INSTALL DRIVE PLATE AND RING GEAR SUB-ASSEMBLY (for Automatic Transmission)

INSTALL CLUTCH RELEASE CYLINDER TO FLEXIBLE HOSE TUBE (for Manual Transmission)

INSTALL FUEL FILTER TO INJECTION PUMP FUEL PIPE SUB-ASSEMBLY

INSTALL NO. 1 VACUUM TRANSMITTING PIPE SUB-ASSEMBLY (w/ DPF)

INSTALL TUBE CONNECTOR TO FLEXIBLE HOSE TUBE (for Manual Transmission)

CONNECT RADIATOR SIDE DEFLECTOR RH (for Manual Transmission)

INSTALL TRANSMISSION OIL COOLER AIR DUCT (for Automatic Transmission)

Engine Assembly -- Installation |

- NOTICE:

- w/ DPF:

- When fuel lines are disconnected, air may enter the fuel lines, leading to engine starting trouble. Therefore, perform forced regeneration and bleed the air from the fuel lines (Click here).

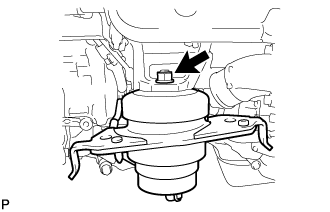

| 1. INSTALL FRONT ENGINE MOUNTING INSULATOR LH |

Install the mounting insulator with the nut.

- Torque:

- 80 N*m{816 kgf*cm, 59 ft.*lbf}

|

| 2. INSTALL FRONT ENGINE MOUNTING INSULATOR RH |

Install the mounting insulator with the nut.

- Torque:

- 80 N*m{816 kgf*cm, 59 ft.*lbf}

|

Connect the vacuum hose.

| 3. INSTALL NO. 1 AND NO. 2 ENGINE HANGER |

Install the No. 1 and No. 2 engine hangers to the cylinder head RH and LH with the 4 bolts as shown in the illustration.

- Torque:

- 25 N*m{250 kgf*cm, 18 ft.*lbf}

- HINT:

No. 1 engine hanger 12281-51040 No. 2 engine hanger 12282-51040 Bolt 91671-80825 Text in Illustration *1 No. 1 Engine Hanger *2 No. 2 Engine Hanger *a RH *b LH

|

| 4. REMOVE ENGINE STAND |

Attach an engine sling device and hang the engine with a chain block.

Lift the engine, and remove it from the engine stand.

- NOTICE:

- With the exception of installing the engine assembly to an engine stand or removing the engine assembly from an engine stand, do not perform any work on the engine while it is suspended, as doing so is dangerous.

- Pay attention to the angle of the sling device as the engine assembly or engine hangers may be damaged or deformed if the angle is incorrect.

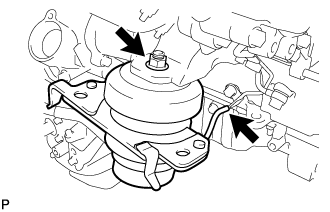

| 5. INSTALL DRIVE PLATE AND RING GEAR SUB-ASSEMBLY (for Automatic Transmission) |

Using a wrench, hold the crankshaft.

Install the rear crankshaft balancer weight.

Text in Illustration

Engine Side - HINT:

- Align the pin hole of the rear crankshaft balancer weight with the pin of the crankshaft.

- As the rear crankshaft balancer weight is not reversible, be sure to install it so that it is facing in the direction shown in the illustration.

|

Install the drive plate and ring gear and rear drive plate spacer with 8 new bolts.

Text in Illustration *1 Drive Plate and Ring Gear *2 Rear Drive Plate Spacer

Automatic Transmission Side - HINT:

- As the drive plate and ring gear and rear drive plate spacer are not reversible, be sure to install them so that they are facing in the direction shown in the illustration.

|

Install and uniformly tighten the 8 bolts in the sequence shown in the illustration.

- Torque:

- 182 N*m{1856 kgf*cm, 134 ft.*lbf}

|

| 6. INSTALL FLYWHEEL SUB-ASSEMBLY (for Manual Transmission) |

Temporarily install the flywheel with 8 new bolts.

- NOTICE:

- Align the crankshaft knock pin and flywheel knock pin hole.

- Do not strike or damage the flywheel installation bolts. Be sure to handle them carefully.

- Make sure there is no oil on the bolts.

|

Using a wrench, hold the crankshaft.

Uniformly install and tighten the 8 bolts in the sequence shown in the illustration.

- Torque:

- 182 N*m{1856 kgf*cm, 134 ft.*lbf}

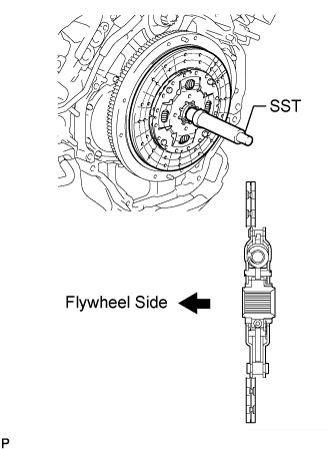

| 7. INSTALL CLUTCH DISC ASSEMBLY (for Manual Transmission) |

|

Insert SST into the clutch disc, then insert the clutch disc into the flywheel.

- SST

- 09301-00120

- NOTICE:

- Take care not to insert the clutch disc in the wrong direction.

| 8. INSTALL CLUTCH COVER ASSEMBLY (for Manual Transmission) |

|

Align the matchmark on the clutch cover with the one on the flywheel.

In the order shown in the illustration, temporarily install the 8 bolts starting from the bolt located near the knock pin on the top.

Check that the disc is in the center by lightly moving SST up and down, and left and right.

- SST

- 09301-00120

Evenly tighten the bolts by following the order shown in the illustration.

- Torque:

- 39 N*m{400 kgf*cm, 29 ft.*lbf}

| 9. INSTALL ENGINE ASSEMBLY |

Slowly lower the engine into the engine compartment.

Install the 4 bolts to the front mounting insulator RH and LH.

- Torque:

- 58 N*m{591 kgf*cm, 43 ft.*lbf}

Remove the 4 bolts and No. 1 and No. 2 engine hangers.

| 10. INSTALL CLUTCH RELEASE CYLINDER TO FLEXIBLE HOSE TUBE (for Manual Transmission) |

Install the clutch release cylinder to flexible hose tube with the bolt.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

| 11. INSTALL MANUAL TRANSMISSION UNIT ASSEMBLY |

| 12. INSTALL AUTOMATIC TRANSMISSION ASSEMBLY |

| 13. INSTALL NO. 2 INTAKE MANIFOLD |

Install a new gasket and the No. 2 intake manifold with the 9 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 14. INSTALL NO. 1 INTAKE MANIFOLD |

Install a new gasket and the No. 1 intake manifold with the 9 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 15. INSTALL NO. 1 FUEL PIPE CLAMP (w/ DPF) |

Install the 2 No. 1 fuel pipe clamps with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 16. INSTALL FUEL HOSE BRACKET (w/ DPF) |

Install the fuel hose bracket with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 17. INSTALL NO. 1 NOZZLE LEAKAGE PIPE (w/ DPF) |

Tighten the union bolt and 4 injector hollow screws.

- Torque:

- for union bolt:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- for injector hollow screw:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

Install the fuel tube and No. 1 nozzle leakage pipe with the check valve and new gasket.

- Torque:

- 32 N*m{321 kgf*cm, 23 ft.*lbf}

| 18. INSTALL NO. 2 NOZZLE LEAKAGE PIPE (w/ DPF) |

Tighten the 4 injector hollow screws and 2 bolts.

- Torque:

- for injector hollow screw:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

- for bolt:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

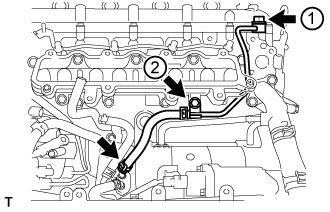

| 19. INSTALL NO. 1 WATER BY-PASS PIPE |

Temporarily install a new gasket and the No. 1 water by-pass pipe with the union bolt and bolt.

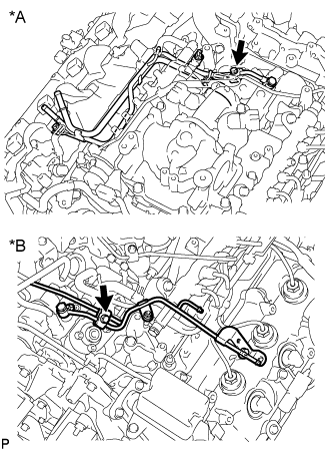

Text in Illustration *A w/ DPF *B w/o DPF

|

Tighten the union bolt and bolt in the order shown in the illustration.

