Fuel System -- Precaution |

- CAUTION:

- Before working on the fuel system, disconnect the cable from the negative (-) battery terminal.

- Do not smoke or be near an open flame when working on the fuel system.

- Keep gasoline away from rubber and leather parts.

| 1.DISCHARGE FUEL SYSTEM PRESSURE |

- CAUTION:

- Do not disconnect any part of the fuel system until you have discharged the fuel system pressure.

- After discharging the fuel pressure, place a cloth or equivalent over fittings as you separate them to reduce the risk of fuel spray on yourself or in the engine compartment.

Disconnect the fuel pump ECU connector (Click here).

Start the engine. After the engine has stopped on its own, turn the engine switch off.

- HINT:

- If DTC P0230 is output, clear the DTC (Click here).

Crank the engine, then check that the engine does not start.

Loosen the fuel tank cap, and then discharge the pressure in the fuel tank completely.

Disconnect the cable from the negative (-) battery terminal.

- NOTICE:

- After turning the ignition switch off, waiting time may be required before disconnecting the cable from the battery terminal. Therefore, make sure to read the disconnecting the cable from the battery terminal notice before proceeding with work (Click here).

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected (Click here).

Connect the fuel pump ECU connector (Click here).

| 2.FUEL SYSTEM |

When disconnecting the high fuel pressure line, a large amount of gasoline will spill out. Follow these procedures.

Perform the "Discharge Fuel System Pressure" procedures above.

Put a container under the connecting part of the pressure line.

Slowly loosen the connection.

Disconnect the connection.

Plug the connection with a rubber plug and cover it with a plastic bag.

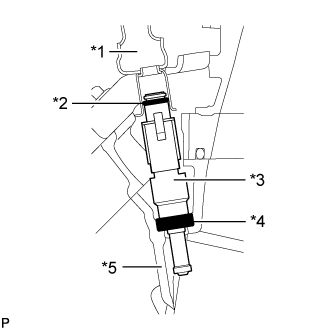

Observe these precautions when installing the injectors:

- Never reuse the O-ring.

- When placing a new O-ring on the injector, do not damage it.

- Coat a new O-ring with spindle oil or gasoline before installing it. Do not use engine oil, gear oil or brake oil.

- Never reuse the O-ring.

Install the injector to the delivery pipe and cylinder head as shown in the illustration.

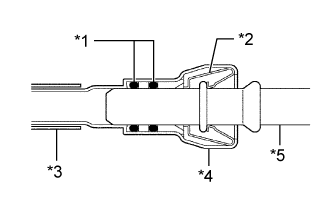

Text in Illustration *1 Delivery Pipe *2 O-Ring *3 Injector *4 Insulator *5 Cylinder Head - NOTICE:

- Before installing the injector, apply spindle oil or gasoline on the place where the delivery pipe contacts the O-ring of the injector.

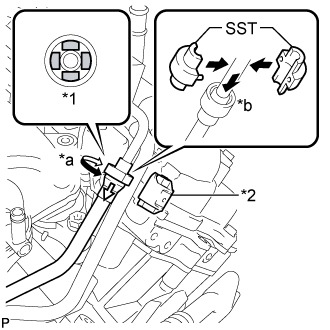

Observe these precautions when disconnecting the fuel tube connector (for metallic type):

Text in Illustration *1 Retainer *2 No. 2 Fuel Pipe Clamp *a Turn *b Push - NOTICE:

- Do not forcibly bend or twist the fuel main tube.

Remove the No. 2 fuel pipe clamp.

- NOTICE:

- Do not reuse the No. 2 fuel pipe clamp.

Wipe off any dirt on the fuel tube connector.

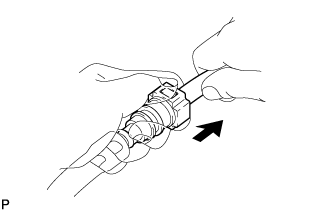

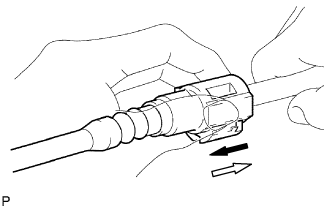

Hold the fuel tube connector and install SST.

