Engine Assembly -- Installation |

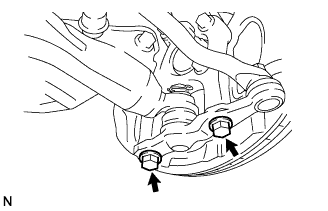

| 1. INSTALL NO. 1 ENGINE MOUNTING BRACKET FRONT LH |

Install the mounting bracket with the 4 bolts.

- Torque:

- 36 N*m{370 kgf*cm, 27 ft.*lbf}

- HINT:

- The LH mounting bracket is marked with "L".

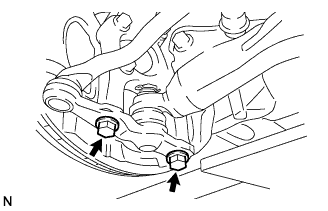

| 2. INSTALL NO. 1 ENGINE MOUNTING BRACKET FRONT RH |

Install the mounting bracket with the 4 bolts.

- Torque:

- 36 N*m{370 kgf*cm, 27 ft.*lbf}

- HINT:

- The RH mounting bracket is marked with "L".

| 3. INSTALL ENGINE OIL LEVEL SENSOR |

Install a new gasket to the sensor.

Install the sensor with the 4 bolts.

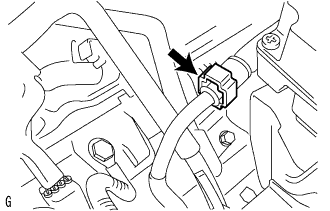

Connect the sensor connector.

| 4. INSTALL OIL FILTER BRACKET SUB-ASSEMBLY |

Install a new gasket and the oil filter bracket with the stud bolt and 2 nuts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

Connect the oil pressure switch connector.

| 5. REMOVE NO. 2 OIL COOLER PIPE SUB-ASSEMBLY |

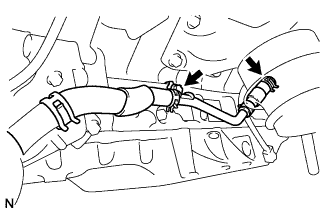

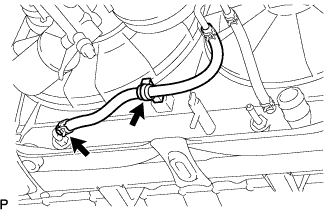

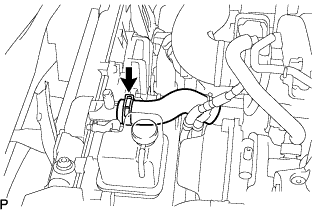

Install the water hoses and bolt.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 ft.*lbf}

|

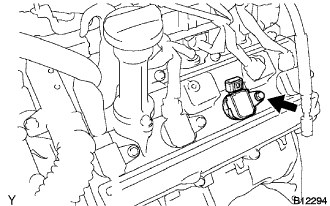

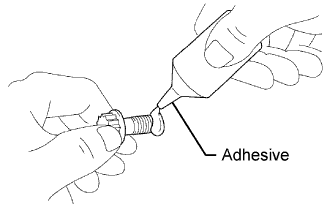

| 6. INSTALL OIL PRESSURE SWITCH |

Install the oil pressure switch.

Apply adhesive to 2 or 3 threads of the oil pressure switch.

- Adhesive:

- Part No. 08833-00070, THREE BOND 1324 or equivalent

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

| 7. INSTALL IGNITION COIL |

Connect a new ignition coil to the spark plug, attach the ignition coil to the cylinder head cover, and install the bolt.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

|

Connect the ignition coil connector.

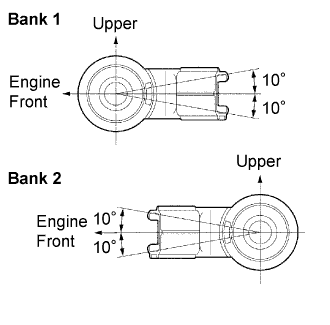

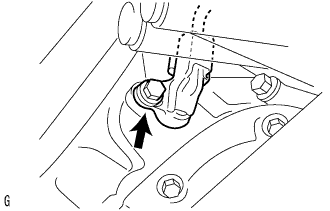

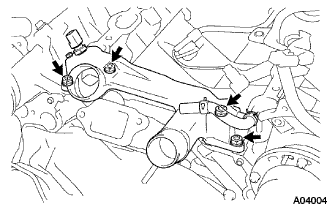

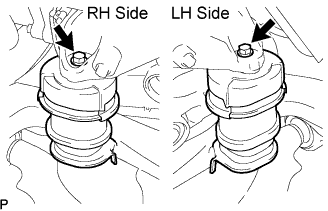

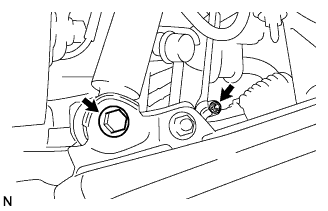

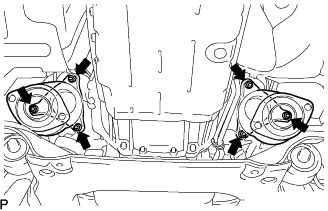

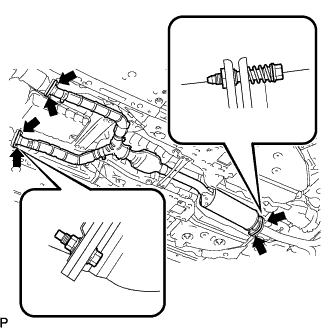

| 8. INSTALL KNOCK SENSOR |

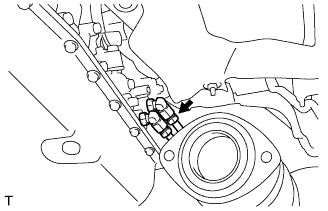

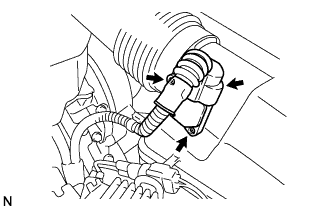

Install the 2 knock sensors with the 2 nuts, as shown in the illustration.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

|

Connect the 2 knock sensor connectors.

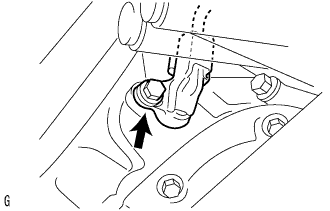

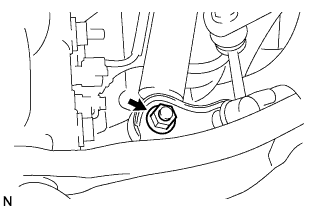

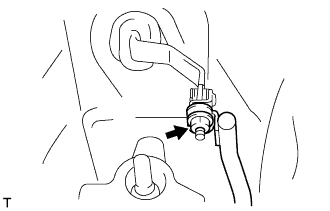

| 9. INSTALL CRANKSHAFT POSITION SENSOR |

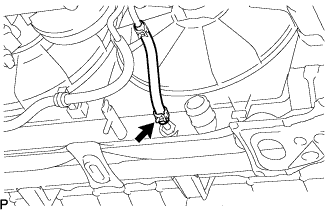

Install the sensor with the bolt.

