Rear Differential Carrier -- Reassembly |

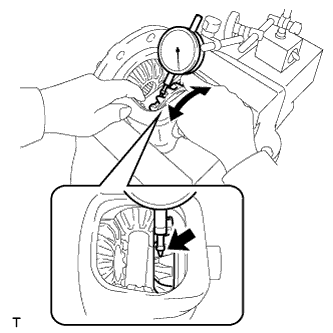

| 1. INSPECT DIFFERENTIAL SIDE GEAR BACKLASH |

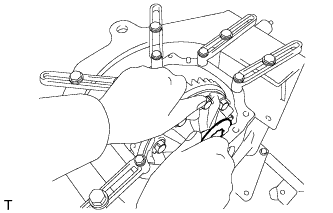

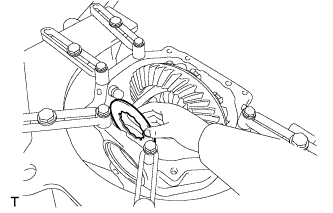

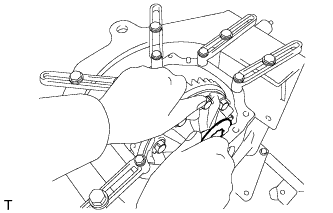

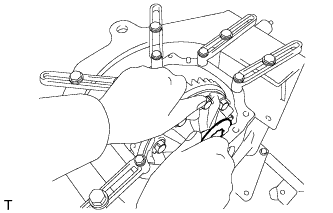

Hold the differential case in a vise between aluminum plates.

- NOTICE:

- Do not overtighten the vise.

|

Place a dial indicator on the tip of the pinion gear tooth at a right angle. Hold the side gear in the differential case and check that the backlash is 0 mm (0 in.).

If not, replace the rear differential case sub-assembly with a new one.

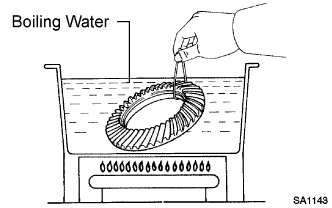

| 2. INSTALL DIFFERENTIAL RING GEAR |

Clean the contact surfaces of the differential case and ring gear.

|

Clean the differential ring gear set bolt hole.

Heat the ring gear to approx. 100°C (212°F) in boiling water.

- CAUTION:

- Use thick gloves to protect hands as the ring gear is hot.

Carefully take the ring gear out of the boiling water.

Hold the differential case in a vise between aluminum plates.

- NOTICE:

- Do not overtighten the vise.

After the moisture on the ring gear has completely evaporated, quickly install the ring gear to the differential case.

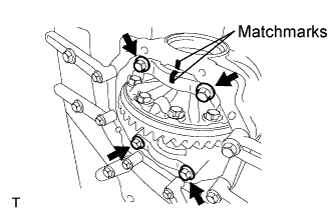

Align the matchmarks on the ring gear and differential case.

|

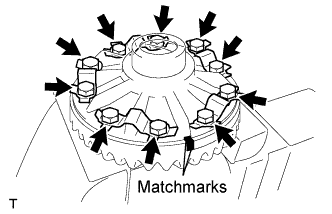

Temporarily install 5 new lock plates and 10 bolts.

After the ring gear cools down, tighten the 10 bolts uniformly.

- Torque:

- 97 N*m{985 kgf*cm, 72 ft.*lbf}

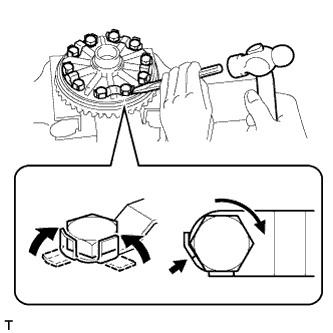

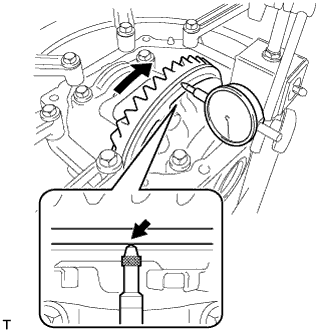

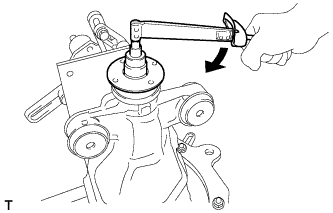

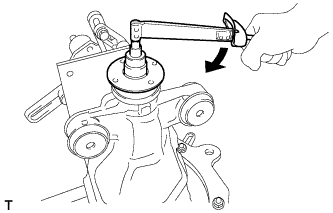

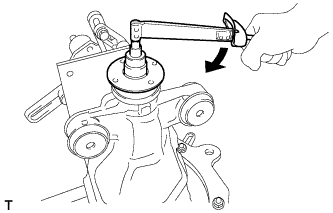

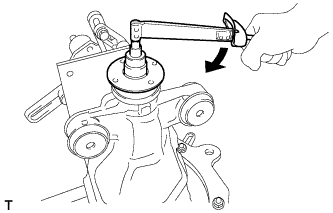

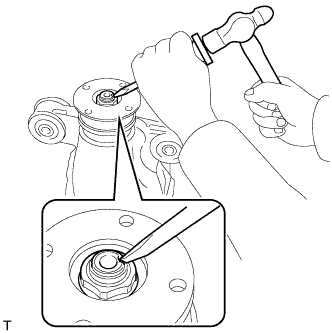

Using a chisel and a hammer, stake the 5 lock plates.

Stake one claw so that it is flush against the flat surface of the bolt.

