CHECK DTC OUTPUT (IN ADDITION TO DTC P0796)

CLEAR DTC AND PERFORM STALL SPEED TEST

INSPECT SHIFT SOLENOID VALVE SL1, SL2 AND SL3

INSPECT SHIFT SOLENOID VALVE SC2

INSPECT SHIFT SOLENOID VALVE SLT

INSPECT TRANSMISSION VALVE BODY ASSEMBLY

DTC P0796 Pressure Control Solenoid "C" Performance or Stuck OFF |

DESCRIPTION

Based on signals from the transmission revolution sensors (NT and SP2), the actual gear is detected.If the detected gear is different than the commanded gear, the TCM detects related mechanical problems in the shift solenoid valves, transmission valve body assembly and automatic transmission assembly (clutch, brake, gear, etc.).

- HINT:

- Actual gear when a problem occurs in shift solenoid valve SL3 (without fail-safe control):

| TCM commanded gear | 1st | 2nd | 3rd | 4th | 5th | 6th | 7th | 8th |

| Actual gear during SL3 stuck ON malfunction*2 | 1st | 2nd | N*1 | 4th | 5th | 6th | N*1 | 8th |

| Actual gear during SL3 stuck OFF malfunction | 3rd | 3rd | 3rd | 3rd | 7th | 7th | 7th | 7th |

- *1: Neutral

- *2: Vehicle does not move with shift lever in R

| DTC No. | DTC Detection Condition

| Trouble Area |

| P0796 | SL3 stuck ON malfunction:

|

|

SL3 stuck ON malfunction:

|

| |

SL3 stuck OFF malfunction:

|

|

MONITOR DESCRIPTION

The TCM commands gear shifts by turning the shift solenoid valves on and off. According to the input shaft speed and output shaft speed, the TCM detects the actual gear (1st, 2nd, 3rd, 4th, 5th, 6th, 7th or 8th gear position). When the gear commanded by the TCM and the actual gear are not the same, the TCM stores this DTC.This DTC indicates a "stuck ON" malfunction of shift solenoid valve SL3.

When the vehicle does not move with the shift lever in R, the TCM stores this DTC.

INSPECTION PROCEDURE

- NOTICE:

- Perform registration and/or initialization when parts related to the automatic transmission are replaced (Click here).

- HINT:

- After performing repair, clear the DTCs and perform the following procedure to check that DTCs are not output.

- Start the engine.*1

- Drive the vehicle backward with the shift lever in R.*2

- Perform the D Position Shift Test in Road Test (Click here).*3

- Turn the engine switch off.

- Perform steps (*1) through (*3) again.

- Check for DTCs again (Click here).

| 1.CHECK DTC OUTPUT (IN ADDITION TO DTC P0796) |

Connect the GTS to the DLC3.

Turn the engine switch on (IG).

Turn the GTS on.

Enter the following menus: Powertrain / ECT / Trouble Codes.

Read the DTCs using the GTS.

Result Result Proceed to DTC P0796 and DTC P0746, P076B, P076C, P0776, P08CD, P08CE, P2714, P2808 and/or P2817 are output A Only DTC P0796 is output B DTCs other than P0746, P076B, P076C, P0776, P0796, P08CD, P08CE, P2714, P2808 and P2817 are also output C - HINT:

- If DTCs other than P0746, P076B, P076C, P0776, P0796, P08CD, P08CE, P2714, P2808 and P2817 are output, perform troubleshooting for those DTCs first.

|

| ||||

|

| ||||

| A | |

| 2.CLEAR DTC AND PERFORM STALL SPEED TEST |

Clear the DTCs (Click here).

- HINT:

- Write down the currently output DTCs before clearing them.

Perform the stall speed test (Click here).

Result Test Condition Proceed to Stall speed test can be performed A Stall speed test cannot be performed B

|

| ||||

| A | |

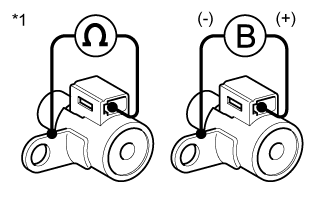

| 3.INSPECT SHIFT SOLENOID VALVE SL1, SL2 AND SL3 |

Remove the shift solenoid valve SL1, SL2 and SL3 (Click here).

|

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition Terminal 1 of the shift solenoid valve SL1 - Terminal 2 20°C (68°F) 5.0 to 5.6 Ω Terminal 1 of the shift solenoid valve SL2 - Terminal 2 20°C (68°F) 5.0 to 5.6 Ω Terminal 1 of the shift solenoid valve SL3 - Terminal 2 20°C (68°F) 5.0 to 5.6 Ω

Apply 12 V battery voltage to the shift solenoid valve and check that the valve moves and makes an operating noise.

- OK:

Measurement Condition Specified Condition - Battery positive (+) with a 21 W bulb → Terminal 2

- Battery negative (-) → Terminal 1

Valve moves and makes an operating noise - Battery positive (+) with a 21 W bulb → Terminal 2

| *1 | Shift Solenoid Valve SL1, SL2 and SL3 |

|

| ||||

| OK | |

| 4.INSPECT SHIFT SOLENOID VALVE SC2 |

Remove the shift solenoid valve SC2 (Click here).

|

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition Terminal of shift solenoid valve SC2 connector - Shift solenoid valve SC2 body 20°C (68°F) 11 to 15 Ω

Apply 12 V battery voltage to the shift solenoid valve and check that the valve moves and makes an operating noise.

- OK:

Measurement Condition Specified Condition - Battery positive (+) → Shift solenoid valve SC2 connector

- Battery negative (-) → Shift solenoid valve SC2 body

Valve moves and makes an operating noise - Battery positive (+) → Shift solenoid valve SC2 connector

| *1 | Shift Solenoid Valve SC2 |

|

| ||||

| OK | |

| 5.INSPECT SHIFT SOLENOID VALVE SLT |

Remove the shift solenoid valve SLT (Click here).

|

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition Terminal 1 of the shift solenoid valve SLT - Terminal 2 20°C (68°F) 5.0 to 5.6 Ω

Apply 12 V battery voltage to the shift solenoid valve and check that the valve moves and makes an operating noise.

- OK:

Measurement Condition Specified Condition - Battery positive (+) with a 21 W bulb → Terminal 2

- Battery negative (-) → Terminal 1

Valve moves and makes an operating noise - Battery positive (+) with a 21 W bulb → Terminal 2

| *1 | Shift Solenoid Valve SLT |

|

| ||||

| OK | |

| 6.INSPECT TRANSMISSION VALVE BODY ASSEMBLY |

Check the transmission valve body assembly (Click here).

- OK:

- There is no foreign matter on each valve and they operate smoothly.

|

| ||||

| OK | ||

| ||