- Torque:

- 6.5 N*m{66 kgf*cm, 57 in.*lbf}

|

Connect the sensor connector.

| 10. INSTALL VVT SENSOR |

Install the 2 sensors with the 2 bolts.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

Connect the 2 sensor connectors.

| 11. INSTALL CAMSHAFT POSITION SENSOR |

Install the sensor with the bolt.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

|

Connect the 2 sensor connectors.

| 12. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY |

Install a new O-ring to the oil control valve.

Install the oil control valve with the bolts.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

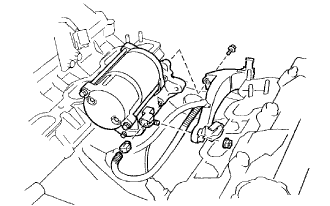

| 13. INSTALL STARTER ASSEMBLY |

|

Connect the starter cable with the nut.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

- HINT:

- If coolant has accumulated on the cylinder block, wipe it off with a clean cloth.

Install the starter cable protector with the bolt.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

Attach the terminal cap.

Connect the starter connector.

Install the starter with the 2 bolts.

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

|

| 14. INSTALL WATER BY-PASS PIPE SUB-ASSEMBLY |

Install a new O-ring to the water by-pass pipe.

Apply soapy water to the O-ring.

Push in the water by-pass pipe end into the pipe hole of the water pump.

Install the water by-pass pipe with the bolt.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

Install the wire clamp to the bracket of the water by-pass pipe.

| 15. INSTALL REAR WATER BY-PASS JOINT |

Install 2 new gaskets and the water by-pass joint with the 4 nuts. Alternately tighten the nuts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

|

| 16. INSTALL FRONT WATER BY-PASS JOINT |

Install 2 new gaskets and the water by-pass joint with the 4 nuts. Alternately tighten the nuts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

|

Connect the ECT sensor connector.

| 17. INSTALL WATER INLET HOUSING |

Install a new O-ring to the inlet housing.

|

Apply soapy water on the O-ring.

Apply seal packing to the sealing groove of the inlet housing as shown in the illustration.

- Seal packing:

- Part No. 08826-00100 or equivalent

- Seal diameter:

- 2 to 3 mm (0.08 to 0.12 in.)

- NOTICE:

- Remove any oil from the contact surface.

- Install the crankcase within 3 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after installing the inlet housing.

Install the water inlet and housing assembly with the 2 bolts. Alternately tighten the bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

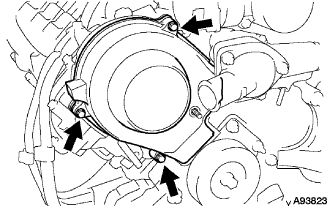

| 18. INSTALL NO. 3 TIMING BELT COVER SUB-ASSEMBLY RH |

Install the gasket to the cover.

|

Install the cover with the cap nut and 3 bolts.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

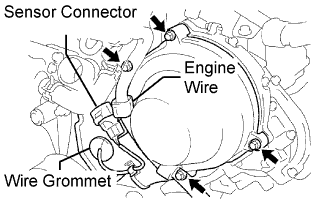

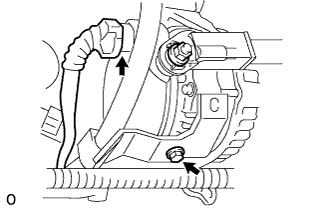

| 19. INSTALL NO. 3 TIMING BELT COVER SUB-ASSEMBLY LH |

Install the gasket to the cover.

|

Pass the camshaft position sensor wire through the cover hole.

Install the cover with the 4 bolts.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

Install the wire grommet to the cover.

Install the sensor connector to the sensor holder.

Connect the sensor connector.

Install the sensor wire to the wire clamp on the cover.

Install the engine wire to the 2 wire clamps on the cover.

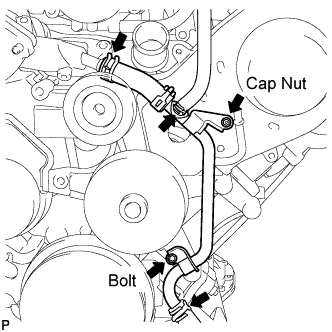

| 20. INSTALL OIL COOLER PIPE |

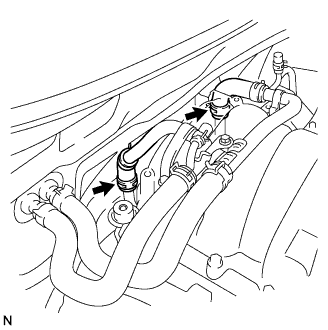

Connect the 3 water by-pass hoses as shown in the illustration.

|

Install the oil cooler pipe to the cover with the cap nut and the bolt.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

| 21. INSTALL NO. 2 ENGINE HANGER |

Install the engine hanger with the 2 bolts.

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

| 22. INSTALL NO. 1 ENGINE HANGER |

Install the engine hanger with the 2 bolts.

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

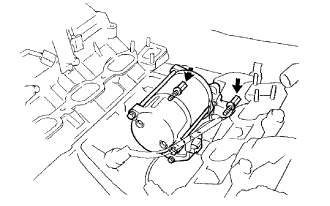

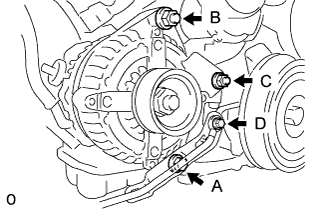

| 23. INSTALL GENERATOR ASSEMBLY |

|

Install the generator with the bolt and 2 nuts.

- HINT:

- Install the bolt and 2 nuts in alphabetical order.

- Torque:

- 39 N*m{398 kgf*cm, 29 ft.*lbf} for bolt A and nut B

- 15.5 N*m{158 kgf*cm, 11 ft.*lbf} for nut C

Install the ground cable with the bolt D.

Install the battery cable with the nut, and then attach the rubber cap.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

|

Install the bracket with the bolt.

- Torque:

- 6.0 N*m{61 kgf*cm, 53 in.*lbf}

Connect the cable to the generator.

| 24. INSTALL INTAKE MANIFOLD ASSEMBLY |

Install the manifold (Click here).

| 25. REMOVE ENGINE STAND |

| 26. INSTALL NO. 2 WIRE HARNESS HEAT INSULATOR |

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

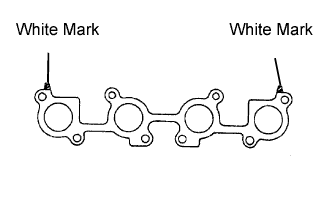

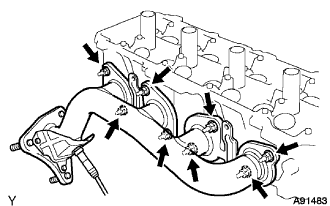

| 27. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY LH |

Place a new gasket on the cylinder head with the white mark facing the manifold side.

- NOTICE:

- Be careful of the installation direction.

|

Install the exhaust manifold with 8 new nuts. Uniformly tighten the nuts in several passes.

- Torque:

- 44 N*m{449 kgf*cm, 32 ft.*lbf}

|

| 28. INSTALL NO. 2 EXHAUST MANIFOLD HEAT INSULATOR |

Install the heat insulator with the 4 bolts.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

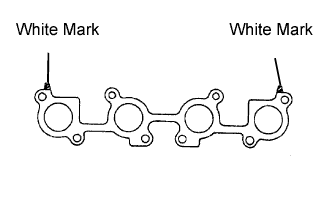

| 29. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY RH |

Place a new gasket on the cylinder head with the white mark facing the manifold side.

- NOTICE:

- Be careful of the installation direction.

|

Install the exhaust manifold with 8 new nuts. Uniformly tighten the nuts in several passes.

