Manual Transmission Unit Reassembly

Drivetrain. Land Cruiser. Urj200, 202 Grj200 Vdj200

INSTALL OUTPUT SHAFT ASSEMBLY

INSTALL OUTPUT SHAFT BEARING SHAFT SNAP RING

INSTALL NO. 2 SYNCHRONIZER RING

INSTALL INPUT SHAFT ASSEMBLY

INSTALL COUNTER GEAR

INSTALL OUTPUT SHAFT REAR BEARING(MTM) RETAINER

INSTALL NO. 1 TRANSMISSION HUB SLEEVE

INSTALL REVERSE GEAR BEARING

INSTALL REVERSE SYNCHRONIZER RING SET

INSTALL REVERSE GEAR

INSTALL NO. 4 TRANSMISSION CLUTCH HUB

INSTALL NO. 3 TRANSMISSION CLUTCH HUB SHAFT SNAP RING

INSPECT REVERSE GEAR THRUST CLEARANCE

INSTALL NO. 2 GEAR SHIFT FORK

INSTALL NO. 2 GEAR SHIFT FORK SHAFT

INSTALL NO. 1 GEAR SHIFT FORK

INSTALL NO. 1 GEAR SHIFT FORK SHAFT

INSTALL NO. 3 GEAR SHIFT FORK

INSTALL NO. 3 GEAR SHIFT FORK SHAFT

INSTALL REVERSE SHIFT FORK

INSTALL NO. 4 GEAR SHIFT FORK SHAFT

INSTALL SHIFT FORK SHAFT SNAP RING

INSTALL SHIFT DETENT BALL PLUG

INSTALL MANUAL TRANSMISSION CASE RECEIVER

INSTALL INTERMEDIATE PLATE STRAIGHT PIN

INSTALL TRANSFER ADAPTER STRAIGHT PIN

INSTALL NO. 1 OIL RECEIVER PIPE (MTM)

INSTALL MANUAL TRANSMISSION CASE SUB-ASSEMBLY

INSTALL REVERSE IDLER GEAR SHAFT WOODRUFF KEY

INSTALL REVERSE IDLER GEAR SHAFT

INSTALL REVERSE IDLER THRUST WASHER

INSTALL REVERSE IDLER GEAR BUSH OR BEARING

INSTALL REVERSE IDLER GEAR

INSTALL NO. 2 REVERSE IDLER THRUST WASHER

INSTALL TRANSMISSION MAGNET

INSTALL MANUAL TRANSMISSION OIL STRAINER SUB-ASSEMBLY

INSTALL TRANSFER ADAPTER STRAIGHT PIN AND RING PIN

INSTALL TRANSFER ADAPTER SUB-ASSEMBLY

INSTALL TRANSFER ADAPTER PLUG

INSTALL SHIFT AND SELECT LEVER SHAFT

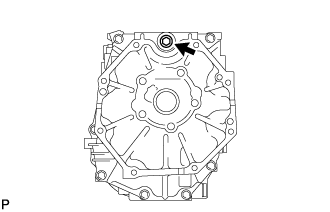

INSTALL TRANSMISSION FRONT BEARING RETAINER OIL SEAL

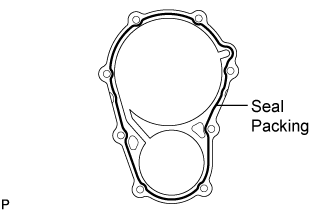

INSTALL FRONT BEARING RETAINER (MTM)

INSTALL TRANSMISSION OIL PUMP COVER OIL SEAL

INSTALL TRANSMISSION OIL PUMP COVER

INSTALL NO. 1 REVERSE RESTRICT PIN

INSTALL FLOOR SHIFT CONTROL SHIFT LEVER RETAINER SUB-ASSEMBLY

INSTALL REVERSE RESTRICT PIN ASSEMBLY

INSTALL CONTROL SHAFT COVER

INSTALL SHIFT POSITION SWITCH (for 1VD-FTV)

