Engine Unit -- Disassembly |

| 1. REMOVE OIL FILLER CAP SUB-ASSEMBLY |

| 2. REMOVE RADIATOR CAP SUB-ASSEMBLY |

| 3. REMOVE NO. 1 ENGINE HANGER |

Remove the 2 bolts and engine hanger.

| 4. REMOVE NO. 2 ENGINE HANGER |

Remove the 2 bolts and engine hanger.

| 5. REMOVE SPARK PLUG |

| 6. REMOVE OIL PAN DRAIN PLUG |

Remove the drain plug and gasket.

| 7. REMOVE VENTILATION VALVE SUB-ASSEMBLY |

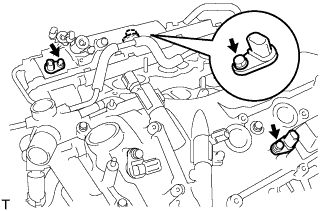

| 8. REMOVE CAMSHAFT POSITION SENSOR |

|

Remove the 4 bolts and 4 sensors.

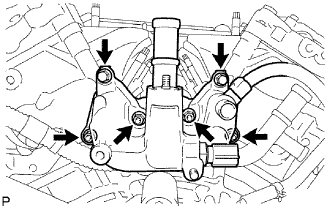

| 9. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY |

|

Remove the 4 bolts and 4 oil control valves.

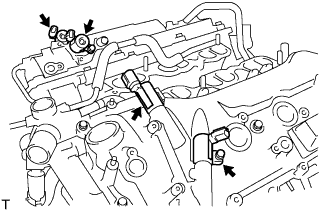

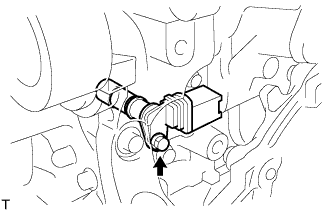

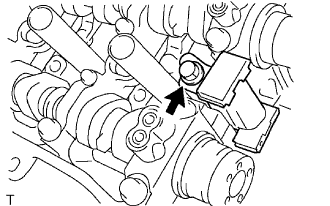

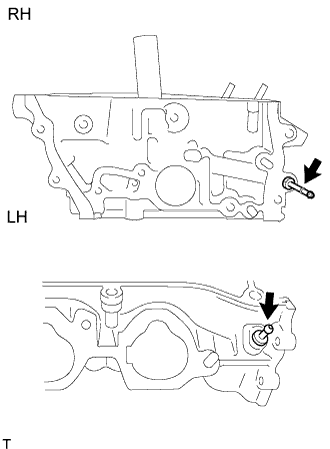

| 10. REMOVE CRANKSHAFT POSITION SENSOR |

|

Remove the bolt and sensor.

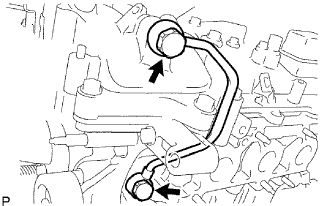

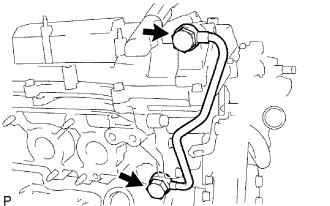

| 11. REMOVE NO. 1 OIL PIPE |

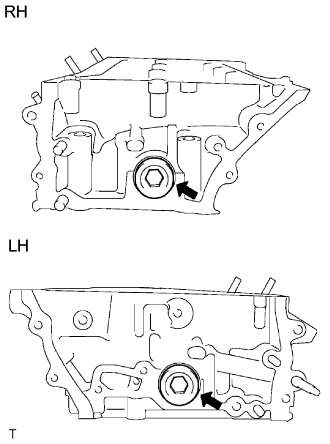

|

Remove the oil check valve bolt, oil pipe union and oil pipe.

Remove the oil control valve filter LH and gaskets.

| 12. REMOVE NO. 2 OIL PIPE |

|

Remove the oil check valve bolt, oil pipe union and oil pipe.

Remove the oil control valve filter RH and gaskets.

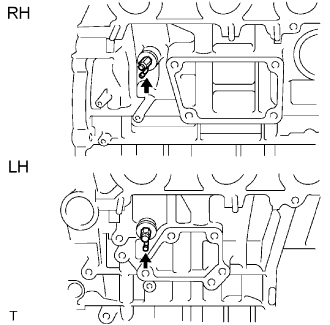

| 13. REMOVE CYLINDER BLOCK WATER DRAIN COCK SUB-ASSEMBLY |

|

Remove the water drain cock from the cylinder block.