- Torque:

- 44 N*m{449 kgf*cm, 32 ft.*lbf}

|

| 30. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

Install the heat insulator with the 4 bolts.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

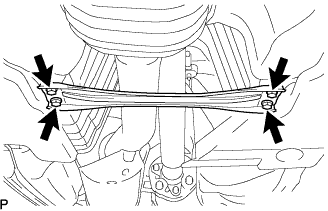

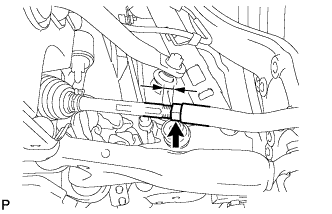

| 31. INSTALL FRONT ENGINE MOUNTING INSULATOR |

Install the front suspension crossmember sub-assembly with the 2 bolts.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

|

| 32. INSTALL OIL DIPSTICK GUIDE |

Install a new O-ring to the guide.

Install the guide with the bolt.

- Torque:

- 15 N*m{153 kgf*cm, 11 ft.*lbf}

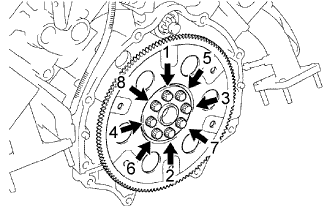

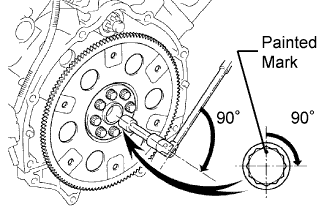

| 33. INSTALL DRIVE PLATE & RING GEAR SUB-ASSEMBLY |

- HINT:

- If any one of the mounting bolts is broken or deformed, replace it.

Apply adhesive to 2 or 3 threads of the mounting bolt end.

- Adhesive:

- Part No. 08833-00070, THREE BOND 1324 or equivalent

|

Install the front spacer, drive plate and rear spacer on the crankshaft.

|

Install and uniformly tighten the 8 mounting bolts in several passes, in the sequence shown in the illustration.

- Torque:

- 49 N*m{500 kgf*cm, 36 ft.*lbf}

Mark the mounting bolts with paint.

|

Tighten the mounting bolts another 90° in the same sequence shown in the step above.

Check that the painted mark is now at a 90° angle.

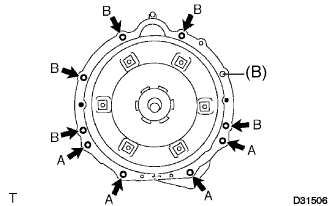

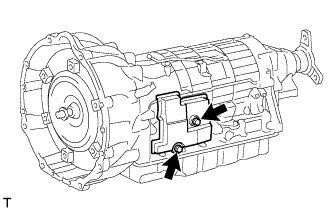

| 34. INSTALL AUTOMATIC TRANSMISSION ASSEMBLY |

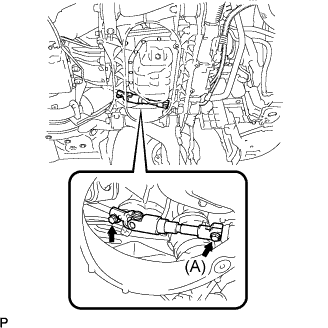

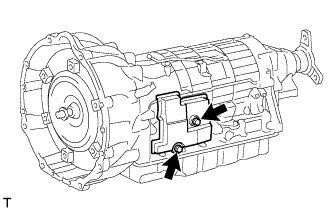

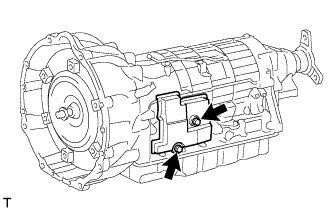

Install the automatic transmission to the engine with the 9 bolts.

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}for 14 mm head bolt A

- 71 N*m{724 kgf*cm, 52 ft.*lbf}for 17 mm head bolt B

- HINT:

- Bolt (B) is tightened to the wire harness clamp.

|

Install the 6 torque converter clutch mounting bolts.

- Torque:

- 48 N*m{489 kgf*cm, 35 ft.*lbf}

- HINT:

- First install the black colored bolt and then the remaining 5 bolts.

|

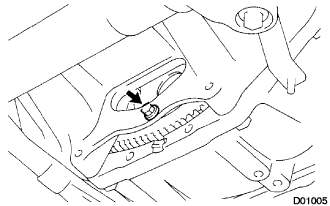

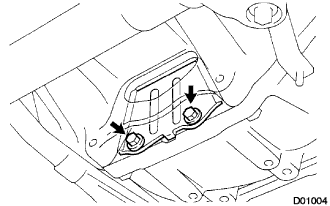

| 35. INSTALL FLYWHEEL HOUSING UNDER COVER |

Install the under cover with the 2 bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

|

| 36. INSTALL WIRE HARNESS AND CONNECTOR |

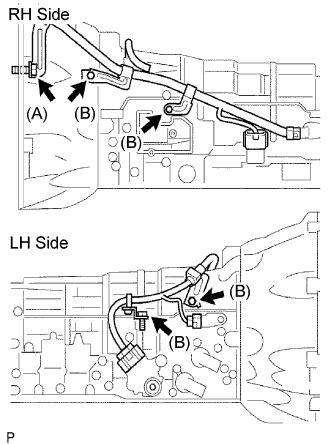

Connect the 2 speed sensor connectors.

Connect the transmission wire connector.

Connect the park/neutral position switch connector.

Install the wire harness clamps with the 5 bolts.

- Torque:

- 71 N*m{724 kgf*cm, 52 ft.*lbf}for bolt A

- 10 N*m{102 kgf*cm, 7 ft.*lbf}for bolt B

- HINT:

- Bolt (A) is tightened to the transmission housing.

|

| 37. INSTALL NO. 1 OIL COOLER OUTLET TUBE |

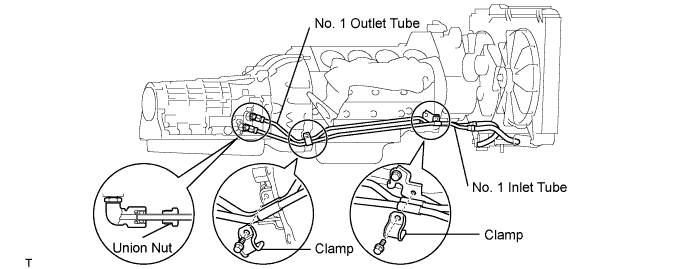

Temporarily install the oil cooler outlet tube.

Temporarily install the oil cooler inlet tube.

Install the 2 clamps with the 2 bolts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Tighten the oil cooler outlet tube No. 1.

- Torque:

- 42 N*m{428 kgf*cm, 31 ft.*lbf}

- NOTICE:

- Use a torque wrench with a fulcrum length of 460 mm (18.11 in.).

|

| 38. INSTALL NO. 1 OIL COOLER INLET TUBE |

Tighten the oil cooler inlet tube.

- Torque:

- 42 N*m{428 kgf*cm, 31 ft.*lbf}

- NOTICE:

- Use a torque wrench with a fulcrum length of 460 mm (18.11 in.).

|

| 39. INSTALL ENGINE WIRE |

| 40. INSTALL ENGINE AND TRANSMISSION ASSEMBLY |

Set the engine lifter.

|

Operate the engine lifter, then install the engine to the vehicle.