INSTALL BACK-UP LIGHT SWITCH ASSEMBLY

INSTALL MANUAL TRANSMISSION CASE PLUG

INSTALL DRAIN PLUG

TEMPORARILY INSTALL FILLER PLUG

INSTALL CLUTCH HOUSING

INSTALL TRANSMISSION BREATHER SUB-ASSEMBLY (for 1VD-FTV)

INSTALL TRANSMISSION BREATHER SUB-ASSEMBLY (for 1GR-FE)

Manual Transmission Unit -- Reassembly |

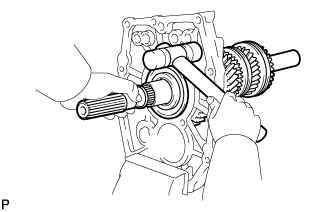

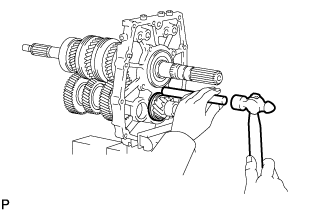

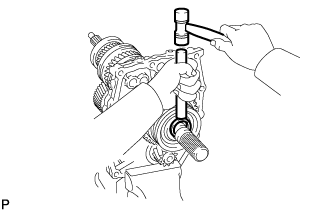

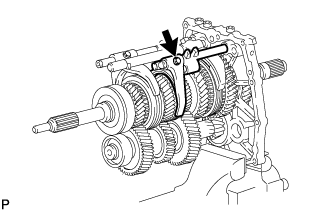

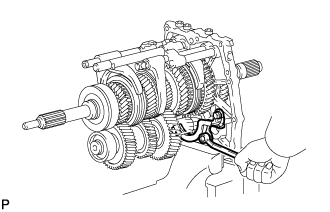

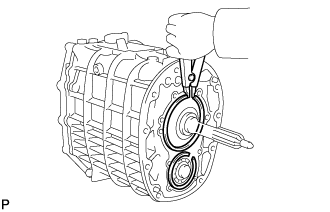

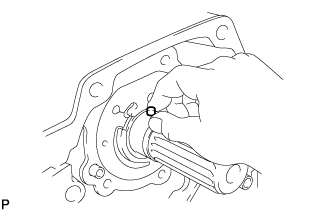

| 1. INSTALL OUTPUT SHAFT ASSEMBLY |

Install the output shaft by lightly tapping on the back side of the intermediate plate with a plastic-faced hammer.

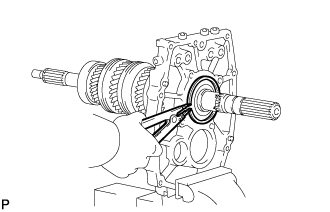

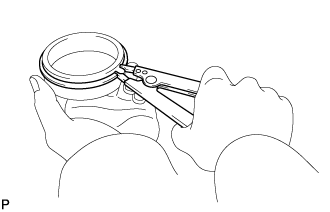

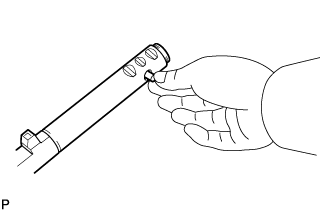

| 2. INSTALL OUTPUT SHAFT BEARING SHAFT SNAP RING |

Using a snap ring expander, install the snap ring to the output shaft bearing.

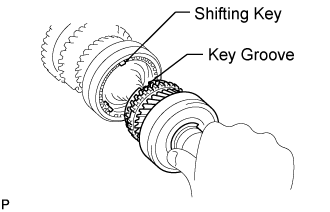

| 3. INSTALL NO. 2 SYNCHRONIZER RING |

Install the No. 2 synchronizer ring to the input shaft.

| 4. INSTALL INPUT SHAFT ASSEMBLY |

Install the input shaft to the output shaft.

- HINT:

- Align the shifting key of the synchronizer ring with the groove of the clutch hub.

Install the clutch hub and confirm that the gear and synchronizer ring move smoothly.

