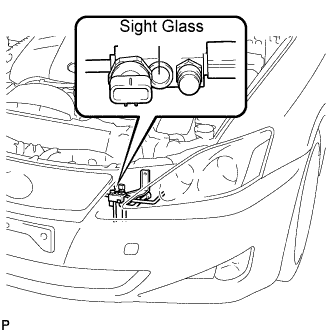

Check the sight glass of the cooler unit refrigerant liquid pipe.

Prepare the vehicle according to the chart below.

Item

| Condition

|

Vehicle Doors

| Fully open

|

Temperature Setting

| MAX COLD

|

Blower Speed

| HI

|

A/C

| ON

|

Compare the sight glass to the following chart.

Item

| Symptom

| Amount of Refrigerant

| Corrective Actions

|

1

| Bubbles visible

| Insufficient*

| - Check for gas leakage and repair if necessary

- Add refrigerant until bubbles disappear

|

2

| No bubbles visible

| Empty, insufficient, or excessive

| Refer to 3 and 4

|

3

| No temperature difference between compressor inlet and outlet

| Empty or nearly empty

| - Check for gas leakage with gas leak detector and repair if necessary

- Evacuate A/C system and recharge with proper amount of refrigerant

|

4

| Considerable temperature difference between compressor inlet and outlet

| Proper or excessive

| Refer to 5 and 6

|

5

| Immediately after air conditioning is turned OFF, refrigerant clears

| Excessive

| - Recover refrigerant

- Evacuate A/C system and recharge with proper amount of refrigerant

|

6

| Immediately after air conditioning is turned OFF, refrigerant foams and then becomes clear

| Proper

| -

|

- *: Bubbles in the sight glass with the vehicle interior temperature above 35°C (95°F) can be considered normal if cooling is sufficient.

| 2.CHECK HARNESS AND CONNECTOR (AIR CONDITIONING AMPLIFIER - LOW PRESSURE SENSOR) |

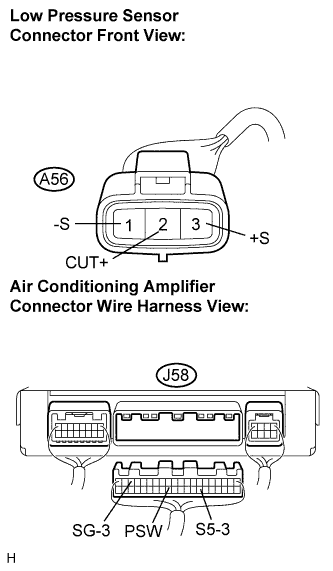

Disconnect the pressure sensor connector.

Disconnect the A/C amplifier connector.

Measure the resistance according to the value(s) in the table below.

Tester Connection

(Symbols)

| Condition

| Specified Condition

|

J58-18 (SG-3) - A56-1 (-S)

| Always

| Below 1 Ω

|

J58-27 (S5-3) - A56-3 (+S)

| Always

| Below 1 Ω

|

J58-32 (PSW) - A56-2 (CUT+)

| Always

| Below 1 Ω

|

J58-18 (SG-3) - Body ground

| Always

| 10 kΩ or higher

|

J58-27 (S5-3) - Body ground

| Always

| 10 kΩ or higher

|

J58-32 (PSW) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 3.INSPECT LOW PRESSURE SENSOR |

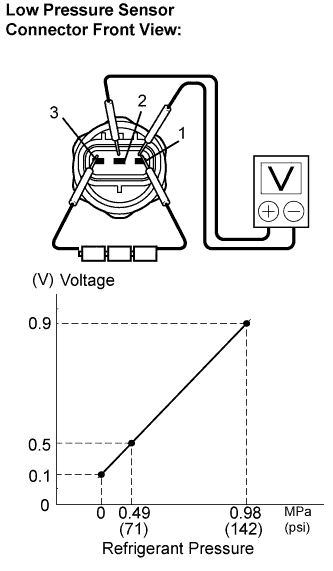

Install the manifold gauge set (Click here).

Connect the three 1.5 V dry cell batterie's positive (+) lead to terminal 3 and the negative (-) lead to terminal 1. Then connect the voltmeter's positive (+) lead to terminal 2 and the negative (-) lead to terminal 1. Measure the voltage.

- OK:

- The voltage changes according to refrigerant pressure, as shown in the graph.

| | REPLACE LOW PRESSURE SENSOR |

|

|

| OK |

|

|

|

| PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE |

|