Stake the other claw against the surface of the bolt head to act as a stopper if the bolt starts to loosen.

|

| 3. INSTALL REAR DIFFERENTIAL CASE BEARING |

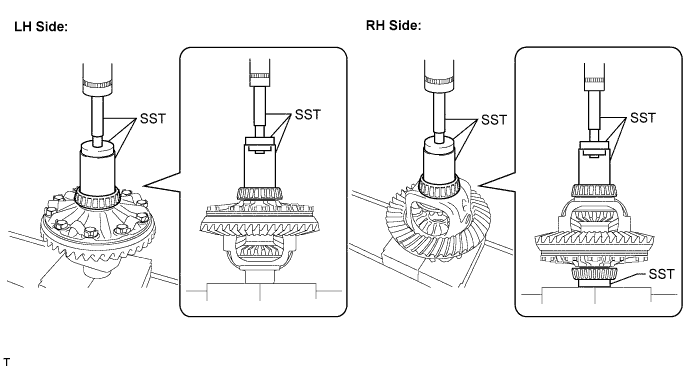

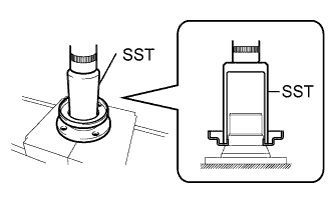

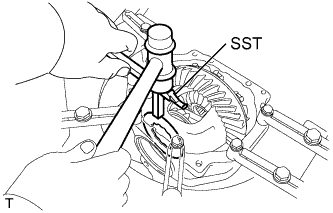

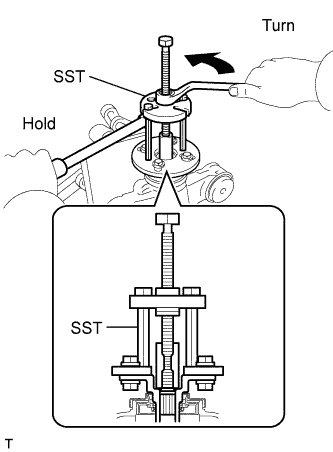

Using SST and a press, install the case bearing inner races LH and RH to the differential case.

- SST

- 09950-60010(09951-00430,09951-00580,09951-00590,09952-06010)

09950-70010(09951-07100)

09710-04081

- NOTICE:

- Do not apply hypoid gear oil to a new bearing.

- Do not deform the bearing cage.

- Place the SST carefully on the inner races of the bearings or on the center of the differential case (as applicable).

- If the bearing is replaced, replace it and the outer race as a set.

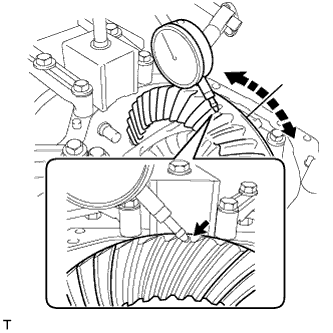

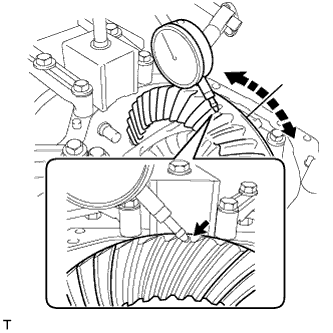

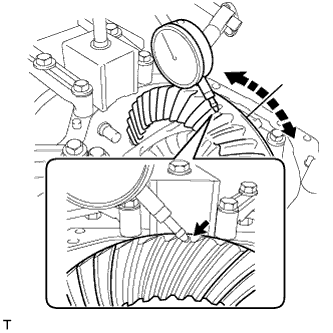

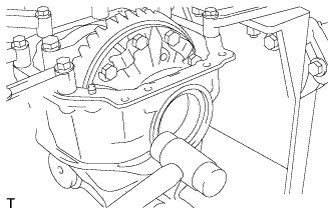

| 4. INSPECT RUNOUT OF DIFFERENTIAL RING GEAR |

Using a dial indicator, measure the runout of the ring gear.

- Maximum runout:

- 0.07 mm (0.0028 in.)

|

| 5. INSTALL REAR DRIVE PINION REAR TAPERED ROLLER BEARING |

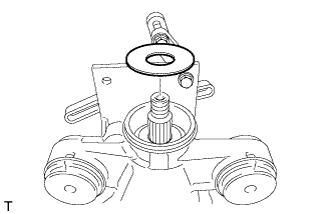

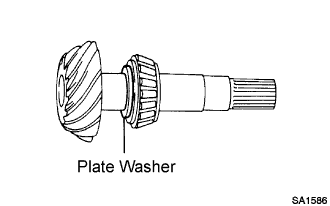

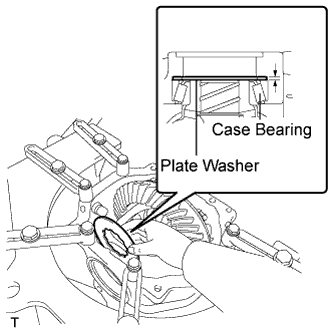

Install the drive pinion plate washer to the drive pinion.

- HINT:

- Temporarily install the inner race of the rear drive pinion rear tapered roller bearing to prevent the drive pinion washer from being dropped.

- The drive pinion washer can be installed in either direction.

|

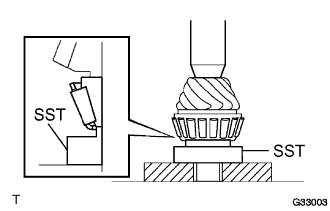

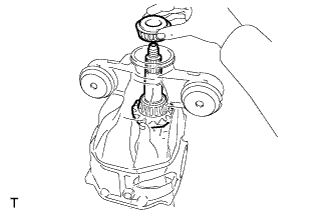

Using SST and a press, install the inner race of the rear drive pinion rear tapered roller bearing to the drive pinion.

- SST

- 09506-30012

|

| 6. INSTALL REAR DRIVE PINION REAR TAPERED ROLLER BEARING |

Using SST and a press, install the outer race of the rear drive pinion rear tapered roller bearing to the differential carrier.

- SST

- 09950-60020(09951-00890)

09950-70010(09951-07200)

|

| 7. INSTALL REAR DRIVE PINION FRONT TAPERED ROLLER BEARING |

Using SST and a press, install the outer race of the rear drive pinion front tapered roller bearing to the differential carrier.

- SST

- 09950-60020(09951-00720)

09950-70010(09951-07100)

|

| 8. INSTALL REAR DIFFERENTIAL DUST DEFLECTOR |

Using SST and a press, install a new dust deflector.