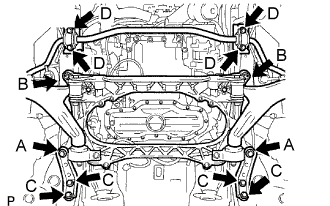

Install the 12 bolts.

- Torque:

- 204 N*m{2,080 kgf*cm, 150 ft.*lbf}for bolt A

- 167 N*m{1,700 kgf*cm, 123 ft.*lbf}for bolt B

- 50 N*m{510 kgf*cm, 37 ft.*lbf}for bolt C

- 49 N*m{500 kgf*cm, 36 ft.*lbf}for bolt D

Install the engine rear mounting member with the 4 bolts.

- Torque:

- 26 N*m{265 kgf*cm, 19 ft.*lbf}

|

| 41. INSTALL POWER STEERING LINK WIRE HARNESS |

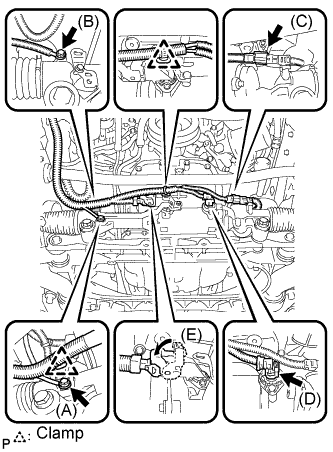

Install the power steering ground wire to the power steering link with bolt (B).

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

|

Connect wire harness connector (E) to the power steering link and securely lock the connector.

Connect 2 wire harness connectors (C) and (D) to the power steering.

Install the 2 wire harness clamps to the power steering link.

Connect the ground wire to the bracket with bolt (A).

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

| 42. INSTALL NO. 2 STEERING INTERMEDIATE SHAFT ASSEMBLY |

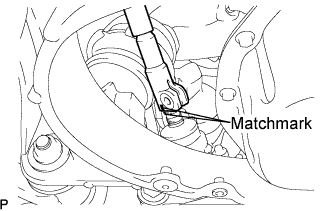

Align the matchmarks on the intermediate shaft assembly No. 2 and the power steering link.

|

Install bolt (A) and tighten the 2 bolts.

- Torque:

- 35 N*m{360 kgf*cm, 26 ft.*lbf}

|

| 43. INSTALL LOWER BALL JOINT ASSEMBLY FRONT LH |

Install the steering knuckle to the lower ball joint with the 2 bolts.

- Torque:

- 120 N*m{1220 kgf*cm, 89 ft.*lbf}

|

| 44. INSTALL LOWER BALL JOINT ASSEMBLY FRONT RH |

Install the steering knuckle to the lower ball joint with the 2 bolts.

- Torque:

- 120 N*m{1220 kgf*cm, 89 ft.*lbf}

|

| 45. INSTALL SHOCK ABSORBER ASSEMBLY FRONT RH |

Fully tighten the bolt on the lower side of the front shock absorber while holding the nut.

- Torque:

- 157 N*m{1,600 kgf*cm, 116 ft.*lbf}

|

| 46. INSTALL SHOCK ABSORBER ASSEMBLY FRONT LH |

Fully tighten the bolt on the lower side of the front shock absorber while holding the nut.

- Torque:

- 157 N*m{1,600 kgf*cm, 116 ft.*lbf}

|

| 47. INSTALL HEIGHT CONTROL SENSOR LINK |

Connect the height control sensor link with the nut.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 48. CONNECT FLOOR SHIFT GEAR SHIFTING ROD SUB-ASSEMBLY |

Connect the floor shift gear shifting rod sub-assembly with the nut.

- Torque:

- 13 N*m{130 kgf*cm, 9 ft.*lbf}

|

| 49. INSPECT SHIFT LEVER POSITION |

When shifting from the P to the R position with the engine switch on (IG) and brake pedal depressed, make sure that the shift lever moves smoothly and moves correctly into position.

Start the engine and make sure that the vehicle moves forward when shifting from the N to the D position and moves rearward when shifting to the R position.

If operation cannot be done as specified, inspect the park/neutral position switch assembly and check the shift lever assembly installation condition.

| 50. INSTALL NO. 1 EXHAUST PIPE SUPPORT BRACKET SUB-ASSEMBLY |

Install the support bracket with the 2 bolts.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

|

| 51. INSTALL FRONT TWC |

Install 2 new gaskets to the 2 TWCs.

- NOTICE:

- Do not reuse gasket.

Install the 2 TWCs to the exhaust manifold with the 6 nuts.

- Torque:

- 62 N*m{632 kgf*cm, 46 ft.*lbf}

|

| 52. INSTALL PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY |

| 53. INSTALL FRONT NO. 1 FLOOR HEAT INSULATOR |

| 54. INSTALL FRONT NO. 6 FLOOR HEAT INSULATOR |

| 55. INSTALL FRONT NO. 5 FLOOR HEAT INSULATOR |

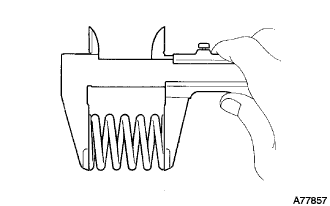

| 56. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

Using a vernier caliper, measure the free length of the compression spring.

- Minimum length:

- 38.5 mm (1.516 in.)

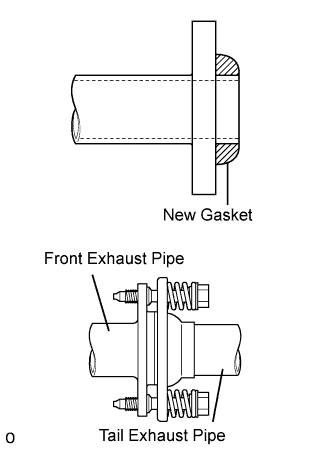

|

Install a new gasket to the rear side of the front exhaust pipe.

- HINT:

- Using a plastic-faced hammer, uniformly strike the gasket so that the gasket and front exhaust pipe are properly fit.

- NOTICE:

- Be careful with the installation direction of the gasket.

- Do not reuse the gasket.

- To ensure a proper seal, do not use the tailpipe to force the gasket onto the front exhaust pipe.

|

Install 2 new gaskets and the 2 TWCs with the 4 bolts.

- Torque:

- 62 N*m{632 kgf*cm, 46 ft.*lbf}

- NOTICE:

- Do not reuse the gaskets.

|

Install the front exhaust pipe to the tailpipe with the 2 compression springs and 2 bolts.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

| 57. INSTALL FRONT FLOOR BRACE CENTER |

Install the floor brace with the 4 bolts.

- Torque:

- 7.4 N*m{75 kgf*cm, 65 in.*lbf}

|

Install the panel brace with the 4 bolts.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

|

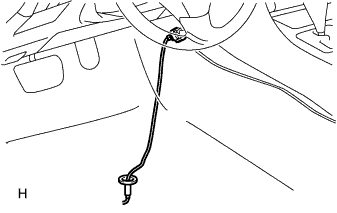

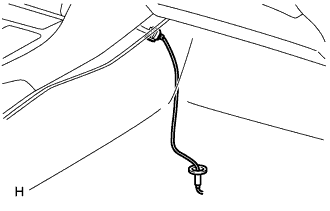

| 58. CONNECT HEATED OXYGEN SENSOR CONNECTOR |

Pass the sensor (bank 1 sensor 2) connector through the cabin and install the grommet.

|

Connect the sensor connector.

