Dtc U0073/94 Control Module Communication Bus Off

Brake. Lexus Is250, Is220D. Gse20 Ale20

DESCRIPTION

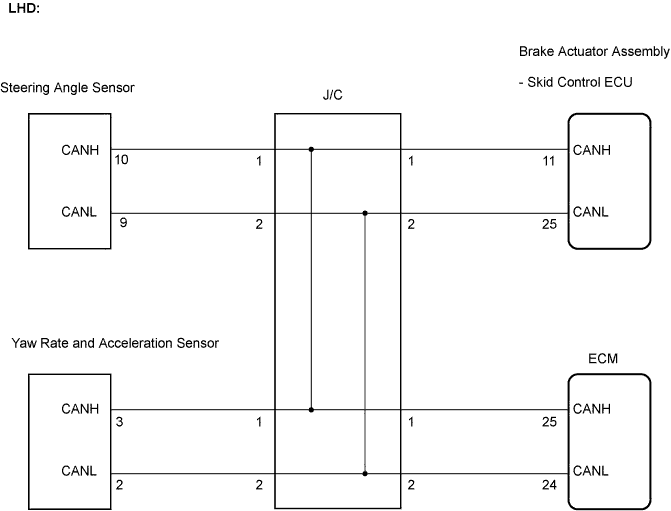

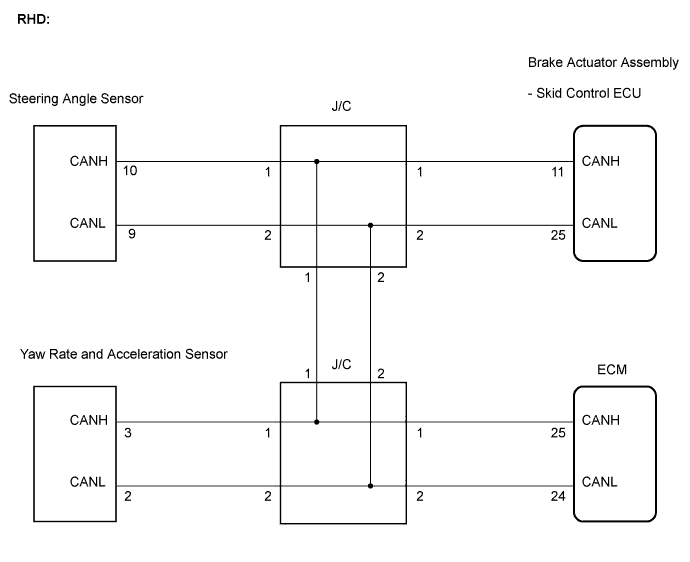

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK HARNESS AND CONNECTOR (MOMENTARY INTERRUPTION)

CHECK IF EACH SENSOR AND ECM CONNECTOR IS SECURELY CONNECTED

RECONFIRM DTC

REPAIR OR REPLACE HARNESS OR CONNECTOR

RECONFIRM DTC

DTC U0073/94 Control Module Communication Bus OFF |

DTC U0100/65 Lost Communication with ECM / PCM |

DTC U0123/62 Lost Communication with Yaw Rate Sensor Module |

DTC U0124/95 Lost Communication with Lateral Acceleration Sensor Module |

DTC U0126/63 Lost Communication with Steering Angle Sensor Module |

DESCRIPTION

The skid control ECU inputs the signals from the ECM, steering angle sensor, and yaw rate and acceleration sensor via CAN communication system.DTC No.

| DTC Detection Condition

| Trouble Area

|

U0073/94

| When any of the following is detected:

- After the output of data from the skid control ECU is completed, the sending continues for 5 seconds or more.

- The condition that bus OFF state occurs once or more within 100 ms occurs 10 times in succession. (Sent signals cannot be received.)

- With the IG1 terminal voltage 10 V or more, a delay in receiving data from the yaw rate and acceleration sensor and steering angle sensor continues for 1 second or more.

- With the IG1 terminal voltage 10 V or more, the condition that a delay in receiving data from the yaw rate and acceleration sensor occurs more than once within 5 seconds occurs 10 times in succession.

| CAN communication system

|

U0100/65

| When either of the following is detected:

- With the IG1 terminal voltage 10 V or more and the vehicle speed 9 mph (15 km/h) or more, data cannot be sent to the ECM for 2 seconds or more.