- SST

- 09636-20010

- NOTICE:

- Slowly press in the dust deflector.

- If any burrs remain after pressing in the deflector, remove them.

|

| 9. ADJUST DIFFERENTIAL DRIVE PINION PRELOAD |

Install the drive pinion and the inner race of the rear drive pinion front tapered roller bearing to the differential carrier.

- NOTICE:

- Do not drop the drive pinion.

- Install the drive pinion bearing spacer and oil seal after adjusting the gear contact pattern.

|

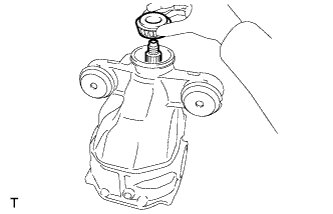

Install the drive pinion oil slinger to the drive pinion.

|

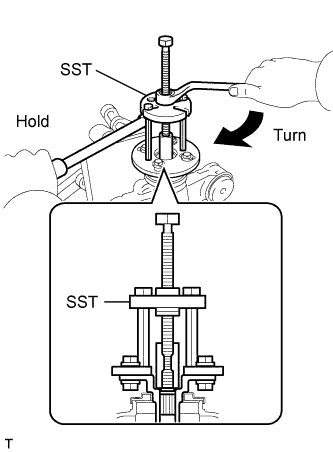

Using SST, install the companion flange.

- SST

- 09950-30012(09951-03010,09953-03010,09954-03010,09955-03030,09956-03030)

- NOTICE:

- Hold the drive pinion until the SST is installed.

- Install the companion flange so that there is slight looseness on the drive pinion because the bearing spacer is not installed.

- Apply grease to the threads and tip of the SST center bolt before use.

|

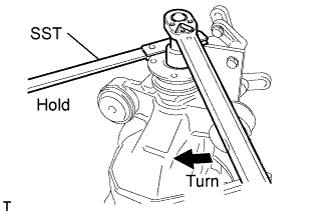

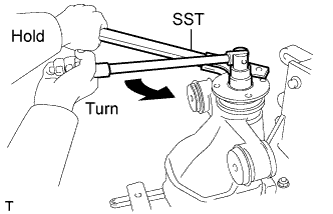

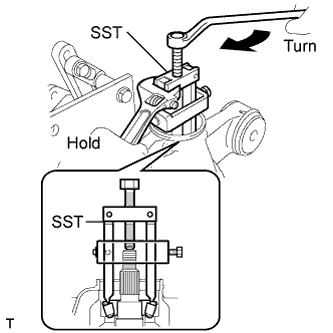

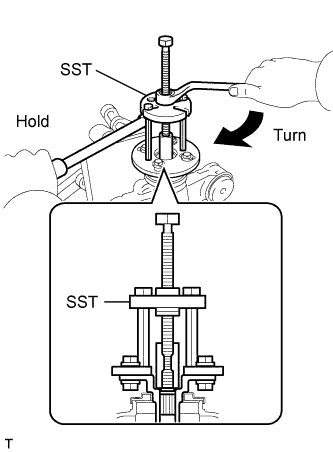

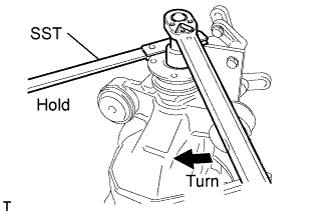

Using SST to hold the flange, tighten the drive pinion nut.

- SST

- 09330-00021

- Torque:

- 338 N*m (3,450 kgf*cm, 249 ft.*lbf) or less

- NOTICE:

- Tighten the nut to approximately 100 N*m (1,020 kgf*cm, 74 ft.*lbf), and tighten it further while checking the preload.

- Apply hypoid gear oil LSD to the nut and the threads of the drive pinion.

- As there is no bearing spacer, tighten the nut a little at a time and do not overtighten it.

|

Turn the bearing clockwise and counterclockwise several times to stabilize it.

Using a torque wrench, measure the drive pinion preload.

- Drive pinion preload (at starting):

Specifications Preload New bearing 1.39 to 2.49 N*m (14.2 to 25.4 kgf*cm, 12.3 to 22.0 in.*lbf) Reused bearing 1.01 to 1.81 N*m (10.3 to 18.5 kgf*cm, 8.9 to 16.0 in.*lbf)

- NOTICE:

- Record the preload for total preload measurement.

- Do not apply hypoid gear oil to a new bearing.

|

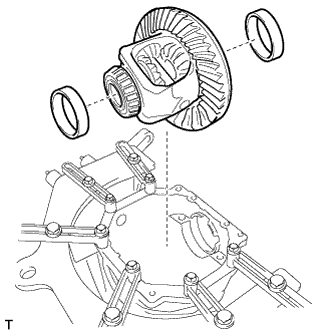

| 10. INSTALL DIFFERENTIAL CASE ASSEMBLY |

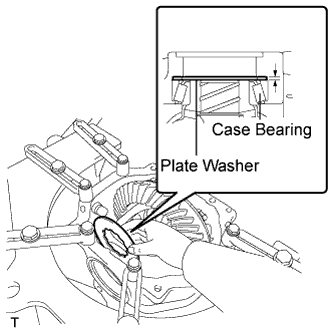

Install the case bearing outer races LH and RH to the case bearing inner races LH and RH respectively.

- NOTICE:

- Be sure to install the bearing outer races in each correct position.

|

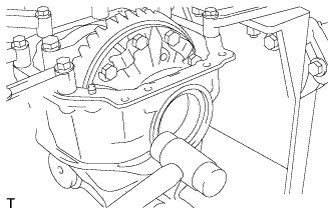

Install the differential case to the differential carrier.

Install the right and left (on the back and tooth sides) side gear shaft washers so that the case bearing is not loose.

- HINT:

- If the final gear set (drive pinion and ring gear) and case bearing are new, select a thinner side gear shaft plate washer and install it.

- If the final gear set (drive pinion and ring gear) and case bearing are reused, install a side gear shaft plate washer with the same thickness as the removed one.