Pass the sensor connector through the cabin and install the grommet.

|

Connect the sensor (bank 2 sensor 2) connector.

| 59. INSTALL INSTRUMENT PANEL FINISH PANEL END LH |

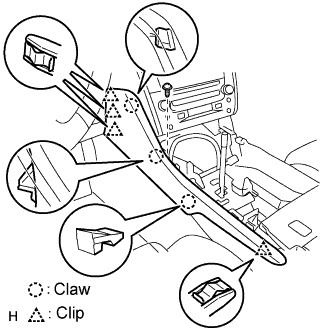

|

Attach the 4 clips and 3 claws to install the finish panel end.

Install the screw.

| 60. INSTALL INSTRUMENT PANEL FINISH PANEL END RH |

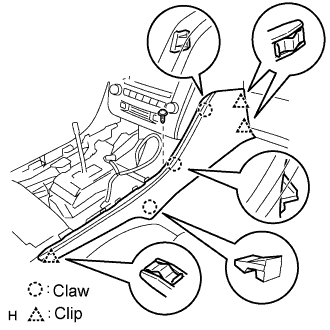

|

Attach the 3 clips and 3 claws to install the finish panel end.

Install the screw.

| 61. INSTALL CONSOLE UPPER PANEL ASSEMBLY |

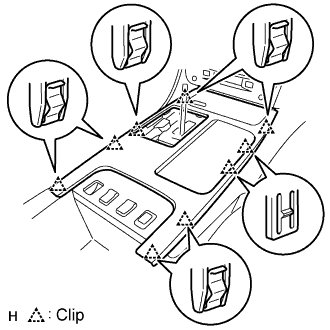

|

Connect the connector.

Attach the 9 clips to install the ash receptacle.

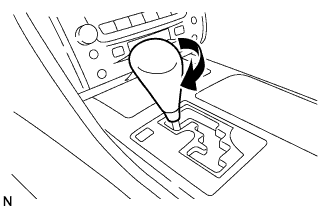

Install the shift lever knob and twist it in the direction indicated by the arrow.

|

| 62. INSTALL FRONT CONSOLE UPPER PANEL GARNISH |

Attach the claws to install the garnish.

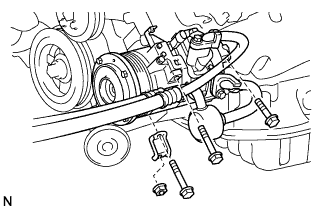

| 63. INSTALL COMPRESSOR ASSEMBLY |

Install the compressor with the 3 bolts, nut and bracket.

- Torque:

- 49 N*m{500 kgf*cm, 36 ft.*lbf}for bolt

- 30 N*m{306 kgf*cm, 22 ft.*lbf}for nut

|

| 64. INSTALL UNION TO CHECK VALVE HOSE |

Connect the union to check valve hose with the clamp.

| 65. INSTALL HEATER WATER OUTLET HOSE A (FROM HEATER UNIT) |

Connect the heater water outlet hose A with the clamp.

|

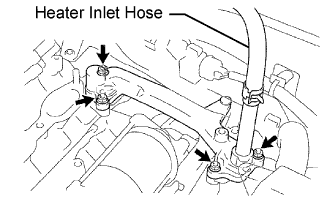

| 66. INSTALL HEATER WATER INLET HOSE A |

Connect the heater water inlet hose A with the clamp.

| 67. CONNECT ENGINE WIRE |

Connect the ground wire and install it with the bolt.

- Torque:

- 10 N*m{102 kgf*cm, 89 ft.*lbf}

Connect the wire to the engine room No. 1 junction block. Then, install it with the nut.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Install the engine room No. 1 relay block cover.

Connect the positive (+) battery cable and install it with the nut.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Connect the ECM connectors.

Connect the engine wire to the connector holder.

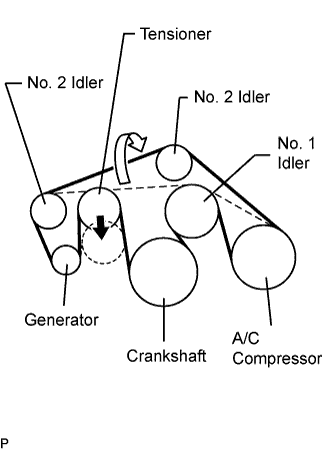

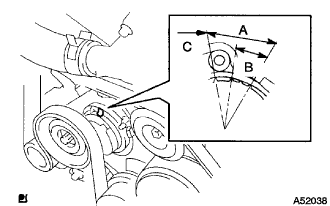

| 68. INSTALL V-RIBBED BELT |

Set the V-belt to everything except the No. 2 idler pulley, as shown in the illustration.

|

Loosen the V-belt by turning the belt tensioner counterclockwise.

Then set the V-belt to the idler pulley.

After a new belt has been installed, check that the mark is within the A range shown in the illustration.

|

| 69. INSTALL NO. 2 FUEL PIPE SUB-ASSEMBLY |

Connect the connector of the fuel tube connected to the fuel main tube, then pinch the connector.

|

| 70. INSTALL RADIATOR ASSEMBLY |

Install the radiator (Click here).

| 71. INSTALL NO. 1 OIL COOLER OUTLET TUBE |

|

Connect the outlet tube.

Attach the tube to the radiator's clamp.

| 72. INSTALL NO. 1 OIL COOLER INLET TUBE |

|

Connect the inlet tube.

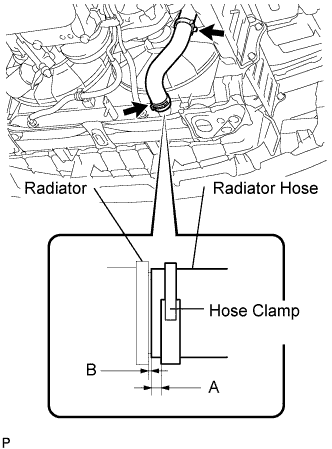

| 73. INSTALL RADIATOR HOSE OUTLET |

|

Connect the hose outlet.

- HINT:

- Face the clamp's claw toward the bottom of the vehicle.

- Make sure the clearance between the clamp edge and radiator hose edge (labeled A) is between 1 to 5 mm (0.039 to 0.197 in.).

- Insert the hose until it contacts the radiator. Make sure the clearance between the hose and radiator (labeled B) is between 0 to 2.5 mm (0 to 0.098 in.).

| 74. INSTALL RADIATOR HOSE INLET |

|

Connect the hose inlet.

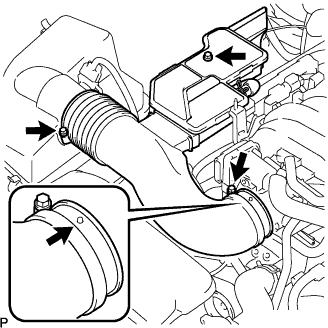

| 75. INSTALL AIR CLEANER ASSEMBLY |

Install the air cleaner assembly with the 3 bolts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Connect the MAF meter connector and clamp to the air cleaner.

|

| 76. INSTALL INTAKE AIR CONNECTOR PIPE |

Install the connector pipe with the bolt and 2 hose clamps.

