Dtc P2759 Torque Converter Clutch Pressure Control Solenoid Control Circuit Electrical (Shift Solenoid Valve Slu)

DESCRIPTION

MONITOR DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

INSPECT TRANSMISSION WIRE (SLU)

CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM)

INSPECT SHIFT SOLENOID VALVE SLU

DTC P2759 Torque Converter Clutch Pressure Control Solenoid Control Circuit Electrical (Shift Solenoid Valve SLU) |

DESCRIPTION

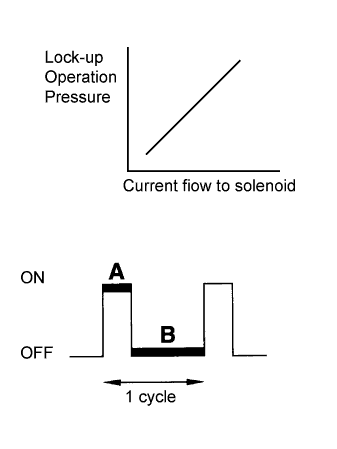

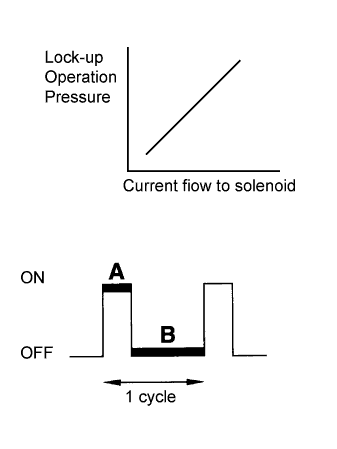

The amount of current flow to the solenoid is controlled by the (*) duty ratio of the ECM output signal. The higher the duty ratio becomes, the higher the lock-up hydraulic pressure becomes during the lock-up operation. (*) Duty RatioThe duty ratio is the ratio of the period of continuity in one cycle. For example, if A is the period of continuity in one cycle, and B is the period of non-continuity, then Duty Ratio = A/(A+B) x 100(%).

(*) Duty RatioThe duty ratio is the ratio of the period of continuity in one cycle. For example, if A is the period of continuity in one cycle, and B is the period of non-continuity, then Duty Ratio = A/(A+B) x 100(%).DTC No.

| DTC Detection Condition

| Trouble Area

|

P2759

| Open or short is detected in shift solenoid valve SLU circuit for 1 second or more while driving (1-trip detection logic).

| - Open or short in shift solenoid valve SLU circuit

- Shift solenoid valve SLU

- ECM

|

MONITOR DESCRIPTION

When an open or short in a shift solenoid valve (SLU) circuit is detected, the ECM determines there is a malfunction. The ECM will turn on the MIL and store this DTC.

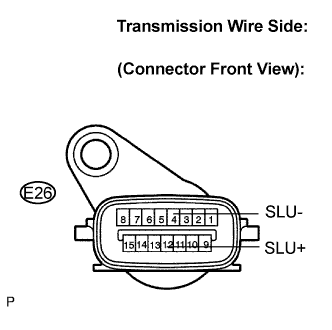

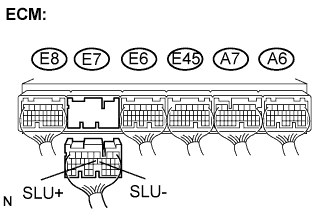

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.INSPECT TRANSMISSION WIRE (SLU) |

Disconnect the transmission wire connector from the transmission.

Measure the resistance according to the value(s) in the table below.

- Resistance:

Tester Connection

| Specified Condition

20°C (68°F)

|

12 (SLU+) - 4 (SLU-)

| 5.0 to 5.6 Ω

|

Measure the resistance according to the value(s) in the table below.

- Resistance (Check for short):

Tester Connection

| Specified Condition

|

12 (SLU+) - Body ground

| 10 kΩ or higher

|

4 (SLU-) - Body ground

| ↑

|

| 2.CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM) |

Connect the transmission wire connector to the transmission.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Resistance:

Tester Connection

| Specified Condition

20°C (68°F)

|

E7 - 13 (SLU+) - E7 - 12 (SLU-)

| 5.0 to 5.6 Ω

|

Measure the resistance according to the value(s) in the table below.

- Resistance (Check for short):

Tester Connection

| Specified Condition

|

E7 - 13 (SLU+) - Body ground

| 10 kΩ or higher

|

E7 - 12 (SLU-) - Body ground

| ↑

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

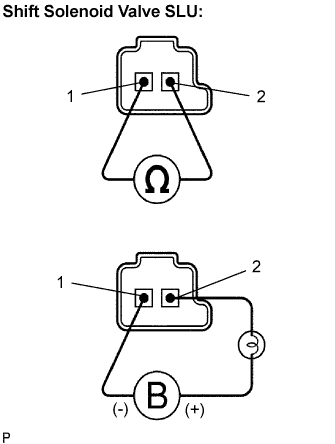

| 3.INSPECT SHIFT SOLENOID VALVE SLU |

Remove the shift solenoid valve SLU.

Measure the resistance according to the value(s) in the table below.

- Resistance:

Tester Connection

| Specified Condition

20°C (68°F)

|

1 - 2

| 5.0 to 5.6 Ω

|

Connect the positive (+) lead with a 21 W bulb to terminal 2 and the negative (-) lead to terminal 1 of the solenoid valve connector, then check the movement of the valve.

- OK:

- The solenoid makes an operating sound.

| | REPLACE SHIFT SOLENOID VALVE SLU |

|

|

| OK |

|

|

|

| REPAIR OR REPLACE TRANSMISSION WIRE |

|