Seat Belt. Land Cruiser. Urj200, 202 Grj200 Vdj200

DESCRIPTION

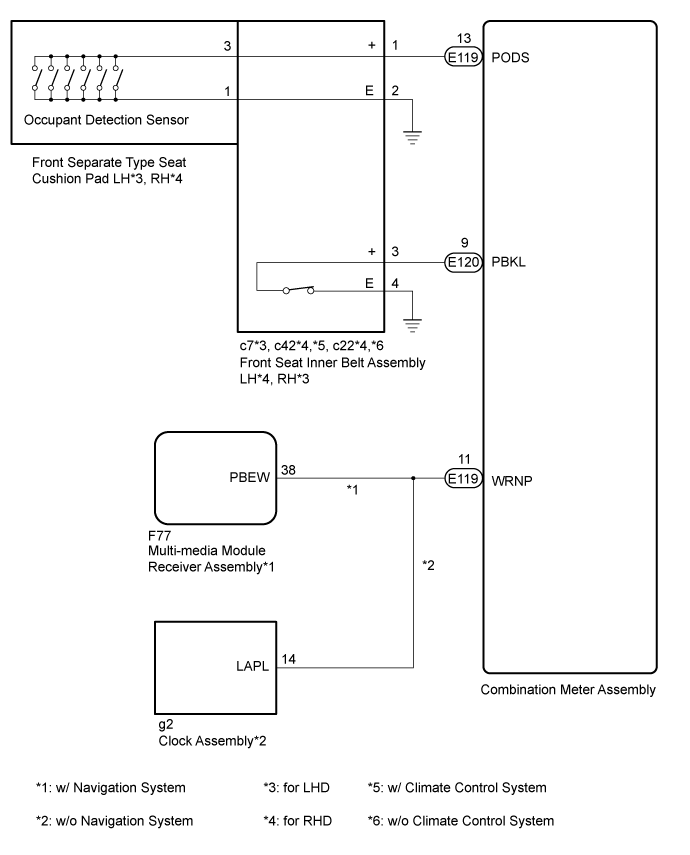

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK VEHICLE TYPE

CHECK FOR DTC

READ VALUE USING GTS (PASSENGER SIDE BUCKLE SWITCH)

CHECK HARNESS AND CONNECTOR (MULTI-MEDIA MODULE RECEIVER ASSEMBLY - COMBINATION METER ASSEMBLY, BATTERY AND BODY GROUND)

CHECK MULTI-MEDIA MODULE RECEIVER ASSEMBLY

CHECK HARNESS AND CONNECTOR (CLOCK ASSEMBLY - COMBINATION METER ASSEMBLY, BATTERY AND BODY GROUND)

CHECK CLOCK ASSEMBLY

INSPECT FRONT SEAT INNER BELT ASSEMBLY LH

CHECK HARNESS AND CONNECTOR (FRONT SEAT INNER BELT ASSEMBLY LH - COMBINATION METER ASSEMBLY, BATTERY AND BODY GROUND)

INSPECT FRONT SEPARATE TYPE SEAT CUSHION PAD LH (OCCUPANT DETECTION SENSOR)

INSPECT FRONT SEAT INNER BELT ASSEMBLY LH

CHECK HARNESS AND CONNECTOR (FRONT SEAT INNER BELT LH - COMBINATION METER ASSEMBLY AND BODY GROUND)

CHECK FOR DTC

READ VALUE USING GTS (PASSENGER SIDE BUCKLE SWITCH)

CHECK HARNESS AND CONNECTOR (MULTI-MEDIA MODULE RECEIVER ASSEMBLY - COMBINATION METER ASSEMBLY, BATTERY AND BODY GROUND)

CHECK COMBINATION METER ASSEMBLY

CHECK HARNESS AND CONNECTOR (CLOCK ASSEMBLY - COMBINATION METER ASSEMBLY, BATTERY AND BODY GROUND)