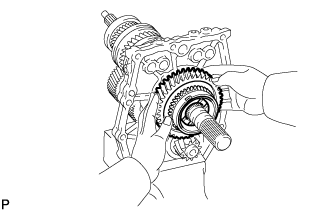

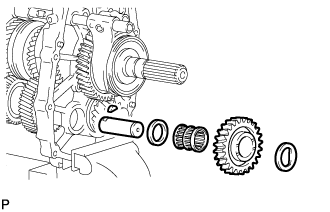

Install the counter gear to the intermediate plate.

Install the center bearing to the counter gear.

Using a snap ring expander, install the snap ring to the outer race.

Using a brass bar and hammer, lightly tap the bearing outer race uniformly to install it.

- NOTICE:

- Do not drop the counter gear. Hold the front side of the counter gear.

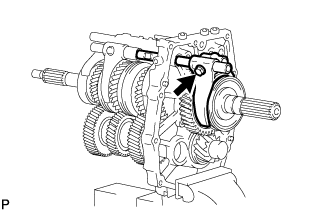

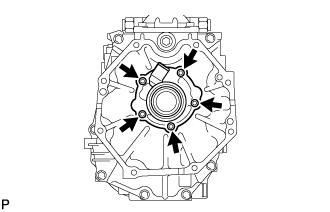

| 6. INSTALL OUTPUT SHAFT REAR BEARING(MTM) RETAINER |

Install the output shaft rear bearing retainer to the intermediate plate with the 4 bolts.

- Torque:

- 18 N*m{185 kgf*cm, 13 ft.*lbf}

| 7. INSTALL NO. 1 TRANSMISSION HUB SLEEVE |

Apply a light coat of gear oil to the sleeve and hub.

Install the No. 1 transmission hub sleeve, 3 shifting keys and 3 springs to the No. 4 transmission clutch hub.

- NOTICE:

- Do not mistake the installation direction of the No. 1 transmission hub sleeve, No. 4 transmission clutch hub, and shifting keys.

| 8. INSTALL REVERSE GEAR BEARING |

Coat the reverse gear bearing with gear oil, and install it to the reverse gear.

| 9. INSTALL REVERSE SYNCHRONIZER RING SET |

Coat the reverse synchronizer ring set with gear oil, and install it to the reverse gear.

Coat the reverse gear with gear oil, and install it to the output shaft.

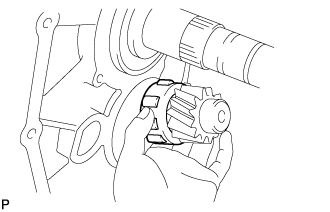

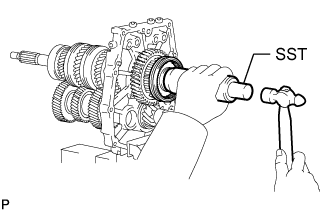

| 11. INSTALL NO. 4 TRANSMISSION CLUTCH HUB |

Using SST and a hammer, install the No. 4 transmission clutch hub.

- SST

- 09316-60011(09316-00011)

- HINT:

- Align the shifting key of the synchronizer ring with the groove of the clutch hub.

Install the clutch hub and confirm that the gear and synchronizer ring move smoothly.

| 12. INSTALL NO. 3 TRANSMISSION CLUTCH HUB SHAFT SNAP RING |

Select a new snap ring that will allow minimum clearance.

- Standard Clearance:

- 0.1 mm (0.00393 in.) or less

- Snap Ring Thickness:

Part No.

| Thickness

| Mark

|

90520-34018

| 2.40 to 2.45 mm

(0.0945 to 0.0965 in.)

| A

|

90520-34019

| 2.45 to 2.50 mm

(0.0965 to 0.0984 in.)

| B

|

90520-34020

| 2.50 to 2.55 mm

(0.0984 to 0.100 in.)

| C

|

90520-34021

| 2.55 to 2.60 mm

(0.100 to 0.102 in.)

| D

|

90520-34022

| 2.60 to 2.65 mm

(0.102 to 0.104 in.)

| E

|

90520-34023

| 2.65 to 2.70 mm

(0.104 to 0.106 in.)

| F

|

Using a brass bar and hammer, install the snap ring to the output shaft.

| 13. INSPECT REVERSE GEAR THRUST CLEARANCE |

Using a feeler gauge, measure the reverse gear thrust clearance.