Remove the water drain cock plug from the water drain cock.

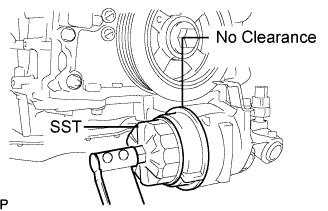

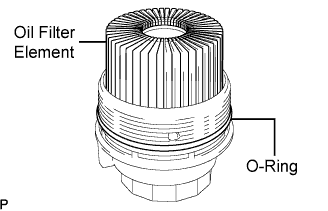

| 14. REMOVE OIL FILTER ELEMENT |

|

Using SST, remove the oil filter cap.

- SST

- 09228-06501

Remove the oil filter element and O-ring from the oil filter cap.

- NOTICE:

- Do not use any tools when removing the O-ring to prevent the O-ring groove from being damaged.

|

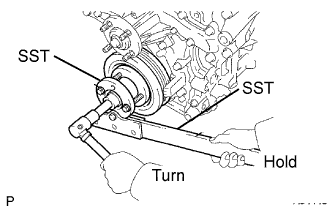

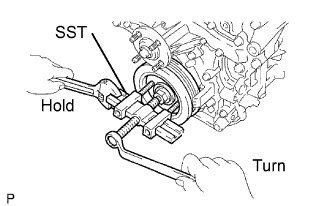

| 15. REMOVE CRANKSHAFT PULLEY |

|

Using SST, loosen the crankshaft pulley bolt.

- SST

- 09213-70011(09213-70020)

09330-00021

Using SST, remove the crankshaft pulley bolt and crankshaft pulley.

- SST

- 09950-50013(09951-05010,09952-05010,09953-05020,09954-05021)

|

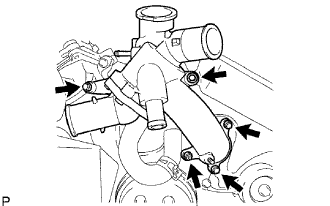

| 16. REMOVE WATER INLET SUB-ASSEMBLY |

|

Remove the 3 water by-pass hoses.

Remove the 4 bolts, nut and water inlet.

Remove the O-rings.

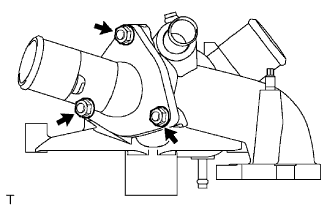

| 17. REMOVE WATER INLET WITH THERMOSTAT |

|

Remove the 3 nuts and water inlet with thermostat.

Remove the gasket from the water inlet with thermostat.

| 18. REMOVE WATER BY-PASS JOINT RR |

|

Remove the 2 bolts, 4 nuts and water by-pass joint.

Remove the 2 gaskets and O-ring.

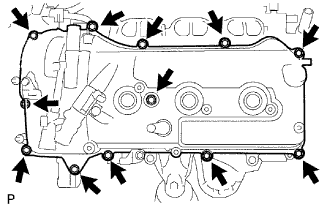

| 19. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY (for Bank 1) |

|

Remove the 12 bolts, head cover and gasket.

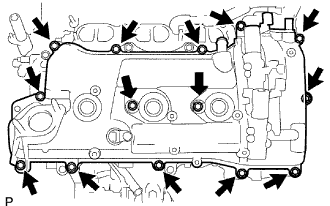

| 20. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY (for Bank 2) |

|

Remove the 14 bolts, head cover and gasket.

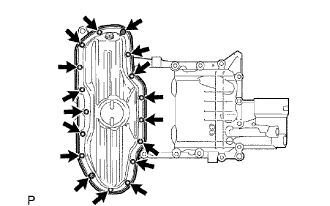

| 21. REMOVE NO. 2 OIL PAN SUB-ASSEMBLY |

|

Remove the 15 bolts and 2 nuts.

Insert the blade of SST between the oil pans. Cut through the applied sealer and remove the oil pan sub-assembly No. 2.

- SST

- 09032-00100

- NOTICE:

- Be careful not to damage the contact surfaces of the oil pans.

| 22. REMOVE OIL PAN SUB-ASSEMBLY |

|

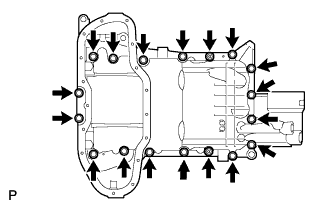

Remove the 16 bolts and 2 nuts.

