Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 3UR-FE ENGINE CONTROL

INSPECT CAMSHAFT POSITION SENSOR (SENSOR POWER SOURCE)

CHECK HARNESS AND CONNECTOR (ECM - CAMSHAFT POSITION SENSOR)

INSPECT CAMSHAFT TIMING PLATE (SIGNAL PLATE TOOTH)

REPLACE CAMSHAFT POSITION SENSOR

CONFIRM WHETHER DTC OUTPUT RECURS

DTC P1340 Camshaft Position Sensor "A" (Bank 1 Sensor 2)

DTC P1342 Camshaft Position Sensor "A" Low Input (MRE)

DTC P1343 Camshaft Position Sensor "A" High Input (MRE)

DESCRIPTION

The camshaft position sensor (G signal) consists of a magnet and MRE (Magnetic Resistance Element).

The camshaft drive gear (LH) has 3 teeth on its inner circumference. When the camshaft gear rotates, air gap changes between the protrusion on the teeth and the MRE. The change affects the magnetic field and results in changes in the resistance of the MRE.

The crankshaft position sensor plate has 34 teeth and is installed to the rear end of the crankshaft. The crankshaft position sensor generates 34 signals with every revolution. The ECM detects the standard crankshaft angle based on the G signal, and the actual crankshaft angle and engine speed by the NE signal.

| DTC Code | DTC Detection Condition | Trouble Area |

| P1340 | No camshaft position sensor signal is sent to the ECM during cranking (2 trip detection logic). | Open or short in camshaft position sensor circuit Camshaft position sensor Camshaft timing plate LH ECM |

| No camshaft position sensor signal is sent to the ECM with an engine speed of 600 rpm or more. | ||

| P1342 | The output voltage of the camshaft position sensor is below 0.3 V for 4 seconds (1 trip detection logic). | |

| P1343 | The output voltage of the camshaft position sensor is higher than 4.7 V for 4 seconds (1 trip detection logic). |

MONITOR DESCRIPTION

The camshaft position sensor (G signal) consists of a magnet and MRE.

The camshaft drive gear has 3 teeth on its inner circumference. When the camshaft gear rotates, air gap changes between the protrusion on the gear and the MRE. The change affects the magnetic field and results in changes in the resistance of the MRE. The crankshaft position sensor plate has 34 teeth and outputs 34 signals with every revolution. The ECM detects the standard crankshaft angle based on the G signal, and the actual crankshaft angle and engine speed by the NE signal.

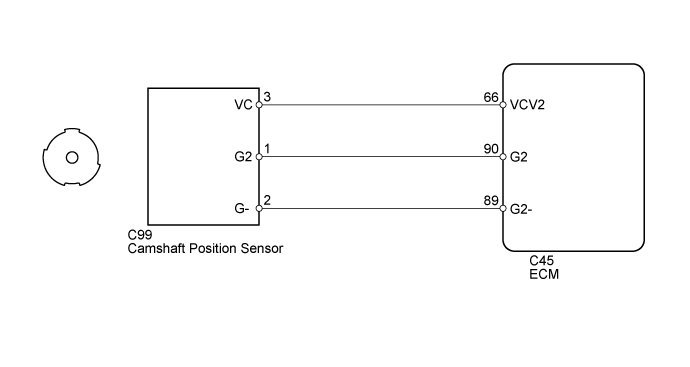

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine conditions when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

| 1.INSPECT CAMSHAFT POSITION SENSOR (SENSOR POWER SOURCE) |

Disconnect the C99 camshaft position sensor connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection Switch Condition Specified Condition C99-3 (VC) - Body ground Engine switch on (IG) 4.5 to 5.0 V

|

| ||||

| OK | |

| 2.CHECK HARNESS AND CONNECTOR (ECM - CAMSHAFT POSITION SENSOR) |

Disconnect the C99 camshaft position sensor connector.

Disconnect the C45 ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition C99-1 (G2) - C45-90 (G2) Always Below 1 Ω C99-2 (G-) - C45-89 (G2-) Always Below 1 Ω C99-1 (G2) or C45-90 (G2) - Body ground Always 10 kΩ or higher C99-2 (G-) or C45-89 (G2-) - Body ground Always 10 kΩ or higher

|

| ||||

| OK | |

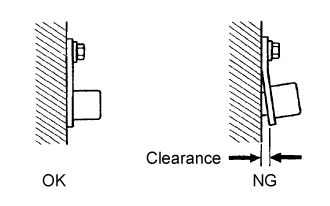

| 3.INSPECT SENSOR INSTALLATION |

Check the camshaft position sensor installation.

- OK:

- The camshaft position sensor is installed properly.

|

| ||||

| OK | |

| 4.INSPECT CAMSHAFT TIMING PLATE (SIGNAL PLATE TOOTH) |

Check the teeth of the signal plate.

- OK:

- Sensor plate teeth do not have any cracks or deformation.

|

| ||||

| OK | |

| 5.REPLACE CAMSHAFT POSITION SENSOR |

Replace the camshaft position sensor ().

| NEXT | |

| 6.CONFIRM WHETHER DTC OUTPUT RECURS |

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG).

Turn the tester on.

Clear DTCs ().

Start the engine.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read DTCs.

| Result | Proceed to |

| No DTC is output | A |

| P1340, P1342 and/or P1343 are output | B |

- HINT:

- If the engine does not start, replace the ECM.

|

| ||||

| A | ||

| ||