Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 1UR-FE ENGINE MECHANICAL

ENGINE UNIT - DISASSEMBLY

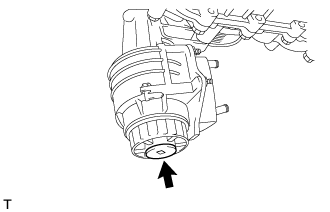

| 1. REMOVE OIL FILTER ELEMENT |

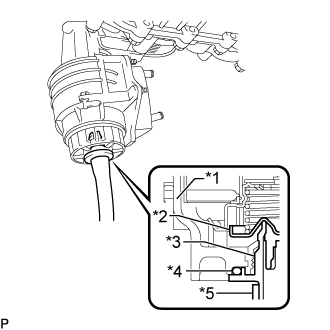

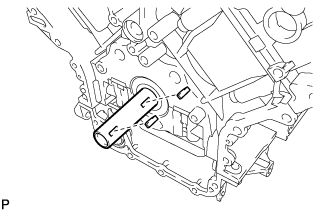

Connect a hose with an inside diameter of 15 mm (0.591 in.) to the pipe.

| *1 | Pipe |

| *2 | Hose |

Remove the oil filter drain plug.

Install the pipe to the oil filter cap.

| *1 | Cap |

| *2 | Valve |

| *3 | Pipe |

| *4 | O-Ring |

| *5 | Hose |

- NOTICE:

- If the O-ring is removed with the drain plug, install the O-ring together with the pipe.

- HINT:

- Use a container to catch the draining oil.

Check that oil is drained from the oil filter. Then disconnect the pipe and remove the O-ring as shown in the illustration.

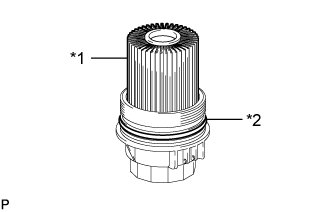

Using SST, remove the oil filter cap.

- SST

- 09228-06501

| *1 | Oil Filter Bracket Clip |

- NOTICE:

- Do not remove the oil filter bracket clip.

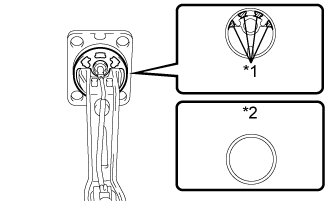

Remove the oil filter element and O-ring from the oil filter cap.

| *1 | Oil Filter Element |

| *2 | O-Ring |

- NOTICE:

- Be sure to remove the cap O-ring by hand, without using any tools, to prevent damage to the cap O-ring groove.

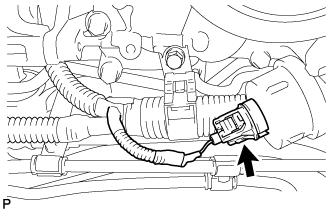

| 2. REMOVE OIL PRESSURE SENDER GAUGE ASSEMBLY |

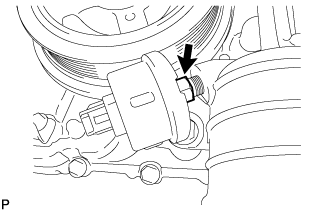

Disconnect the oil pressure sender gauge connector.

Remove the oil pressure sender gauge.

| 3. REMOVE OIL FILTER BRACKET SUB-ASSEMBLY |

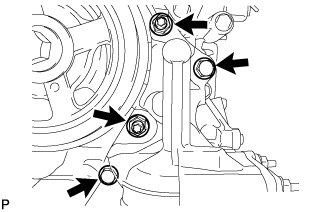

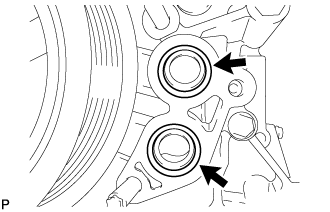

Remove the 2 bolts, 2 nuts and filter bracket.