- Torque:

- for union bolt:

- 59 N*m{600 kgf*cm, 43 ft.*lbf}

- for bolt:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 20. INSTALL FUEL TUBE SUB-ASSEMBLY (w/ DPF) |

Attach the 3 clamps to install the fuel tube.

Connect the 3 fuel tube connectors (Click here).

| 21. INSTALL FUEL COOLER ASSEMBLY (w/o DPF) |

Install the fuel cooler with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

| 22. CONNECT NO. 6 WATER BY-PASS HOSE (w/o DPF) |

| 23. INSTALL NO. 4 NOZZLE LEAKAGE PIPE (w/o DPF) |

Temporarily install a new gasket and the No. 4 nozzle leakage pipe with the union bolt and bolt.

|

Tighten the union bolt and bolt in the order shown in the illustration.

- Torque:

- for union bolt:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- for bolt:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Connect the No. 2 fuel hose to the fuel cooler.

| 24. INSTALL NO. 3 NOZZLE LEAKAGE PIPE (w/o DPF) |

Temporarily install a new gasket and the No. 3 nozzle leakage pipe with the union bolt and bolt.

|

Tighten the union bolt and bolt in the order shown in the illustration.

- Torque:

- for union bolt:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- for bolt:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Connect the No. 1 fuel hose to the fuel cooler.

| 25. INSTALL EGR COOLER INSULATOR (w/ EGR System) |

| 26. INSTALL EGR VALVE ASSEMBLY WITH EGR COOLER (w/ EGR System) |

Connect the No. 5 water by-pass hose to the water by-pass outlet.

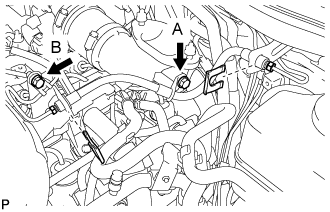

Install 2 new gaskets and the EGR valve with EGR cooler with the 6 bolts labeled A and 4 bolts labeled B shown in the illustration.

- Torque:

- for bolt A:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- for bolt B:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

- HINT:

- The gasket claws should face toward the No. 1 and No. 2 EGR pipes.

|

| 27. INSTALL EGR PIPE INSULATOR (w/ EGR System) |

Install the EGR pipe insulator with the 2 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- NOTICE:

- If the No. 1 and No. 2 EGR pipe insulator installation stay is deformed, or the bolt holes of the EGR pipe insulator do not align, replace the No. 1 and No. 2 EGR pipes as a set.

| 28. INSTALL INTAKE MANIFOLD INSULATOR (w/ EGR System) |

| 29. INSTALL NO. 3 INTAKE MANIFOLD |

|

Install 2 new gaskets to the No. 1 and No. 2 intake manifolds.

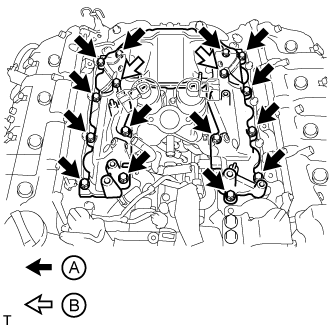

Install the No. 3 intake manifold with the 16 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Bolt Length Item Length Bolt A 25 mm (0.984 in.) Bolt B 70 mm (2.76 in.)

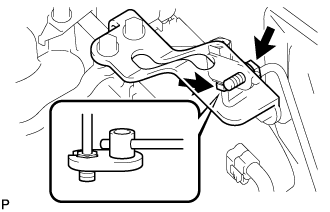

| 30. CONNECT NO. 2 ENGINE WIRE |

Connect the No. 2 engine wire with the 3 bolts.

- Torque:

- for bolt A:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

- for bolt B:

- 32 N*m{326 kgf*cm, 24 ft.*lbf}

|

Attach the 2 wire harness clamps.

| 31. INSTALL INTAKE PIPE |

w/ EGR System:

Install 2 new gaskets and the intake pipe with the 6 bolts and 2 nuts.- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

w/o EGR System:

Install a new gasket and the intake pipe with the 4 bolts and 2 nuts.- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 32. INSTALL NO. 3 NOZZLE LEAKAGE PIPE (w/ DPF) |

Temporarily install 2 new gaskets and the No. 3 nozzle leakage pipe with the 2 injector hollow screws and 3 bolts.

Tighten the 2 injector hollow screws and 3 bolts.

- Torque:

- for injector hollow screw:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- for bolt:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- HINT:

- Tighten the injector hollow screws first, and then tighten the bolts.

| 33. INSTALL CONNECTING WIRE (w/ DPF) |

Attach the 2 clamps to install the connecting wire.

| 34. INSTALL NO. 2 INTAKE MANIFOLD INSULATOR (w/ Intercooler) |

| 35. INSTALL NO. 1 INTAKE MANIFOLD INSULATOR (w/ Intercooler) |

| 36. INSTALL COMMON RAIL ASSEMBLY RH |

Install the common rail with the 2 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 37. INSTALL INJECTION PIPE RH |

Using a union nut wrench, install 4 new injection pipes.

- Torque:

- 34 N*m{347 kgf*cm, 25 ft.*lbf}

- NOTICE:

- Make sure there is no damage or foreign matter on the seal surfaces.

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (Click here).

w/ Intercooler:

Install the 4 injection pipe clamps with the 2 nuts.- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

| 38. INSTALL NO. 1 PROTECTOR FUEL INJECTOR (w/ DPF) |

Install the No. 1 fuel injector protector with the bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

- HINT:

- Press the ventilation hose clip against the No. 1 fuel injector protector as shown in the illustration.

|

| 39. INSTALL NO. 2 PROTECTOR FUEL INJECTOR (w/ DPF) |

Install the No. 2 fuel injector protector with the bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

- HINT:

- Press the ventilation hose clip against the No. 2 fuel injector protector as shown in the illustration.

|

Attach the hose clamp.

| 40. INSTALL CYLINDER HEAD COVER SILENCER RH (w/ DPF) |

| 41. INSTALL NO. 5 INJECTION PIPE SUB-ASSEMBLY |

Temporarily install a new No. 5 injection pipe by hand.

- NOTICE:

- Make sure there is no damage or foreign matter on the seal surfaces.

w/ DPF:

Temporarily install the used gasket and fuel filter to injection pump fuel pipe with the nut, bolt and union bolt.

|

w/o DPF:

Temporarily install the used gasket and No. 2 fuel pipe with the nut, bolt and union bolt.

|

Install the No. 2 injection pipe clamp with the bolt.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Text in Illustration *A w/ DPF *B w/o DPF

|

Using a union nut wrench, tighten the No. 5 injection pipe ends.

- Torque:

- 34 N*m{347 kgf*cm, 25 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (Click here).

Remove the bolt and No. 2 injection pipe clamp.

Remove the union bolt and gasket.

w/ DPF:

Remove the bolt, nut and fuel filter to injection pump fuel pipe.

w/o DPF:

Remove the bolt, nut and No. 2 fuel pipe.

| 42. CONNECT FUEL PUMP MOTOR WIRE |

Install the fuel pump motor wire bracket to the No. 3 intake manifold with the bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Connect the connector to the fuel supply pump.

| 43. INSTALL FUEL FILTER TO INJECTION PUMP FUEL PIPE SUB-ASSEMBLY |

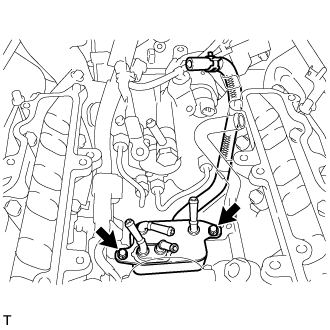

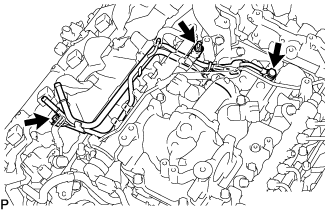

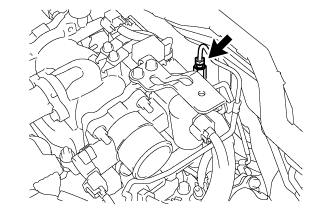

w/ DPF:

- NOTICE:

- Check for damage and foreign matter on the fuel pipe installation surface of the fuel supply pump.

- If there is foreign matter, remove it from the installation surface.

- If the installation surface is damaged, replace the fuel supply pump.