CHECK CLOCK ASSEMBLY

INSPECT FRONT SEAT INNER BELT ASSEMBLY RH

CHECK HARNESS AND CONNECTOR (FRONT SEAT INNER BELT ASSEMBLY RH - COMBINATION METER ASSEMBLY, BATTERY AND BODY GROUND)

INSPECT FRONT SEPARATE TYPE SEAT CUSHION PAD RH (OCCUPANT DETECTION SENSOR)

INSPECT FRONT SEAT INNER BELT ASSEMBLY RH

CHECK HARNESS AND CONNECTOR (FRONT SEAT INNER BELT RH - COMBINATION METER ASSEMBLY AND BODY GROUND)

SEAT BELT WARNING SYSTEM - Front Passenger Side Seat Belt Warning Light Malfunction |

DESCRIPTION

The combination meter detects the state of the front seat inner belt assembly (for Front Passenger Side) when the front passenger seat is occupied with the ignition switch ON. If the front passenger seat belt is not fastened, the front passenger side seat belt warning light on the multi-media module receiver assembly*1 (clock assembly*2) blinks. If the seat belt is fastened, the warning light goes off.- *1: w/ Navigation System

- *2: w/o Navigation System

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

Check the vehicle type.

ResultResult

| Proceed to

|

for LHD

| A

|

for RHD

| B

|

Check for DTCs.

ResultResult

| Proceed to

|

DTC is not output

| A

|

CAN communication system DTC is output (for LHD with Central Gateway ECU)

| B

|

CAN communication system DTC is output (for LHD without Central Gateway ECU)

| C

|

Airbag system DTC is output

| D

|

| 3.READ VALUE USING GTS (PASSENGER SIDE BUCKLE SWITCH) |

Check the Data List for proper functioning of the front passenger side seat belt buckle switch.

Combination MeterTester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

P-Seatbelt Buckle SW

| Front passenger side seat belt buckle signal / ON or OFF

| ON: Front passenger side seat belt is fastened

OFF: Front passenger side seat belt is unfastened

| -

|

Passenger Occupant Detection Switch

| Occupant detection sensor signal / ON or OFF

| ON: Front passenger seat occupied

OFF: Front passenger seat not occupied

| -

|

ResultResult

| Proceed to

|

ON or OFF is displayed on the GTS screen according (w/ Navigation System)

| A

|

ON or OFF is displayed on the GTS screen according (w/o Navigation System)

| B

|

ON or OFF is not displayed normally on the GTS screen according to the front passenger side seat belt condition

| C

|

ON or OFF is not displayed normally on the GTS screen according to the front passenger seat condition (occupied or unoccupied)

| D

|

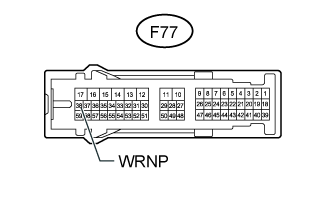

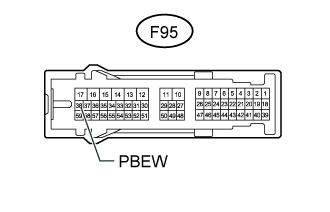

| 4.CHECK HARNESS AND CONNECTOR (MULTI-MEDIA MODULE RECEIVER ASSEMBLY - COMBINATION METER ASSEMBLY, BATTERY AND BODY GROUND) |

Disconnect the F77 multi-media module receiver assembly connector.

Disconnect the E119 combination meter assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

F77-38 (PBEW) - E119-11 (WRNP)

| Always

| Below 1 Ω

|

F77-38 (PBEW) or E119-11 (WRNP) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 5.CHECK MULTI-MEDIA MODULE RECEIVER ASSEMBLY |

Disconnect the F77 multi-media module receiver assembly connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

