Clutch Drum And Input Shaft Assembly Inspection

INSPECT NO. 4 ONE WAY CLUTCH ASSEMBLY

INSPECT DIRECT CLUTCH RETURN SPRING SUB-ASSEMBLY

INSPECT REVERSE CLUTCH RETURN SPRING SUB-ASSEMBLY

INSPECT NO. 2 DIRECT CLUTCH DISC

INSPECT PACK CLEARANCE OF NO. 2 DIRECT CLUTCH

INSPECT PACK CLEARANCE OF NO. 3 CLUTCH

INSPECT FORWARD CLUTCH RETURN SPRING SUB-ASSEMBLY

INSPECT COAST CLUTCH DISC

INSPECT PACK CLEARANCE OF NO. 1 CLUTCH

INSPECT NO. 1 CLUTCH DISC

INSPECT PACK CLEARANCE OF COAST CLUTCH

INSPECT CLUTCH HUB SUB-ASSEMBLY

INSPECT NO. 3 CLUTCH DISC

INSPECT REVERSE CLUTCH HUB SUB-ASSEMBLY

Clutch Drum And Input Shaft Assembly -- Inspection |

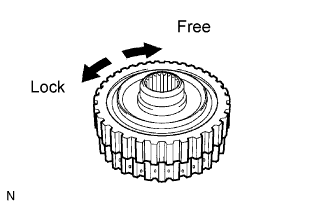

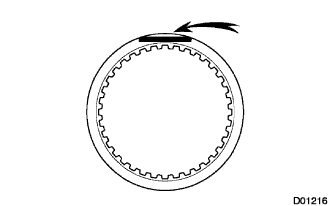

| 1. INSPECT NO. 4 ONE WAY CLUTCH ASSEMBLY |

Hold the coast clutch hub and turn the one way clutch assembly.

Check that the one way clutch assembly turns freely clockwise and locks counterclockwise.

If there is a problem with the one way clutch, replace it.

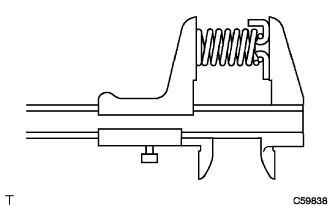

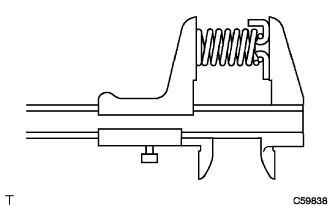

| 2. INSPECT DIRECT CLUTCH RETURN SPRING SUB-ASSEMBLY |

Using vernier calipers, measure the free length of the spring together with the spring seat.

- Standard free length:

- 20.02 mm (0.788 in.)

If the free length is shorter than the standard free length, replace the clutch return spring sub-assembly.

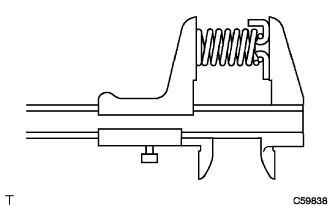

| 3. INSPECT REVERSE CLUTCH RETURN SPRING SUB-ASSEMBLY |

Using vernier calipers, measure the free length of the spring together with the spring seat.

- Standard free length:

- 21.03 mm (0.828 in.)

If the free length is shorter than the standard free length, replace the clutch return spring sub-assembly.

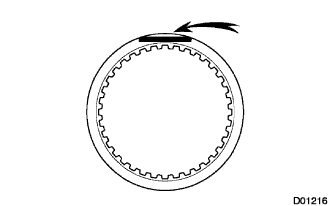

| 4. INSPECT NO. 2 DIRECT CLUTCH DISC |

Check whether the sliding surfaces of the discs, the plates, and the flange are worn or burnt.

If necessary, replace them.

- NOTICE:

- If the linings of the discs are peeled off or discolored, or even a part of the printed numbers is damaged, replace all discs.

- Before assembling new discs, soak them in ATF for at least 15 minutes.

