Headlight Assembly (For Led Headlight) -- Adjustment |

- HINT:

- Use the same procedure for RHD and LHD vehicles.

- The procedure listed below is for LHD vehicles.

- Use the same procedure for the RH and LH sides.

- The procedure listed below is for the LH side.

| 1. VEHICLE PREPARATION FOR HEADLIGHT AIMING ADJUSTMENT |

Prepare the vehicle:

- HINT:

- Make sure that there is no damage to the body around the headlights.

- Fill the fuel tank.

- Make sure that the oil is filled to the specified level.

- Make sure that the coolant is filled to the specified level.

- Inflate the tires to the appropriate pressure.

- Unload the trunk and vehicle, ensuring that the spare tire, tools and jack are in their original positions.

- Have a person of average weight (75 kg, 165 lb) sit in the driver seat.

| 2. PREPARATION FOR HEADLIGHT AIMING (Using a screen) |

|

Prepare the vehicle.

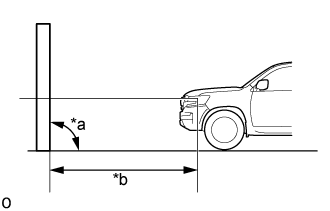

Text in Illustration *a 90° *b 25 m or 3 m - Place the vehicle in a location that is dark enough to clearly observe the cutoff line. The cutoff line is a distinct line, below which light from the headlights can be observed and above which it cannot.

- Place the vehicle at a 90° angle to the wall.

Create a 25 m (82 ft.) distance between the vehicle (center marks of the low beam) and the wall.

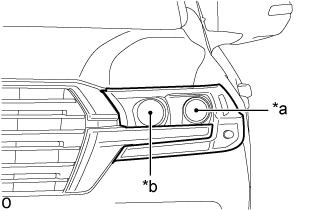

Text in Illustration *a Low Beam Center Mark *b High Beam Center Mark - Make sure that the vehicle is on a level surface.

- Bounce the vehicle up and down to settle the suspension.

- NOTICE:

- A distance of 25 m (82 ft.) between the vehicle (center marks of the low beam) and the wall is necessary for proper aim adjustment. If unavailable, secure a distance of exactly 3 m (9.84 ft.) for the check and adjustment. (The target zone will change with the distance, so follow the instructions in the illustration).

- Place the vehicle in a location that is dark enough to clearly observe the cutoff line. The cutoff line is a distinct line, below which light from the headlights can be observed and above which it cannot.

Prepare a piece of thick white paper approximately 2 m (6.56 ft.) (height) x 4 m (13.1 ft.) (width) to use as a screen.

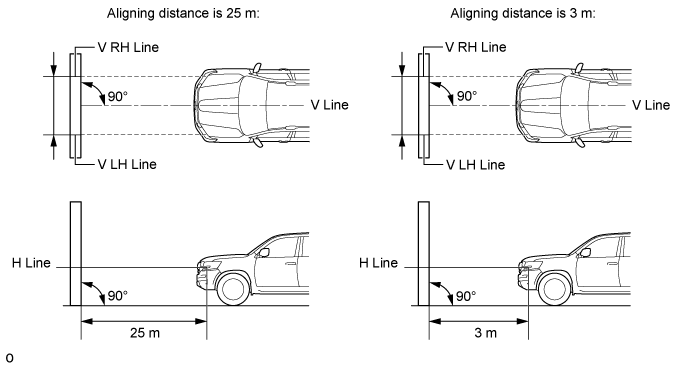

Draw a vertical line down the center of the screen (V line).

Set the screen as shown in the illustration.

- HINT:

- Stand the screen perpendicular to the ground.

- Align the V line on the screen with the center of the vehicle.

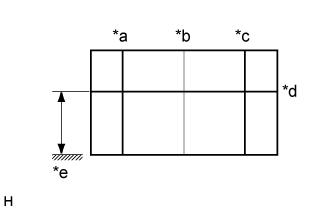

Draw base lines (H, V LH, and V RH lines) on the screen as shown in the illustration.

Text in Illustration *a V LH Line *b V Line *c V RH Line *d H Line *e Ground - HINT:

- The base lines differ for "low beam inspection" and "high beam inspection".

- Mark the headlight center marks on the screen.

H Line (Headlight height):

Draw a horizontal line across the screen so that it passes through the center marks. The H line should be at the same height as the headlight low beam center marks of the low beam headlights.V LH Line, V RH Line (Center mark position of the left-hand (LH) and right-hand (RH) headlights):

Draw 2 vertical lines so that they intersect the H line at each center mark (aligned with the center marks of the low beam).

|

| 3. INSPECT HEADLIGHT AIMING |

Cover the headlight to prevent light from the headlight that is not being inspected from affecting the headlight aiming.

- NOTICE:

- Do not keep the headlight covered for more than 3 minutes. The headlight lens is made of synthetic resin, which may melt or be damaged due to excessive heat.