F77-38 (WRNP) - Body ground

| Ignition switch ON

| 11 to 14 V

|

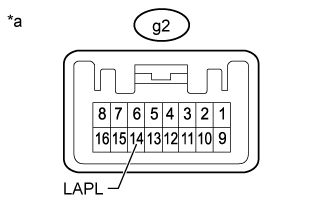

Text in Illustration*a

| Front view of wire harness connector

(to Multi-media Module Receiver Assembly)

|

| | REPLACE MULTI-MEDIA MODULE RECEIVER ASSEMBLY (Click here) |

|

|

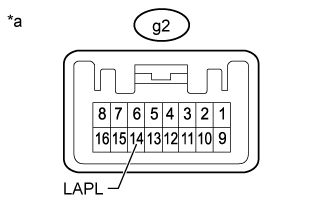

| 6.CHECK HARNESS AND CONNECTOR (CLOCK ASSEMBLY - COMBINATION METER ASSEMBLY, BATTERY AND BODY GROUND) |

Disconnect the g2 clock assembly connector.

Disconnect the E119 combination meter assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

g2-14 (LAPL) or E119-11 (WRNP) - Body ground

| Always

| 10 kΩ or higher

|

g2-14 (LAPL) - E119-11 (WRNP)

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

Disconnect the g2 clock assembly connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

g2-14 (LAPL) - Body ground

| Ignition switch ON

| 11 to 14 V

|

Text in Illustration*a

| Front view of wire harness connector

(to Clock Assembly)

|

| 8.INSPECT FRONT SEAT INNER BELT ASSEMBLY LH |

Remove the front seat inner belt assembly LH.

- except Bench Seat: Click here

- for Bench Seat: Click here

Inspect the front seat inner belt assembly LH.

- except Bench Seat: Click here

- for Bench Seat: Click here

ResultResult

| Proceed to

|

OK

| A

|

NG (except Bench Seat)

| B

|

NG (for Bench seat)

| C

|

| | REPLACE FRONT SEAT INNER BELT ASSEMBLY (for Front Passenger Side) (Click here) |

|

|

| | REPLACE FRONT SEAT INNER BELT ASSEMBLY (for Front Passenger Side) (Click here) |

|

|

| 9.CHECK HARNESS AND CONNECTOR (FRONT SEAT INNER BELT ASSEMBLY LH - COMBINATION METER ASSEMBLY, BATTERY AND BODY GROUND) |

Disconnect the c7 front seat inner belt assembly LH connector.

Disconnect the E120 combination meter assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

c7-3 (+) - E120-9 (PBKL)

| Always

| Below 1 Ω

|

c7-3 (+) or E120-9 (PBKL) - Body ground

| Always

| 10 kΩ or higher

|

c7-4 (E) - Body ground

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

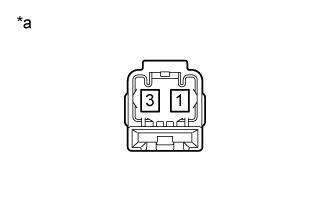

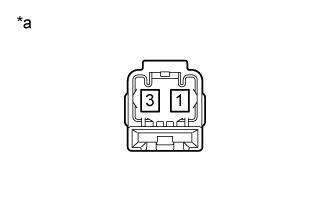

| 10.INSPECT FRONT SEPARATE TYPE SEAT CUSHION PAD LH (OCCUPANT DETECTION SENSOR) |

Remove the front separate type seat cushion pad LH.

- for Manual Seat: Click here

- for Power Seat: Click here

- for Bench Seat: Click here

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

1 - 3

| Front passenger seat occupied

| Below 100 Ω

|

1 - 3

| Front passenger seat not occupied

| 10 kΩ or higher

|

ResultResult

| Proceed to

|

OK

| A

|

NG (for Manual Seat)

| B

|

NG (for Power Seat)

| C

|

NG (for Bench Seat)

| D

|

Text in Illustration*a

| Component without harness connected

(Occupant Detection Sensor)

|

| | REPLACE FRONT SEPARATE TYPE SEAT CUSHION PAD (Click here) |

|

|

| | REPLACE FRONT SEPARATE TYPE SEAT CUSHION PAD (Click here) |

|

|

| | REPLACE FRONT SEPARATE TYPE SEAT CUSHION PAD (Click here) |

|

|

| 11.INSPECT FRONT SEAT INNER BELT ASSEMBLY LH |

Remove the front seat inner belt assembly LH.