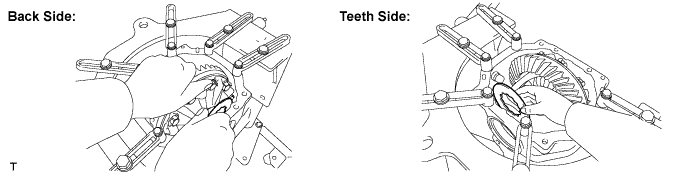

| 11. INSPECT AND ADJUST DIFFERENTIAL RING GEAR BACKLASH |

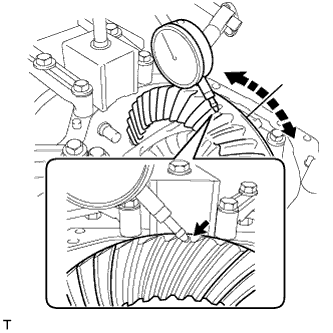

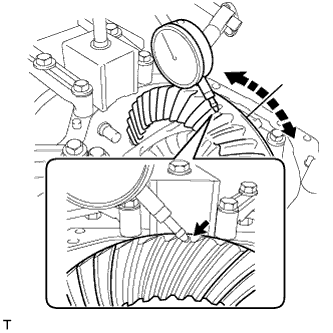

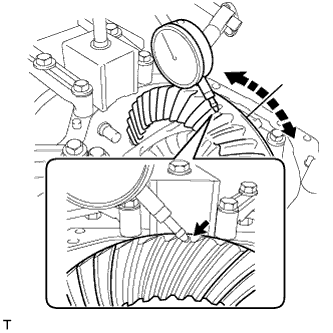

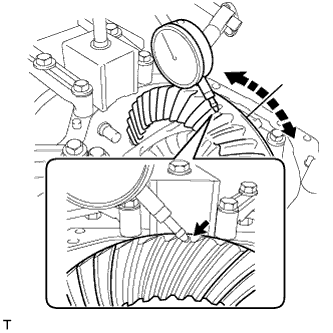

Set the dial indicator perpendicular to the end of the ring gear face.

|

While holding the rear drive pinion companion flange, rotate the ring gear and measure the backlash.

- Backlash:

- 0.13 to 0.18 mm (0.0051 to 0.0071 in.)

- HINT:

- Record the measured backlash to use as a reference for selecting a side gear shaft plate washer.

- Inspect tooth contact to use the result as a reference for selecting a side gear shaft plate washer.

Select a side gear shaft plate washer that will set ring gear backlash within the specified range, and install it to the ring gear back side.

Washer thickness Thickness mm (in.) Thickness mm (in.) Thickness mm (in.) 2.57 to 2.59 (0.1012 to 0.1020) 2.89 to 2.91 (0.1138 to 0.1146) 3.21 to 3.23 (0.1264 to 0.1271) 2.59 to 2.61 (0.1020 to 0.1028) 2.91 to 2.93 (0.1146 to 0.1154) 3.23 to 3.25 (0.1271 to 0.1280) 2.61 to 2.63 (0.1028 to 0.1035) 2.93 to 2.95 (0.1154 to 0.1161) 3.25 to 3.27 (0.1280 to 0.1287) 2.63 to 2.65 (0.1035 to 0.1043) 2.95 to 2.97 (0.1161 to 0.1169) 3.27 to 3.29 (0.1287 to 0.1295) 2.65 to 2.67 (0.1043 to 0.1051) 2.97 to 2.99 (0.1169 to 0.1177) 3.29 to 3.31 (0.1295 to 0.1303) 2.67 to 2.69 (0.1051 to 0.1059) 2.99 to 3.01 (0.1177 to 0.1185) 3.31 to 3.33 (0.1303 to 0.1311) 2.69 to 2.71 (0.1059 to 0.1067) 3.01 to 3.03 (0.1185 to 0.1193) 3.33 to 3.35 (0.1311 to 0.1319) 2.71 to 2.73 (0.1067 to 0.1075) 3.03 to 3.05 (0.1193 to 0.1201) 3.35 to 3.37 (0.1319 to 0.1327) 2.73 to 2.75 (0.1075 to 0.1083) 3.05 to 3.07 (0.1201 to 0.1209) 3.37 to 3.39 (0.1327 to 0.1335) 2.75 to 2.77 (0.1083 to 0.1091) 3.07 to 3.09 (0.1209 to 0.1217) 3.39 to 3.41 (0.1335 to 0.1343) 2.77 to 2.79 (0.1091 to 0.1098) 3.09 to 3.11 (0.1217 to 0.1224) 3.41 to 3.43 (0.1343 to 0.1350) 2.79 to 2.81 (0.1098 to 0.1106) 3.11 to 3.13 (0.1224 to 0.1232) 3.43 to 3.45 (0.1350 to 0.1358) 2.81 to 2.83 (0.1106 to 0.1114) 3.13 to 3.15 (0.1232 to 0.1240) 3.45 to 3.47 (0.1358 to 0.1366) 2.83 to 2.85 (0.1114 to 0.1122) 3.15 to 3.17 (0.1240 to 0.1248) 3.47 to 3.49 (0.1366 to 0.1374) 2.85 to 2.87 (0.1122 to 0.1130) 3.17 to 3.19 (0.1248 to 0.1256) - 2.87 to 2.89 (0.1130 to 0.1138) 3.19 to 3.21 (0.1256 to 0.1264) -

|

Make the differential case bearing and side gear shaft plate washer snug by tapping on the ring gear with a plastic hammer.

|

Set the dial indicator perpendicular to the end of the ring gear face.

|

While holding the rear drive pinion companion flange rear, rotate the ring gear and measure the backlash.

- Backlash:

- 0.13 to 0.18 mm (0.0051 to 0.0071 in.)

If the backlash is not within the specified range, select a side gear shaft plate washer that will set the ring gear backlash within the specified range and install it into the ring gear back side.

|

Select a thicker side gear shaft plate washer so that the clearance between the case bearing outer race end on the ring gear teeth side and the carrier becomes zero or close to zero.

|

Make the differential case bearing and side gear shaft plate washer snug by tapping on the ring gear with a plastic hammer.

|

Set the dial indicator perpendicular to the end of the ring gear face.

|

While holding the rear drive pinion companion flange, rotate the ring gear and measure the backlash.