- Torque:

- 4.0 N*m{41 kgf*cm, 35 ft.*lbf} for hose clamps

- 5.0 N*m{51 kgf*cm, 44 ft.*lbf} for bolt

|

Connect the air hose and No. 1 ventilation hose.

| 77. ADD AUTOMATIC TRANSMISSION FLUID |

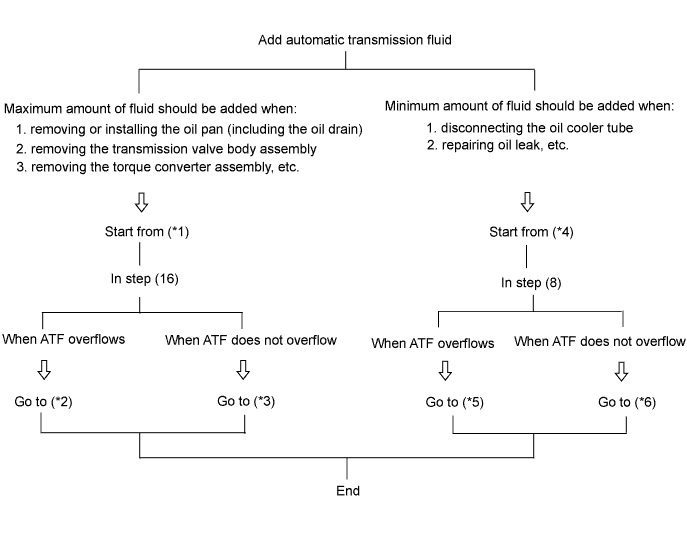

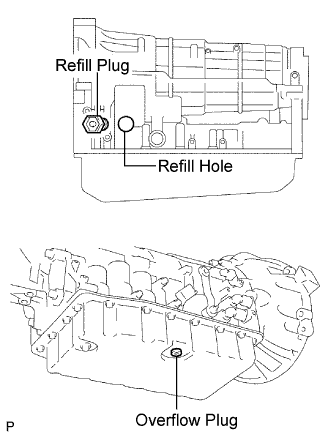

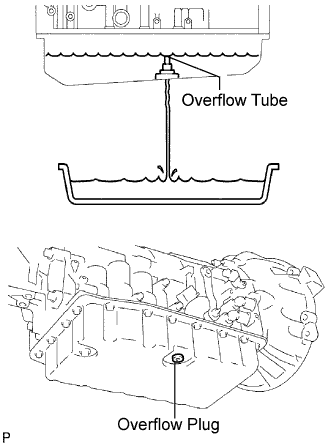

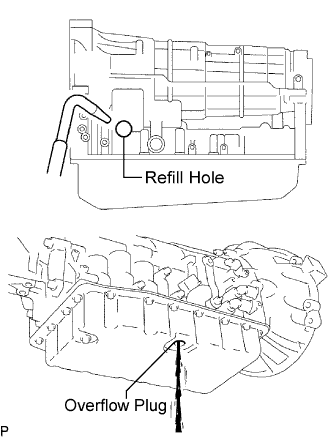

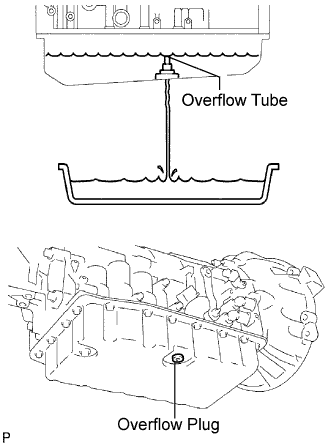

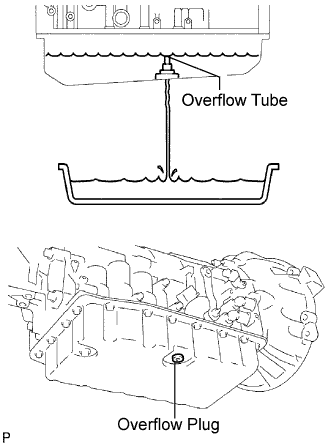

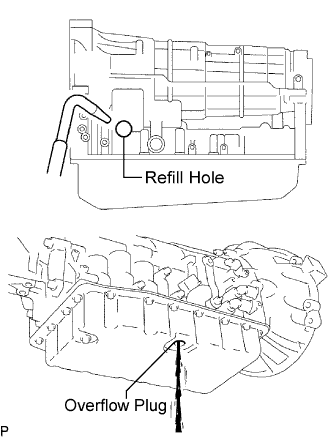

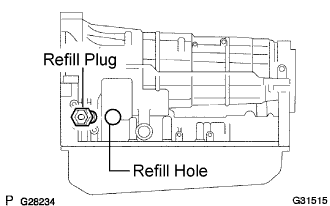

Add the automatic transmission fluid following the flow chart below.

When adding the maximum amount of fluid: [*1]

Lift up the vehicle.

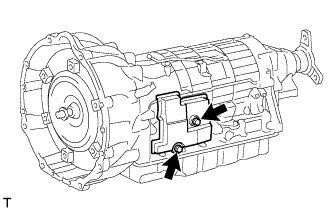

Remove the 2 bolts and transmission case cover.

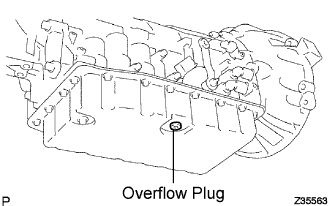

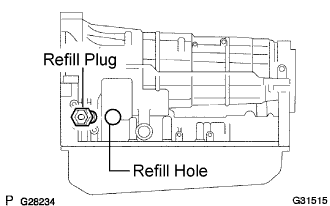

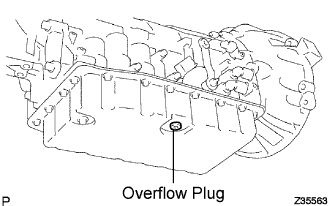

Remove the refill plug and overflow plug.

Add ATF through the refill hole until it drains out from the overflow hole.

- NOTICE:

- Be sure to use ATF WS.

Install a new gasket and the overflow plug.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Add proper amount of ATF through the refill hole.

- NOTICE:

- Refill amount differs depending on the related procedures indicated below.

Related procedures Refill amount Removal and installation of oil pan

(Including the oil drain)1.3 liters (1.4 US qts, 1.1 lmp.qts) Removal of transmission valve body assembly 3.9 liters (4.1 US qts, 3.4 lmp.qts) Removal of torque converter assembly 5.3 liters (5.6 US qts, 4.7 lmp.qts) Install a new O-ring and the refill plug.

- Torque:

- 39 N*m{400 kgf*cm, 29 ft.*lbf}

Lower the vehicle.

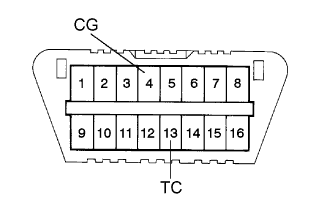

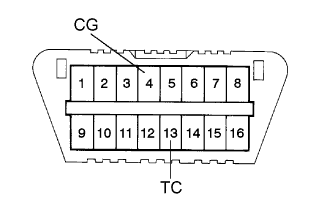

Using SST, create a short-circuit between terminals TC and CG of the DLC3.

- SST

- 09843-18040

Start the engine.

- NOTICE:

- Be sure to place the key inside the cabin in order to start the engine.

- Turn the A/C off.

Slowly move the shift lever from the P to the S position, shift the gear from 1st to 6th and then return the shift lever to the P position.

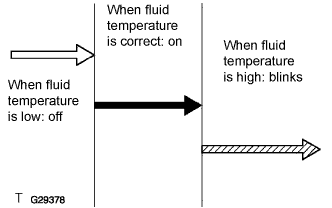

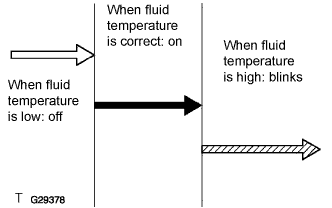

Switch to the fluid temperature detection mode.