- HINT:

- Be sure to clean the bolts and stud bolts and check the threads for cracks or other damage.

Remove the oil pan by prying between the oil pan and cylinder block with a screwdriver.

- NOTICE:

- Be careful not to damage the contact surfaces of the cylinder block and oil pan.

- HINT:

- Tape the screwdriver tip before use.

|

Remove the 2 O-rings.

| 23. REMOVE OIL STRAINER SUB-ASSEMBLY |

|

Remove the 3 nuts, oil strainer and gasket.

| 24. REMOVE OIL PAN BAFFLE PLATE |

|

Remove the 8 bolts and baffle plate.

| 25. REMOVE REAR ENGINE OIL SEAL RETAINER |

|

Remove the 6 bolts.

Using a screwdriver, pry out the oil seal retainer.

- HINT:

- Tape the screwdriver tip before use.

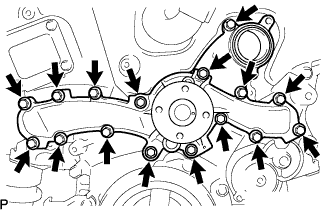

| 26. REMOVE WATER PUMP ASSEMBLY |

|

Remove the 16 bolts, water pump and gasket.

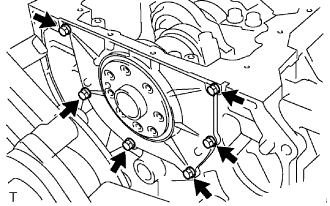

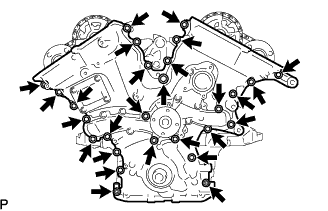

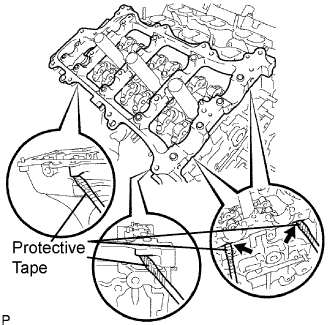

| 27. REMOVE TIMING CHAIN OR BELT COVER SUB-ASSEMBLY |

|

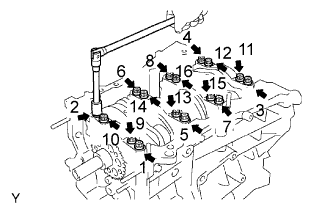

Remove the 16 bolts and 2 nuts as shown in the illustration.

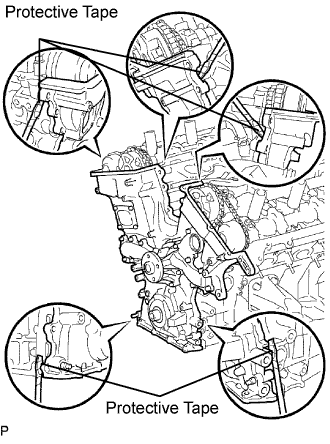

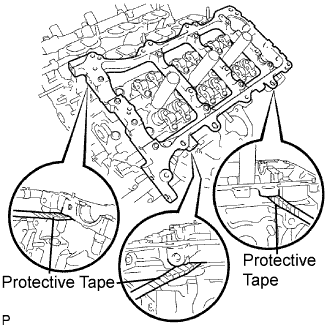

Remove the timing chain cover by prying between the timing chain cover and cylinder head or cylinder block with a screwdriver.

- NOTICE:

- Be careful not to damage the contact surfaces of the cylinder head, cylinder block and chain cover.

- HINT:

- Tape the screwdriver tip before use.

|

Remove the 4 bolts, chain cover plate and gasket.

Remove the gasket.

| 28. SET NO. 1 CYLINDER TO TDC / COMPRESSION |

|

Temporarily tighten the pulley set bolt.

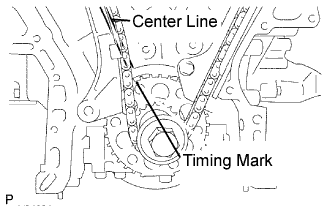

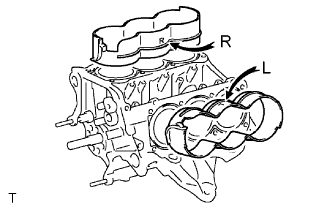

Set the timing mark on the crank angle sensor plate to the RH block bore center line (TDC / compression).

