Power Window Control System (For Models With Jam Protection Function On 4 Windows) Driver Side Power Window Does Not Operate With Power Window Master Switch

DESCRIPTION

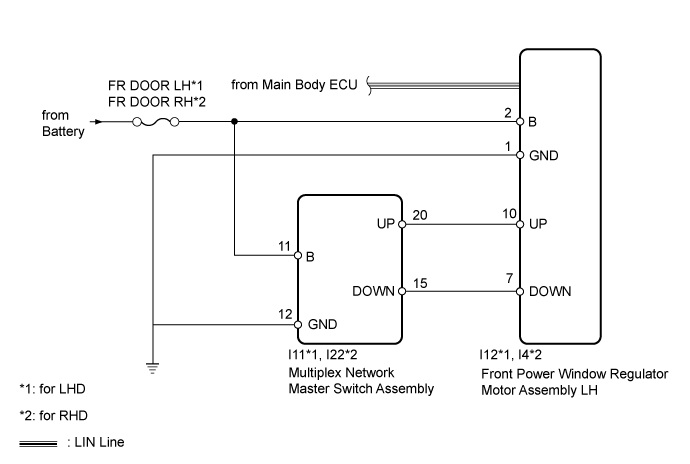

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK LIN COMMUNICATION SYSTEM

CHECK FOR DTC (B2312)

READ VALUE USING INTELLIGENT TESTER (POWER WINDOW REGULATOR MOTOR)

CHECK HARNESS AND CONNECTOR (MULTIPLEX NETWORK MASTER SWITCH - BATTERY AND BODY GROUND)

CHECK HARNESS AND CONNECTOR (FRONT POWER WINDOW REGULATOR MOTOR - BATTERY AND BODY GROUND)

CHECK HARNESS AND CONNECTOR (MULTIPLEX NETWORK MASTER SWITCH - FRONT POWER WINDOW REGULATOR MOTOR)

INSPECT FRONT POWER WINDOW REGULATOR MOTOR ASSEMBLY LH

INSPECT FRONT POWER WINDOW REGULATOR MOTOR ASSEMBLY RH

POWER WINDOW CONTROL SYSTEM (for Models with Jam Protection Function on 4 Windows) - Driver Side Power Window does not Operate with Power Window Master Switch |

DESCRIPTION

- If the manual up/down function does not operate, there may be a malfunction in the multiplex network master switch, power window regulator motor, harness or connector.

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.CHECK LIN COMMUNICATION SYSTEM |

Check for LIN communication system DTCs related to the power window control system (Click here).

- OK:

- LIN communication system DTCs are not output.

Check if DTC B2312 is output (Click here).

- OK:

- DTC B2312 is not output.

| 3.READ VALUE USING INTELLIGENT TESTER (POWER WINDOW REGULATOR MOTOR) |

Use the Data List to check if the power window regulator motor is functioning properly (Click here).

D-Door MotorTester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

D Door P/W Up SW

| Driver side power window manual up signal / ON or OFF

| ON: Driver side power window manual up switch operated

OFF: Driver side power window switch not operated

| -

|

D Door P/W Down SW

| Driver side power window manual down signal / ON or OFF

| ON: Driver side power window manual down switch operated

OFF: Driver side power window switch not operated

| -

|

- OK:

- The display changes according to operation of the multiplex network master switch.

ResultResult

| Proceed to

|

NG

| A

|

OK (for LHD)

| B

|

OK (for RHD)

| C

|

| | REPLACE FRONT POWER WINDOW REGULATOR MOTOR ASSEMBLY LH (Click here) |

|

|

| | REPLACE FRONT POWER WINDOW REGULATOR MOTOR ASSEMBLY RH (Click here) |

|

|

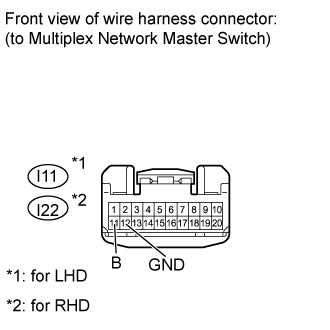

| 4.CHECK HARNESS AND CONNECTOR (MULTIPLEX NETWORK MASTER SWITCH - BATTERY AND BODY GROUND) |

Disconnect the I11*1 or I22*2 switch connector.