- Move the shift lever from the N to the D position, or from D to N, within 1.5 seconds.

- Continue this procedure for 6 seconds or more.

- Standard:

- Meter indicator light "D" comes on for 2 seconds and then goes off.

- Move the shift lever from the N to the D position, or from D to N, within 1.5 seconds.

Return the shift lever to the P position and disconnect terminals TC and CG after confirming the above condition.

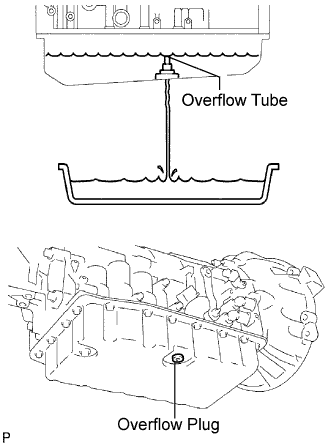

Idle the engine to raise fluid temperature.

Lift up the vehicle immediately after meter indicator light "D" comes on.

- NOTICE:

- Add fluid only when the meter indicator light is on.

- Perform this procedure while the engine is idling.

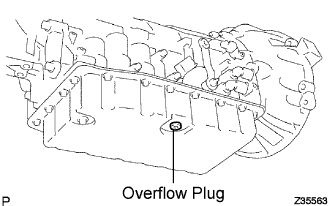

Remove the overflow plug. If ATF overflows, proceed to [*2].

If ATF does not overflow, proceed to [*3].- HINT:

- "Overflow" indicates the condition under which ATF drains out from the overflow tube.

When fluid overflows: [*2]

- NOTICE:

- Capacity of the overflow tube is approximately 3 cc.

Install a new gasket and the overflow plug when the draining ATF has become a trickle.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

- NOTICE:

- Be careful when handling the drained ATF as it will be hot.

Install a new O-ring and tighten the refill plug.

- Torque:

- 39 N*m{400 kgf*cm, 29 ft.*lbf}

Install the transmission case cover with the 2 bolts.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

Lower the vehicle.

Turn the engine switch off and remove the SST.

|

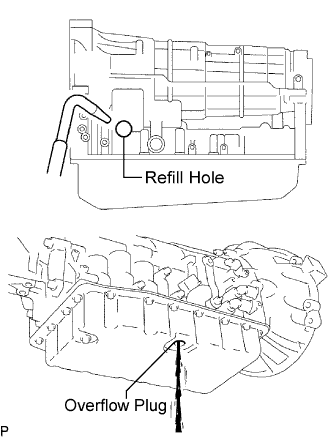

When fluid does not overflow:[*3]

Remove the refill plug.

Add ATF through the refill hole until it drains out from the overflow hole.

Install a new gasket and the overflow plug when the draining ATF has become a trickle.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Install a new O-ring and tighten the refill plug.

- Torque:

- 39 N*m{400 kgf*cm, 29 ft.*lbf}

Install the transmission case cover with the 2 bolts.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

Lower the vehicle.

Turn the engine switch off and remove the SST.

|

When adding a minimum amount of fluid: [*4]

Using SST, create a short-circuit between terminals TC and CG of the DLC3.

- SST

- 09843-18040

Start the engine.

- NOTICE:

- Be sure to place the key inside the cabin in order to start the engine.

- Turn the A/C off.

Slowly move the shift lever from the P to the S position, shift the gear from 1st to 6th and then return the shift lever to the P position.

Switch to the fluid temperature detection mode.

- Move the shift lever from the N to the D position, or from D to N, within 1.5 seconds.

- Continue this the above procedure for 6 seconds or more.

- Standard:

- Meter indicator light "D" comes on for 2 seconds and then goes off.

- Move the shift lever from the N to the D position, or from D to N, within 1.5 seconds.

Return the shift lever to the P position and disconnect terminal TC and CG after confirming the above condition.

Idle the engine to raise fluid temperature.

Lift up the vehicle immediately after meter indicator light "D" comes on.

- NOTICE:

- Add fluid only when the meter indicator light is on.

- Perform this procedure while the engine is idling.

Remove the overflow plug. If ATF overflows, proceed to [*5]. If ATF does not overflow, proceed to [*6].

- HINT:

- "Overflow" indicates the condition under which ATF drains out from the overflow tube.

|

When fluid overflows: [*5]

Install a new gasket and the overflow plug when the draining ATF has become a trickle.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

- NOTICE:

- Be careful when handling the drained ATF as it will be hot.

Install the transmission case cover with the 2 bolts.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

Lower the vehicle.

Turn the engine switch off and remove the SST.

|

When fluid does not overflow: [*6]

Remove the refill plug.

Add ATF through the refill hole until it drains out from the overflow hole.

Install a new gasket and the overflow plug when the draining ATF has become a trickle.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Install a new O-ring and tighten the refill plug.

- Torque:

- 39 N*m{400 kgf*cm, 29 ft.*lbf}

Install the transmission case cover with the 2 bolts.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

Lower the vehicle.

Turn the engine switch off and remove the SST.

|

| 78. ADD ENGINE COOLANT |

Tighten the radiator drain cock plug by hand.

Tighten the 2 cylinder block drain cock plugs.

- Torque:

- 12.7 N*m{130 kgf*cm, 9 ft.*lbf}

Add engine coolant.

- HINT:

- Add engine coolant until coolant overflows from the vent plug.

- Specified capacity:

- 11.0 liters (11.7 US qts, 9.7 lmp. qts)

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

- Please contact your TOYOTA dealer for further details.

Install the vent plug.

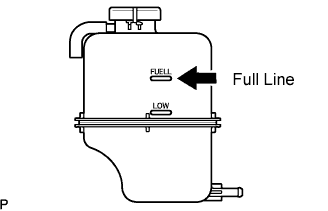

Slowly pour coolant into the radiator reservoir until it reaches the FULL line.

Press the inlet and outlet radiator hoses several times by hand, and then check the level of the coolant.

If the coolant level is low, add coolant.

Install the radiator cap.

Bleed air from the cooling system.

Warm up the engine until the thermostat opens. While the thermostat is open, circulate the coolant for several minutes.

- HINT:

- Adjust the air conditioner set temperature to MAX (HOT).

Maintain the engine speed at 2,000 to 2,500 rpm.

Press the inlet and outlet radiator hoses several times by hand to bleed air.

- NOTICE:

- When pressing the radiator hoses:

- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the radiator fan.

Stop the engine, and wait until the engine coolant cools down to ambient temperature.

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Check the coolant level in the radiator reservoir.

If the coolant level is low, add SLLC to the radiator reservoir FULL line.

|

| 79. ADD ENGINE OIL |

Install a new gasket and the drain plug.

- Torque:

- 39 N*m{398 kgf*cm, 29 ft.*lbf}

Add new oil.

- Oil Capacity:

Item Capacity Drain and refill with oil filter change 5.2 liters (5.5 US qts, 4.6 lmp. qts) Drain and refill without oil filter change 4.5 liters (4.8 US qts, 4.0 lmp. qts) Dry fill 6.1 liters (6.4 US qts, 5.4 lmp. qts)

Reinstall the oil filler cap.

| 80. INSTALL ENGINE UNDER COVER REAR LH |

| 81. INSTALL ENGINE UNDER COVER REAR RH |

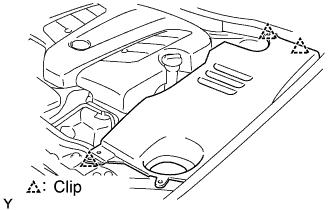

| 82. INSTALL NO. 2 ENGINE UNDER COVER |

Install the under cover with the clips.

| 83. INSTALL ENGINE UNDER COVER |

Install the under cover with the 10 screws and 3 clips.

| 84. INSTALL FRONT WHEELS |

| 85. INSTALL ECM COVER |

Install the ECM cover with the 3 bolts.