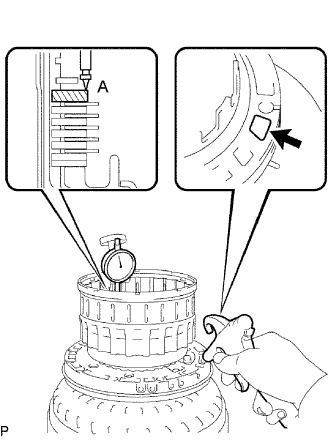

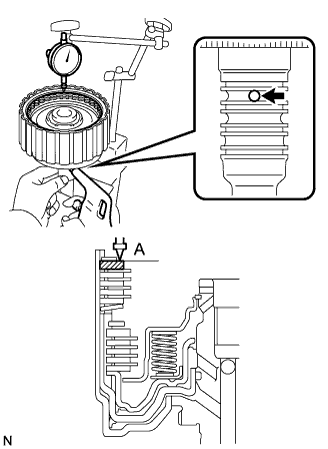

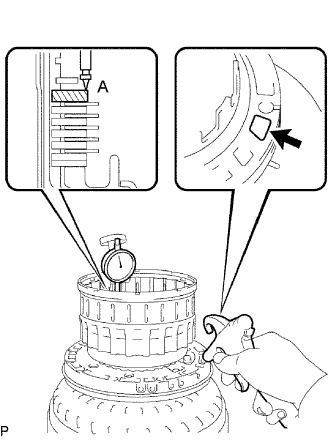

| 5. INSPECT PACK CLEARANCE OF NO. 2 DIRECT CLUTCH |

|

Inspect the pack clearance of the No. 2 direct clutch.

Using a dial indicator, measure the moving distance (distance A) of the clutch flange at both ends across a diameter while blowing air to the oil hole as shown in the illustration, and calculate the average.

- HINT:

- Flange moving distance A = 0.24 to 1.12 mm (0.0094 to 0.0441 in.)

- Pack clearance = Flange moving distance A - 0.03 mm (0.0012 in.)

- Pack Clearance:

- 0.5 to 0.8 mm (0.020 to 0.031 in.)

- NOTICE:

- Install a selective flange {t = 3.4 mm (0.134 in.)} when measuring the moving distance (shaded area in the illustration).

If the pack clearance is outside the specified range, select and install a clutch flange that brings the pack clearance within the specified range.

- HINT:

- There are 9 types of flanges that can be used to adjust the pack clearance. Select the one with the most appropriate thickness.

- Flange thickness:

No.

| Thickness

|

0

| 3.0 mm (0.118 in.)

|

1

| 3.1 mm (0.122 in.)

|

2

| 3.2 mm (0.126 in.)

|

3

| 3.3 mm (0.130 in.)

|

4

| 3.4 mm (0.134 in.)

|

5

| 3.5 mm (0.138 in.)

|

6

| 3.6 mm (0.142 in.)

|

7

| 3.7 mm (0.146 in.)

|

8

| 3.8 mm (0.150 in.)

|

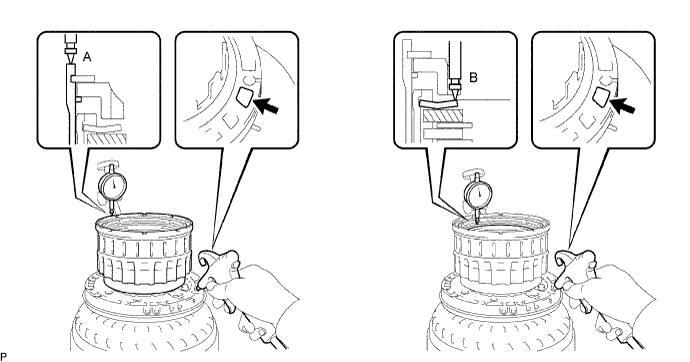

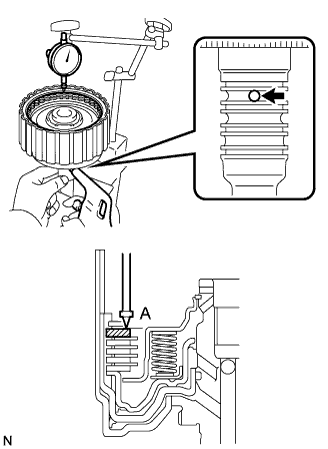

| 6. INSPECT PACK CLEARANCE OF NO. 3 CLUTCH |

Inspect the pack clearance of the reverse clutch hub sub-assembly.