Remove the 2 O-rings.

| 4. REMOVE CRANKSHAFT PULLEY |

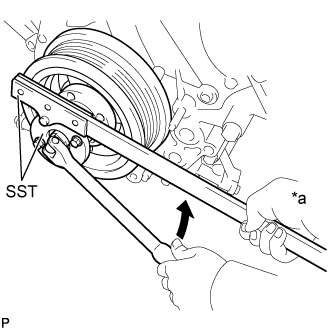

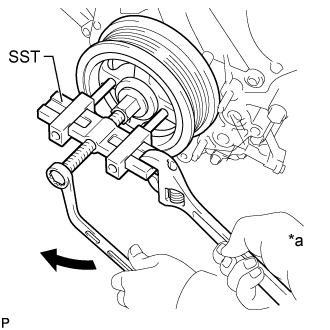

Using SST, remove the crankshaft pulley set bolt.

- SST

- 09213-70011

09330-00021

| *a | Hold |

| Turn |

Temporarily install the pulley set bolt to the crankshaft until 2 or 3 threads are engaged.

Using the pulley set bolt and SST, remove the crankshaft pulley.

- SST

- 09950-50013(09951-05010,09952-05010,09953-05010,09954-05011)

| *a | Hold |

| Turn |

| 5. REMOVE OIL FILLER CAP SUB-ASSEMBLY |

Remove the oil filler cap.

Remove the gasket from the oil filler cap.

| 6. REMOVE OIL FILLER CAP HOUSING |

Remove the 2 bolts, oil filler cap housing and gasket.

| 7. REMOVE SPARK PLUG |

Using a 16 mm plug wrench, remove the 8 spark plugs.

| 8. REMOVE KNOCK SENSOR |

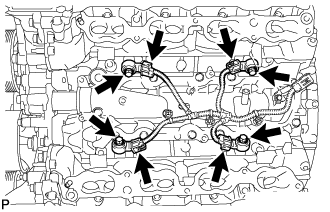

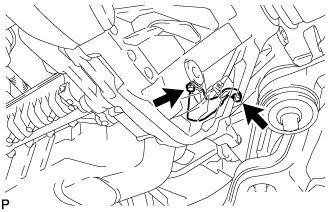

Disconnect the 4 knock sensor connectors.

Remove the 4 bolts and 4 knock sensors.

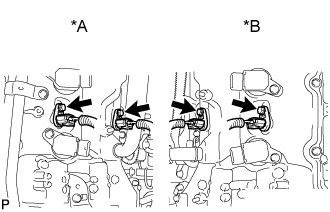

| 9. REMOVE VVT SENSOR |

Disconnect the 4 VVT sensor connectors.

| *A | for Bank 2 |

| *B | for Bank 1 |

Remove the 4 bolts and 4 VVT sensors.

| 10. REMOVE CAMSHAFT POSITION SENSOR |

Disconnect the camshaft position sensor connector.

Remove the bolt and camshaft position sensor.

| 11. REMOVE CRANKSHAFT POSITION SENSOR PROTECTOR |

Remove the 2 bolts and crankshaft position sensor protector.

| 12. REMOVE CRANKSHAFT POSITION SENSOR |

Disconnect the crankshaft position sensor connector.

Remove the bolt and crankshaft position sensor.

| 13. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY |

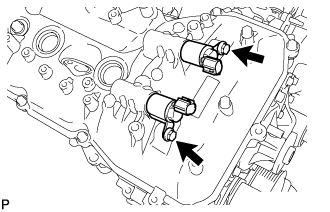

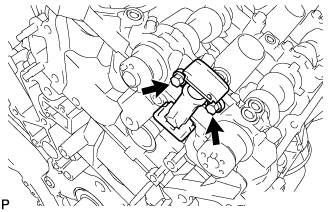

for Bank 1:

Remove the 2 bolts and 2 camshaft oil control valves.

for Bank 2:

Remove the 2 bolts and 2 camshaft oil control valves.

| 14. REMOVE CYLINDER BLOCK WATER DRAIN COCK SUB-ASSEMBLY |

Remove the 2 water drain cock plugs from the cylinder block water drain cocks.

| *A | for LH Side |

| *B | for RH Side |

Remove the 2 cylinder block water drain cocks from the cylinder block.

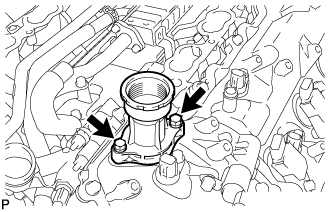

| 15. REMOVE WATER INLET HOUSING |

Remove the 3 bolts and water inlet housing.