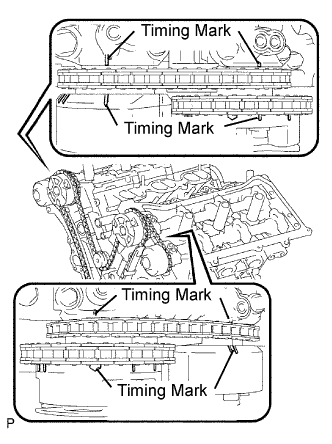

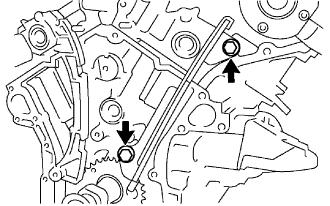

Check that the timing marks of the camshaft timing gears are aligned with the timing marks of the bearing cap as shown in the illustration.

If not, turn the crankshaft 1 revolution (360°) and align the timing marks as above.

|

| 29. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY |

|

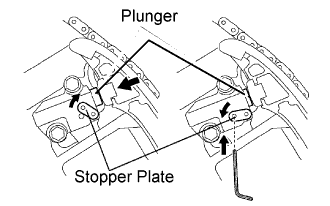

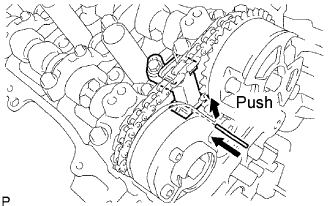

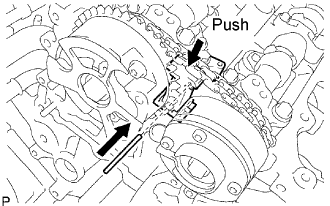

Move the stopper plate upward to release the lock, and push the plunger deep into the tensioner.

Move the stopper plate downward to set the lock, and insert a hexagon wrench into the stopper plate's hole.

Remove the 2 bolts and chain tensioner.

| 30. REMOVE CHAIN TENSIONER SLIPPER |

Remove the chain tensioner slipper.

| 31. REMOVE CHAIN SUB-ASSEMBLY |

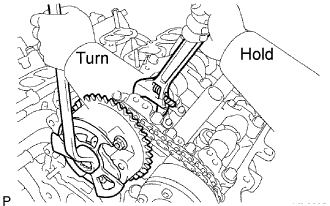

Turn the crankshaft counterclockwise 10° to loosen the chain of the crankshaft timing gear.

Remove the chain from the crank timing gear and place it on the crankshaft.

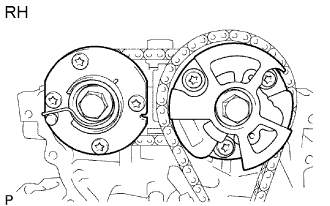

Turn the camshaft timing gear assembly on the RH bank clockwise (approximately 60°) and set it as shown in the illustration. Be sure to loosen the chain between the center banks.

|

Remove the chain.

| 32. REMOVE IDLE SPROCKET ASSEMBLY |

Using a 10 mm hexagon wrench, remove the No. 2 idle gear shaft, sprocket and No. 1 idle gear shaft.

| 33. REMOVE NO. 1 CHAIN VIBRATION DAMPER |

|

Remove the 2 bolts and vibration damper.

| 34. REMOVE NO. 2 CHAIN VIBRATION DAMPER |

Remove the 2 vibration dampers.

| 35. REMOVE CRANKSHAFT TIMING GEAR OR SPROCKET |

|

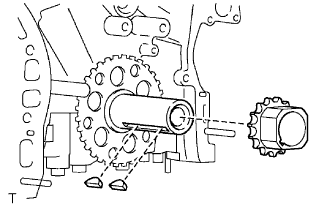

Remove the pulley set bolt.

Remove the crankshaft timing gear from the crankshaft.

Remove the 2 pulley set keys from the crankshaft.

| 36. REMOVE NO. 2 CAMSHAFT TIMING GEARS AND CHAIN (for Bank 1) |

|

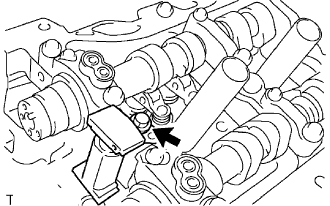

While raising up the chain plunger, insert a pin of φ 1.0 mm (0.039 in.) into the hole to fix the plunger.