- Backlash:

- 0.13 to 0.18 mm (0.0051 to 0.0071 in.)

| 12. ADJUST DIFFERENTIAL SIDE BEARING PRELOAD |

After adjusting the backlash of the differential ring gear, remove the teeth side side gear shaft plate washer.

|

Using a micrometer, measure the thickness of the removed side gear shaft plate washer.

Select a new side gear shaft plate washer which is 0.06 to 0.09 mm (0.0024 to 0.0035 in.) thicker than the removed one.

- HINT:

- Select a side gear shaft plate washer which can be pressed in 2/3 of the way with a finger.

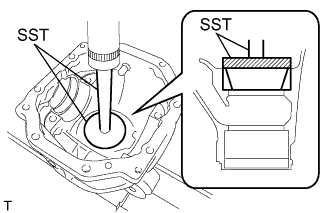

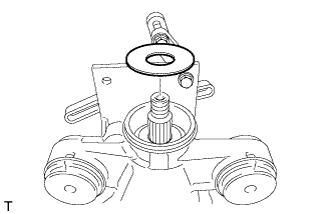

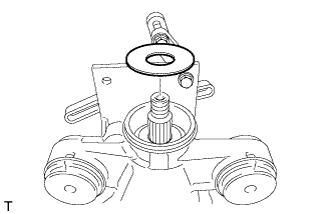

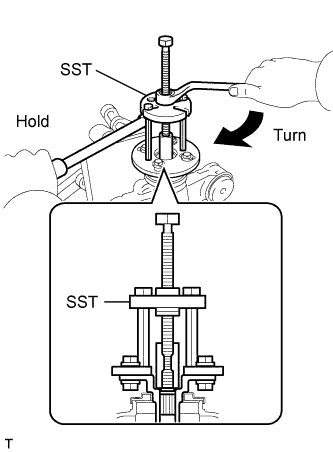

Using SST and a plastic hammer, drive in the side gear shaft plate washer.

- SST

- 09504-22011

|

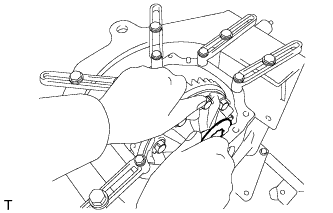

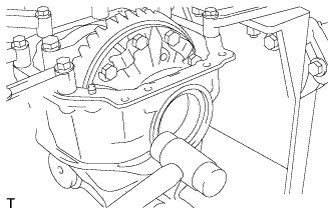

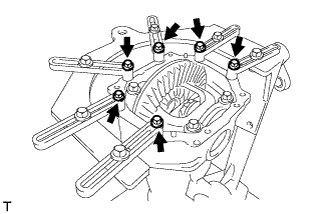

Align the matchmarks on the bearing cap and differential carrier, and install the 2 bearing caps.

- NOTICE:

- Make sure the right and left bearing caps are not interchanged.

|

Tighten both bearing caps with the 4 bolts.

- Torque:

- 85 N*m{870 kgf*cm, 63 ft.*lbf}

Set the dial indicator to the end of the differential ring gear face.

|

While holding the rear drive pinion companion flange rear, rotate the differential ring gear and measure the backlash.

- Backlash:

- 0.13 to 0.18 mm (0.0051 to 0.0071 in.)

- HINT:

- Record the measured backlash to use as a reference for selecting a side gear shaft plate washer.

- Inspect tooth contact to use the result as a reference for selecting a side gear shaft plate washer.

| 13. INSPECT TOTAL PRELOAD |

Using a torque wrench, measure the preload with the teeth of the drive pinion and ring gear in contact.

- Preload (at starting):

Specifications New drive pinion tapered roller bearing Reused drive pinion tapered roller bearing New differential case bearing 2.47 to 4.16 N*m (25.2 to 42.4 kgf*cm, 21.9 to 36.8 in.*lbf) 2.09 to 3.48 N*m (21.3 to 35.5 kgf*cm, 18.5 to 30.8 in.*lbf) Reused differential case bearing 1.88 to 3.27 N*m (20.2 to 33.3 kgf*cm, 16.6 to 28.9 in.*lbf) 1.50 to 2.59 N*m (15.3 to 26.4 kgf*cm, 13.3 to 22.9 in.*lbf)

- HINT:

- If the measured preload is less than the specified value, replace the side gear shaft plate washer of the ring gear tooth surface side with a thicker one.

- If the preload is greater than the specified value, replace the side gear shaft plate washer of the ring gear tooth surface side with a thinner one.

|

Set the dial indicator perpendicular to the end of the ring gear face.

|

While holding the rear drive pinion companion flange rear, rotate the ring gear and measure the backlash.

- Backlash:

- 0.13 to 0.18 mm (0.0051 to 0.0071 in.)

- HINT:

- If the backlash is not within the specified range, change the thickness of the right and left side gear shaft plate washers by equal amounts to adjust it.

- Record the measured backlash to use as a reference for selecting a side gear shaft plate washer.

- Inspect tooth contact to use the result as a reference for selecting a side gear shaft plate washer.

| 14. INSPECT TOOTH CONTACT BETWEEN RING GEAR AND DRIVE PINION |

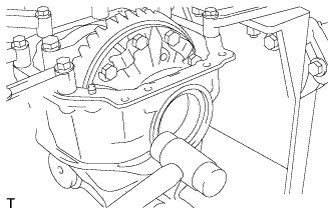

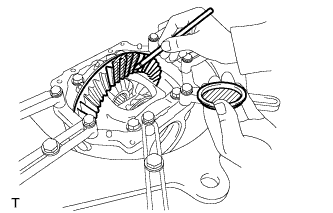

Coat 3 or 4 teeth at 3 different positions on the ring gear with red lead primer.

|

Rotate the ring gear in both directions.