- except Bench Seat: Click here

- for Bench Seat: Click here

Inspect the front seat inner belt assembly LH.

- except Bench Seat: Click here

- for Bench Seat: Click here

ResultResult

| Proceed to

|

OK

| A

|

NG (except Bench Seat)

| B

|

NG (for Bench seat)

| C

|

| | REPLACE FRONT SEAT INNER BELT ASSEMBLY (for Front Passenger Side) (Click here) |

|

|

| | REPLACE FRONT SEAT INNER BELT ASSEMBLY (for Front Passenger Side) (Click here) |

|

|

| 12.CHECK HARNESS AND CONNECTOR (FRONT SEAT INNER BELT LH - COMBINATION METER ASSEMBLY AND BODY GROUND) |

Disconnect the c7 front seat inner belt assembly LH connector.

Disconnect the E119 combination meter assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

c7-1 (+) - E119-13 (PODS)

| Always

| Below 1 Ω

|

c7-1 (+) or E119-13 (PODS) - Body ground

| Always

| 10 kΩ or higher

|

c7-2 (E) - Body ground

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

Check for DTCs.

ResultResult

| Proceed to

|

DTC is not output

| A

|

CAN communication system DTC is output (for RHD with Central Gateway ECU)

| B

|

CAN communication system DTC is output (for RHD without Central Gateway ECU)

| C

|

Airbag system DTC is output

| D

|

| 14.READ VALUE USING GTS (PASSENGER SIDE BUCKLE SWITCH) |

Check the Data List for proper functioning of the front passenger side seat belt buckle switch.

Combination MeterTester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

P-Seatbelt Buckle SW

| Front passenger side seat belt buckle signal / ON or OFF

| ON: Front passenger side seat belt is fastened

OFF: Front passenger side seat belt is unfastened

| -

|

Passenger Occupant Detection Switch

| Occupant detection sensor signal / ON or OFF

| ON: Front passenger seat occupied

OFF: Front passenger seat not occupied

| -

|

ResultResult

| Proceed to

|

ON or OFF is displayed on the GTS screen according (w/ Navigation System)

| A

|

ON or OFF is displayed on the GTS screen according (w/o Navigation System)

| B

|

ON or OFF is not displayed normally on the GTS screen according to the front passenger side seat belt condition

| C

|

ON or OFF is not displayed normally on the GTS screen according to the front passenger seat condition (occupied or unoccupied)

| D

|

| 15.CHECK HARNESS AND CONNECTOR (MULTI-MEDIA MODULE RECEIVER ASSEMBLY - COMBINATION METER ASSEMBLY, BATTERY AND BODY GROUND) |

Disconnect the F77 multi-media module receiver assembly connector.

Disconnect the E119 combination meter assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

F77-38 (PBEW) - E119-11 (WRNP)

| Always

| Below 1 Ω

|

F77-38 (PBEW) or E119-11 (WRNP) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 16.CHECK COMBINATION METER ASSEMBLY |

Disconnect the F77 multi-media module receiver assembly connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

F77-38 (PBEW) - Body ground

| Ignition switch ON

| 11 to 14 V

|

Text in Illustration*a

| Front view of wire harness connector

(to Multi-media Module Receiver Assembly)

|

| | REPLACE MULTI-MEDIA MODULE RECEIVER ASSEMBLY (Click here) |

|

|

| 17.CHECK HARNESS AND CONNECTOR (CLOCK ASSEMBLY - COMBINATION METER ASSEMBLY, BATTERY AND BODY GROUND) |

Disconnect the g2 clock assembly connector.

Disconnect the E119 combination meter assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

g2-14 (LAPL) or E119-11 (WRNP) - Body ground

| Always

| 10 kΩ or higher

|

g2-14 (LAPL) - E119-11 (WRNP)

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

Disconnect the g2 clock assembly connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

g2-14 (LAPL) - Body ground

| Ignition switch ON

| 11 to 14 V

|

Text in Illustration*a

| Front view of wire harness connector

(to Clock Assembly)

|

| 19.INSPECT FRONT SEAT INNER BELT ASSEMBLY RH |

Remove the front seat inner belt assembly RH.