Using a dial indicator, measure the reverse clutch piston stroke (distance A) and the moving distance (distance B) of the reverse clutch flange at both ends across a diameter while blowing air (392 kPa, 4 kgf/cm2, 57 psi) from the oil hole as shown in the illustration, and calculate the average.

- HINT:

- Piston stroke A = 1.62 to 2.68 mm (0.0638 to 0.1055 in.)

- Flange moving distance B = 1.22 to 1.67 mm (0.0480 to 0.0657 in.)

- Pack clearance = Piston stroke A - Flange moving distance B - 0.02 mm (0.0008 in.)

- Pack Clearance:

- 0.4 to 0.7 mm (0.016 to 0.028 in.)

- NOTICE:

- Install a selective flange {t = 2.8 mm (0.110 in.)} when measuring the moving distance (shaded area in the illustration).

If the pack clearance is outside the specified range, select and install a clutch flange that brings the pack clearance within the specified range.

- HINT:

- There are 12 types of flanges that can be used to adjust the pack clearance. Select the one with the most appropriate thickness.

- Flange thickness:

No.

| Thickness

|

0

| 2.4 mm (0.094 in.)

|

1

| 2.5 mm (0.098 in.)

|

2

| 2.6 mm (0.102 in.)

|

3

| 2.7 mm (0.106 in.)

|

4

| 2.8 mm (0.110 in.)

|

5

| 2.9 mm (0.114 in.)

|

6

| 3.0 mm (0.118 in.)

|

7

| 3.1 mm (0.122 in.)

|

8

| 3.2 mm (0.126 in.)

|

9

| 3.3 mm (0.130 in.)

|

A

| 3.4 mm (0.134 in.)

|

B

| 3.5 mm (0.138 in.)

|

| 7. INSPECT FORWARD CLUTCH RETURN SPRING SUB-ASSEMBLY |

Using vernier calipers, measure the free length of the spring together with the spring seat.

- Standard free length:

- 26.29 mm (1.035 in.)

If the free length is shorter than the standard free length, replace the clutch return spring sub-assembly.

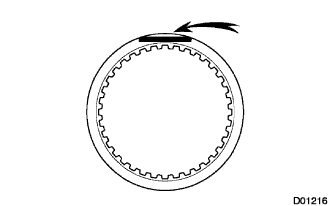

| 8. INSPECT COAST CLUTCH DISC |

Check whether the sliding surfaces of the discs, the plates, and the flange are worn or burnt.

If necessary, replace them.

- NOTICE:

- If the linings of the discs are peeled off or discolored, or even a part of the printed numbers is damaged, replace all discs.

- Before assembling new discs, soak them in ATF for at least 15 minutes.

| 9. INSPECT PACK CLEARANCE OF NO. 1 CLUTCH |

Inspect the pack clearance of the No. 1 clutch.

Using a dial indicator, measure the moving distance (distance A) of the clutch flange at both ends across a diameter while blowing air from the oil hole as shown in the illustration, and calculate the average.

- HINT:

- Flange moving distance A = 0.14 to 0.17 mm (0.0055 to 0.0067 in.)

- Pack clearance = Flange moving distance A - 0.01 mm (0.00039 in.)

- Pack Clearance:

- 0.56 to 0.86 mm (0.0220 to 0.0339 in.)

- NOTICE:

- Install a selective flange {t = 3.5 mm (0.138 in.)} when measuring the moving distance (shaded area in the illustration).

If the pack clearance is outside the specified range, select and install a clutch flange that brings the pack clearance within the specified range.

- HINT:

- There are 10 types of flanges that can be used to adjust the pack clearance. Select the one with the most appropriate thickness.

