Throttle Body -- Installation |

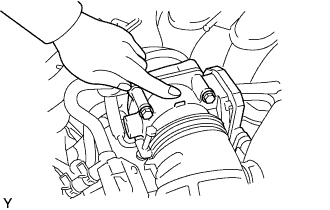

| 1. INSTALL THROTTLE BODY |

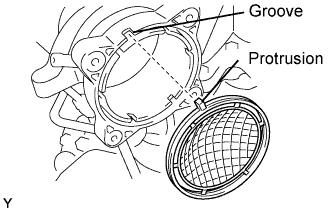

Install a new gasket to the intake air surge tank.

- HINT:

- Align the protrusion of the gasket on the intake air surge tank.

|

Install the throttle body with the 4 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

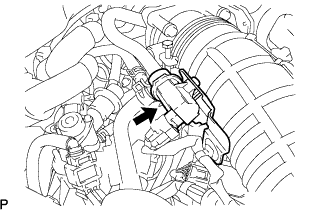

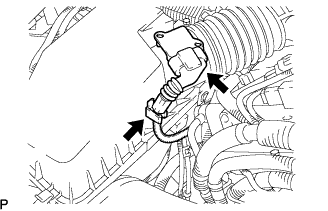

Connect the throttle motor connector.

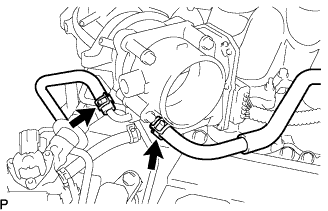

| 2. CONNECT WATER BY-PASS HOSE |

|

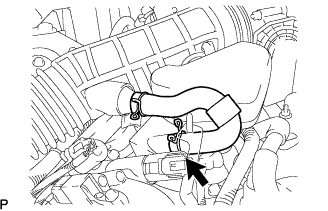

Connect the 2 water by-pass hoses to the throttle body.

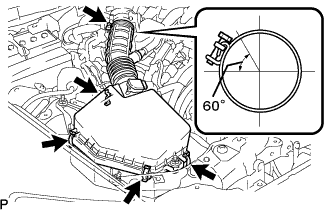

| 3. INSTALL AIR CLEANER CAP WITH AIR CLEANER HOSE |

|

Install the air cleaner cap with air cleaner hose assembly with the 4 clamps and hose clamp.

- HINT:

- Be sure to install the air cleaner assembly so that the screw part of the hose clamp is as shown in the illustration.

Install the VSV (for EVAP )to the air cleaner hose.

|

Connect the MAF meter connector and clamp to the air cleaner.

|

| 4. CONNECT NO. 2 VENTILATION HOSE |

|

Connect the ventilation hose to the cylinder head cover with the clamp.

| 5. ADD ENGINE COOLANT |

- NOTICE:

- Before adding engine coolant, turn the A/C switch OFF.

Tighten all the plugs and fill the radiator with TOYOTA Super Long Life Coolant (SLLC).

- Torque:

- 12.7 N*m{130 kgf*cm, 9 ft.*lbf} for cylinder block drain cock plug

Add engine coolant.

- Specified capacity:

- 9.1 liters (9.6 US qts, 8.0 lmp. qts)

- NOTICE:

- When pressing the radiator hose:

- Wear protective gloves.

- Be careful as the radiator hose is hot.

- Keep your hands away from the radiator fan.

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

- Please contact your TOYOTA dealer for further details.

- The thermostat open timing can be confirmed by pressing the inlet radiator hose by hand, and checking when the engine coolant starts to flow inside the hose.

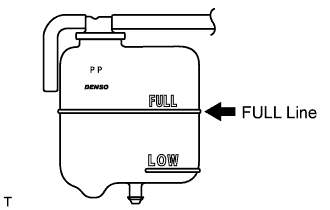

Slowly pour coolant into the radiator reservoir until it reaches the FULL line.

Press the inlet and outlet radiator hoses several times by hand, and then check the level of the coolant.

If the coolant level is low, add coolant.

Install the radiator cap and reservoir cap.

Bleed air from the cooling system.

- NOTICE:

- Before starting the engine to warm up the engine, turn the A/C switch OFF.

Warm up the engine until the thermostat opens. While the thermostat is open, circulate the coolant for several minutes.