Temporarily install a new gasket and fuel filter to injection pump fuel pipe with the nut, bolt and union bolt.

Install the No. 2 injection pipe clamp with the bolt.

- Torque:

- 4.0 N*m{41 kgf*cm, 35 in.*lbf}

Tighten the union bolt, bolt and nut.

- Torque:

- for union bolt:

- 12 N*m{125 kgf*cm, 9 ft.*lbf}

- for bolt and nut:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Connect the fuel hose.

w/o DPF:

Install the fuel filter to injection pump fuel pipe with the bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Connect the 2 hoses to the fuel pipe.

| 44. INSTALL COMMON RAIL ASSEMBLY LH |

Install the common rail with the 2 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 45. INSTALL NO. 5 NOZZLE LEAKAGE PIPE (w/ DPF) |

Install a new gasket and the leakage pipe with the union bolt.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

- NOTICE:

- Make sure there is no foreign matter or damage on the seal surface.

w/ DPF:

Connect the fuel hose.

| 46. INSTALL INJECTION PIPE LH |

Using a union nut wrench, install the 4 new injection pipes.

- Torque:

- 34 N*m{347 kgf*cm, 25 ft.*lbf}

- NOTICE:

- Make sure there is no damage or foreign matter on the seal surfaces.

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (Click here).

w/ Intercooler:

Install the 4 injection pipe clamps with the 2 nuts.- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

| 47. INSTALL NO. 4 NOZZLE LEAKAGE PIPE (w/ DPF) |

Temporarily install a new gasket and No. 4 nozzle leakage pipe with the fuel check valve.

Tighten the fuel check valve.

- Torque:

- 32 N*m{321 kgf*cm, 23 ft.*lbf}

Connect the fuel hose.

| 48. INSTALL CYLINDER HEAD COVER SILENCER LH (w/ DPF) |

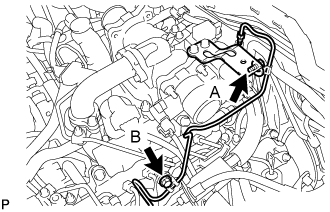

| 49. INSTALL NO. 1 VACUUM TRANSMITTING PIPE SUB-ASSEMBLY (w/ DPF) |

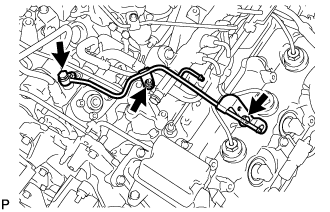

Install the vacuum transmitting pipe with the 3 bolts.

- Torque:

- 6.0 N*m{61 kgf*cm, 53 in.*lbf}

Connect the 2 vacuum hoses.

| 50. INSTALL NO. 1 VACUUM SWITCHING VALVE ASSEMBLY (w/ DPF) |

Install the vacuum switching valve with the bolt.

- Torque:

- 6.0 N*m{61 kgf*cm, 53 in.*lbf}

Connect the 2 vacuum hoses.

| 51. INSTALL NO. 2 FUEL PIPE SUB-ASSEMBLY (w/o DPF) |

- NOTICE:

- Check for damage and foreign matter on the fuel pipe installation surface of the supply pump.

- If there is foreign matter, remove it from the installation surface. If the installation surface is damaged, replace the fuel supply pump.

Temporarily install a new gasket and the No. 2 fuel pipe with the union bolt, nut and bolt.

|

Tighten the union bolt, nut and bolt in the order shown in the illustration.

- Torque:

- for union bolt:

- 25 N*m{255 kgf*cm, 18 ft.*lbf}

- for bolt and nut:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Install the No. 2 injection pipe clamp with the bolt.

- Torque:

- 4.0 N*m{41 kgf*cm, 35 in.*lbf}

Connect the fuel hose to the No. 5 nozzle leakage pipe.

| 52. CONNECT NO. 6 INJECTION PIPE SUB-ASSEMBLY |

w/ EGR System:

Temporarily install a new No. 6 injection pipe to the common rail LH and RH.

- NOTICE:

- Make sure there is no damage or foreign matter on the seal surfaces.

Install the 2 No. 2 injection pipe clamps with the 2 nuts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Using a union nut wrench, tighten the No. 6 injection pipe ends.

- Torque:

- 34 N*m{347 kgf*cm, 25 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (Click here).

w/o EGR System:

Temporarily install a new No. 6 injection pipe to the common rail LH and RH.

- NOTICE:

- Make sure there is no damage or foreign matter on the seal surfaces.

Install the bracket to the No. 3 intake manifold with the bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Install the No. 2 injection pipe clamp with the nut.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Using a union nut wrench, tighten the No. 6 injection pipe ends.

- Torque:

- 34 N*m{347 kgf*cm, 25 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (Click here).

| 53. CONNECT ENGINE WIRE |

Rear Side:

Install the glow plug wire harness with the nut and screw grommet.

- Torque:

- 4.0 N*m{41 kgf*cm, 35 in.*lbf}

w/ DPF:

Connect the 3 connectors.w/o DPF:

Connect the connector.Install the engine wire harness protector with the 2 bolts.

Install the 2 ground wires with the 2 bolts.

- Torque:

- 8.4 N*m{86 kgf*cm, 74 in.*lbf}

LH Side:

Install the engine wire protector with the 2 bolts.

Connect the 8 connectors.

Attach the wire harness clamp.

Install the engine wire harness bracket with the bolt.

for RHD:

Connect the wire harness with the wire harness clamp holder.Attach the 3 wire harness clamps and connect the 2 connectors.

w/ DPF:

Connect the 7 connectors to the injection driver.w/o DPF:

Connect the 4 connectors to the injection driver.Install the ground wire with the bolt.

- Torque:

- 8.4 N*m{86 kgf*cm, 74 in.*lbf}

Connect the wire harness holder to the relay block.

Connect the 4 connectors to the relay block.

Connect the wire harness with the wire harness clamp holder.

for RHD:

Connect the wire harness with the wire harness clamp holder.for RHD:

Connect the ECM connector to the ECM.for RHD:

Attach the wire harness tab to the relay block.Connect the 4 connectors to the relay block.

Connect the generator positive (+) cable to the body panel with the 2 clamps.

Attach the generator positive (+) cable holder to the relay block, and install the cable to the relay block with the nut.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Connect the wire harness with the wire harness clamp holder, and attach the ground wire clamp to the relay block side.

Install the ground wire to the body panel with the bolt.

- Torque:

- 8.4 N*m{86 kgf*cm, 74 in.*lbf}

RH Side:

w/ Winch:

Install the ground wire with the bolt.- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

Install the engine wire harness protector with the 3 bolts.

Connect the 7 connectors.

Install the wire harness bracket with the bolt.

Install the glow plug wire harness with the nut and screw grommet.

- Torque:

- 4.0 N*m{41 kgf*cm, 35 in.*lbf}

for RHD:

Install the wire harness holder with the bolt.for RHD:

Connect the wire harness with the wire harness holder.for LHD:

Connect the wire harness with the wire harness clamp holder.for LHD:

Connect the ECM connector to the ECM.for LHD:

Attach the wire harness tab to the relay block.for LHD:

Connect the 4 connectors to the relay block.

| 54. INSTALL NO. 4 WATER BY-PASS PIPE |

w/ EGR System:

w/ DPF:

Connect the 3 water hose ends, and temporarily install the No. 4 water by-pass pipe with the 2 bolts and nut.w/o DPF:

Connect the 4 water hose ends, and temporarily install the No. 4 water by-pass pipe with the 2 bolts and nut.

w/o EGR System:

Connect the 3 water hose ends, and temporarily install the No. 4 water by-pass pipe with the 2 bolts and nut.

First tighten the 2 bolts and then tighten the nut.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 55. INSTALL NO. 3 WATER BY-PASS PIPE (w/o Viscous Heater) |

Connect the 2 water hose ends, and install the No. 3 water by-pass pipe with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 56. CONNECT FUEL HOSE |

| 57. INSTALL NO. 1 AIR CLEANER PIPE SUB-ASSEMBLY |

Connect the No. 1 air cleaner pipe to the No. 1 intake air connector pipe.

Install the pipe with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Tighten the hose clamp.