- Flange thickness:

No.

| Thickness

|

0

| 3.0 mm (0.118 in.)

|

1

| 3.1 mm (0.122 in.)

|

2

| 3.2 mm (0.126 in.)

|

3

| 3.3 mm (0.130 in.)

|

4

| 3.4 mm (0.134 in.)

|

5

| 3.5 mm (0.138 in.)

|

6

| 3.6 mm (0.142 in.)

|

7

| 3.7 mm (0.146 in.)

|

8

| 3.8 mm (0.150 in.)

|

9

| 3.9 mm (0.154 in.)

|

| 10. INSPECT NO. 1 CLUTCH DISC |

Check whether the sliding surfaces of the discs, the plates, and the flange are worn or burnt.

If necessary, replace them.

- NOTICE:

- If the linings of the discs are peeled off or discolored, or even a part of the printed numbers is damaged, replace all discs.

- Before assembling new discs, soak them in ATF for at least 15 minutes.

| 11. INSPECT PACK CLEARANCE OF COAST CLUTCH |

Inspect the pack clearance of the coast clutch.

Using a dial indicator, measure the moving distance (distance A) of the clutch flange at both ends across a diameter while blowing air from the oil hole as shown in the illustration, and calculate the average.

- HINT:

- Flange moving distance A = 0.02 to 1.01 mm (0.0008 to 0.0398 in.)

- Pack clearance = Flange moving distance A - 0.01 mm (0.00039 in.)

- Pack Clearance:

- 0.4 to 0.7 mm (0.0157 to 0.0276 in.)

- NOTICE:

- Install a selective flange {t = 3.5 mm (0.138 in.)} when measuring the moving distance (shaded area in the illustration).

If the pack clearance is outside the specified range, select and install a clutch flange that brings the pack clearance within the specified range.

- HINT:

- There are 10 types of flanges that can be used to adjust the pack clearance. Select the one with the most appropriate thickness.

- Flange thickness:

No.

| Thickness

|

0

| 3.0 mm (0.118 in.)

|

1

| 3.1 mm (0.122 in.)

|

2

| 3.2 mm (0.126 in.)

|

3

| 3.3 mm (0.130 in.)

|

4

| 3.4 mm (0.134 in.)

|

5

| 3.5 mm (0.138 in.)

|

6

| 3.6 mm (0.142 in.)

|

7

| 3.7 mm (0.146 in.)

|

8

| 3.8 mm (0.150 in.)

|

9

| 3.9 mm (0.154 in.)

|

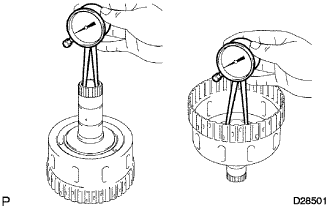

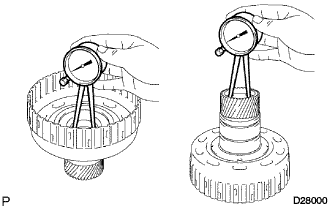

| 12. INSPECT CLUTCH HUB SUB-ASSEMBLY |

Using a dial indicator, measure the inside diameter of the clutch hub bushing.

- Standard inside diameter:

- 23.037 to 23.062 mm (0.907 to 0.908 in.)

If the inside diameter is greater than the standard inside diameter, replace the clutch hub.

| 13. INSPECT NO. 3 CLUTCH DISC |

Check whether the sliding surfaces of the discs, the plates, and the flange are worn or burnt.

If necessary, replace them.

- NOTICE:

- If the linings of the discs are peeled off or discolored, or even a part of the printed numbers is damaged, replace all discs.

- Before assembling new discs, soak them in ATF for at least 15 minutes.

| 14. INSPECT REVERSE CLUTCH HUB SUB-ASSEMBLY |

Using a dial indicator, measure the inside diameter of the reverse clutch hub bushing.

- Standard inside diameter:

- 33.312 to 33.337 mm (1.3115 to 1.3125 in.)

If the inside diameter is greater than the standard inside diameter, replace the reverse clutch hub.