Remove the gasket from the engine water pump.

| 16. REMOVE FRONT WATER BY-PASS JOINT |

Remove the 4 nuts, water by-pass joint and 2 gaskets.

| 17. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY LH |

Remove the 14 bolts, seal washer, cylinder head cover sub-assembly LH and cylinder head cover gasket LH.

- HINT:

- Make sure the removed parts are returned to the same places they were removed from.

Remove the 5 gaskets from the camshaft bearing caps (No. 2, No. 3).

| Gasket |

| 18. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY RH |

Remove the 14 bolts, seal washer, cylinder head cover sub-assembly RH and cylinder head cover gasket RH.

- HINT:

- Make sure the removed parts are returned to the same places they were removed from.

Remove the 5 gaskets from the camshaft bearing caps (No. 1, No. 3).

| Gasket |

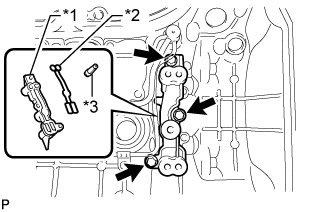

| 19. REMOVE OIL CONTROL VALVE FILTER |

for Bank 1:

Remove the 3 bolts, cylinder head cover spacer, gasket and oil control valve filter.

| *1 | Cylinder Head Cover Spacer |

| *2 | Gasket |

| *3 | Oil Control Valve Filter |

for Bank 2:

Remove the 3 bolts, cylinder head cover spacer, gasket and oil control valve filter.

| *1 | Cylinder Head Cover Spacer |

| *2 | Gasket |

| *3 | Oil Control Valve Filter |

| 20. REMOVE SPARK PLUG TUBE GASKET |

Bend the 4 ventilation baffle plate claws on the cylinder head cover to an angle of 90° or more.

| *1 | Ventilation Baffle Plate Claw |

| *2 | Protective Tape |

Using a screwdriver, pry out the gaskets.

- NOTICE:

- Be careful not to damage the cylinder head cover.

- HINT:

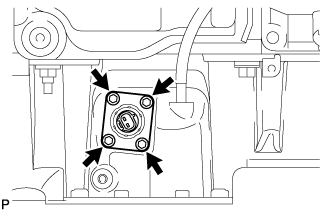

| 21. REMOVE ENGINE OIL LEVEL SENSOR |

Disconnect the oil level sensor connector.

Remove the 4 bolts and oil level sensor.

Cut away part of the gasket and remove the gasket from the engine oil level sensor.

| *1 | Cutting Position |

| *2 | Supply Part |

- HINT:

- Remove the only the outer part of the gasket.

| 22. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY |

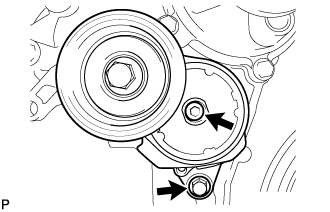

Remove the bolt, 6 mm hexagon bolt and belt tensioner.

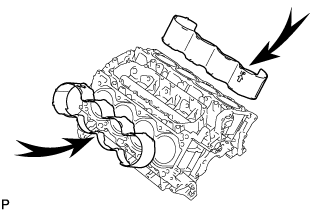

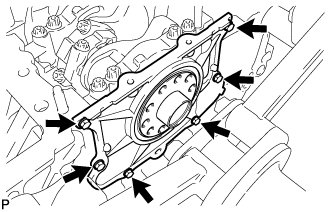

| 23. REMOVE TIMING CHAIN COVER SUB-ASSEMBLY |

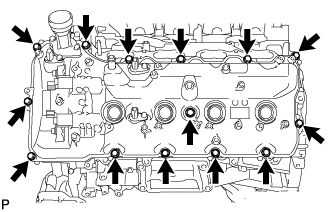

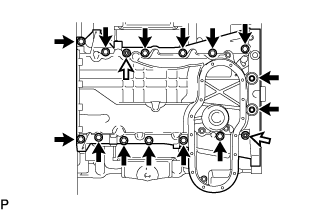

Remove the 26 bolts and nut shown in the illustration.