- Torque:

- 6.3 N*m{64 kgf*cm, 56 in.*lbf}

| 58. INSTALL HEATER WATER PIPE SUB-ASSEMBLY (w/ Viscous Heater) |

Connect the 4 water hose ends, and install the water pipe with the 4 bolts.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

| 59. INSTALL NO. 2 INTAKE AIR CONNECTOR PIPE |

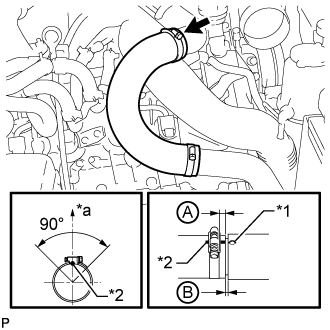

Install the No. 2 intake air connector pipe to the No. 2 inlet compressor elbow.

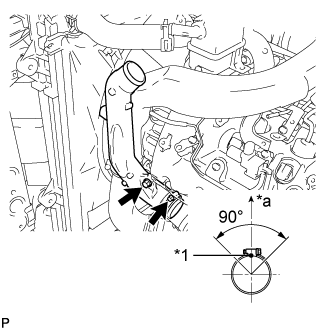

Text in Illustration *1 Hose Stopper *a No Gap - NOTICE:

- Make sure there is no gap between the air pipe and hose stopper on the elbow side.

|

Install the bolt of the No. 2 intake air connector pipe.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- NOTICE:

- Do not excessively pull the air pipe towards the front of the engine.

Tighten the hose clamp on the elbow side.

- Torque:

- 6.0 N*m{61 kgf*cm, 53 in.*lbf}

- HINT:

- Align the 2 protrusions of the air pipe and elbow.

- Install the air pipe so that the protrusion on the pipe side is within the range of the protrusion on the elbow side.

- After tightening, a gap between the air pipe and hose stopper on the elbow side is acceptable.

- Make sure the direction of the hose clamp is as shown in the illustration.

Text in Illustration *1 Protrusion

w/ Intercooler:

Connect the vacuum hose.

| 60. ADJUST COMPRESSOR OIL |

When replacing the compressor and magnetic clutch with a new one, gradually discharge the refrigerant gas from the service valve, and drain the following amount of oil from the new compressor and magnetic clutch before installation.

- Standard:

- VDJ200L-GNMNZV, GNTNZV, GPMNZV:

- (Oil capacity inside the new compressor and magnetic clutch: 140 + 15 cc (4.7 + 0.51 fl.oz.)) - (Remaining oil amount in the removed compressor and magnetic clutch) = (Oil amount to be removed from the new compressor when replacing)

- Except VDJ200L-GNMNZV, GNTNZV, GPMNZV:

- (Oil capacity inside the new compressor and magnetic clutch: 135 + 15 cc (4.6 + 0.51 fl.oz.)) - (Remaining oil amount in the removed compressor and magnetic clutch) = (Oil amount to be removed from the new compressor when replacing)

- NOTICE:

- When checking the compressor oil level, follow the A/C system precautions.

- If a new compressor and magnetic clutch is installed without removing some oil remaining in the pipes of the vehicle, the oil amount will be too large. This prevents heat exchange in the refrigerant cycle and causes refrigerant failure.

- If the volume of oil remaining in the removed compressor and magnetic clutch is too small, check for oil leakage.

- Be sure to use ND-OIL 8 or equivalent for compressor oil.

| 61. INSTALL COOLER COMPRESSOR ASSEMBLY |

Temporarily install the cooler compressor with the 4 bolts.

|

Tighten the 4 bolts in the order shown in the illustration.

- Torque:

- 25 N*m{250 kgf*cm, 18 ft.*lbf}

Attach the 3 wire harness clamps and connect the 4 connectors.

| 62. INSTALL SUCTION HOSE SUB-ASSEMBLY |

Remove the attached vinyl tape from the cooler refrigerant suction hose.

|

Sufficiently apply compressor oil to a new O-ring and the fitting surface of the cooler compressor.

- Compressor oil:

- ND-OIL 8 or equivalent

Install the O-ring to the suction hose.

Connect the suction hose to the cooler compressor with the bolt.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

| 63. INSTALL NO. 1 COOLER REFRIGERANT DISCHARGE HOSE |

|

Remove the attached vinyl tape from the discharge hose.

Sufficiently apply compressor oil to a new O-ring and the fitting surface of the cooler compressor.

- Compressor oil:

- ND-OIL 8 or equivalent

Install the O-ring to the discharge hose.

Connect the discharge hose to the cooler compressor with the bolt.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

| 64. INSTALL NO. 2 AIR CLEANER PIPE SUB-ASSEMBLY |

Connect the No. 2 air cleaner pipe to the No. 2 intake air connector pipe.

Connect the ventilation hose to the oil separator.

Install the pipe with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Tighten the hose clamp.

- Torque:

- 6.3 N*m{64 kgf*cm, 56 in.*lbf}

| 65. INSTALL NO. 2 AIR TUBE ASSEMBLY |

Apply a light coat of washer fluid to a new O-ring, and install it to the No. 2 air tube.

Install the No. 2 air tube with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 66. INSTALL NO. 4 AIR TUBE |

Install the No. 4 air tube with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Text in Illustration *1 Paint Mark *a Top

|

Tighten the hose clamp.

- Torque:

- 6.3 N*m{64 kgf*cm, 56 in.*lbf}

- HINT:

- Make sure the direction of the hose clamp is as shown in the illustration.

Install the suction hose with the bolt.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

| 67. INSTALL NO. 2 AIR HOSE |

Connect the No. 2 air hose with the hose clamp.

- Torque:

- 6.3 N*m{64 kgf*cm, 56 in.*lbf}

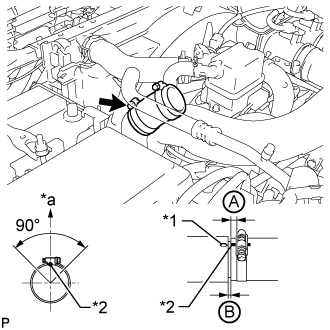

Text in Illustration *1 Protrusion *2 Paint Mark *a Top - HINT:

- Align the paint mark of the air hose with the protrusion and push on the air hose so that distance B is 0 to 3 mm (0 to 0.118 in.).

- Position the clamp so that distance A is 2 to 6 mm (0.0787 to 0.236 in.).

- Make sure the direction of the hose clamp is as shown in the illustration.

|

| 68. INSTALL NO. 1 AIR TUBE ASSEMBLY |

Apply a light coat of washer fluid to a new O-ring, and install it to the No. 1 air tube.

Install the No. 1 air tube with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 69. INSTALL NO. 3 AIR TUBE |

Install the No. 3 air tube with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Text in Illustration *1 Paint Mark *a Top

|

Tighten the hose clamp.

- Torque:

- 6.3 N*m{64 kgf*cm, 56 in.*lbf}

- HINT:

- Make sure the direction of the hose clamp is as shown in the illustration.

Install the wire harness bracket with the bolt.

Install the ground wire with the nut, and attach the wire harness clamp.

- Torque:

- 8.4 N*m{85 kgf*cm, 74 in.*lbf}

| 70. INSTALL NO. 1 AIR HOSE |

Connect the No. 1 air hose with the hose clamp.

- Torque:

- 6.3 N*m{64 kgf*cm, 56 in.*lbf}

Text in Illustration *1 Protrusion *2 Paint Mark *a Top - HINT:

- Align the paint mark of the air hose with the protrusion and push on the air hose so that distance B is 0 to 3 mm (0 to 0.118 in.).

- Position the clamp so that distance A is 2 to 6 mm (0.0787 to 0.236 in.).

- Make sure the direction of the hose clamp is as shown in the illustration.

|

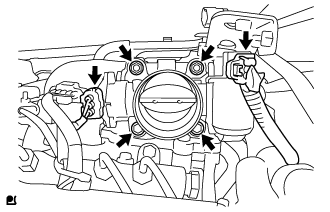

| 71. INSTALL DIESEL THROTTLE BODY ASSEMBLY LH |

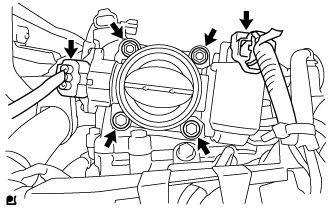

Install a new gasket to the intake pipe.

Install the throttle body with the 2 bolts and 2 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

Connect the throttle position sensor connector.

Connect the throttle motor connector.

| 72. INSTALL NO. 3 INTERCOOLER SUPPORT BRACKET |

Install the No. 3 intercooler support bracket with the 2 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

for Manual Transmission:

Connect the clutch tube to release cylinder 2 way with the bolt.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Check that the union nut is tightened to the specified torque.

- Torque:

- 15 N*m{154 kgf*cm, 11 ft.*lbf}

- HINT:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (Click here).

|

| 73. INSTALL NO. 1 GAS FILTER |

Install the No. 1 gas filter.