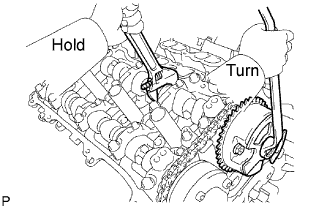

Hold the hexagonal portion of the camshaft with a wrench, and remove the 2 bolts and 2 camshaft timing gear assemblies.

- NOTICE:

- Be careful not to damage the cylinder head with the wrench.

- Do not disassemble the camshaft timing gear assembly.

|

Remove the No. 2 chain.

| 37. REMOVE NO. 2 CHAIN TENSIONER ASSEMBLY |

|

Remove the bolt and chain tensioner.

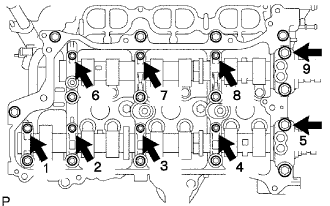

| 38. REMOVE CAMSHAFT BEARING CAP |

|

Remove the 3 gaskets.

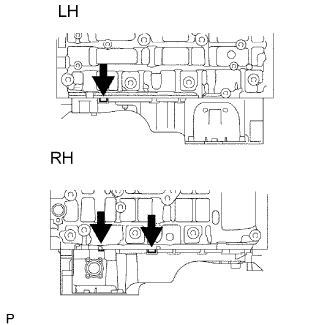

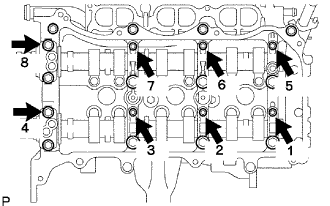

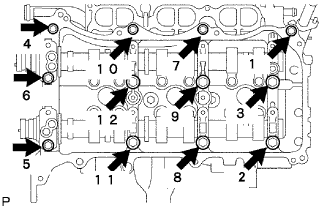

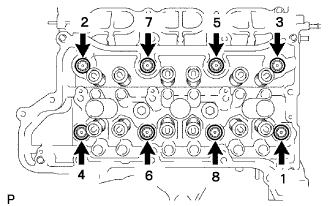

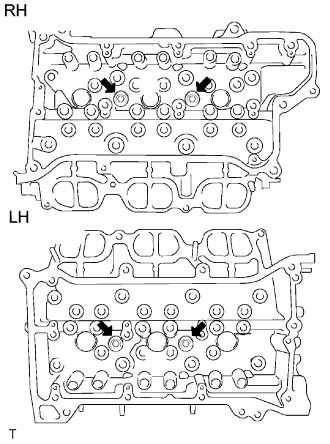

Uniformly loosen and remove the 9 bearing cap bolts in the sequence shown in the illustration.

Uniformly loosen and remove the 14 bearing cap bolts in the sequence shown in the illustration.

- NOTICE:

- Uniformly loosen the bolts while keeping the camshaft level.

|

Remove the 6 bearing caps.

| 39. REMOVE CAMSHAFT |

| 40. REMOVE NO. 2 CHAMSHAFT |

| 41. REMOVE CAMSHAFT HOUSING SUB-ASSEMBLY RH |

|

Remove the camshaft housing sub-assembly RH by prying between the cylinder head and camshaft housing sub-assembly RH with a screwdriver.

- NOTICE:

- Be careful not to damage the contact surfaces of the cylinder head and camshaft housing.

- HINT:

- Tape the screwdriver tip before use.

| 42. REMOVE NO. 2 CAMSHAFT TIMING GEARS AND CHAIN (for Bank 2) |

|

While pushing down the plunger, insert a pin of φ 1.0 mm (0.039 in.) into the hole to fix the plunger.

Hold the hexagonal portion of the camshaft with a wrench, and remove the 2 bolts and 2 camshaft timing gear assemblies.

- NOTICE:

- Be careful not to damage the cylinder head with the wrench.

- Do not disassemble the camshaft timing gear assembly.

|

Remove the No. 2 chain.

| 43. REMOVE NO. 3 CHAIN TENSIONER ASSEMBLY |

|

Remove the bolt and chain tensioner.

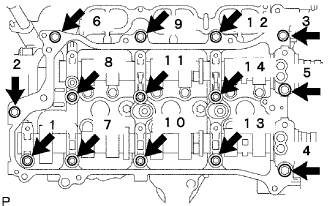

| 44. REMOVE CAMSHAFT BEARING CAP |

|

Remove the 3 gaskets.

