Rear Propeller Shaft Assembly (For 3Gr-Fse) Disassembly

REMOVE PROPELLER SHAFT ASSEMBLY

REMOVE CENTER SUPPORT BEARING ASSEMBLY NO.1

INSPECT PROPELLER SHAFT ASSEMBLY

INSPECT INTERMEDIATE SHAFT

INSPECT SPIDER BEARING

INSPECT CENTER SUPPORT BEARING ASSEMBLY NO.1

Rear Propeller Shaft Assembly (For 3Gr-Fse) -- Disassembly |

| 1. REMOVE PROPELLER SHAFT ASSEMBLY |

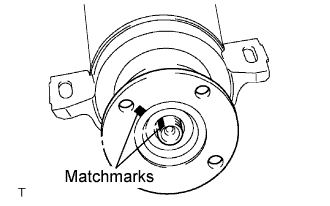

Put matchmarks on both flanges.

Remove the 4 nuts, bolts, washers and propeller shaft assembly.

| 2. REMOVE CENTER SUPPORT BEARING ASSEMBLY NO.1 |

Hold the intermediate shaft assembly in a vise between aluminium plates.

- NOTICE:

- Do not overtighten the vise.

Using a chisel and a hammer, release the staked part of the nut.

- NOTICE:

- Release the staked part of the nut completely, otherwise the threads of the intermediate shaft may be damaged.

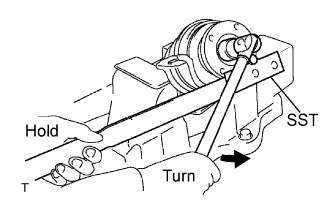

Using SST to hold the universal joint flange, remove the nut and intermediate shaft washer.

- SST

- 09330-00021

Put matchmarks on the intermediate shaft assembly and universal joint flange.

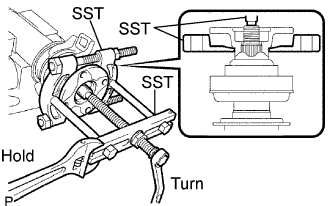

Using SST, remove the universal joint flange from the intermediate shaft assembly.

- SST

- 09950-00020

09950-00030

- NOTICE:

- Apply grease to the threads and tip of the SST center bolt before use.

Remove the center support bearing assembly No.1 and 2 center support bearing washers from the intermediate shaft assembly.

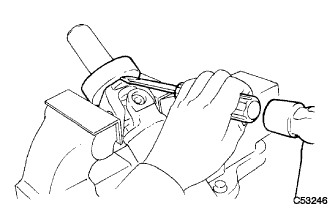

Hold the intermediate shaft assembly in a vise between aluminium plates.

- NOTICE:

- Do not overtighten the vise.

Using a screwdriver and a hammer, remove the sliding shaft dust cover.

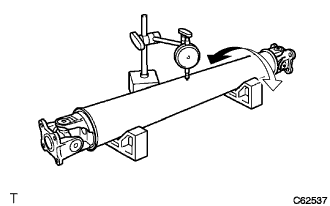

| 3. INSPECT PROPELLER SHAFT ASSEMBLY |

Using a dial indicator, inspect the runout of the propeller shaft.

- Maximum runout:

- 0.8 mm (0.031 in.)

- NOTICE:

- The dial indicator must be set at a right angle to the center of the propeller shaft.

- HINT:

- If the shaft runout exceeds the maximum, replace the propeller shaft.

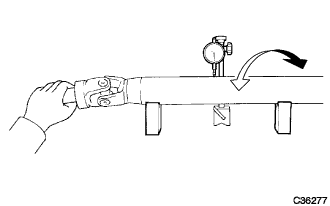

| 4. INSPECT INTERMEDIATE SHAFT |

Using a dial indicator, inspect the runout of the intermediate shaft.

- Maximum runout:

- 0.8 mm (0.031 in.)

- NOTICE:

- The dial indicator must be set at a right angle to the center of the propeller shaft.

- HINT:

- If the shaft runout exceeds the maximum, replace the intermediate shaft.

| 5. INSPECT SPIDER BEARING |

Check that the spider bearing rotates smoothly.

Check that there is no play in the spider bearing.

- HINT:

- If necessary, replace the intermediate shaft.

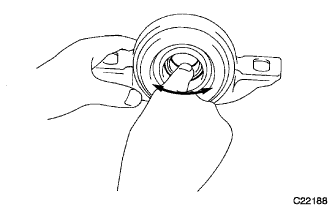

| 6. INSPECT CENTER SUPPORT BEARING ASSEMBLY NO.1 |

Turn the center support bearing by hand in the rotating direction. Check the center support bearing turns smoothly.

Check that the seals are not cracked or damaged.

- HINT:

- If the center support bearing is damaged, worn, or does not turn smoothly, replace it.