- Standard Clearance:

- 0.15 to 0.52 mm (0.00591 to 0.0204 in.)

If the clearance is outside the specification, replace the defective gear or shaft.

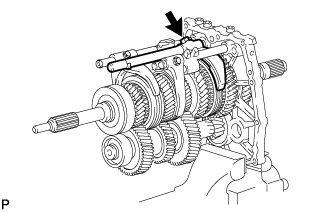

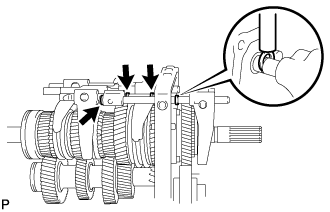

| 14. INSTALL NO. 2 GEAR SHIFT FORK |

Install the No. 2 gear shift fork.

| 15. INSTALL NO. 2 GEAR SHIFT FORK SHAFT |

Install the No. 2 gear shift fork shaft to the No. 2 gear shift fork and intermediate plate with the bolt.

- Torque:

- 46 N*m{472 kgf*cm, 34 ft.*lbf}

| 16. INSTALL NO. 1 GEAR SHIFT FORK |

Install the No. 1 gear shift fork.

| 17. INSTALL NO. 1 GEAR SHIFT FORK SHAFT |

Using a magnet hand, install the interlock pin to the intermediate plate.

Apply MP grease to the interlock pin.

Install the interlock pin to the No. 1 gear shift fork shaft.

Install the No. 1 gear shift fork shaft to the No. 2 gear shift fork and intermediate plate with the bolt.

- Torque:

- 46 N*m{472 kgf*cm, 34 ft.*lbf}

| 18. INSTALL NO. 3 GEAR SHIFT FORK |

Install the No. 3 gear shift fork.

| 19. INSTALL NO. 3 GEAR SHIFT FORK SHAFT |

Using a magnet hand, install the interlock pin to the intermediate plate.

Apply MP grease to the interlock pin.

Install the interlock pin to the No. 3 gear shift fork shaft.

Install the No. 3 gear shift fork shaft to the No. 3 gear shift fork and intermediate plate with the bolt.

- Torque:

- 46 N*m{472 kgf*cm, 34 ft.*lbf}

| 20. INSTALL REVERSE SHIFT FORK |

Install the reverse shift fork.

| 21. INSTALL NO. 4 GEAR SHIFT FORK SHAFT |

Using a magnet hand, install the ball to the intermediate plate.

Using a magnet hand, install the ball to the reverse shift head.

Install the No. 4 gear shift fork shaft to the reverse gear shift fork and intermediate plate with the bolt.

- Torque:

- 34 N*m{350 kgf*cm, 25 ft.*lbf}

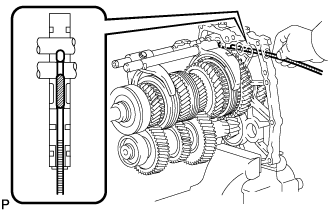

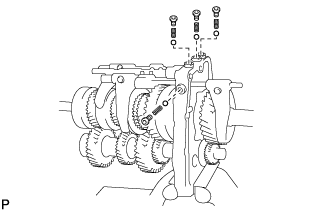

| 22. INSTALL SHIFT FORK SHAFT SNAP RING |

Using a brass bar and hammer, install the 4 snap rings.

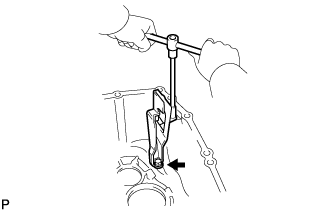

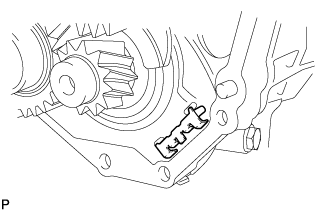

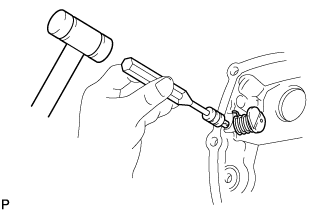

| 23. INSTALL SHIFT DETENT BALL PLUG |

Install the 4 balls and 4 springs to the intermediate plate.