- With the IG1 terminal voltage 10 V or more and the vehicle speed 9 mph (15 km/h) or more, data from the ECM cannot be received for 2 seconds or more.

| CAN communication system

(Skid control ECU to ECM)

|

U0123/62

| When either of the following is detected:

- With the IG1 terminal voltage 10 V or more, data from the yaw rate sensor cannot be received for 1 second or more.

- With the IG1 terminal voltage 10 V or more, the following occurs 10 times in succession within 60 seconds.

- The condition that data from the yaw rate sensor cannot be received occurs once or more within 5 seconds.

| CAN communication system

(Skid control ECU to yaw rate and acceleration sensor)

|

U0124/95

| When either of the following is detected:

- With the IG1 terminal voltage 10 V or more, data from the acceleration sensor cannot be received for 1 second or more.

- With the IG1 terminal voltage 10 V or more, the following occurs 10 times in succession within 60 seconds.

- The condition that data from the acceleration sensor cannot be received occurs once or more within 5 seconds.

| CAN communication system

(Skid control ECU to yaw rate and acceleration sensor)

|

U0126/63

| When either of the following is detected:

- With the IG1 terminal voltage 10 V or more, data from the steering angle sensor cannot be received for 1 second or more.

- With the IG1 terminal voltage 10 V or more, the following occurs 10 times in succession within 60 seconds.

- The condition that data from the steering angle sensor cannot be received occurs once or more within 5 seconds.

| CAN communication system

(Skid control ECU to steering angle sensor)

|

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.CHECK HARNESS AND CONNECTOR (MOMENTARY INTERRUPTION) |

Using the intelligent tester, check for any momentary interruption in the wire harness and connector corresponding to a DTC (Click here).

ABS / VSC:Item (Display)

| Measurement Item / Range (Display)

| Normal Condition

|

EFI Communication Open

| EFI communication open detection / ERROR or NORMAL

| ERROR: Momentary interruption

NORMAL: Normal

|

Steering Open

| Steering sensor open detection / ERROR or NORMAL

| ERROR: Momentary interruption

NORMAL: Normal

|

Yaw Rate Open

| Yaw rate sensor open detection / ERROR or NORMAL

| ERROR: Momentary interruption

NORMAL: Normal

|

- Result:

Condition

| Proceed to

|

There is a constant open circuit

| A

|

There are no momentary interruptions

| B

|

There are momentary interruptions

| C

|

- HINT:

- Perform the above inspection before removing the sensor and connector.

| 2.CHECK IF EACH SENSOR AND ECM CONNECTOR IS SECURELY CONNECTED |

Check if each sensor or ECM connector is securely connected.

- OK:

- The connector should be securely connected.

| | CONNECT CONNECTOR TO EACH SENSOR OR ECM CORRECTLY |

|

|

Record the output DTCs (for ABS, VSC, and CAN communication) (Click here).

- HINT:

- If the CAN communication system DTC and the relevant sensor DTCs are output simultaneously, troubleshoot the relevant sensor DTCs (for ABS and VSC) after the CAN communication system returns to normal.

- Result:

Condition

| Proceed to

|

DTC (CAN communication system DTC) is output

| A

|

DTC (ABS and/or VSC DTC) is output

| B (Click here)

|

DTC is not output

| C

|

| | REPAIR CIRCUIT INDICATED BY OUTPUT DTC |

|

|

| | USE SIMULATION METHOD TO CHECK |

|

|

| A |

|

|

|

| INSPECT CAN COMMUNICATION SYSTEM |

|

| 4.REPAIR OR REPLACE HARNESS OR CONNECTOR |

Repair or replace the harness or connector.

Check for any momentary interruption between the skid control ECU and each sensor or ECM (Click here).

Check that there is no momentary interruption.

Clear the DTC (Click here).

Start the engine.

Drive the vehicle and turn the steering wheel to the right and left at a speed of 9 mph (15 km/h) or more.

Check that no CAN communication system DTC is output.

If ABS and VSC DTCs are output, record them.

- Result:

Condition

| Proceed to

|

DTC is output for the CAN communication system

| A

|

No DTC is output (ABS and/or VSC DTC is output)

| B (Click here)

|

No DTC is output (No ABS and/or VSC DTC is output)

| C

|

- HINT:

- The CAN communication system must be normal when repairing each sensor DTC (for ABS and VSC).

| | REPAIR CIRCUIT INDICATED BY OUTPUT DTC |

|

|

| |

|

| A |

|

|

|

| INSPECT CAN COMMUNICATION SYSTEM |

|