- HINT:

- *1: for LHD

- *2: for RHD

Measure the voltage and resistance according to the value(s) in the table below.

- Standard Voltage:

for LHDTester Connection

| Condition

| Specified Condition

|

I11-11 (B) - Body ground

| Always

| 11 to 14 V

|

for RHDTester Connection

| Condition

| Specified Condition

|

I22-11 (B) - Body ground

| Always

| 11 to 14 V

|

- Standard Resistance:

for LHDTester Connection

| Condition

| Specified Condition

|

I11-12 (GND) - Body ground

| Always

| Below 1 Ω

|

for RHDTester Connection

| Condition

| Specified Condition

|

I22-12 (GND) - Body ground

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 5.CHECK HARNESS AND CONNECTOR (FRONT POWER WINDOW REGULATOR MOTOR - BATTERY AND BODY GROUND) |

Disconnect the I12*1 or I4*2 motor connector.

- HINT:

- *1: for LHD

- *2: for RHD

Measure the voltage and resistance according to the value(s) in the table below.

- Standard Voltage:

for LHDTester Connection

| Condition

| Specified Condition

|

I12-2 (B) - Body ground

| Always

| 11 to 14 V

|

for RHDTester Connection

| Condition

| Specified Condition

|

I4-2 (B) - Body ground

| Always

| 11 to 14 V

|

- Standard Resistance:

for LHDTester Connection

| Condition

| Specified Condition

|

I12-1 (GND) - Body ground

| Always

| Below 1 Ω

|

for RHDTester Connection

| Condition

| Specified Condition

|

I4-1 (GND) - Body ground

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

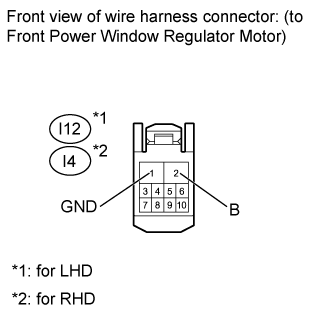

| 6.CHECK HARNESS AND CONNECTOR (MULTIPLEX NETWORK MASTER SWITCH - FRONT POWER WINDOW REGULATOR MOTOR) |

Disconnect the I11*1 or I22*2 switch connector.

- HINT:

- *1: for LHD

- *2: for RHD

Disconnect the I12*1 or I4*2 motor connector.

- HINT:

- *1: for LHD

- *2: for RHD

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

for LHDTester Connection

| Condition

| Specified Condition

|

I11-20 (UP) - I12-10 (UP)

| Always

| Below 1 Ω

|

I11-15 (DOWN) - I12-7 (DOWN)

| Always

| Below 1 Ω

|

I11-20 (UP) or I12-10 (UP) - Body ground

| Always

| 10 kΩ or higher

|

I11-15 (DOWN) or I12-7 (DOWN) - Body ground

| Always

| 10 kΩ or higher

|

for RHDTester Connection

| Condition

| Specified Condition

|

I22-20 (UP) - I4-10 (UP)

| Always

| Below 1 Ω

|

I22-15 (DOWN) - I4-7 (DOWN)

| Always

| Below 1 Ω

|

I22-20 (UP) or I4-10 (UP) - Body ground

| Always

| 10 kΩ or higher

|

I22-15 (DOWN) or I4-7 (DOWN) - Body ground

| Always

| 10 kΩ or higher

|

ResultResult

| Proceed to

|

NG

| A

|

OK (for LHD)

| B

|

OK (for RHD)

| C

|

| A |

|

|

|

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 7.INSPECT FRONT POWER WINDOW REGULATOR MOTOR ASSEMBLY LH |

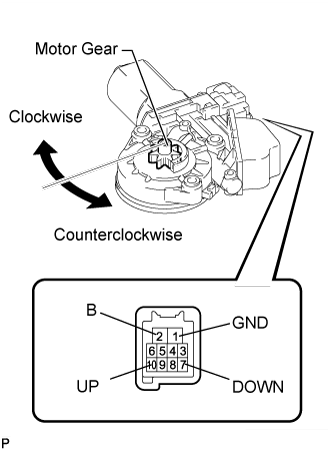

Remove the motor (Click here).