- Torque:

- 5.5 N*m{56 kgf*cm, 49 in.*lbf}

|

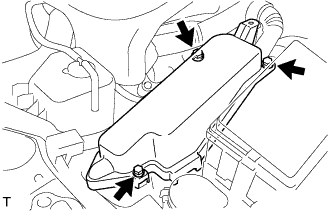

| 86. INSTALL V-BANK COVER |

Install the V-bank cover with the 2 nuts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

- NOTICE:

- Make sure that the wire harness does not get caught between parts.

| 87. INSTALL NO. 1 AIR CLEANER INLET |

Install the air cleaner inlet and bolt.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

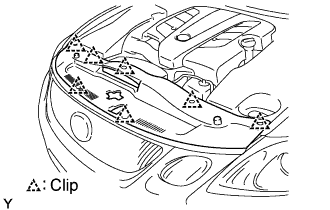

| 88. INSTALL ENGINE ROOM SIDE COVER LH |

Install the side cover with the 3 clips.

|

| 89. INSTALL ENGINE ROOM SIDE COVER RH |

Install the side cover with the 2 clips and nut.

|

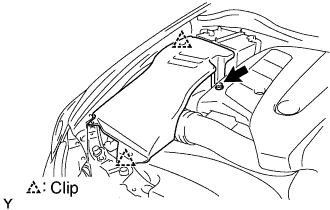

| 90. INSTALL COOL AIR INTAKE DUCT SEAL |

Install the intake duct seal with the 7 clips.

|

| 91. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 92. INSTALL FRONT WHEELS |

| 93. CHECK FOR FUEL LEAKS |

Start the engine, and check that there are no fuel leaks after performing maintenance anywhere on the system.

| 94. PERFORM INITIALIZATION |

Perform initialization (Click here).

- NOTICE:

- Certain systems need to be initialized after disconnecting and reconnecting the cable from the negative (-) battery terminal.

| 95. CHECK AND ADJUST FRONT WHEEL ALIGNMENT |

Measure the thread lengths of the right and left rack ends.

- Standard:

- Difference in thread lengths is 1.5 mm (0.059 in.) or less

Remove the rack boot set clips.

Loosen the tie rod end lock nuts.

Adjust the rack ends if the difference in thread length between the right and left rack ends is not within the specified range.

Extend the shorter rack end if the measured toe-in deviates toward the outer-side.

Shorten the longer rack end if the measured toe-in deviates toward the inner-side.

Turn the right and left rack ends by an equal amount to adjust toe-in.

- HINT:

- Try to adjust toe-in to the center of the specified range.

Make sure that the lengths of the right and left rack ends are the same.

|

Tighten the tie rod end lock nuts.

- Torque:

- 56 N*m{571 kgf*cm, 41 ft.*lbf}

- NOTICE:

- Temporarily tighten the lock nut while holding the hexagonal part of the steering rack end so that the lock nut and the steering rack end do not turn together. Hold the width across flat of the tie rod end and tighten the lock nut.

Place the boots on the seats and install the clips.

- NOTICE:

- Perform VGRS calibration after adjusting toe-in.

- HINT:

- Make sure that the boots are not twisted.

| 96. CHECK IGNITION TIMING |

Warm up the engine and stop the engine.

- NOTICE:

- A warmed up engine should have an engine coolant temperature of over 80°C (176°F), have an engine oil temperature of 60°C (140°F), and the engine rpm should be stabilized.

|

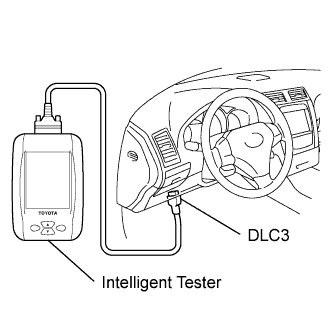

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

Start the engine and idle it.

Push the intelligent tester main switch ON.

Enter the following items: Powertrain / Engine and ECT / Data list / IGN Advance.

- Ignition timing:

- 8 to 12° BTDC @ idle (Shift lever on N)

- HINT:

- Please refer to the intelligent tester operator's manual for further details.

| 97. CHECK ENGINE IDLE SPEED |

Warm up the engine.

- NOTICE:

- A warmed up engine should have an engine coolant temperature of over 80°C (176°F) and an engine oil temperature of 60°C (140°F), and the engine rpm should be stabilized.

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

- NOTICE:

- Switch off all accessories and A/C before connecting the intelligent tester.

Rev the engine at 2,500 rpm for approximately 90 seconds.

Push the intelligent tester main switch ON.

Enter the following items: Powertrain / Engine and ECT / Data list / Engine SPD.

- Idle speed:

- 700 to 800 rpm

- NOTICE:

- When checking the idle speed, the transmission should be in neutral.

- HINT:

- Please refer to the intelligent tester operator's manual for further details.

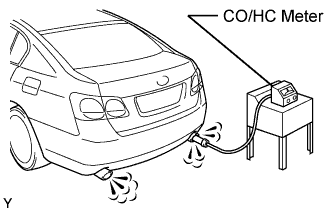

| 98. CHECK CO/HC |

Start the engine.

|

Rev the engine at 2,500 rpm for approximately 180 seconds.

Insert a CO/HC meter testing probe at least 40 cm (1.3 ft.) into the tailpipe during idling.

Check CO/HC concentration at idle and/or 2,500 rpm.

- HINT:

- Complete the measurement within 3 minutes.

- Check regulations in your area when performing 2 mode CO/HC concentration testing (engine check at both idle speed and at 2,500 rpm).

If the CO/HC concentration does not comply with regulations, perform troubleshooting in the order given below.

Check the heated oxygen sensor operation (Click here).

See the table below for possible causes, and then inspect and repair.

CO HC Symptom Causes Normal High Rough idle 1. Faulty ignitions: - Incorrect timing

- Fouled, shorted or improperly gapped plugs.

3. Leaky intake and exhaust valves

4. Leaky cylinderLow High Rough idle

(fluctuating HC reading)1. Vacuum leaks: - PCV hose

- Intake manifold

- Throttle body

High High Rough idle

(black smoke from exhaust)1. Restricted air filter

2. Faulty SFI system:- Faulty pressure regulator

- Defective ECT sensor

- Faulty ECM

- Faulty injector

- Faulty throttle position sensor

- MAF sensor

- Incorrect timing

| 99. CHECK FOR ENGINE OIL LEAKS |

| 100. CHECK FOR ENGINE COOLANT LEAKS |

Check for engine coolant leaks (Click here).

| 101. CHECK ENGINE OIL LEVEL |

Warm up the engine, stop the engine and wait 5 minutes. The oil level should be between the dipstick's low and full level mark.

- If low, check for leakage and add oil up to the full level mark.

- NOTICE:

- Do not fill the engine oil above the full level mark.

- HINT:

- SAE 5W-30 is the recommended choice for this engine for good fuel economy and good starting in cold weather.

- If low, check for leakage and add oil up to the full level mark.

| 102. CHECK AUTOMATIC TRANSMISSION FLUID LEVEL |