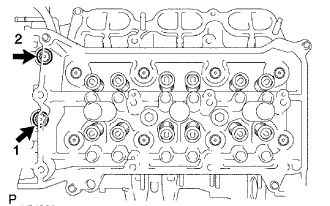

Uniformly loosen and remove the 8 bearing cap bolts in the sequence shown in the illustration.

Uniformly loosen and remove the 12 bearing cap bolts in the sequence shown in the illustration.

- NOTICE:

- Uniformly loosen the bolts while keeping the camshaft level.

|

Remove the 5 bearing caps.

| 45. REMOVE NO. 4 CAMSHAFT SUB-ASSEMBLY |

| 46. REMOVE NO. 3 CAMSHAFT SUB-ASSEMBLY |

| 47. REMOVE CAMSHAFT HOUSING SUB-ASSEMBLY LH |

|

Remove the camshaft housing by prying between the cylinder head and camshaft housing with a screwdriver.

- NOTICE:

- Be careful not to damage the contact surfaces of the cylinder head and camshaft housing.

- HINT:

- Tape the screwdriver tip before use.

| 48. REMOVE NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY |

Remove the 24 valve rocker arms.

- HINT:

- Arrange the removed parts in the correct order.

| 49. REMOVE VALVE LASH ADJUSTER ASSEMBLY |

Remove the 24 valve lash adjusters from the cylinder head.

- HINT:

- Arrange the removed parts in the correct order.

| 50. REMOVE CYLINDER HEAD SUB-ASSEMBLY LH |

|

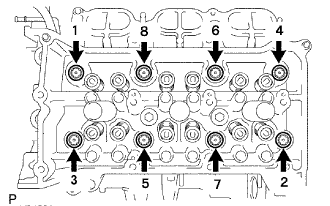

Uniformly loosen and remove the bolts in the sequence shown in the illustration.

Using a 10 mm bi-hexagon wrench, uniformly loosen the 8 bolts in the sequence shown in the illustration. Remove the 8 cylinder head bolts and plate washers.

- NOTICE:

- Be careful not to drop washers into the cylinder head.

- Head warpage or cracking could result from removing bolts in an incorrect order.

- HINT:

- Be sure to keep separate the removed parts for each installation position.

|

Remove the cylinder head and gasket.

| 51. REMOVE CYLINDER HEAD SUB-ASSEMBLY RH |

|

Using a 10 mm bi-hexagon wrench, uniformly loosen the 8 bolts in the sequence shown in the illustration. Remove the 8 cylinder head bolts and plate washers.

- NOTICE:

- Be careful not to drop washers into the cylinder head.

- Head warpage or cracking could result from removing bolts in an incorrect order.

- HINT:

- Be sure to keep separate the removed parts for each installation position.

Remove the cylinder head and gasket.

| 52. REMOVE CYLINDER BLOCK WATER JACKET SPACER LH |

|

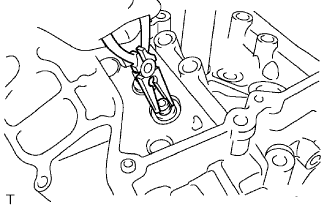

Using needle-nose pliers, remove the water jacket spacer.

- NOTICE:

- Be sure to remove the water jacket spacer if turning the cylinder block cover.

| 53. REMOVE CYLINDER BLOCK WATER JACKET SPACER RH |

Using needle-nose pliers, remove the water jacket spacer.

- NOTICE:

- Be sure to remove the water jacket spacer if turning the cylinder block cover.

| 54. REMOVE WATER OUTLET PIPE SUB-ASSEMBLY |

|

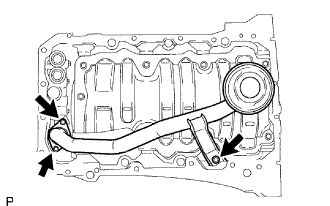

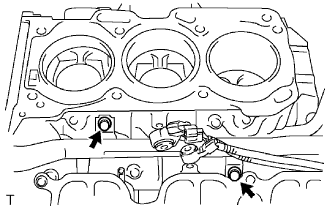

Separate the knock sensor wire.

Remove the 2 bolts and water outlet pipe.

| 55. REMOVE VALVE STEM CAP |

Remove the valve stem caps from the cylinder head.

