Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 3UR-FE ENGINE CONTROL

INSPECT HEATED OXYGEN SENSOR (HEATER RESISTANCE)

CHECK TERMINAL VOLTAGE (+B OF HO2 SENSOR)

INSPECT INTEGRATION RELAY (EFI)

CHECK HARNESS AND CONNECTOR (HO2 SENSOR - INTEGRATION RELAY)

CHECK HARNESS AND CONNECTOR (HO2 SENSOR - ECM)

CHECK WHETHER DTC OUTPUT RECURS

DTC P0037 Oxygen Sensor Heater Control Circuit Low (Bank 1 Sensor 2)

DTC P0038 Oxygen Sensor Heater Control Circuit High (Bank 1 Sensor 2)

DTC P0057 Oxygen Sensor Heater Control Circuit Low (Bank 2 Sensor 2)

DTC P0058 Oxygen Sensor Heater Control Circuit High (Bank 2 Sensor 2)

DTC P102D O2 Sensor Heater Circuit Performance Bank 1 Sensor 2 Stuck ON

DTC P105D O2 Sensor Heater Circuit Performance Bank 2 Sensor 2 Stuck ON

DESCRIPTION

- HINT:

| DTC Code | DTC Detection Condition | Trouble Area |

| P0037 P0057 | The Heated Oxygen (HO2) sensor heater current is below 0.3 A (1 trip detection logic) | Open in Heated Oxygen (HO2) sensor heater circuit HO2 sensor heater (for Sensor 2) Integration relay ECM |

| P0038 P0058 | The Heated Oxygen (HO2) sensor heater current is higher than 2 A (1 trip detection logic) | Short in HO2 sensor heater circuit HO2 sensor heater (for Sensor 2) Integration relay ECM |

| P102D P105D | The heater current is higher than the specified value while the heater is not operating. (1 trip detection logic) | ECM |

MONITOR DESCRIPTION

The sensing portion of the Heated Oxygen (HO2) sensor has a zirconia element which is used to detect the oxygen concentration in the exhaust gas. If the zirconia element is at the appropriate temperature, and the difference between the oxygen concentrations surrounding the inside and outside surfaces of the sensor is large, the zirconia element generates voltage signals. In order to increase the oxygen concentration detecting capacity of the zirconia element, the ECM supplements the heat from the exhaust with heat from a heating element inside the sensor.

The ECM monitors the current applied to the heated oxygen sensor heater to check the heater for malfunctions.

If the heater current is outside the normal range, the signal transmitted by the heated oxygen sensor becomes inaccurate. When the current in the heated oxygen sensor heater is outside the normal operating range, the ECM interprets this as a malfunction in the sensor heater and stores a DTC.

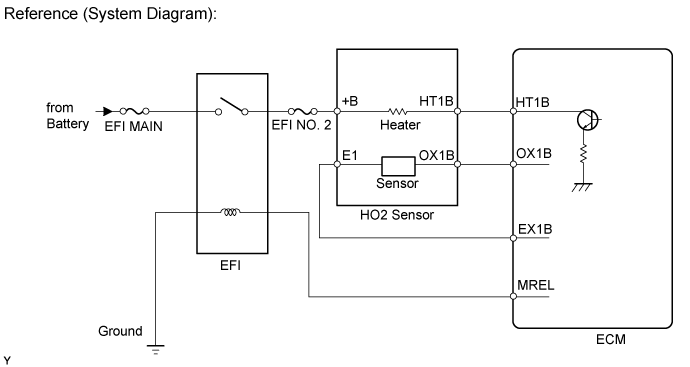

WIRING DIAGRAM

Refer to DTC P0137 ().

CONFIRMATION DRIVING PATTERN

These DTCs are stored when the engine idles for 110 seconds or more.