- HINT:

- The thermostat open timing can be confirmed by pressing the inlet radiator hose by hand, and checking when the engine coolant starts to flow inside the hose.

- NOTICE:

- When pressing the radiator hoses:

- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the radiator fan.

Maintain the engine speed at 2,000 to 2,500 rpm.

Press the inlet and outlet radiator hoses several times by hand to bleed air.

- NOTICE:

- When pressing the radiator hoses:

- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the radiator fan.

Stop the engine, and wait until the engine coolant cools down to ambient temperature.

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Check the coolant level in the radiator reservoir.

If the coolant level is low, add SLLC to the radiator reservoir FULL line.

|

| 6. CHECK FOR ENGINE COOLANT LEAKS |

|

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

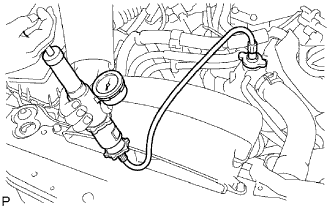

Fill the radiator with coolant and attach a radiator cap tester.

Warm up the engine.

Using a radiator cap tester, increase the pressure inside the radiator to 118 kPa (1.2 kgf/cm, 17 psi), and check that the pressure does not drop.

If the pressure drops, check the hoses, radiator and water pump for leaks. If no external leaks are found, check the heater core, cylinder block and head.

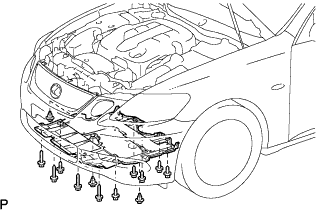

| 7. INSTALL ENGINE UNDER COVER |

Install the under cover with the 10 bolts and 3 clips.

|

| 8. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 9. CHECK FUNCTION OF THROTTLE BODY |

Check the throttle control motor operating sounds.

Turn the engine switch on (IG).

When pressing the accelerator pedal, check the operating sound of the running motor. Make sure that no friction noises emit from the motor.

If friction noise exists, replace the throttle body.

|

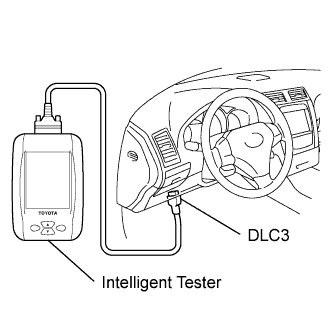

Check the throttle position sensor.

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG).

Push the intelligent tester main switch ON.

Enter the following menus: Powertrain / Engine / Data List / Throttle Sensor Position and Throttle Position Sensor Position #2.

Depress the accelerator pedal. When the throttle valve is fully opened, check that the value of the "Throttle Sensor Position" is within the specification.

- Standard throttle valve opening percentage:

- 60% or more

- NOTICE:

- When checking the standard throttle valve opening percentage, the shift lever should be in the N position.

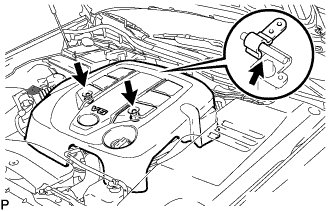

| 10. INSTALL V-BANK COVER |

|

Install the V-bank cover with the 2 nuts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

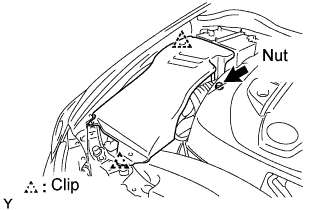

| 11. INSTALL ENGINE ROOM SIDE COVER RH |

|

Install the side cover with the 2 clips and nut.

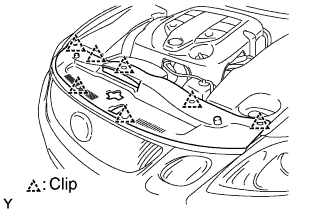

| 12. INSTALL COOL AIR INTAKE DUCT SEAL |

|

Install the intake duct seal with the 7 clips.

| 13. PERFORM INITIALIZATION |

Perform initialization (Click here).

- NOTICE:

- Certain systems need to be initialized after disconnecting and reconnecting the cable from the negative (-) battery terminal.

| 14. WARM UP ENGINE |

After the engine is warmed up, check that the maintained parts operate normally.