- HINT:

- Arrange the removed parts in the correct order.

| 56. REMOVE INTAKE VALVE |

|

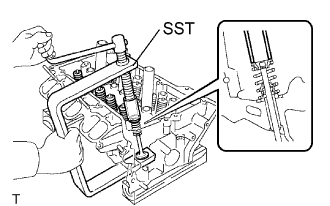

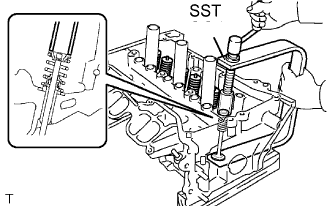

Using SST, compress the compression spring and remove the valve retainer locks.

- SST

- 09202-70020(09202-00010)

Remove the retainer, compression spring and valve.

- HINT:

- Arrange the removed parts in the correct order.

| 57. REMOVE EXHAUST VALVE |

|

Using SST, compress the compression spring and remove the valve retainer locks.

- SST

- 09202-70020(09202-00010)

Remove the retainer, compression spring and valve.

- HINT:

- Arrange the removed parts in the correct order.

| 58. REMOVE VALVE STEM OIL SEAL |

|

Using needle-nose pliers, remove the oil seals.

| 59. REMOVE VALVE SPRING SEAT |

|

Using compressed air and a magnetic finger, remove the valve spring seat by blowing air onto it.

| 60. REMOVE NO. 1 STRAIGHT SCREW PLUG |

|

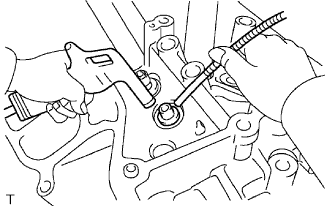

Using a 10 mm hexagon wrench, remove the 4 screw plugs and 4 gaskets.

- NOTICE:

- If water leaks from the straight screw plug or the plug corrodes, replace it.

| 61. REMOVE NO. 2 STRAIGHT SCREW PLUG |

|

Using a 14 mm hexagon wrench, remove the screw plug and gasket.

- NOTICE:

- If water leaks from the straight screw plug or the plug corrodes, replace it.

| 62. REMOVE UNION |

|

Remove the union from the cylinder head.

| 63. REMOVE RING PIN |

- NOTICE:

- It is not necessary to remove ring pin unless it is being replaced.

| 64. REMOVE STUD BOLT |

- NOTICE:

- If the stud bolt is deformed or the threads are damaged, replace it.

| 65. REMOVE PISTON SUB-ASSEMBLY WITH CONNECTING ROD |

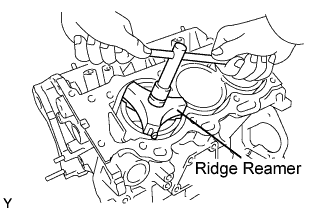

|

Using a ridge reamer, remove all the carbon from the top of the cylinder.

Push the piston, connecting rod assembly and upper bearing through the top of the cylinder block.

- HINT:

- Keep the bearing, connecting rod and cap together.

- Arrange the piston and connecting rod assemblies in the correct order.

| 66. REMOVE CONNECTING ROD BEARING |

- NOTICE:

- Arrange the removed parts in the correct order.

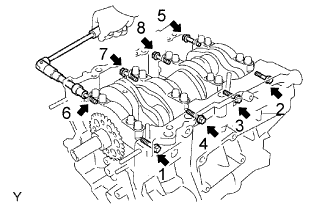

| 67. REMOVE CRANKSHAFT |

|

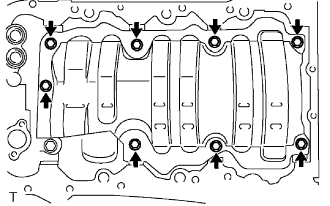

Uniformly loosen and remove the 8 main bearing cap bolts and seal washers in the several steps and in the sequence shown in the illustration.

Uniformly loosen the 16 bearing cap bolts, in several steps, in the sequence shown in the illustration.

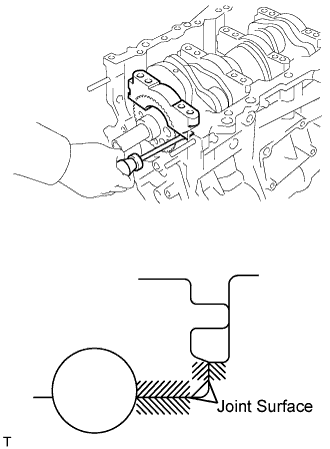

|

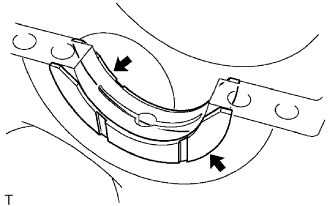

Using a screwdriver, pry out main bearing caps. Remove the 4 main bearing caps and lower bearings.