- except Bench Seat: Click here

- for Bench Seat: Click here

Inspect the front seat inner belt assembly RH.

- except Bench Seat: Click here

- for Bench Seat: Click here

ResultResult

| Proceed to

|

OK

| A

|

NG (except Bench Seat)

| B

|

NG (for Bench seat)

| C

|

| | REPLACE FRONT SEAT INNER BELT ASSEMBLY (for Front Passenger Side) (Click here) |

|

|

| | REPLACE FRONT SEAT INNER BELT ASSEMBLY (for Front Passenger Side) (Click here) |

|

|

| 20.CHECK HARNESS AND CONNECTOR (FRONT SEAT INNER BELT ASSEMBLY RH - COMBINATION METER ASSEMBLY, BATTERY AND BODY GROUND) |

Disconnect the c22 front seat inner belt assembly RH connector.

Disconnect the E120 combination meter assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

c22-3 (+) - E120-9 (PBKL)

| Always

| Below 1 Ω

|

c22-3 (+) or E120-9 (PBKL) - Body ground

| Always

| 10 kΩ or higher

|

c22-4 (E) - Body ground

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 21.INSPECT FRONT SEPARATE TYPE SEAT CUSHION PAD RH (OCCUPANT DETECTION SENSOR) |

Remove the front separate type seat cushion pad RH.

- for Manual Seat: Click here

- for Power Seat: Click here

- for Bench Seat: Click here

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

1 - 3

| Front passenger seat occupied

| Below 100 Ω

|

1 - 3

| Front passenger seat not occupied

| 10 kΩ or higher

|

ResultResult

| Proceed to

|

OK

| A

|

NG (for Manual Seat)

| B

|

NG (for Power Seat)

| C

|

NG (for Bench Seat)

| D

|

| | REPLACE FRONT SEPARATE TYPE SEAT CUSHION PAD (Click here) |

|

|

| | REPLACE FRONT SEPARATE TYPE SEAT CUSHION PAD (Click here) |

|

|

| | REPLACE FRONT SEPARATE TYPE SEAT CUSHION PAD (Click here) |

|

|

| 22.INSPECT FRONT SEAT INNER BELT ASSEMBLY RH |

Remove the front seat inner belt assembly RH.

- except Bench Seat: Click here

- for Bench Seat: Click here

Inspect the front seat inner belt assembly RH.

- except Bench Seat: Click here

- for Bench Seat: Click here

ResultResult

| Proceed to

|

OK

| A

|

NG (except Bench Seat)

| B

|

NG (for Bench seat)

| C

|

| | REPLACE FRONT SEAT INNER BELT ASSEMBLY (for Front Passenger Side) (Click here) |

|

|

| | REPLACE FRONT SEAT INNER BELT ASSEMBLY (for Front Passenger Side) (Click here) |

|

|

| 23.CHECK HARNESS AND CONNECTOR (FRONT SEAT INNER BELT RH - COMBINATION METER ASSEMBLY AND BODY GROUND) |

Disconnect the c22*1 or c42*2 front seat inner belt assembly RH connector.

- *1: w/o Climate Control System

- *2: w/ Climate Control System

Disconnect the E119 combination meter assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

- w/ Climate Control System:

Tester Connection

| Condition

| Specified Condition

|

c42-1 (+) - E119-13 (PODS)

| Always

| Below 1 Ω

|

c42-1 (+) or E119-13 (PODS) - Body ground

| Always

| 10 kΩ or higher

|

c42-2 (E) - Body ground

| Always

| Below 1 Ω

|

- Standard Resistance:

- w/o Climate Control System:

Tester Connection

| Condition

| Specified Condition

|

c22-1 (+) - E119-13 (PODS)

| Always

| Below 1 Ω

|

c22-1 (+) or E119-13 (PODS) - Body ground

| Always

| 10 kΩ or higher

|

c22-2 (E) - Body ground

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|