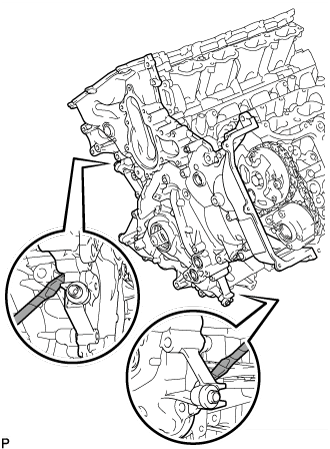

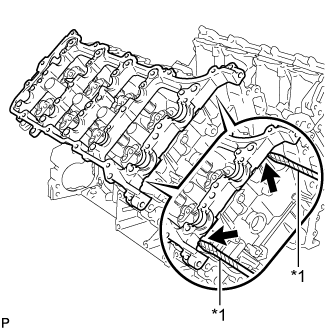

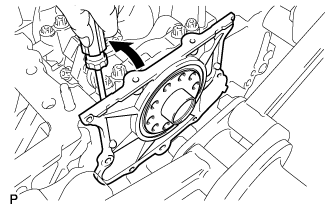

Remove the timing chain cover by prying between it and the cylinder head and cylinder block with a screwdriver as shown in the illustration.

| Protective Tape |

- NOTICE:

- Be careful not to damage the cylinder head, camshaft housing and cylinder block contact surfaces of the chain cover.

- HINT:

- Tape the screwdriver tip before use.

Remove the gasket from the cylinder block.

Remove the O-ring from the oil pan.

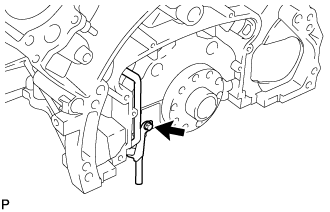

| 24. REMOVE ENGINE WATER PUMP ASSEMBLY |

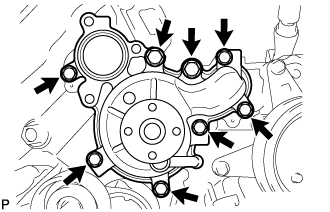

Remove the 8 bolts, engine water pump and gasket.

| 25. REMOVE WATER INLET PIPE |

Remove the water inlet pipe.

Remove the 2 O-rings from the water inlet pipe.

| 26. REMOVE FRONT CRANKSHAFT OIL SEAL |

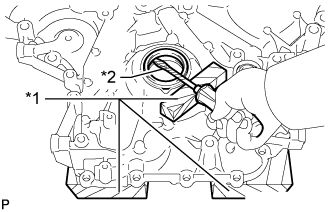

Place the timing chain cover on wooden blocks.

Place the oil pump on a wooden block.

| *1 | Wooden Block |

| *2 | Protective Tape |

Using a screwdriver and wooden block, pry out the front crankshaft oil seal.

- NOTICE:

- Do not damage the surface of the front crankshaft oil seal press fit hole.

- HINT:

- Tape the screwdriver tip before use.

| 27. SET NO. 1 CYLINDER TO TDC/COMPRESSION |

Temporarily install the pulley set bolt.

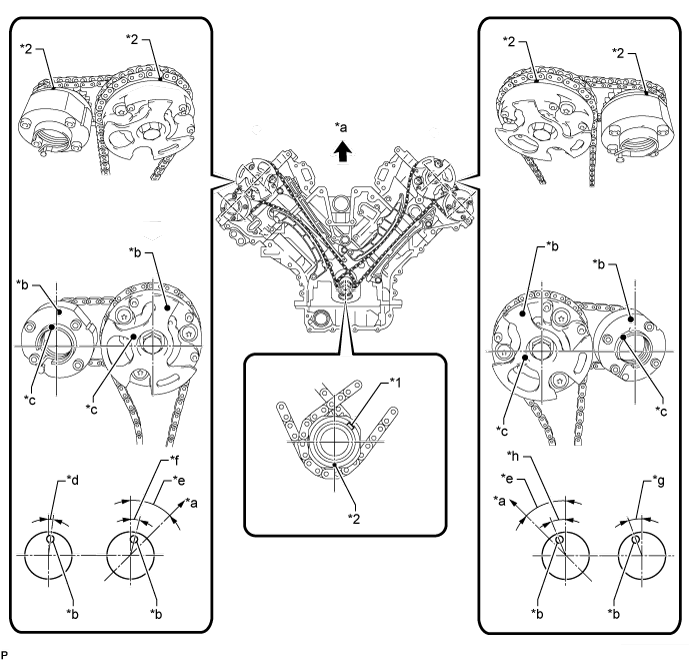

Rotate the crankshaft clockwise so that the timing marks on the crankshaft timing gear and camshaft timing gears are as shown in the illustration.