Connect the hose to the intake pipe.

| 74. INSTALL TUBE CONNECTOR TO FLEXIBLE HOSE TUBE (for Manual Transmission) |

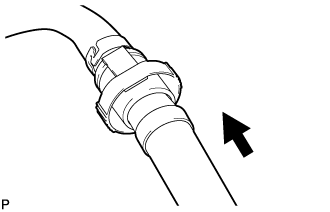

Temporarily install the flare nut of the tube connector to flexible hose tube to the clutch tube to release cylinder 2 way by hand.

|

Temporarily install the tube connector to flexible hose tube with the 2 bolts.

|

Tighten the bolt labeled A.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

- NOTICE:

- Tighten the bolt labeled B after installing the clutch hose.

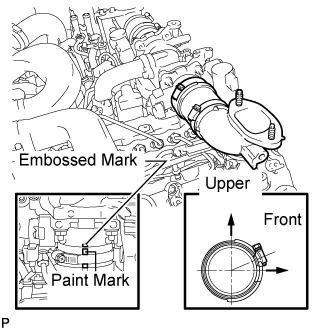

| 75. INSTALL AIR TUBE SUB-ASSEMBLY LH |

|

Install the air tube to the throttle body.

Align the embossed mark of the throttle body with the paint mark of the No. 4 air hose.

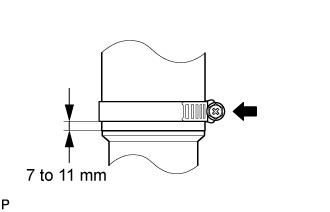

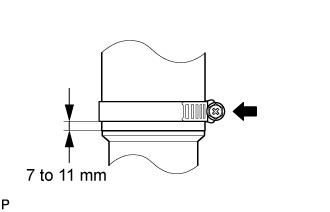

Tighten the hose clamp so that it is 7 to 11 mm (0.276 to 0.433 in.) from the end of the hose as shown in the illustration.

- Torque:

- 6.3 N*m{64 kgf*cm, 56 in.*lbf}

|

| 76. INSTALL CLUTCH HOSE (for Manual Transmission) |

Connect the clutch hose to the air tube with the bolt labeled A.

|

Temporarily install the clutch hose to the clutch master cylinder tube to flexible hose tube and tube connector to flexible hose tube, and fix it in place with the 2 clips.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Tighten the bolt labeled B.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Tighten the flexible hose tube.

- NOTICE:

- Do not bend or damage the flexible hose tube.

- Do not allow any foreign matter such as dirt and dust to enter the flexible hose tube from the connecting points.

- HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.8 in.). If using a torque wrench with a length that is not 30 cm (11.8 in.), calculate the torque specification for the torque wrench and SST based on the "without SST" torque specification (Click here).

- Make sure union nut wrench and the wrench are connected in a straight line.

Using a 10 mm union nut wrench, tighten the 2 flare nuts of the flexible hose tube.

- Torque:

- without union nut wrench:

- 15 N*m{154 kgf*cm, 11 ft.*lbf}

- with union nut wrench:

- 14 N*m{141 kgf*cm, 10 ft.*lbf}

Using a 10 mm union nut wrench, tighten the flare nut of the flexible hose tube.

- Torque:

- without union nut wrench:

- 15 N*m{154 kgf*cm, 11 ft.*lbf}

- with union nut wrench:

- 14 N*m{141 kgf*cm, 10 ft.*lbf}

| 77. INSTALL DIESEL THROTTLE BODY ASSEMBLY RH |

Install a new gasket to the intake pipe.

Install the throttle body with the 2 bolts and 2 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

Connect the throttle position sensor connector.

Connect the throttle motor connector.

| 78. INSTALL AIR TUBE SUB-ASSEMBLY RH |

|

Install the air tube to the throttle body.

Align the embossed mark of the throttle body with the paint mark of the No. 4 air hose.

Tighten the hose clamp so that it is 7 to 11 mm (0.276 to 0.433 in.) from the end of the hose as shown in the illustration.

- Torque:

- 6.3 N*m{64 kgf*cm, 56 in.*lbf}

|

| 79. INSTALL NO. 2 ENGINE OIL LEVEL DIPSTICK GUIDE |

Apply a light coat of engine oil to a new O-ring.

Install the O-ring to the No. 2 engine oil level dipstick guide.

Install the No. 2 engine oil level dipstick guide with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Connect the ventilation hose to the cylinder head cover RH.

Connect the wire harness clamp to the No. 2 engine oil level dipstick guide bracket.

| 80. CONNECT WATER HOSE SUB-ASSEMBLY |

| 81. INSTALL NO. 2 COOL AIR INLET (w/o Intercooler) |

Install a new gasket to the air tube LH.

Text in Illustration *1 Protrusion *a Front *b LH Side - HINT:

- Install the gasket with the protrusion facing as shown in the illustration.

|

Install the No. 2 cool air inlet with the 3 nuts and bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Connect the No. 2 air hose to the No. 2 cool air inlet.

Text in Illustration *1 Protrusion *2 Paint Mark *a Top

|

Tighten the No. 2 air hose clamp.

- Torque:

- 6.3 N*m{64 kgf*cm, 56 in.*lbf}

- HINT:

- Align the paint mark of the air hose with the protrusion and push on the air hose so that distance B is 0 to 3 mm (0 to 0.118 in.).

- Position the clamp so that distance A is 2 to 6 mm (0.0787 to 0.236 in.).

- Make sure the direction of the hose clamp is as shown in the illustration.

| 82. INSTALL NO. 1 COOL AIR INLET (w/o Intercooler) |

Install a new gasket to the air tube RH.

Text in Illustration *1 Protrusion *a Front *b RH Side - HINT:

- Install the gasket with the protrusion facing as shown in the illustration.

|

Install the No. 1 cool air inlet with the 3 nuts and bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Connect the vacuum hose, intake air temperature sensor connector and turbo pressure sensor connector.

Connect the No. 1 air hose to the No. 1 cool air inlet.

Text in Illustration *1 Protrusion *2 Paint Mark *a Top

|

Tighten the No. 1 air hose clamp.

- Torque:

- 6.3 N*m{64 kgf*cm, 56 in.*lbf}

- HINT:

- Align the paint mark of the air hose with the protrusion and push on the air hose so that distance B is 0 to 3 mm (0 to 0.118 in.).

- Position the clamp so that distance A is 2 to 6 mm (0.0787 to 0.236 in.).

- Make sure the direction of the hose clamp is as shown in the illustration.

| 83. CONNECT FUEL TUBE |

Install new No. 1 and No. 3 fuel tube clamps.

w/ DPF:

Connect the 2 fuel tubes to the clamps.

w/o DPF:

Connect the 3 fuel tubes to the clamps.

| 84. CONNECT FRONT DIFFERENTIAL BREATHER TUBE |

| 85. ADD ENGINE OIL |

Add fresh oil.

- Standard Engine Oil:

Item Oil Grade Oil Viscosity (SAE) w/ DPF ACEA C2

(Using engine oil other than ACEA C2 may damage catalytic converter)- 0W-30

- 5W-30

(0W-30 is best choice for fuel economy and good starting in cold weather)w/o DPF G-DLD-1, API CF-4, API CF or ACEA B1

(You may also use API CE or CD)- 5W-30

- 10W-30

- 15W-40

- 20W-50

(5W-30 is best choice for fuel economy and good starting in cold weather).

- Standard Capacity:

Item Specified Condition Drain and refill with oil filter change 9.2 liters (9.7 US qts, 8.1 Imp. qts) Drain and refill without oil filter change 8.2 liters (8.7 US qts, 7.2 Imp. qts) Dry fill 9.9 liters (10.5 US qts, 8.7 Imp. qts)

Install the oil filler cap.

| 86. INSTALL RADIATOR ASSEMBLY |

Install the radiator with the 4 bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

| 87. CONNECT RADIATOR SIDE DEFLECTOR LH |

Install the side deflector with the 4 clips.

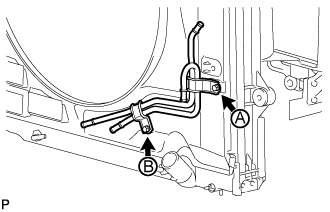

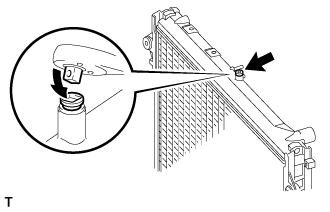

| 88. CONNECT RADIATOR SIDE DEFLECTOR RH (for Manual Transmission) |

Install the deflector with the 4 clips.

| 89. INSTALL TRANSMISSION OIL COOLER AIR DUCT (for Automatic Transmission) |

Install the oil cooler air duct with the 4 bolts.