- SST

- 09268-21011

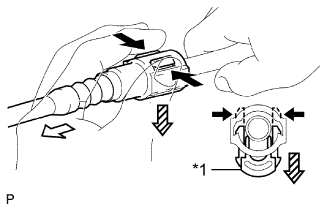

Turn SST to align the retainer inside the fuel tube connector with the chamfered part of SST.

Insert SST into the fuel tube connector and hold it. Then push the fuel tube connector toward SST.

Mount the retainer of the fuel tube connector onto the chamfered part of SST.

Slide SST and the fuel tube connector together towards the fuel tube until they make a "click" sound, and then disconnect the fuel tube.

Text in Illustration *1 O-Ring *2 Retainer *3 Nylon Tube *4 Housing *5 Pipe - HINT:

- The structure of a fuel tube connector is as shown in the illustration.

Drain the fuel remaining inside the fuel tube.

Cover the fuel tube and fuel pipe with a plastic bag to protect the disconnected parts.

Observe these precautions when connecting the fuel tube connector (for metallic type):

Check if there is any damage or foreign objects on the pipe connection area.

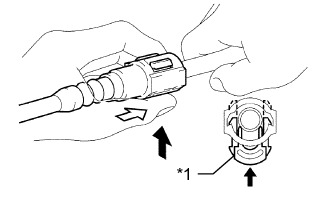

Match the axis of the connector with the axis of the pipe, and push the pipe into the connector until the connector makes a "click" sound. If the pipe is difficult to push into the connector, apply a small amount of clean engine oil to the tip of the pipe.

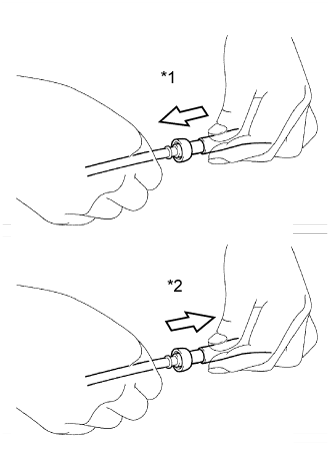

Text in Illustration *1 Push *2 Pull After connecting, check if the pipe and the connector are securely connected by pulling on them.

Install a new No. 2 fuel pipe clamp.

Check that there is no fuel leakage.

Observe these precautions when disconnecting the fuel tube connector (for quick type A).

for Fuel Pipe Clamp Type:

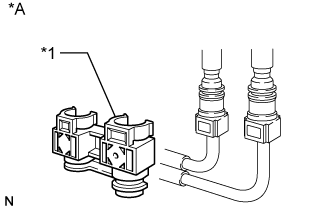

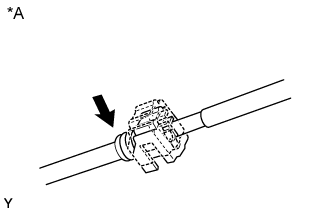

Remove the fuel pipe clamp from the fuel tube connector.Text in Illustration *A for Fuel Pipe Clamp Type *1 Fuel Pipe Clamp for Fuel Hose Connector Cover Type:

Detach the lock claw by lifting up the cover, as shown in the illustration.Text in Illustration *A for Fuel Hose Connector Cover Type

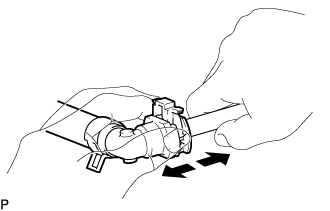

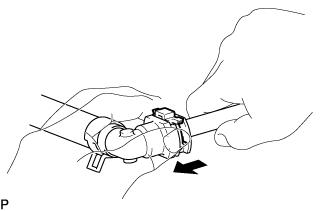

Pull Check for dirt or mud on the pipe and around the connector before disconnection. Clean if necessary.

Pinch the connector and disconnect the connector and pipe.

If the connector and the pipe are stuck together, pinch the connector, then push and pull the pipe to disconnect the pipe and pull it out.Text in Illustration

Pinch

Pull - NOTICE:

- Do not use any tools in this procedure.

Check for dirt or mud on the seal surface of the disconnected pipe. Clean if necessary.

To protect the disconnected pipe and connector from damage and contamination, cover it with a plastic bag.

Observe these precautions when connecting the fuel tube connector (for quick type A).

Check that there is no damage or contamination in the connection part of the pipe.