INSPECTION PROCEDURE

- HINT:

*: The No. 1 cylinder is the cylinder which is farthest from the transmission.

| 1.INSPECT HEATED OXYGEN SENSOR (HEATER RESISTANCE) |

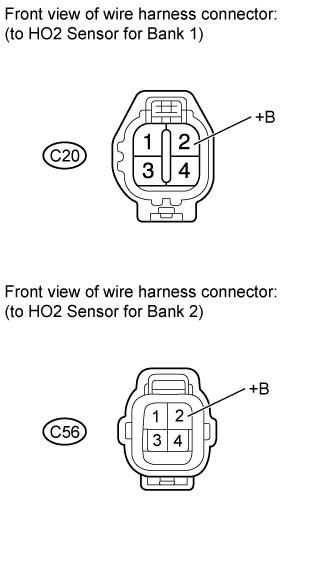

Disconnect the C20 or C56 heated oxygen (HO2) sensor connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition 1 (HT1B) - 2 (+B) 20°C (68°F) 11 to 16 Ω 1 (HT1B) - 4 (E1) Always 10 kΩ or higher 1 (HT2B) - 2 (+B) 20°C (68°F) 11 to 16 Ω 1 (HT2B) - 4 (E1) Always 10 kΩ or higher

|

| ||||

| OK | |

| 2.CHECK TERMINAL VOLTAGE (+B OF HO2 SENSOR) |

Disconnect the C20 or C56 HO2 sensor connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection Switch Condition Specified Condition C20-2 (+B) - Body ground Engine switch on (IG) 11 to 14 V C56-2 (+B) - Body ground Engine switch on (IG) 11 to 14 V

| Result | Proceed to |

| NG | A |

| OK | B |

|

| ||||

| A | |

| 3.INSPECT INTEGRATION RELAY (EFI) |

Remove the integration relay from the engine room relay block.

Inspect the EFI MAIN fuse.

Remove the EFI MAIN fuse from the integration relay.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition EFI MAIN fuse Always Below 1 Ω

Reinstall the EFI MAIN fuse.

Inspect the EFI relay.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition 1C-1 - 1B-4 No battery voltage applied to terminals 1B-2 and 1B-3 10 kΩ or higher Battery voltage applied to terminals 1B-2 and 1B-3 Below 1 Ω

|

| ||||

| OK | |

| 4.CHECK HARNESS AND CONNECTOR (HO2 SENSOR - INTEGRATION RELAY) |

Check the EFI NO. 2 fuse.

Remove the EFI NO. 2 fuse from the engine room relay block.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition EFI NO. 2 fuse Always Below 1 Ω

Reinstall the EFI NO. 2 fuse.

Disconnect the C20 or C56 HO2 sensor connector.

Remove the integration relay from the engine room relay block.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition C20-2 (+B) - 1B-4 Always Below 1 Ω C56-2 (+B) - 1B-4 Always Below 1 Ω C20-2 (+B) or 1B-4 - Body ground Always 10 kΩ or higher C56-2 (+B) or 1B-4 - Body ground Always 10 kΩ or higher

|

| ||||

| OK | ||

| ||

| 5.CHECK HARNESS AND CONNECTOR (HO2 SENSOR - ECM) |

Disconnect the C20 or C56 HO2 sensor connector.

Disconnect the C45 ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition C20-1 (HT1B) - C45-45 (HT1B) Always Below 1 Ω C56-1 (HT2B) - C45-44 (HT2B) Always Below 1 Ω C20-1 (HT1B) or C45-45 (HT1B) - Body ground Always 10 kΩ or higher C56-1 (HT2B) or C45-44 (HT2B) - Body ground Always 10 kΩ or higher

|

| ||||

| OK | |

| 6.CHECK WHETHER DTC OUTPUT RECURS |

Connect the GTS to the DLC3.

Turn the engine switch on (IG).

Turn the tester on.

Clear DTCs ().

Start the engine.

Allow the engine to idle for 2 minutes or more.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read DTCs.

| Result | Proceed to |

| No DTC is output | A |

| P0037, P0038, P0057, P0058, P102D and/or P105D are output | B |

|

| ||||

| A | ||

| ||