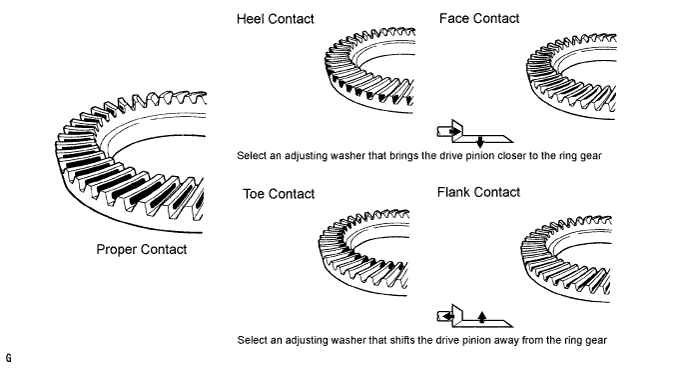

Inspect the tooth contact pattern.

If the teeth are not contacting properly, use the following table to select a proper washer for correction.

- NOTICE:

- If the contact pattern is face contact or flank contact, tooth contact may be adjustable while keeping the backlash within the specified range.

- If the thickness of the drive pinion washer has been changed, adjust the backlash and measure the total preload.

Washer thickness: Thickness mm (in.) Thickness mm (in.) Thickness mm (in.) 1.69 to 1.71 (0.0665 to 0.0673) 1.93 to 1.95 (0.0760 to 0.0768) 2.17 to 2.19 (0.0854 to 0.0862) 1.72 to 1.74 (0.0677 to 0.0685) 1.96 to 1.98 (0.0772 to 0.0780) 2.20 to 2.22 (0.0866 to 0.0874) 1.75 to 1.77 (0.0688 to 0.0697) 1.99 to 2.01 (0.0783 to 0.0791) 2.23 to 2.25 (0.0878 to 0.0886) 1.78 to 1.80 (0.0701 to 0.0709) 2.02 to 2.04 (0.0795 to 0.0803) 2.26 to 2.28 (0.0890 to 0.0898) 1.81 to 1.83 (0.0713 to 0.0720) 2.05 to 2.07 (0.0807 to 0.0815) 2.29 to 2.31 (0.0902 to 0.0909) 1.84 to 1.86 (0.0724 to 0.0732) 2.08 to 2.10 (0.0819 to 0.0827) 2.32 to 2.34 (0.0913 to 0.0921) 1.87 to 1.89 (0.0736 to 0.0744) 2.11 to 2.13 (0.0831 to 0.0839) - 1.90 to 1.92 (0.0748 to 0.0756) 2.14 to 2.16 (0.0843 to 0.0850) -

|

| 15. REMOVE REAR DRIVE PINION NUT |

Using SST to hold the flange, remove the drive pinion nut.

|

| 16. REMOVE REAR DRIVE PINION COMPANION FLANGE |

Using SST, remove the companion flange.

- SST

- 09950-30012(09951-03010,09953-03010,09954-03010,09955-03030,09956-03030)

- NOTICE:

- Apply grease to the threads and tip of the SST center bolt before use.

|

| 17. REMOVE REAR DIFFERENTIAL DRIVE PINION OIL SLINGER |

Remove the drive pinion oil slinger.

|

| 18. REMOVE REAR DRIVE PINION FRONT TAPERED ROLLER BEARING |

Using SST, remove the inner race of the rear drive pinion front tapered roller bearing from the drive pinion.

- SST

- 09556-22010

- NOTICE:

- Apply grease to the threads and tip of the SST center bolt before use.

|

| 19. INSTALL REAR DIFFERENTIAL DRIVE PINION BEARING SPACER |

Install a new drive pinion bearing spacer to the drive pinion.

- NOTICE:

- Be sure to face the larger inner diameter side rearward as shown in the illustration.

|

| 20. INSTALL REAR DRIVE PINION FRONT TAPERED ROLLER BEARING |

Install the rear drive pinion front tapered roller bearing to the drive pinion.

|

| 21. INSTALL REAR DIFFERENTIAL DRIVE PINION OIL SLINGER |

Install the drive pinion oil slinger to the drive pinion.

|

| 22. INSTALL REAR DRIVE PINION COMPANION FLANGE |

Using SST and companion flange, install the rear drive pinion front tapered roller bearing.

- SST

- 09950-30012(09951-03010,09953-03010,09954-03010,09955-03030,09956-03030)

- NOTICE:

- Apply grease to the threads and tip of the SST center bolt before use.

|

| 23. REMOVE REAR DRIVE PINION COMPANION FLANGE |

Using SST, remove the companion flange.

- SST

- 09950-30012(09951-03010,09953-03010,09954-03010,09955-03030,09956-03030)

- NOTICE:

- Apply grease to the threads and tip of the SST center bolt before use.

|

| 24. INSTALL REAR DIFFERENTIAL CARRIER OIL SEAL |

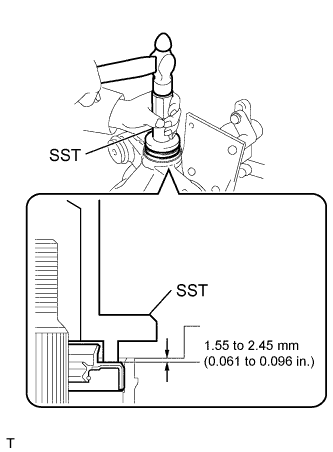

Using SST and a hammer, install a new oil seal.

- SST

- 09554-22010

- Oil seal installation depth:

- 1.55 to 2.45 mm (0.061 to 0.096 in.)

|

Apply MP grease to the oil seal lip.

| 25. INSTALL REAR DRIVE PINION COMPANION FLANGE |

Using SST, install the companion flange.

- SST

- 09950-30012(09951-03010,09953-03010,09954-03010,09955-03030,09956-03030)

- NOTICE:

- Apply grease to the threads and tip of the SST center bolt before use.

|

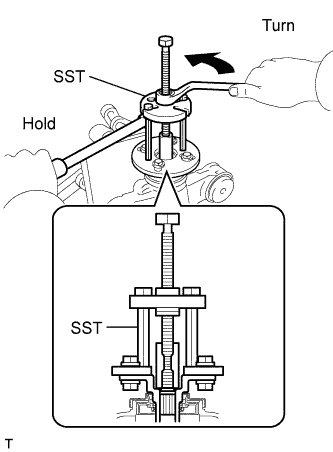

Using SST to hold the flange, tighten the drive pinion nut.