Align the axis of the connector with the axis of the pipe. Push the pipe into the connector until the connector makes a "click" sound. If the connection is tight, apply a small amount of fresh spindle oil or gasoline on the tip of the pipe.

Text in Illustration

Push After having finished the connection, try to pull apart the pipe and the connector to confirm that they are securely connected.

Text in Illustration

Pull for Fuel Hose Connector Cover Type:

Attach the lock claw to the connector by pushing down on the cover, as shown in the illustration.Text in Illustration *A for Fuel Hose Connector Cover Type

Push for Fuel Pipe Clamp Type:

Install the fuel pipe clamp to the connector.Text in Illustration *A for Fuel Pipe Clamp Type *1 Fuel Pipe Clamp Check that there is no fuel leakage.

Observe these precautions when disconnecting the fuel tube connector (for quick type B).

Check that there is no damage or foreign matter on the part of the pipe that contacts the connector.

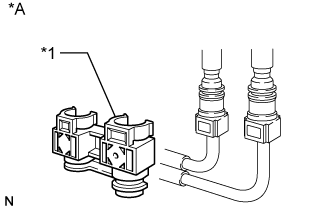

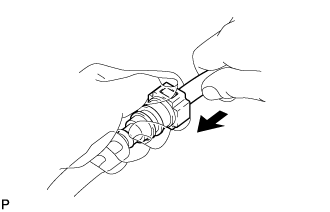

Detach the 2 claws of the connector retainer. Push down on the connector and disconnect it from the pipe.

Text in Illustration *1 Retainer

Push

Pull

Down - HINT:

- If the connector and pipe are stuck, pinch the fuel pipe by hand, and push and pull the connector to disconnect it.

Text in Illustration

Pull

Push - NOTICE:

- Do not use any tools in this procedure.

Check for foreign matter on the seal surface of the disconnected pipe. Clean it if necessary.

To protect the disconnected pipe and connector from damage and foreign matter, cover it with a plastic bag.

Observe these precautions when connecting the fuel tube connector (for quick type B).

Check for foreign matter on the pipe and around the connector before connecting it. Clean it if necessary.

Align the axis of the connector with the axis of the pipe. Push the pipe into the connector, and push up on the retainer.

Text in Illustration *1 Retainer

Push

Push After connecting the pipe and connector, try to pull them apart to confirm that they are securely connected.

Text in Illustration

Pull Check that there is no fuel leakage.

Observe the following precautions when disconnecting the fuel tube connector (for quick type C).

Check for dirt or mud on the fuel tube connector and pipe before disconnection. Clean if necessary.

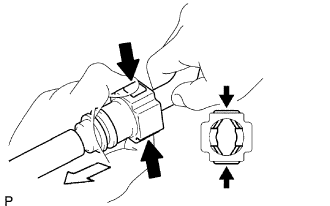

Pull the retainer up while pinching it on both sides by hand as shown in the illustration, and disconnect the fuel tube connector from the pipe.

Text in Illustration *1 Retainer

Push

Pull up

Pull - NOTICE:

- Do not use any tools.

If the fuel tube connector and pipe are stuck, pinch the fuel pipe by hand and push and pull the connector to disconnect it.

- NOTICE:

- Do not use any tools.

Check for dirt or mud on the pipe seal after disconnecting the fuel tube. Clean it if necessary.

Cover the disconnected fuel tube connector and pipe with a plastic bag.

- NOTICE:

- Do not allow the fuel tube connector or pipe to be damaged or contaminated by foreign matter.

Observe the following precautions when connecting the fuel tube connector (for quick type C).

Align the shaft of the fuel tube connector with the shaft of the pipe, push the fuel tube connector in, and push down the retainer.

Text in Illustration *1 Retainer

Connect

Push down After connecting the fuel tube connector, check that the fuel tube connector and pipe are securely connected by trying to pull them apart.

Observe these precautions when handling the nylon tube.

- NOTICE:

- Be careful not to turn the connection part of the nylon tube and quick connector when connecting them.

- Do not kink the nylon tube.

- Do not bend the nylon tube as this may cause blockage.

|

|

|

| 3.CHECK FOR FUEL LEAK |

Check that there are no fuel leaks after performing maintenance anywhere on the fuel system (Click here).