- HINT:

- If the timing marks do not align, rotate the crankshaft clockwise again and align the timing marks.

| *1 | Crankshaft Timing Gear Key | *2 | Timing Mark |

| *a | Toward Ceiling | *b | Timing Mark Position |

| *c | Knock Pin Position | *d | Approximately 2° |

| *e | Approximately 45° | *f | Approximately 16° |

| *g | Approximately 18° | *h | Approximately 32° |

| 28. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY LH |

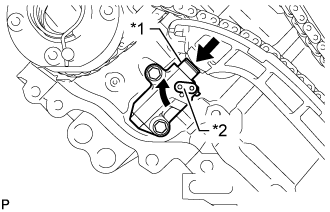

Move the stopper plate upward to release the lock and push the plunger deep into the No. 1 chain tensioner.

| *1 | Plunger |

| *2 | Stopper Plate |

Move the stopper plate downward to set the lock and insert a hexagon wrench into the stopper plate hole.

| *1 | Plunger |

| *2 | Stopper Plate |

| *3 | Hexagon Wrench |

Remove the 2 bolts, No. 1 chain tensioner LH and gasket.

| 29. REMOVE CHAIN TENSIONER SLIPPER LH |

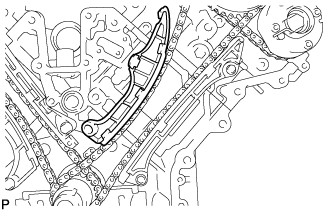

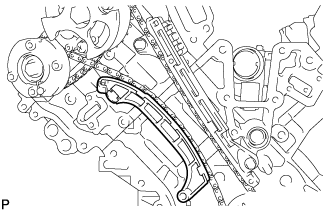

| 30. REMOVE NO. 1 CHAIN VIBRATION DAMPER LH |

Remove the 2 bolts and No. 1 chain vibration damper LH.

| 31. REMOVE NO. 1 CHAIN SUB-ASSEMBLY LH |

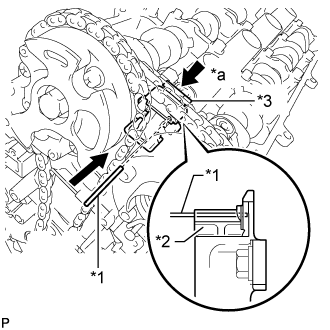

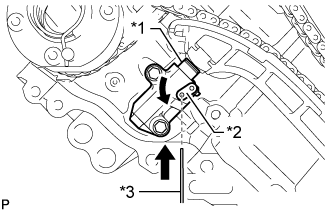

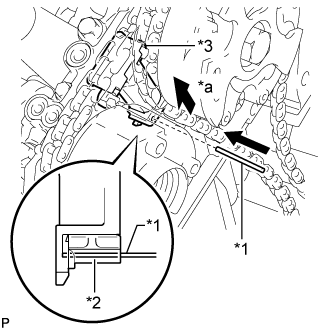

While pushing down the No. 3 chain tensioner, insert a pin with a diameter of 1.0 mm (0.0394 in.) into the hole to fix the tensioner in place.

| *1 | Pin |

| *2 | Plunger |

| *3 | No. 3 Chain Tensioner |

| *a | Push |

Hold the hexagonal portion of the camshaft with a wrench and loosen the bolt.

| *a | Hold |

| Turn |

- NOTICE:

Hold the hexagonal portion of the camshaft with a wrench and loosen the bolt.

| *a | Hold |

| Turn |

- NOTICE:

Remove the 2 bolts. Then with the No. 1 and No. 2 chains still connected to the gears, remove the camshaft timing gear, camshaft timing exhaust gear and crankshaft timing sprocket LH.

Remove the No. 1 and No. 2 chains from the gears.

| 32. REMOVE NO. 3 CHAIN TENSIONER ASSEMBLY |

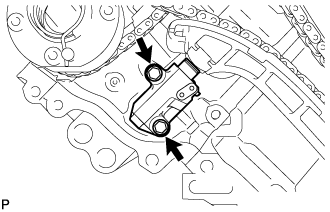

Remove the 2 bolts and No. 3 chain tensioner.

| 33. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY RH |

Move the stopper plate upward to release the lock and push the plunger deep into the No. 1 chain tensioner.

| *1 | Plunger |

| *2 | Stopper Plate |

Move the stopper plate downward to set the lock and insert a hexagon wrench into the stopper plate hole.

| *1 | Plunger |

| *2 | Stopper Plate |

| *3 | Hexagon Wrench |

Remove the 2 bolts and No. 1 chain tensioner RH.