Apply adhesive to 2 or 3 threads of the 4 detent ball plugs.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

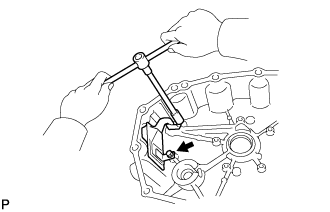

Using a T40 "TORX" socket wrench, install the 4 detent ball plugs.

- Torque:

- 19 N*m{190 kgf*cm, 14 ft.*lbf}

| 24. INSTALL MANUAL TRANSMISSION CASE RECEIVER |

Install the transmission case receiver to the intermediate plate with the 3 bolts.

- Torque:

- 18 N*m{185 kgf*cm, 13 ft.*lbf}

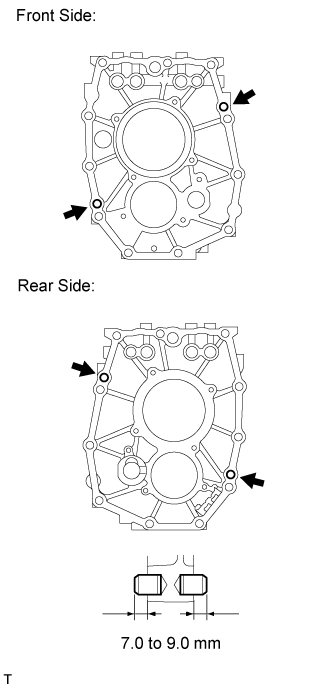

| 25. INSTALL INTERMEDIATE PLATE STRAIGHT PIN |

Using a plastic-faced hammer, tap 4 new straight pins into the intermediate plate.

- Standard Protrusion Height:

- 7.0 to 9.0 mm (0.276 to 0.354 in.)

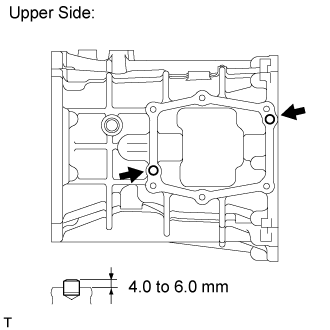

| 26. INSTALL TRANSFER ADAPTER STRAIGHT PIN |

Using a plastic-faced hammer, tap 2 new straight pins into the transmission case.

- Standard Protrusion Height:

- 4.0 to 6.0 mm (0.158 to 0.236 in.)

Using a plastic-faced hammer, tap 2 new straight pins into the transmission case.

- Standard Protrusion Height:

- 9.0 to 11.0 mm (0.355 to 0.433 in.)

| 27. INSTALL NO. 1 OIL RECEIVER PIPE (MTM) |

Install the oil receiver pipe to the transmission case with the 2 bolts.

- Torque:

- 12 N*m{120 kgf*cm, 9 ft.*lbf}

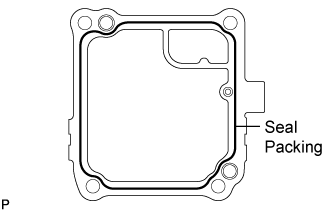

| 28. INSTALL MANUAL TRANSMISSION CASE SUB-ASSEMBLY |

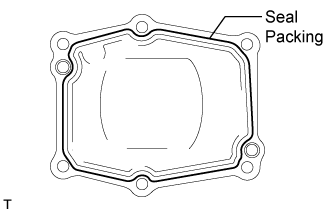

Apply seal packing to the transmission case, as shown in the illustration.

- Seal Packing:

- Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent

- NOTICE:

- Parts must be assembled within 10 minutes of application. Otherwise, the packing (FIPG) material must be removed and reapplied.

Install the transmission case by lightly tapping it into place with a plastic-faced hammer.

- NOTICE:

- Make sure that the oil receiver installed on the transmission side is above the oil application area of the intermediate plate side oil receiver.

