Generator (For 100 A Type) Inspection

INSPECT GENERATOR PULLEY WITH CLUTCH

INSPECT GENERATOR BRUSH HOLDER ASSEMBLY

INSPECT GENERATOR ROTOR ASSEMBLY

Generator (For 100 A Type) -- Inspection |

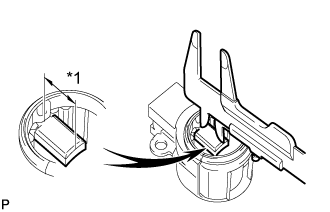

| 1. INSPECT GENERATOR PULLEY WITH CLUTCH |

Using SST, hold the center of the generator pulley with clutch and check that the outer ring turns counterclockwise and does not turn clockwise.

- SST

- 09820-63021

Text in Illustration*a

| Hold

|

| Free

|

| Lock

|

If the result is not as specified, replace the generator pulley with clutch.

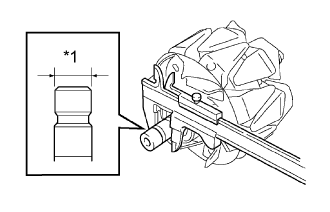

| 2. INSPECT GENERATOR BRUSH HOLDER ASSEMBLY |

Using a vernier caliper, measure the brush length.

- Standard exposed length:

- 9.5 to 11.5 mm (0.374 to 0.453 in.)

- Minimum exposed length:

- 4.5 mm (0.177 in.)

Text in Illustration*1

| Length

|

If the brush length is less than the minimum, replace the generator brush holder assembly.

| 3. INSPECT GENERATOR ROTOR ASSEMBLY |

Check that the generator rotor bearing is not rough or worn.

If necessary, replace the generator rotor assembly.

Check the resistance.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

Slip ring - Slip ring

| 20°C (68°F)

| 3.4 to 3.8 Ω

|

Text in Illustration*1

| Slip Ring

|

If the result is not as specified, replace the generator rotor assembly.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

Slip ring - Rotor core

| Always

| 10 MΩ or higher

|

Text in Illustration*1

| Slip Ring

|

*2

| Rotor Core

|

If the result is not as specified, replace the generator rotor assembly.

Using a vernier caliper, measure the slip ring diameter.

- Standard diameter:

- 14.2 to 14.8 mm (0.559 to 0.583 in.)

- Minimum diameter:

- 14.0 mm (0.551 in.)

Text in Illustration*1

| Diameter

|

If the diameter is less than the minimum, replace the generator rotor assembly.