Apply positive (+) battery voltage to connector terminal 2 (B).

- NOTICE:

- Do not apply positive (+) battery voltage to any terminals, except terminal 2 (B), to avoid damaging the pulse sensor inside the motor.

- Reset the power window regulator motor (initialize the pulse sensor) after installing the power window regulator motor and regulator assembly onto the door.

Apply negative (-) battery voltage to connector terminals 1 (GND), and 7 (DOWN) or 10 (UP).

Check that the motor gear rotates smoothly as follows.

- OK:

Measurement Condition

| Specified Condition

|

- Connect the positive (+) battery cable to terminal 2(B), and connect the negative (-) battery cable to terminal 1(GND), and keep them connected for 3 seconds or more.

- With terminals 2(B) and 1(GND) connected, connect the negative (-) battery cable to terminal 10(UP).

- Disconnect and reconnect the negative (-) battery cable to terminal 10(UP) within 1 second.

| Motor gear rotates clockwise (Up)

|

- Connect the positive (+) battery cable to terminal 2(B), and connect the negative (-) battery cable to terminal 1(GND), and keep them connected for 3 seconds or more.

- With terminals 2(B) and 1(GND) connected, connect the negative (-) battery cable to terminal 7(DOWN).

- Disconnect and reconnect the negative (-) battery cable to terminal 7(DOWN) within 1 second.

| Motor gear rotates counterclockwise (Down)

|

| | REPLACE FRONT POWER WINDOW REGULATOR MOTOR ASSEMBLY LH (Click here) |

|

|

| OK |

|

|

|

| REPLACE MULTIPLEX NETWORK MASTER SWITCH ASSEMBLY (Click here) |

|

| 8.INSPECT FRONT POWER WINDOW REGULATOR MOTOR ASSEMBLY RH |

Remove the motor (Click here).

Apply positive (+) battery voltage to connector terminal 2 (B).

- NOTICE:

- Do not apply positive (+) battery voltage to any terminals, except terminal 2 (B), to avoid damaging the pulse sensor inside the motor.

- Reset the power window regulator motor (initialize the pulse sensor) after installing the power window regulator motor and regulator assembly onto the door.

Apply negative (-) battery voltage to the connector terminals 1 (GND), and 7 (DOWN) or 10 (UP).

Check that the motor gear rotates smoothly as follows.

- OK:

Measurement Condition

| Specified Condition

|

- Connect the positive (+) battery cable to terminal 2(B), and connect the negative (-) battery cable to terminal 1(GND), and keep them connected for 3 seconds or more.

- With terminals 2(B) and 1(GND) connected, connect the negative (-) battery cable to terminal 10(UP).

- Disconnect and reconnect the negative (-) battery cable to terminal 10(UP) within 1 second.

| Motor gear rotates counterclockwise (Up)

|

- Connect the positive (+) battery cable to terminal 2(B), and connect the negative (-) battery cable to terminal 1(GND), and keep them connected for 3 seconds or more.

- With terminals 2(B) and 1(GND) connected, connect the negative (-) battery cable to terminal 7(DOWN).

- Disconnect and reconnect the negative (-) battery cable to terminal 7(DOWN) within 1 second.

| Motor gear rotates clockwise (Down)

|

| | REPLACE FRONT POWER WINDOW REGULATOR MOTOR ASSEMBLY RH (Click here) |

|

|

| OK |

|

|

|

| REPLACE MULTIPLEX NETWORK MASTER SWITCH ASSEMBLY (Click here) |

|