Using a snap ring expander, install the 2 snap rings to the counter gear and input shaft.

| 29. INSTALL REVERSE IDLER GEAR SHAFT WOODRUFF KEY |

Install the woodruff key to the reverse idler gear shaft.

| 30. INSTALL REVERSE IDLER GEAR SHAFT |

Install the reverse idler gear shaft to the intermediate plate.

| 31. INSTALL REVERSE IDLER THRUST WASHER |

Install the thrust washer to the reverse idler gear shaft.

- NOTICE:

- Align the protrusion of the washer with the groove of the intermediate plate during installation.

- Install the washer so that the dimpled surface of the washer contacts the reverse idler gear thrust surface.

| 32. INSTALL REVERSE IDLER GEAR BUSH OR BEARING |

Install the bearing to the reverse idler gear shaft.

| 33. INSTALL REVERSE IDLER GEAR |

Install the reverse idler gear to the reverse idler gear shaft.

| 34. INSTALL NO. 2 REVERSE IDLER THRUST WASHER |

Install the thrust washer to the reverse idler gear shaft.

- NOTICE:

- Install the washer so that the dimpled surface of the washer contacts the reverse idler gear thrust surface.

| 35. INSTALL TRANSMISSION MAGNET |

Install the transmission magnet to the intermediate plate.

| 36. INSTALL MANUAL TRANSMISSION OIL STRAINER SUB-ASSEMBLY |

Install a new O-ring to the oil strainer.

Apply a light coat of gear oil to the O-ring.

Install the oil strainer to the transfer adapter with the 2 bolts.

- Torque:

- 12 N*m{120 kgf*cm, 9 ft.*lbf}

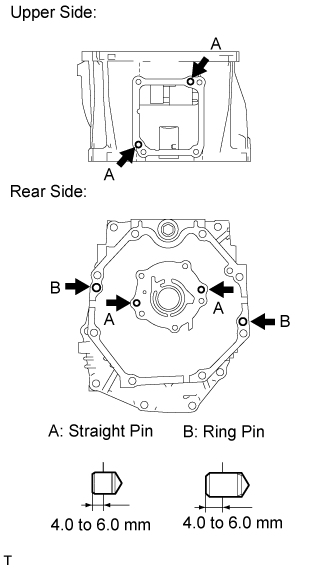

| 37. INSTALL TRANSFER ADAPTER STRAIGHT PIN AND RING PIN |

Using a plastic-faced hammer, tap in 4 new straight pins and 2 new ring pins to the transfer adapter.

- Standard Protrusion Height A (Straight Pin):

- 4.0 to 6.0 mm (0.157 to 0.236 in.)

- Standard Protrusion Height B (Ring Pin):

- 4.0 to 6.0 mm (0.157 to 0.236 in.)

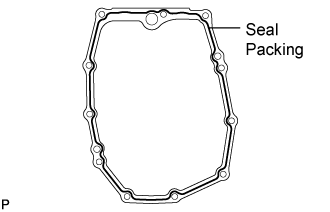

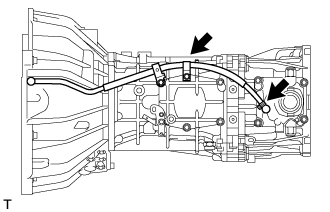

| 38. INSTALL TRANSFER ADAPTER SUB-ASSEMBLY |

Apply seal packing to the transfer adapter, as shown in the illustration.

- Seal Packing:

- Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent

- NOTICE:

- Parts must be assembled within 10 minutes of application. Otherwise, the packing (FIPG) material must be removed and reapplied.

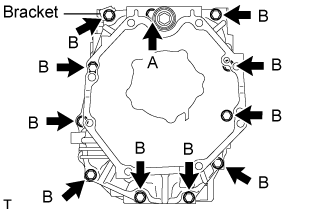

Install the transfer adapter and bracket to the transmission case with the 11 bolts.

- Torque:

- 37 N*m{380 kgf*cm, 27 ft.*lbf}

- Bolt Length:

Item

| Length

|

Bolt A

| 110 mm (4.33 in.)

|

Bolt B

| 70 mm (2.75 in.)

|

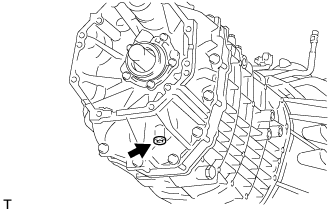

| 39. INSTALL TRANSFER ADAPTER PLUG |

Using a T40 "TORX" socket wrench, install the transfer adapter plug to the transfer adapter.