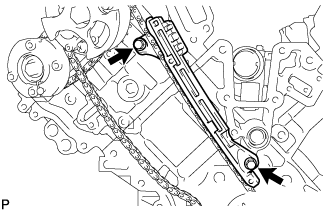

| 34. REMOVE CHAIN TENSIONER SLIPPER RH |

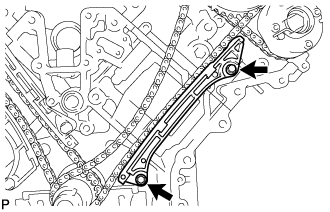

| 35. REMOVE NO. 1 CHAIN VIBRATION DAMPER RH |

Remove the 2 bolts and No. 1 chain vibration damper RH.

| 36. REMOVE NO. 1 CHAIN SUB-ASSEMBLY RH |

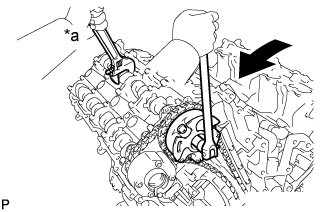

While raising up the No. 2 chain tensioner, insert a pin with a diameter of 1.0 mm (0.0394 in.) into the hole to fix the tensioner in place.

| *1 | Pin |

| *2 | Plunger |

| *3 | No. 2 Chain Tensioner |

| *a | Push |

Hold the hexagonal portion of the camshaft with a wrench and loosen the bolt.

| *a | Hold |

| Turn |

- NOTICE:

Hold the hexagonal portion of the camshaft with a wrench and loosen the bolt.

| *a | Hold |

| Turn |

- NOTICE:

Remove the 2 bolts. Then with the No. 1 and No. 2 chains still connected to the gears, remove the camshaft timing gear, camshaft timing exhaust gear and crankshaft timing sprocket RH.

Remove the No. 1 and No. 2 chains from the gears.

| 37. REMOVE NO. 2 CHAIN TENSIONER ASSEMBLY |

Remove the 2 bolts and No. 2 chain tensioner.

| 38. REMOVE CRANKSHAFT TIMING GEAR KEY |

Using a screwdriver, remove the 2 crankshaft timing gear keys from the crankshaft.

| 39. REMOVE CAMSHAFT BEARING CAP LH |

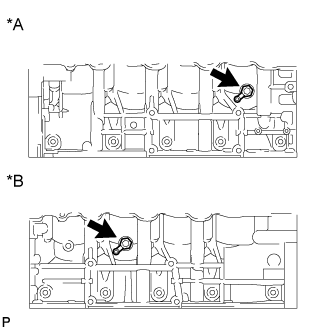

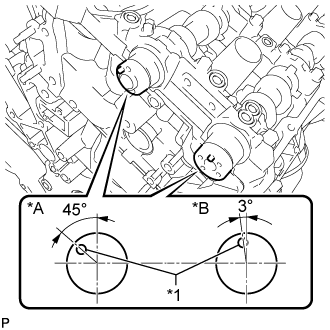

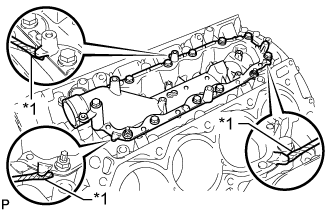

Make sure that the knock pins of the camshafts are positioned as shown in the illustration.

| *A | for Intake Side |

| *B | for Exhaust Side |

| *1 | Knock Pin |

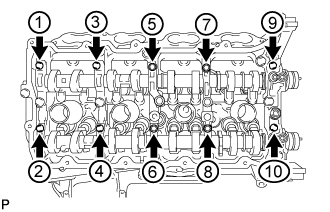

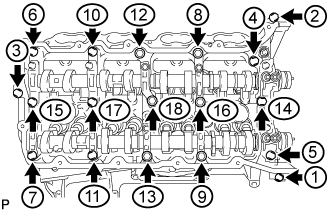

Uniformly loosen and remove the 10 bearing cap bolts in the sequence shown in the illustration.