- Torque:

- 4.9 N*m{50 kgf*cm, 43 in.*lbf}

| 90. INSTALL FRONT BUMPER COVER |

- HINT:

- For the front bumper cover with garnish, use the procedure described below.

w/ Headlight Cleaner System:

Connect the headlight cleaner hose.

|

w/ TOYOTA Parking Assist-sensor System or w/ Fog Light:

Connect the No. 4 engine room wire connector.

Attach the 10 claws to install the front bumper cover.

Install the 3 clips, 4 screws and 4 bolts.

Using a T30 "TORX" socket, install the 6 screws.

| 91. INSTALL RADIATOR GRILLE |

w/ Wide View Front Monitor System:

Connect the connector.

Attach the 2 clips and 8 claws to install the radiator grille assembly.

Install the 3 screws.

| 92. INSTALL FRONT BUMPER WINCH COVER (w/ Winch) |

Attach the 3 guides.

Attach the 2 claws and front bumper winch cover sub-assembly.

| 93. INSTALL FAN PULLEY |

| 94. INSTALL FAN SHROUD WITH FAN |

Install the shroud together with the fluid coupling fan between the radiator and engine components.

- NOTICE:

- Be careful not to damage the radiator core.

Temporarily install the fluid coupling fan to the fan bracket with the 4 nuts.

- HINT:

- Tighten the nuts as much as possible by hand.

|

Attach the shroud claws to the radiator.

|

Install the shroud with the 2 bolts.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

Tighten the 4 nuts of the fluid coupling fan.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

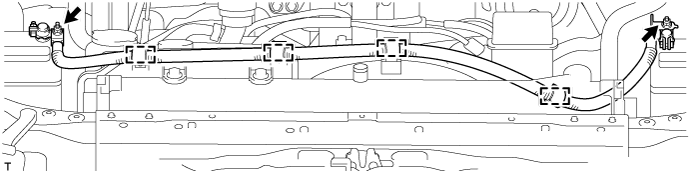

| 95. INSTALL OIL COOLER TUBE (for Automatic Transmission) |

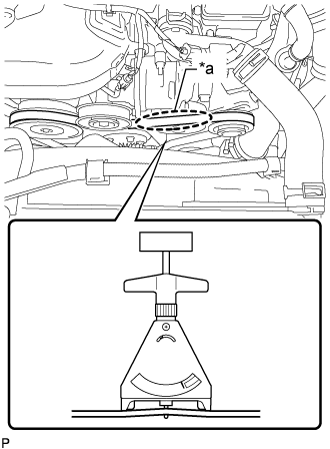

Temporarily install the oil cooler tube to the fan shroud with the bolt labeled A. Install the bolt labeled B. Then tighten the bolt labeled A to the specified torque.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

|

Connect the inlet No. 4 oil cooler hose as shown in the illustration.

Text in Illustration *1 Paint Mark - NOTICE:

- Make sure the pinching portion of each clip is facing the direction shown in the illustration.

|

Connect the inlet No. 2 and No. 3 oil cooler hoses as shown in the illustration.

- NOTICE:

- Make sure the pinching portion of each clip is facing the direction shown in the illustration.

|

Connect the inlet and outlet No. 1 oil cooler hoses as shown in the illustration.

Text in Illustration *1 Paint Mark - NOTICE:

- Make sure the pinching portion of each clip is facing the direction shown in the illustration.

|

Pass the hose through the flexible hose clamp and close the clamp shown in the illustration.

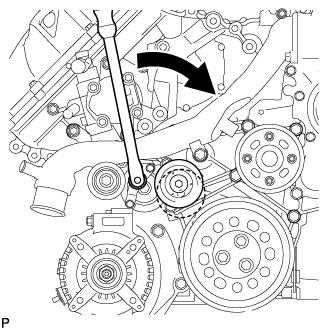

| 96. INSTALL V-RIBBED BELT |

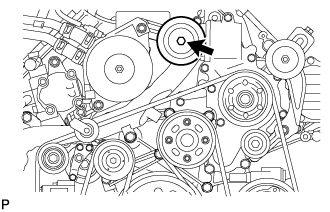

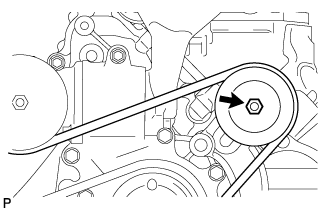

Attach a wrench to the V-ribbed belt tensioner bracket and turn the wrench clockwise.

|

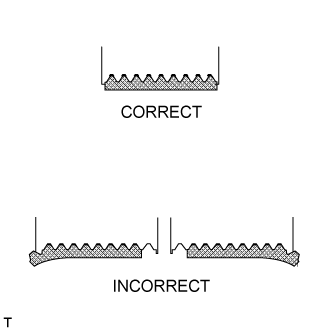

Install the V-ribbed belt as shown in the illustration.

|

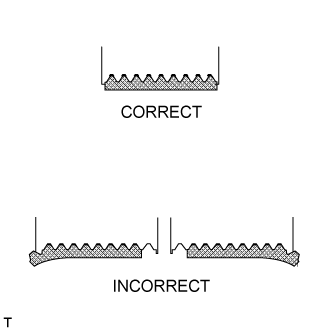

Check that the belt fits properly in the ribbed grooves.

- HINT:

- Check with your hand to confirm that the belt has not slipped out of the groove on the bottom of the pulley.

- If it has slipped out, replace the V-ribbed belt. Install a new V-ribbed belt.

|

| 97. INSTALL NO. 3 IDLER PULLEY (w/ Viscous Heater) |

Align the No. 3 idler pulley bracket knock pin and No. 1 idler pulley bracket knock pin hole and install the No. 3 idler pulley with the nut.

- Torque:

- 88 N*m{898 kgf*cm, 64 ft.*lbf}

|

| 98. INSTALL NO. 1 IDLER PULLEY (w/ Viscous Heater) |

Install the collar, No. 1 idler pulley and cover with the bolt.

- Torque:

- 49 N*m{495 kgf*cm, 36 ft.*lbf}

|

| 99. INSTALL V-RIBBED BELT (w/ Viscous Heater) |

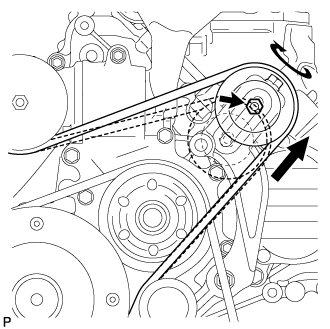

Install the V-ribbed belt as shown in the illustration.

|

Temporarily install the lock nut, and turn the bolt clockwise.

|

Using a belt tension gauge, inspect the belt tension.

- Standard Belt Tension:

Item Condition Specified Condition New belt 5 to 35°C (41 to 95°F) 550 to 800 N (56 to 82 kgf, 123.6 to 179.8 lbf) Used belt 5 to 35°C (41 to 95°F) 300 to 500 N (31 to 51 kgf, 67.4 to 112.4 lbf)

Text in Illustration *a Measuring Point - HINT:

- When measuring the tension of a new belt, measure the tension immediately after installing it to the engine but before starting the engine.

- A "new belt" is a belt which has been used for less than 5 minutes on a running engine.

- A "used belt" is a belt which has been used on a running engine for 5 minutes or more.

- After installing a new belt, run the engine for approximately 5 minutes and then recheck the tension.

|

Tighten the nut.

- Torque:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

|

Check that the belt fits properly in the ribbed grooves.

- HINT:

- Check with your hand to confirm that the belt has not slipped out of the groove on the bottom of the pulley.

- If it has slipped out, replace the V-ribbed belt. Install a new V-ribbed belt.

|

| 100. CONNECT NO. 2 RADIATOR HOSE |

| 101. CONNECT NO. 1 RADIATOR HOSE |

| 102. INSTALL VANE PUMP ASSEMBLY |

- w/ DPF: (Click here)

- w/o DPF: (Click here)

| 103. INSTALL RADIATOR RESERVOIR ASSEMBLY |

Install the radiator reservoir with the 3 bolts.

|

Connect the 2 hoses to the upper radiator tank and water inlet.

- HINT:

- Make sure the directions of the hose clamps are as shown in the illustration.