- SST

- 09330-00021

- Torque:

- 338 N*m (3,450 kgf*cm, 249 ft.*lbf) or less

- NOTICE:

- Tighten the nut to approximately 100 N*m (1,020 kgf*cm, 74 ft.*lbf), and tighten it further while checking the preload.

- Apply hypoid gear oil LSD to the nut and the threads of the drive pinion.

|

| 26. ADJUST DIFFERENTIAL DRIVE PINION PRELOAD |

Using a torque wrench, measure the preload of the drive pinion.

- Drive Pinion Preload (at starting):

Specifications Preload New bearing 1.49 to 2.59 N*m (15.2 to 26.4 kgf*cm, 13.2 to 22.9 in.*lbf) Reused bearing 1.11 to 1.91 N*m (11.3 to 19.5 kgf*cm, 9.8 to 16.9 in.*lbf)

- If the preload is less than the specified minimum value, check the preload while retightening the drive pinion nut by 5 to 10° to adjust it into the specified range.

- Torque:

- 338 N*m (3,450 kgf*cm, 249 ft.*lbf) or less

- If the preload is less than the specified minimum value even when the tightening torque of the drive pinion nut is greater than the specified maximum value, loosen the nut and check that the threads of the drive pinion nut and drive pinion are not stripped.

- If the threads are not stripped, replace the bearing spacer. Apply hypoid gear oil LSD to the threads of the drive pinion and repeat the procedure.

|

| 27. INSPECT TOTAL PRELOAD |

Using a torque wrench, measure the preload with the teeth of the drive pinion and ring gear in contact.

- Preload (at starting):

Specifications New drive pinion tapered roller bearing Reused drive pinion tapered roller bearing New differential case bearing 2.57 to 4.26 N*m (26.2 to 43.4 kgf*cm, 22.7 to 37.7 in.*lbf) 2.19 to 3.58 N*m (22.3 to 36.5 kgf*cm, 19.4 to 31.7 in.*lbf) Reused differential case bearing 1.98 to 3.37 N*m (20.2 to 34.4 kgf*cm, 17.5 to 29.8 in.*lbf) 1.60 to 2.69 N*m (16.3 to 27.4 kgf*cm, 14.2 to 23.8 in.*lbf)

|

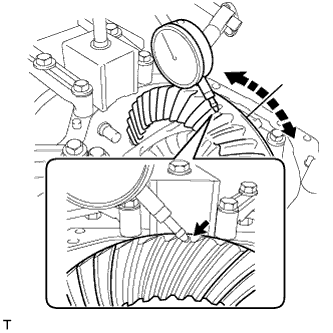

| 28. INSPECT DIFFERENTIAL RING GEAR BACKLASH |

Set the dial indicator perpendicular to the end of the ring gear face.

|

While holding the rear drive pinion companion flange, rotate the ring gear and measure the backlash.

- Backlash:

- 0.13 to 0.18 mm (0.0051 to 0.0071 in.)

- HINT:

- Record the measured backlash to use as a reference for selecting a side gear shaft plate washer.

- Inspect tooth contact to use the result as a reference for selecting a side gear shaft plate washer.

Select a side gear shaft plate washer that will set ring gear backlash within the specified range, and install it to the ring gear back side.

Washer thickness Thickness mm (in.) Thickness mm (in.) Thickness mm (in.) 2.57 to 2.59 (0.1012 to 0.1020) 2.89 to 2.91 (0.1138 to 0.1146) 3.21 to 3.23 (0.1264 to 0.1271) 2.59 to 2.61 (0.1020 to 0.1028) 2.91 to 2.93 (0.1146 to 0.1154) 3.23 to 3.25 (0.1271 to 0.1280) 2.61 to 2.63 (0.1028 to 0.1035) 2.93 to 2.95 (0.1154 to 0.1161) 3.25 to 3.27 (0.1280 to 0.1287) 2.63 to 2.65 (0.1035 to 0.1043) 2.95 to 2.97 (0.1161 to 0.1169) 3.27 to 3.29 (0.1287 to 0.1295) 2.65 to 2.67 (0.1043 to 0.1051) 2.97 to 2.99 (0.1169 to 0.1177) 3.29 to 3.31 (0.1295 to 0.1303) 2.67 to 2.69 (0.1051 to 0.1059) 2.99 to 3.01 (0.1177 to 0.1185) 3.31 to 3.33 (0.1303 to 0.1311) 2.69 to 2.71 (0.1059 to 0.1067) 3.01 to 3.03 (0.1185 to 0.1193) 3.33 to 3.35 (0.1311 to 0.1319) 2.71 to 2.73 (0.1067 to 0.1075) 3.03 to 3.05 (0.1193 to 0.1201) 3.35 to 3.37 (0.1319 to 0.1327) 2.73 to 2.75 (0.1075 to 0.1083) 3.05 to 3.07 (0.1201 to 0.1209) 3.37 to 3.39 (0.1327 to 0.1335) 2.75 to 2.77 (0.1083 to 0.1091) 3.07 to 3.09 (0.1209 to 0.1217) 3.39 to 3.41 (0.1335 to 0.1343) 2.77 to 2.79 (0.1091 to 0.1098) 3.09 to 3.11 (0.1217 to 0.1224) 3.41 to 3.43 (0.1343 to 0.1350) 2.79 to 2.81 (0.1098 to 0.1106) 3.11 to 3.13 (0.1224 to 0.1232) 3.43 to 3.45 (0.1350 to 0.1358) 2.81 to 2.83 (0.1106 to 0.1114) 3.13 to 3.15 (0.1232 to 0.1240) 3.45 to 3.47 (0.1358 to 0.1366) 2.83 to 2.85 (0.1114 to 0.1122) 3.15 to 3.17 (0.1240 to 0.1248) 3.47 to 3.49 (0.1366 to 0.1374) 2.85 to 2.87 (0.1122 to 0.1130) 3.17 to 3.19 (0.1248 to 0.1256) - 2.87 to 2.89 (0.1130 to 0.1138) 3.19 to 3.21 (0.1256 to 0.1264) -

|

Make the differential case bearing and side gear shaft plate washer snug by tapping on the ring gear with a plastic hammer.

|

Set the dial indicator perpendicular to the end of the ring gear face.

|

While holding the rear drive pinion companion flange rear, rotate the ring gear and measure the backlash.