- HINT:

- When checking the aim of the high beam headlight, cover the low beam headlight.

Start the engine.

Turn on the headlight and check if the cutoff line matches the preferred cutoff line in the following illustration.

- HINT:

- The low beam and high beam headlight are a unit, Adjusting the aim on the low beam to the correct position should also result in the high beam adjustment being correct.

- The illustration for LHD vehicles. RHD vehicles are the opposite of the illustration.

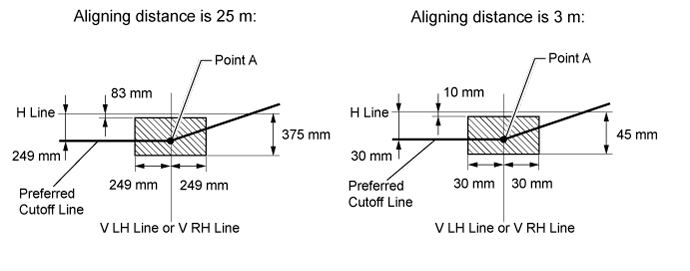

- If the alignment distance is 25 m (82 ft.):

The low beam cutoff line should be within 83 mm (3.27 in.) and 375 mm (14.8 in.) below the H line as well as 249 mm (9.80 in.) left or right of the V LH or V RH line. - If the alignment distance is 3 m (9.84 ft.):

The low beam cutoff line should be within 10 mm (0.394 in.) and 45 mm (1.77 in.) below the H line as well as 30 mm (1.18 in.) left or right of the V LH or V RH line. - If the alignment distance is 25 m (82 ft.):

The horizontal line of the preferred low beam cutoff line is 249 mm (9.80 in.) below the H line and point A of the preferred low beam cutoff line is on the V LH or V RH line. - If the alignment distance is 3 m (9.84 ft.):

The horizontal line of the preferred low beam cutoff line is 30 mm (1.18 in.) below the H line and point A of the preferred low beam cutoff line is on the V LH or V RH line.

Turn on the high beams and check if the center of intensity for each high beam matches the center of intensity in the illustration.

- HINT:

- The low beam and high beam headlight are a unit, Adjusting the aim on the low beam to the correct position should also result in the high beam adjustment being correct.

- The illustration for LHD vehicles. RHD vehicles are the opposite of the illustration.

- If the alignment distance is 25 m (82 ft.):

The high beam center of intensity should be within 175 mm (6.88 in.) above and 249 mm (9.80 in.) below the H line as well as 497 mm (1.63 ft.) left or right of the V LH or V RH line. - If the alignment distance is 3 m (9.84 ft.):

The high beam center of intensity should be within 21 mm (0.82 in.) above and 30 mm (1.18 in.) below the H line as well as 60 mm (2.36 in.) left or right of the V LH or V RH line.

| 4. ADJUSTMENT HEADLIGHT AIMING |

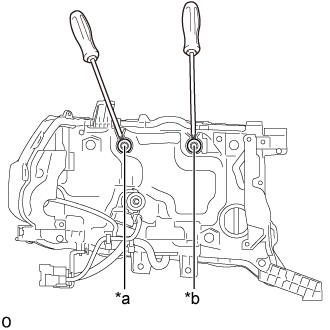

Using a screwdriver, adjust the aim.

Adjust the aim of each headlight so that it is within the specified range by turning each aiming screw with a screwdriver.Text in Illustration *a Vertical Aiming Screw *b Horizontal Aiming Screw - NOTICE:

- The final turn of the aiming screw should be made in the clockwise direction. If the screw is tightened excessively, loosen it and then retighten it, so that the final turn of the screw is in the clockwise direction.

- HINT:

- The low beam and high beam headlight are a unit, Adjusting the aim on the low beam to the correct position should also result in the high beam adjustment being correct.

- When adjusting the horizontal axis of the headlight, the vertical axis will also change. It is necessary to adjust the horizontal position first, and then correct the vertical position.

- If it is not possible to correctly adjust headlight aim, check the headlight assembly, headlight LED unit installation.

- for LH Side:

The headlight aim moves up when turning the vertical aiming screw counterclockwise, and moves down when turning the vertical aiming screw clockwise. The headlight aim moves right when turning the horizontal aiming screw counterclockwise, and moves left when turning the horizontal aiming screw clockwise. - for RH Side:

The headlight aim moves up when turning the vertical aiming screw counterclockwise, and moves down when turning the vertical aiming screw clockwise. The headlight aim moves right when turning the horizontal aiming screw clockwise, and moves left when turning the horizontal aiming screw counterclockwise. - Confirm the direction of rotation of the aiming screw by observing it while it is being adjusted. Due to the position of the screwdriver, the direction of rotation of the adjusting screw can be different than the direction of rotation of the screwdriver being used to adjust it.

|