Uniformly loosen and remove the 18 bearing cap bolts in the sequence shown in the illustration.

- NOTICE:

- Uniformly loosen the bolts while keeping the camshaft level.

Remove the 6 camshaft bearing caps.

- HINT:

- Arrange the removed parts in the correct order.

| 40. REMOVE NO. 3 CAMSHAFT SUB-ASSEMBLY |

Remove the No. 3 camshaft from the camshaft housing LH.

| 41. REMOVE NO. 4 CAMSHAFT SUB-ASSEMBLY |

Remove the No. 4 camshaft from the camshaft housing LH.

| 42. REMOVE CAMSHAFT HOUSING SUB-ASSEMBLY LH |

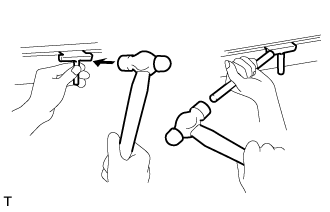

Remove the camshaft housing by prying between the cylinder head and camshaft housing with a screwdriver.

| *1 | Protective Tape |

- NOTICE:

- Be careful not to damage the contact surfaces of the cylinder head and camshaft housing.

- HINT:

- Tape the screwdriver tip before use.

| 43. REMOVE CAMSHAFT BEARING CAP RH |

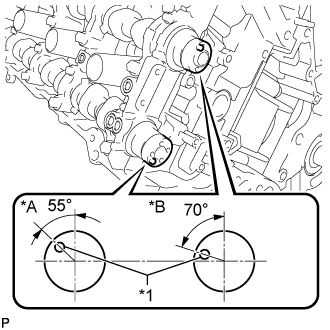

Make sure that the knock pins of the camshafts are positioned as shown in the illustration.

| *A | for Exhaust Side |

| *B | for Intake Side |

| *1 | Knock Pin |

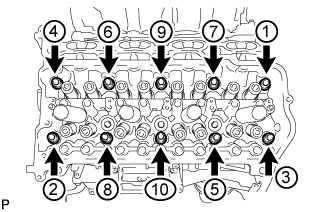

Uniformly loosen and remove the 10 bearing cap bolts in the sequence shown in the illustration.

Uniformly loosen and remove the 18 bearing cap bolts in the sequence shown in the illustration.

- NOTICE:

- Uniformly loosen the bolts while keeping the camshaft level.

Remove the 6 camshaft bearing caps.

- HINT:

- Arrange the removed parts in the correct order.

| 44. REMOVE NO. 1 CAMSHAFT SUB-ASSEMBLY |

Remove the No. 1 camshaft from the camshaft housing RH.

| 45. REMOVE NO. 2 CAMSHAFT SUB-ASSEMBLY |

Remove the No. 2 camshaft from the camshaft housing RH.

| 46. REMOVE CAMSHAFT HOUSING SUB-ASSEMBLY RH |

Remove the camshaft housing by prying between the cylinder head and camshaft housing with a screwdriver.

| *1 | Protective Tape |

- NOTICE:

- Be careful not to damage the contact surfaces of the cylinder head and camshaft housing.

- HINT:

- Tape the screwdriver tip before use.

| 47. REMOVE NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY |

Remove the 32 No. 1 valve rocker arms from the cylinder head.

- HINT:

- Arrange the removed parts in the correct order.

| 48. REMOVE VALVE LASH ADJUSTER ASSEMBLY |

Remove the 32 valve lash adjusters from the cylinder head.

- HINT:

- Arrange the removed parts in the correct order.

| 49. REMOVE VALVE STEM CAP |

Remove the 32 valve stem caps from the cylinder head.

- HINT:

- Arrange the removed parts in the correct order.

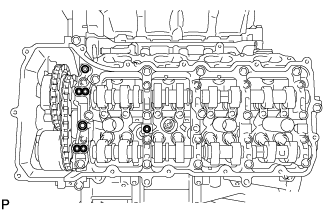

| 50. REMOVE CYLINDER HEAD SUB-ASSEMBLY LH |

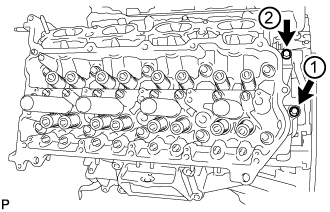

Uniformly loosen and remove the 2 bolts in the sequence shown in the illustration.

