Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 1UR-FE ENGINE CONTROL

CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE)

CHECK HARNESS AND CONNECTOR (VVT SENSOR - ECM)

CHECK SENSOR INSTALLATION (VVT SENSOR FOR EXHAUST CAMSHAFT)

CHECK WHETHER DTC OUTPUT RECURS

DTC P0365 Camshaft Position Sensor "B" Circuit (Bank 1)

DTC P0367 Camshaft Position Sensor "B" Circuit Low Input (Bank 1)

DTC P0368 Camshaft Position Sensor "B" Circuit High Input (Bank 1)

DTC P0390 Camshaft Position Sensor "B" Circuit (Bank 2)

DTC P0392 Camshaft Position Sensor "B" Circuit Low Input (Bank 2)

DTC P0393 Camshaft Position Sensor "B" Circuit High Input (Bank 2)

DESCRIPTION

The exhaust camshaft VVT sensor (EV1 and EV2 signals) consists of a magnet and MRE (Magnetoresistive Element).

The exhaust camshaft has 3 teeth on its outer circumference. When the exhaust camshaft rotates, changes occur in the air gaps between the 3 teeth and MRE, which affects the magnetic field. As a result, the resistance of the MRE fluctuates. The VVT sensor converts the exhaust camshaft rotation data into pulse signals, uses the pulse signals to determine the camshaft angle, and sends the data to the ECM.

| DTC No. | DTC Detection Condition | Trouble Area |

| P0365 P0390 | No VVT sensor signal is sent to the ECM at an engine speed of 600 rpm or more (1 trip detection logic). | Open or short in VVT sensor for exhaust camshaft circuit VVT sensor for exhaust camshaft Exhaust camshaft Timing chain jumped tooth ECM |

| P0367 P0392 | Output voltage of VVT sensor is below 0.3 V for 4 seconds (1 trip detection logic). | Open or short in VVT sensor for exhaust camshaft circuit VVT sensor for exhaust camshaft Exhaust camshaft Timing chain jumped tooth ECM |

| P0368 P0393 | Output voltage of VVT sensor is higher than 4.7 V for 4 seconds (1 trip detection logic). | Open or short in VVT sensor for exhaust camshaft circuit VVT sensor for exhaust camshaft Exhaust camshaft Timing chain jumped tooth ECM |

- Standard:

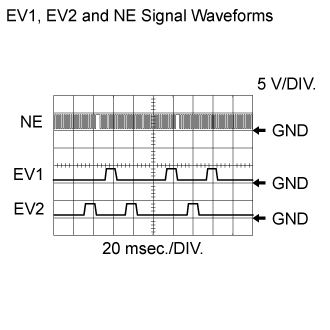

for RHD Tester Connection Tool Setting Condition Specified Condition C46-110 (NE+) - C46-111 (NE-) 5 V/DIV.

20 msec./DIV.Cranking or idling The correct waveform is as shown C46-69 (EV1+) - C46-68 (EV1-) 5 V/DIV.

20 msec./DIV.Cranking or idling The correct waveform is as shown C46-64 (EV2+) - C46-65 (EV2-) 5 V/DIV.

20 msec./DIV.Cranking or idling The correct waveform is as shown for LHD Tester Connection Tool Setting Condition Specified Condition C45-110 (NE+) - C45-111 (NE-) 5 V/DIV.

20 msec./DIV.Cranking or idling The correct waveform is as shown C45-69 (EV1+) - C45-68 (EV1-) 5 V/DIV.

20 msec./DIV.Cranking or idling The correct waveform is as shown C45-64 (EV2+) - C45-65 (EV2-) 5 V/DIV.

20 msec./DIV.Cranking or idling The correct waveform is as shown

- HINT:

- EV1 and EV2 are the VVT sensor signals, and NE is the crankshaft position sensor signal.

MONITOR DESCRIPTION

If no signal is transmitted by the VVT sensor despite the engine running, or the rotations of the camshaft and crankshaft are not synchronized, the ECM interprets this as a malfunction of the sensor.

Also, when the sensor output voltage remains at below 0.3 V, or higher than 4.7 V for more than 4 seconds, the ECM stores a DTC.

CONFIRMATION DRIVING PATTERN

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

*: The No. 1 cylinder is the cylinder which is farthest from the transmission.

| 1.CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE) |

Disconnect the VVT sensor connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection Switch Condition Specified Condition 3 (VC2) - Body ground Engine switch on (IG) 4.5 to 5.0 V

| *a | Front view of wire harness connector (to VVT Sensor) |

| *b | Bank 1 |

| *c | Bank 2 |

|

| ||||

| OK | |

| 2.CHECK HARNESS AND CONNECTOR (VVT SENSOR - ECM) |

Disconnect the VVT sensor connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

for RHD Tester Connection Condition Specified Condition C121-1 (EX+) - C46-69 (EV1+) Always Below 1 Ω C121-2 (EX-) - C46-68 (EV1-) Always Below 1 Ω C122-1 (EX+) - C46-64 (EV2+) Always Below 1 Ω C122-2 (EX-) - C46-65 (EV2-) Always Below 1 Ω C121-1 (EX+) or C46-69 (EV1+) - Body ground Always 10 kΩ or higher C121-2 (EX-) or C46-68 (EV1-) - Body ground Always 10 kΩ or higher C122-1 (EX+) or C46-64 (EV2+) - Body ground Always 10 kΩ or higher C122-2 (EX-) or C46-65 (EV2-) - Body ground Always 10 kΩ or higher for LHD Tester Connection Condition Specified Condition C121-1 (EX+) - C45-69 (EV1+) Always Below 1 Ω C121-2 (EX-) - C45-68 (EV1-) Always Below 1 Ω C122-1 (EX+) - C45-64 (EV2+) Always Below 1 Ω C122-2 (EX-) - C45-65 (EV2-) Always Below 1 Ω C121-1 (EX+) or C45-69 (EV1+) - Body ground Always 10 kΩ or higher C121-2 (EX-) or C45-68 (EV1-) - Body ground Always 10 kΩ or higher C122-1 (EX+) or C45-64 (EV2+) - Body ground Always 10 kΩ or higher C122-2 (EX-) or C45-65 (EV2-) - Body ground Always 10 kΩ or higher

|

| ||||

| OK | |

| 3.CHECK SENSOR INSTALLATION (VVT SENSOR FOR EXHAUST CAMSHAFT) |

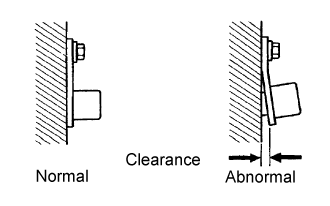

Check the VVT sensor installation.

- OK:

- Sensor is installed correctly.

|

| ||||

| OK | |

| 4.INSPECT EXHAUST CAMSHAFT |

Check the teeth of the camshaft.

- OK:

- Teeth do not have any cracks or deformation.

|

| ||||

| OK | |

| 5.REPLACE VVT SENSOR |

Replace the VVT sensor ().

| NEXT | |

| 6.CHECK WHETHER DTC OUTPUT RECURS |

Connect the GTS to the DLC3.

Turn the engine switch on (IG).

Turn the GTS on.

Clear DTCs ().

Start the engine and idle it for 10 seconds or more.

Enter the following menus: Powertrain / Engine and ECT / Trouble Codes / Pending.

Read DTCs.

| Display (DTC Output) | Proceed to |

| No DTC is output | A |

| P0365, P0367, P0368, P0390, P0392 or P0393 is output | B |

- HINT:

- If the engine does not start, replace the ECM.

|

| ||||

| A | ||

| ||