- Torque:

- 19 N*m{190 kgf*cm, 14 ft.*lbf}

| 40. INSTALL SHIFT AND SELECT LEVER SHAFT |

Install the shift and select lever, shift lever housing, and shift and select lever shaft to the transmission as shown in the illustration.

Install the 2 bolts to the shift and select lever.

- Torque:

- 38 N*m{390 kgf*cm, 28 ft.*lbf}

Install the bolt to the shift lever housing.

- Torque:

- 38 N*m{390 kgf*cm, 28 ft.*lbf}

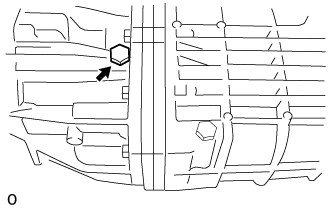

Using a 14 mm hexagon wrench, install the interlock hole plug to the transfer adapter.

- Torque:

- 18 N*m{185 kgf*cm, 13 ft.*lbf}

| 41. INSTALL TRANSMISSION FRONT BEARING RETAINER OIL SEAL |

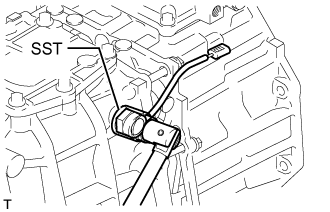

Using SST and a press, drive in a new oil seal.

- SST

- 09950-60010(09951-00460)

09950-70010(09951-07150)

- Standard Drive in Depth:

- 15.4 to 16.2 mm (0.607 to 0.637 in.)

Apply gear oil to the lip of the oil seal.

| 42. INSTALL FRONT BEARING RETAINER (MTM) |

Apply seal packing to the front bearing retainer, as shown in the illustration.

- Seal Packing:

- Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent

- NOTICE:

- Parts must be assembled within 10 minutes of application. Otherwise, the packing (FIPG) material must be removed and reapplied.

Apply adhesive to 2 or 3 threads of the bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Install the front bearing retainer to the transmission case with the 8 bolts.

- Torque:

- 17 N*m{170 kgf*cm, 12 ft.*lbf}

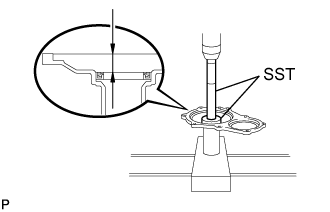

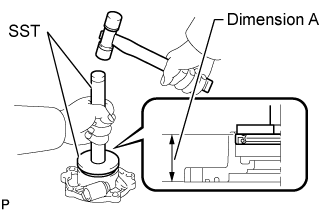

| 43. INSTALL TRANSMISSION OIL PUMP COVER OIL SEAL |

Using SST and a hammer, tap a new oil seal into the oil pump cover in accordance with the dimension specified in the illustration.

- SST

- 09950-70010(09951-07150)

09950-60010(09951-00640)

| 44. INSTALL TRANSMISSION OIL PUMP COVER |

Apply MP grease to the straight pins.

Install the 2 straight pins.

Install a new O-ring to the oil pump cover.

Align the oil pump drive rotor groove with the straight pin, and install the oil pump cover to the transfer adapter.

Apply adhesive to 2 or 3 threads of the bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Install the oil pump cover to the transfer adapter with the 5 bolts.

- Torque:

- 17 N*m{170 kgf*cm, 12 ft.*lbf}

| 45. INSTALL NO. 1 REVERSE RESTRICT PIN |

Install the No. 1 reverse restrict pin and spring to the shift lever retainer.

Using a 5 mm pin punch and hammer, tap a new slotted pin into the shift lever retainer.

| 46. INSTALL FLOOR SHIFT CONTROL SHIFT LEVER RETAINER SUB-ASSEMBLY |

Apply seal packing to the shift lever retainer, as shown in the illustration.