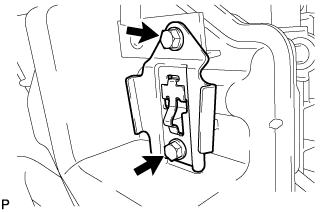

| 104. INSTALL NO. 1 OIL RESERVOIR BRACKET |

Install a new bracket with the 2 bolts.

- Torque:

- 4.5 N*m{46 kgf*cm, 40 in.*lbf}

|

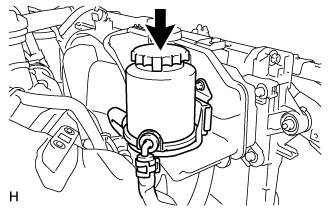

| 105. INSTALL VANE PUMP OIL RESERVOIR ASSEMBLY |

Install the vane pump oil reservoir to the bracket.

|

| 106. INSTALL AIR CLEANER CASE |

Install the air cleaner case with the 3 bolts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Attach the wire harness clamp to the air cleaner case.

| 107. INSTALL AIR CLEANER FILTER ELEMENT |

| 108. INSTALL INTAKE AIR CONNECTOR |

Connect the intake air connector to the No. 1 and No. 2 air cleaner pipes.

Install the connector with the 2 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Tighten the 2 hose clamps.

- Torque:

- 6.3 N*m{64 kgf*cm, 56 in.*lbf}

Attach the 3 wire harness clamps.

w/o Viscous Heater:

Connect the connector to the water temperature sensor.

w/ Viscous Heater:

Connect the 2 connectors to the water temperature sensor and viscous with magnet clutch heater.

| 109. TEMPORARILY INSTALL NO. 1 AIR CLEANER HOSE |

Temporarily install the air cleaner hose to the intake air connector.

| 110. INSTALL AIR CLEANER CAP SUB-ASSEMBLY |

Connect the air cleaner cap to the air cleaner hose, and install the air cleaner cap with the 4 clamps.

Connect the mass air flow meter connector and attach the wire harness clamp to the air cleaner cap.

Attach the wire harness clamp.

Align the protrusion of the air cleaner cap and the concave portion of the air cleaner hose.

Tighten the 2 hose clamps.

- Torque:

- 2.5 N*m{25 kgf*cm, 22 in.*lbf}

| 111. INSTALL INTERCOOLER ASSEMBLY (w/ Intercooler) |

| 112. INSTALL SUB-BATTERY |

| 113. INSTALL MAIN BATTERY |

| 114. INSTALL NO. 3 ENGINE ROOM WIRE |

Install the No. 3 engine room wire to the main battery and sub-battery positive terminals with the 2 nuts.

- Torque:

- 7.6 N*m{77 kgf*cm, 67 in.*lbf}

Connect the No. 3 engine room wire with the 4 clamps.

| 115. INSTALL FRONT WHEEL |

| 116. BLEED CLUTCH LINE |

|

Remove the release cylinder bleeder plug cap.

Connect a vinyl tube to the bleeder plug.

Depress the clutch pedal several times, and then loosen the bleeder plug while the pedal is depressed.

When fluid no longer comes out, tighten the bleeder plug, and then release the clutch pedal.

Repeat the previous 2 steps until all the air in the fluid is completely bled.

Tighten the bleeder plug.

- Torque:

- 11 N*m{110 kgf*cm, 8 ft.*lbf}

Install the bleeder plug cap.

Check that all the air has been bled from the clutch line.

| 117. CHECK FOR CLUTCH FLUID LEAK |

| 118. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- NOTICE:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected (Click here).

Connect the cables to the negative (-) main battery and sub-battery terminals.

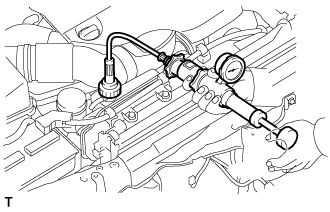

| 119. BLEED AIR FROM FUEL SYSTEM |

Using the hand pump mounted on the fuel filter cap, bleed air from the fuel system. Continue pumping until the pump resistance increases.

- NOTICE:

- The maximum hand pump pumping speed is 2 strokes per second.

- The hand pump must be pushed with a full stroke during pumping.

- When the fuel pressure at the supply pump inlet port reaches a saturated pressure, the hand pump resistance increases.

- If pumping is interrupted during the air bleeding process, fuel in the fuel line may return to the fuel tank. Continue pumping until the hand pump resistance increases.

- If the hand pump resistance does not increase despite consecutively pumping 200 times or more, there may be a fuel leak between the fuel tank and fuel filter, the hand pump may be malfunctioning, or the vehicle may have run out of fuel.

- If air bleeding using the hand pump is incomplete, the common rail pressure does not rise to the pressure range necessary for normal use and the engine cannot be started.

|

Check if the engine starts.

- NOTICE:

- Even if air bleeding using the hand pump has been completed, the starter may need to be cranked for 10 seconds or more to start the engine.

- Do not crank the engine continuously for more than 20 seconds. The battery may be discharged.

- Use a fully-charged battery.

When the engine can be started, proceed to the next step.

If the engine cannot be started, bleed air again using the hand pump until the hand pump resistance increases (refer to the procedures above). Then start the engine.

Turn the engine switch off.

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON (IG) and turn the intelligent tester on.

Clear the DTCs (Click here).

Start the engine.*1

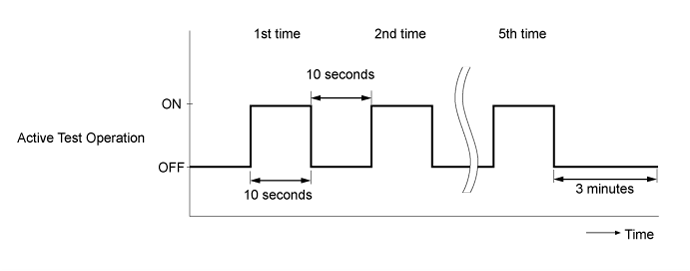

Enter the following menus: Powertrain / Engine and ECT / Active Test / Test the Fuel Leak.*2

|

Perform the following test 5 times with on/off intervals of 10 seconds: Active Test / Test the Fuel Leak.*3

Allow the engine to idle for 3 minutes or more after performing the Active Test for the 5th time.

- HINT:

- When the Active Test "Test the Fuel Leak" is used to change the pump control mode, the actual fuel pressure inside the common rail drops below the target fuel pressure when the Active Test is off, but this is normal and does not indicate a pump malfunction.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read Current DTCs.

Clear the DTCs (Click here).

- HINT:

- It is necessary to clear the DTCs as DTC P1604 or P1605 may be stored when air is bled from the fuel system after replacing or repairing fuel system parts.

Repeat steps *1 to *3.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read Current DTCs.

- OK:

- No DTCs are output.

| 120. ADD ENGINE COOLANT |

Remove the engine air bleed cap.

|

Connect a clear hose to the engine air bleed pipe.

|

Using a wrench, remove the vent plug.

|

Fill the radiator with TOYOTA SLLC to the radiator reservoir filler neck.

- HINT:

- Pour TOYOTA SLLC until it spills out of the engine air bleed pipe.

- Standard Capacity (for Automatic Transmission):

Item Specified Condition Front heater only 14.8 liters (15.6 US qts, 13.0 Imp. qts) Front heater and rear heater 17.6 liters (18.6 US qts, 15.5 Imp. qts) Front heater with viscous heater 15.2 liters (16.1 US qts, 13.4 Imp. qts) Front heater and rear heater with viscous heater 18.0 liters (19.0 US qts, 15.4 Imp. qts)

- Standard capacity (for Manual Transmission):

- 15.4 liters (16.3 US qts, 13.5 Imp. qts)

- NOTICE:

- Do not substitute plain water for engine coolant.

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

|

Install the vent plug.

- Torque:

- 2.0 N*m{20 kgf*cm, 18 in.*lbf}

- NOTICE:

- Do not tighten the plug to 5.0 N*m (51 kgf*cm, 44 in.*lbf) or more, as the plug will be damaged.

|

Disconnect the clear hose from the engine air bleed pipe.

|

Install the engine air bleed cap when coolant comes out.

|

Install the radiator reservoir cap.

Start the engine.

- NOTICE:

- Immediately after starting the engine, if the radiator reservoir does not have any coolant, perform the following: 1) stop the engine, 2) wait until the coolant has cooled down, and 3) add coolant until the coolant is filled to the FULL line.

Maintain an engine speed of 3000 rpm for approximately 10 minutes so that the thermostat opens and air bleeding is performed.