- NOTICE:

- Push up on the cap little by little, alternating from the right and left side until the cap can be removed.

- Be careful not to damage the joint surface of the cylinder block and the main bearing cap.

|

| 68. REMOVE CRANKSHAFT BEARING |

- HINT:

- Arrange the removed parts in the correct order.

| 69. REMOVE CRANKSHAFT THRUST WASHER SET |

|

Remove the upper bearings and upper thrust washers from the cylinder block.

| 70. REMOVE PISTON RING SET |

|

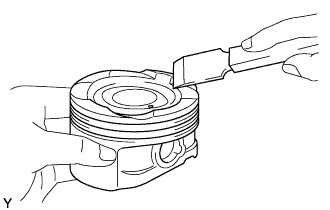

Using a piston ring expander, remove the 2 compression rings.

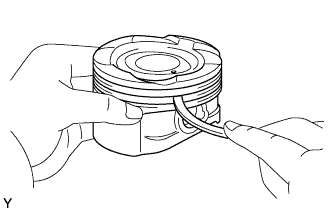

Using a piston ring expander, remove the oil ring rail.

Remove the oil ring expander by hand.

- HINT:

- Arrange the removed parts in the correct order.

| 71. REMOVE PISTON SUB-ASSEMBLY WITH PIN |

|

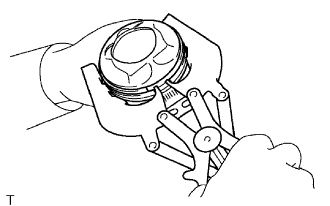

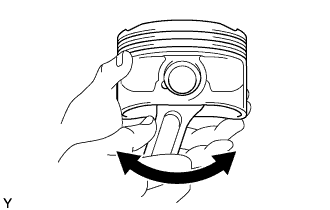

Check the fitting condition between the piston and piston pin.

Try to move the piston back and forth on the piston pin.

If any movement is felt, replace the piston and pin as a set.

Disconnect the connecting rod from the piston.

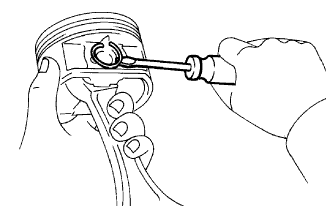

Using a screwdriver, pry off the snap rings from the piston.

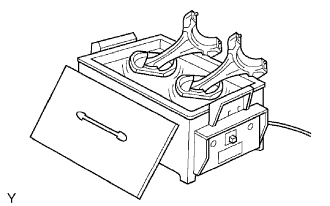

Gradually heat the piston to approximately 80 to 90°C (176 to 194°F).

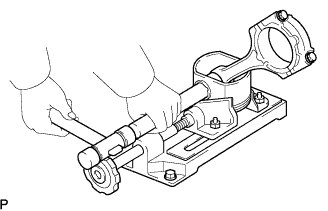

Using a brass bar and plastic-faced hammer, lightly tap out the piston pin and remove the connecting rod.

- HINT:

- The piston and pin are a matched set.

- Arrange the pistons, pins, rings, connecting rods and bearings in the correct order.

|

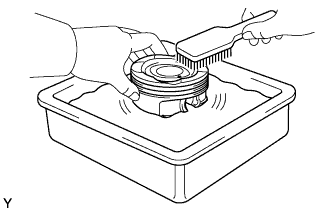

Using a gasket scraper, remove the carbon from the piston top.

|

Using a groove cleaning tool or broken ring, clean the piston ring grooves.

|

Using solvent and a brush, thoroughly clean the piston.

- NOTICE:

- Do not use a wire brush.

|

| 72. REMOVE NO. 1 OIL NOZZLE SUB-ASSEMBLY |

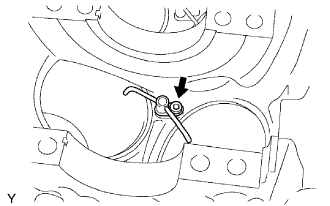

|

Using a 5 mm hexagon wrench, remove the oil nozzles.

Check the 3 oil nozzles for damage or clogging.