- Seal Packing:

- Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent

- NOTICE:

- Parts must be assembled within 10 minutes of application. Otherwise, the packing (FIPG) material must be removed and reapplied.

Apply adhesive to 2 or 3 threads of the bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Install the shift lever retainer to the transfer adapter with the 4 bolts.

- Torque:

- 17 N*m{170 kgf*cm, 12 ft.*lbf}

| 47. INSTALL REVERSE RESTRICT PIN ASSEMBLY |

Apply adhesive to 2 or 3 threads of the reverse restrict pins.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Install the 2 reverse restrict pins to the shift lever retainer.

- Torque:

- 37 N*m{380 kgf*cm, 27 ft.*lbf}

| 48. INSTALL CONTROL SHAFT COVER |

Apply seal packing to the control shaft cover, as shown in the illustration.

- Seal Packing:

- Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent

- NOTICE:

- Parts must be assembled within 10 minutes of application. Otherwise, the packing (FIPG) material must be removed and reapplied.

Apply adhesive to 2 or 3 threads of the bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Install the control shaft cover to the manual transmission with the 6 bolts.

- Torque:

- 17 N*m{170 kgf*cm, 12 ft.*lbf}

| 49. INSTALL SHIFT POSITION SWITCH (for 1VD-FTV) |

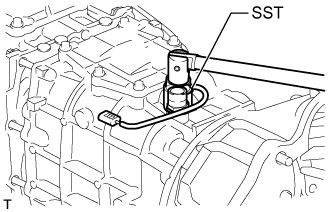

Using SST, install a new gasket and the shift position switch to the transmission.

- SST

- 09817-16011

- Torque:

- 44 N*m{450 kgf*cm, 33 ft.*lbf}

Connect the wire harness clamp.

| 50. INSTALL BACK-UP LIGHT SWITCH ASSEMBLY |

Using SST, install a new gasket and the back-up light switch to the transmission.

- SST

- 09817-16011

- Torque:

- 44 N*m{450 kgf*cm, 33 ft.*lbf}

Connect the wire harness clamp.

| 51. INSTALL MANUAL TRANSMISSION CASE PLUG |

Using a T55 "TORX" socket wrench, install a new gasket and the manual transmission case plug to the transmission.

- Torque:

- 37 N*m{380 kgf*cm, 27 ft.*lbf}

Install a new gasket and the drain plug to the manual transmission.

- Torque:

- 37 N*m{380 kgf*cm, 27 ft.*lbf}

| 53. TEMPORARILY INSTALL FILLER PLUG |

Temporarily install a new gasket and the filler plug to the manual transmission.

- Torque:

- 37 N*m{380 kgf*cm, 27 ft.*lbf}

- HINT:

- The filler plug will be tightened to a torque specification in the "Inspect Transmission Oil" procedure.

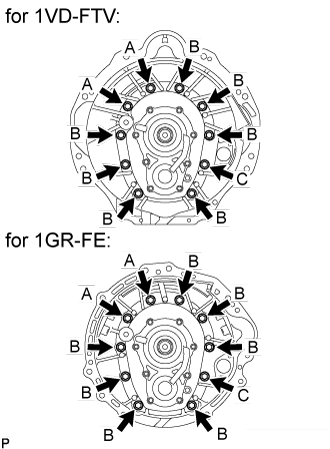

| 54. INSTALL CLUTCH HOUSING |

Apply adhesive to 2 or 3 threads of the bolts labeled A only.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Install the clutch housing with the 10 bolts.

- Torque:

- 37 N*m{380 kgf*cm, 27 ft.*lbf}

- Bolt Length:

Item

| Length

|

Bolt A

| 45 mm (1.77 in.)

|

Bolt B

| 45 mm (1.77 in.)

|

Bolt C

| 35 mm (1.38 in.)

|

| 55. INSTALL TRANSMISSION BREATHER SUB-ASSEMBLY (for 1VD-FTV) |

Connect the breather hose with the clamp.

Install the wire harness clamp.

| 56. INSTALL TRANSMISSION BREATHER SUB-ASSEMBLY (for 1GR-FE) |

Connect the breather hose with the clamp.