- Backlash:

- 0.13 to 0.18 mm (0.0051 to 0.0071 in.)

If the backlash is not within the specified range, select a side gear shaft plate washer that will set the ring gear backlash within the specified range and install it into the ring gear back side.

|

Select a thicker side gear shaft plate washer so that the clearance between the case bearing outer race end on the ring gear teeth side and the carrier becomes zero or close to zero.

|

Make the differential case bearing and side gear shaft plate washer snug by tapping on the ring gear with a plastic hammer.

|

Set the dial indicator perpendicular to the end of the ring gear face.

|

While holding the rear drive pinion companion flange, rotate the ring gear and measure the backlash.

- Backlash:

- 0.13 to 0.18 mm (0.0051 to 0.0071 in.)

| 29. INSPECT RUNOUT OF REAR DRIVE PINION COMPANION FLANGE |

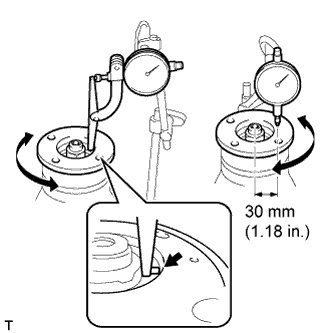

Using a dial indicator, measure the runout of the companion flange vertically and horizontally.

- Maximum runout:

- 0.09 mm (0.0035 in.)

|

| 30. INSTALL REAR DRIVE PINION NUT |

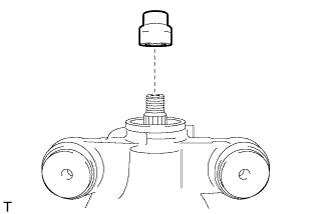

Using a SST and a hammer, stake the drive pinion nut.

- SST

- 09930-00010

|

| 31. INSTALL REAR DIFFERENTIAL SIDE GEAR SHAFT OIL SEAL |

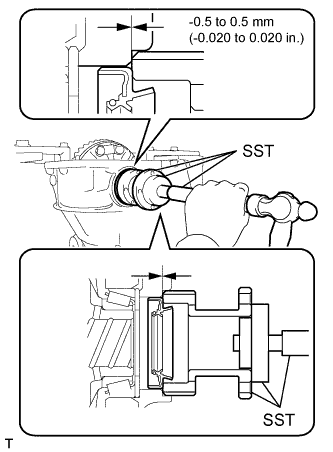

Using SST and a hammer, install 2 new oil seals.

- SST

- 09213-70011

09950-60010(09951-00410,09951-00620,09952-06010)

09950-70010(09951-07100)

- Oil seal installation depth:

- -0.5 to 0.5 mm (-0.020 to 0.020 in.)

|

Apply MP grease to the oil seal lip.

| 32. INSTALL REAR DIFFERENTIAL DRAIN PLUG |

Using a hexagon wrench (10 mm), install the differential drain plug with a new gasket.

- Torque:

- 49 N*m{500 kgf*cm, 36 ft.*lbf}

| 33. REMOVE REAR DIFFERENTIAL CARRIER |

Remove the differential carrier from the overhaul stand, etc.

|

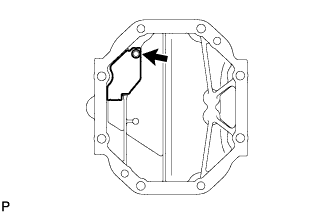

| 34. INSTALL REAR DIFFERENTIAL BREATHER PLUG OIL DEFLECTOR |

Install the oil deflector and bolt to the carrier cover.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

|

| 35. INSTALL REAR DIFFERENTIAL CARRIER COVER |

Clean any residual FIPG material on the contact surfaces using gasoline or alcohol.

Apply FIPG to the carrier cover.

- FIPG:

- 08826-00090, THREE BOND 1281 or equivalent

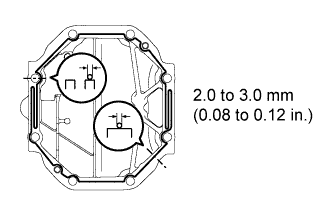

- HINT:

- Apply FIPG in a continuous bead, approximately 2 to 3 mm (0.08 to 0.12 in.) in diameter on the entire sealing surface.

- Overlap FIPG at least 10 mm (0.39 in.) or more at the beginning and the end of application.

- Install the carrier cover within 3 minutes after applying FIPG.

- Do not fill the differential with oil or drive the vehicle immediately after installing the differential carrier cover. Allow at least one hour for the sealant to dry before filling the differential. Avoid sudden acceleration and deceleration for at least 12 hours after installation of parts using FIPG sealant.

|

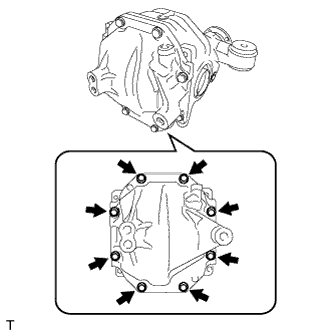

Install the carrier cover with the 8 bolts.

- Torque:

- 47 N*m{480 kgf*cm, 35 ft.*lbf}

|

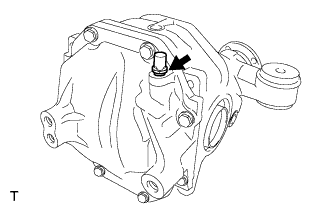

| 36. INSTALL REAR DIFFERENTIAL BREATHER PLUG |

Install the breather plug to the carrier cover.

- Torque:

- 21 N*m{210 kgf*cm, 15 ft.*lbf}

|