Using a 10 mm bi-hexagon wrench, uniformly loosen the 10 cylinder head bolts in the sequence shown in the illustration. Remove the 10 cylinder head bolts and plate washers.

- NOTICE:

- HINT:

- Be sure to arrange the removed parts for each installation position separately.

Remove the cylinder head LH.

| 51. REMOVE NO. 2 CYLINDER HEAD GASKET |

| 52. REMOVE CYLINDER HEAD SUB-ASSEMBLY |

Uniformly loosen and remove the 2 bolts in the sequence shown in the illustration.

Using a 10 mm bi-hexagon wrench, uniformly loosen the 10 cylinder head bolts in the sequence shown in the illustration. Remove the 10 cylinder head bolts and plate washers.

- NOTICE:

- HINT:

- Be sure to arrange the removed parts for each installation position separately.

Remove the cylinder head.

| 53. REMOVE CYLINDER HEAD GASKET |

| 54. REMOVE CYLINDER BLOCK WATER JACKET SPACER |

Remove the 2 cylinder block water jacket spacers from the cylinder block.

- NOTICE:

- Be sure to remove the cylinder block water jacket spacers. Otherwise, they may fall and become damaged when the cylinder block is inverted.

| 55. REMOVE OIL RETURN PIPE GASKET |

Using a screwdriver, pry out the oil return pipe gasket.

| *1 | Protective Tape |

- HINT:

- Tape the screwdriver tip before use.

| 56. REMOVE VENTILATION PIPE GASKET |

Using a screwdriver, pry out the ventilation pipe gasket.

| *1 | Protective Tape |

- HINT:

- Tape the screwdriver tip before use.

| 57. REMOVE NO. 1 HEAT EXCHANGER COVER |

Remove the 12 bolts and 2 nuts.

| Bolt |

| Nut |

Remove the No. 1 heat exchanger cover by prying between the No. 1 heat exchanger cover and cylinder block with a screwdriver.

| *1 | Protective Tape |

- HINT:

- Tape the screwdriver tip before use.

| 58. REMOVE NO. 2 OIL PAN SUB-ASSEMBLY |

Remove the 14 bolts and 2 nuts.

| Bolt |

| Nut |

Insert the blade of an oil pan seal cutter between the oil pans. Cut through the applied sealer and remove the No. 2 oil pan.

- NOTICE:

- Be careful not to damage the contact surfaces of the oil pans.

| 59. REMOVE NO. 1 OIL PAN SUB-ASSEMBLY |

Remove the 14 bolts and 2 nuts.

| Bolt |

| Nut |

- HINT:

- Be sure to clean the bolts and stud bolts and check the threads for cracks or other damage.

Remove the No. 1 oil pan by prying between the No. 1 oil pan and cylinder block with a screwdriver.

| *a | for LH Side |

| *b | for RH Side |

- NOTICE:

- Be careful not to damage the contact surfaces of the cylinder block and No. 1 oil pan.

- HINT:

- Tape the screwdriver tip before use.

| 60. REMOVE NO. 1 OIL PAN BAFFLE PLATE |

Remove the 7 bolts and No. 1 oil pan baffle plate.

| 61. REMOVE OIL STRAINER SUB-ASSEMBLY |

Remove the 2 bolts, oil strainer and O-ring.

| 62. REMOVE REAR ENGINE OIL SEAL RETAINER |

Remove the 6 bolts and rear engine oil seal retainer.

Using a screwdriver, pry out the rear engine oil seal retainer.

- HINT:

- Tape the screwdriver tip before use.

| 63. REMOVE REAR CRANKSHAFT OIL SEAL |

Place the rear engine oil seal retainer on wooden blocks.

| *1 | Wooden Block |

Using a screwdriver and hammer, tap out the rear crankshaft oil seal.

| 64. REMOVE OIL DRAIN PIPE SUB-ASSEMBLY |

Remove the bolt and oil drain pipe.

Remove the O-ring.

| 65. REMOVE RING PIN |

- NOTICE:

- It is not necessary to remove a ring pin unless it is being replaced.

| 66. REMOVE STUD BOLT |

- NOTICE:

- If a stud bolt is deformed or its threads are damaged, replace it.