- CAUTION:

When pressing the radiator hoses:- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the radiator fan

- NOTICE:

- Pay attention to the needle of the water temperature meter. Make sure that the needle does not show an abnormally high temperature.

- If there is not enough coolant, the engine may burn out or overheat.

- HINT:

- The thermostat opening timing can be confirmed by pressing the No. 2 radiator hose by hand, and checking when the engine coolant starts to flow inside the hose.

Stop the engine, and wait until the engine coolant cools down to ambient temperature.

- CAUTION:

- Do not remove the radiator reservoir cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Check that the coolant level is between the FULL and LOW lines.

If the coolant level is above the FULL line, drain coolant so that the coolant level is between the FULL and LOW lines.

|

| 121. INSPECT FOR FUEL LEAK |

Perform Active Test.

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Start the engine.

Turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine and ECT / Active Test.

Perform the Active Test.

Tester Display Test Detail Control Range Diagnostic Note Test the Fuel Leak Pressurizes fuel inside common rail and checks for fuel leaks Stop/Start - The fuel inside the common rail is pressurized to the specified value and the engine speed increases to 2000 rpm when Start is selected.

- The above conditions are preserved while Start is selected.

- The fuel inside the common rail is pressurized to the specified value and the engine speed increases to 2000 rpm when Start is selected.

| 122. INSPECT FOR OIL LEAK |

Warm up the engine and check for an engine oil leak.

| 123. INSPECT FOR COOLANT LEAK |

- CAUTION:

- Do not remove the radiator reservoir cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Fill the radiator with coolant and attach a radiator cap tester to the radiator reservoir.

|

Warm up the engine.

Using the radiator cap tester, increase the pressure inside the radiator to 123 kPa (1.3 kgf/cm2, 17.8 psi), and check that the pressure does not drop.

If the pressure drops, check the hoses, radiator and water pump for leaks.

If no external leaks are found, check the cylinder block and cylinder head.

| 124. INSPECT FOR EXHAUST GAS LEAK |

| 125. CHARGE REFRIGERANT |

- SST

- 09985-20010(09985-02130,09985-02150,09985-02090,09985-02110,09985-02010,09985-02050,09985-02060,09985-02070)

Perform vacuum purging using a vacuum pump.

Charge refrigerant HFC-134a (R134a).

Standard: Condenser Core Thickness Air Conditioning Type Cool Box Refrigerant Charging Amount 22 mm (0.866 in.) w/o Rear Cooler w/ Cool Box 870 +/-50 g (30.7 +/-1.76 oz.) w/o Cool Box 870 +/-50 g (30.7 +/-1.76 oz.) w/ Rear Cooler w/ Cool Box 1010 +/-50 g (35.6 +/-1.76 oz.) w/o Cool Box 970 +/-50 g (34.2 +/-1.76 oz.) 16 mm (0.630 in.) w/o Rear Cooler w/ Cool Box 770 +/-50 g (27.2 +/-1.76 oz.) w/o Cool Box 770 +/-50 g (27.2 +/-1.76 oz.) w/ Rear Cooler w/ Cool Box 970 +/-50 g (34.2 +/-1.76 oz.) w/o Cool Box 920 +/-50 g (32.5 +/-1.76 oz.)

- NOTICE:

- Do not operate the cooler compressor before charging refrigerant as the cooler compressor will not work properly without any refrigerant, and will overheat.

- Approximately 100g (3.53 oz.) of refrigerant may need to be charged after bubbles disappear. The refrigerant amount should be checked by measuring its quantity, and not with the sight glass.

| 126. WARM UP ENGINE |

Warm up the engine at less than 1850 rpm for 2 minutes or more after charging the refrigerant.

- NOTICE:

- Be sure to warm up the compressor when turning the A/C switch is on after removing and installing the cooler refrigerant lines (including the compressor), to prevent damage to the compressor.

| 127. CHECK FOR REFRIGERANT GAS LEAK |

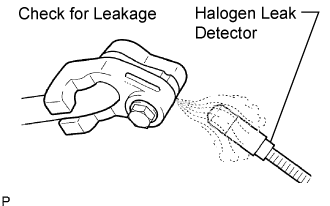

After recharging the refrigerant gas, check for refrigerant gas leakage using a halogen leak detector.

Perform the operation under these conditions:

- Stop the engine.

- Secure good ventilation (the halogen leak detector may react to volatile gases other than refrigerant, such as evaporated gasoline or exhaust gas).

- Repeat the test 2 or 3 times.

- Make sure that some refrigerant remains in the refrigeration system. When compressor is off: approximately 392 to 588 kPa (4.0 to 6.0 kgf/cm2, 57 to 85 psi).

- Stop the engine.

Using a halogen leak detector, check the refrigerant line for leakage.

|

If a gas leak is not detected on the drain hose, remove the blower motor control (blower resistor) from the cooling unit. Insert the halogen leak detector sensor into the unit and perform the test.

Disconnect the connector and wait for approximately 20 minutes. Bring the halogen leak detector close to the pressure switch and perform the test.

| 128. INSTALL FRONT FENDER APRON SEAL REAR LH |

Install the front fender apron seal rear LH with the 4 clips.

| 129. INSTALL FRONT FENDER APRON SEAL FRONT LH |

w/o KDSS:

Install the front fender apron seal front LH with the 4 clips.

w/ KDSS:

Install the front fender apron seal front LH with the 3 clips.

| 130. INSTALL FRONT FENDER APRON SEAL REAR RH |

Install the front fender apron seal rear RH with the 4 clips.

| 131. INSTALL FRONT FENDER APRON SEAL FRONT RH |

Install the front fender apron seal front RH with the 3 clips.

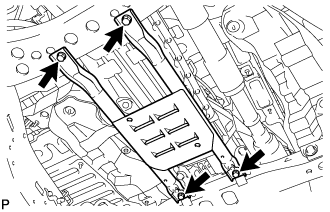

| 132. INSTALL OIL PAN PROTECTOR ASSEMBLY |

|

Install the oil pan protector with the 4 bolts.

- Torque:

- 63 N*m{642 kgf*cm, 46 ft.*lbf}

| 133. INSTALL NO. 2 ENGINE UNDER COVER |

Install the No. 2 engine under cover with the 2 bolts.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

| 134. INSTALL NO. 1 ENGINE UNDER COVER SUB-ASSEMBLY |

Install the No. 1 engine under cover with the 10 bolts.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

| 135. INSTALL FRONT FENDER SPLASH SHIELD SUB-ASSEMBLY RH |

Install the front fender splash shield RH with the clip, and then install the 3 bolts and 2 screws.

| 136. INSTALL FRONT FENDER SPLASH SHIELD SUB-ASSEMBLY LH |

Install the front fender splash shield LH with the clip, and then install the 3 bolts and screw.

| 137. INSTALL COWL TOP VENTILATOR LOUVER SUB-ASSEMBLY |

| 138. INSTALL HOOD SUB-ASSEMBLY |

Install the hood with the 4 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Install the 2 hood supports with the 2 bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

- NOTICE:

- As much as possible avoid touching the stroke portions of the rod to prevent foreign matter from attaching to it. Be sure to hold the cylinders while servicing.

- Do not wear cotton gloves or other similar materials when handling the rod. Fibers may attach to the rod and result in gas leaks.

- Do not apply any load to the cylinders in the horizontal direction in order to prevent the rod from being deformed.

- Install the hood support while supporting the hood by hand.

| 139. ADJUST HOOD SUB-ASSEMBLY |

| 140. INSPECT ENGINE OIL LEVEL |

Warm up the engine, stop the engine and wait 5 minutes. The engine oil level should be between the dipstick low level mark and full level mark.

If low, check for leakage and add oil up to the full level mark.- NOTICE:

- Do not fill engine oil above the full level mark.

- HINT:

- A certain amount of engine oil will be consumed while driving. In the following situations, oil consumption may increase, and engine oil may need to be refilled in between oil maintenance intervals.

- When the engine is new, for example directly after purchasing the vehicle or after replacing the engine.

- If low quality oil or oil of an inappropriate viscosity is used.

- When driving at high engine speed or with a heavy load, (when towing, or), when driving while accelerating or decelerating frequently.

- When leaving the idling for a long time, or when driving frequently through heavy traffic.

- When judging the amount of oil consumption, keep in mind that the oil may have become diluted, making it difficult to judge the true level accurately.

| 141. INSPECT ENGINE COOLANT LEVEL IN RESERVOIR |

|

Check that the engine coolant level is between the LOW and FULL lines when the engine is cold.

If the engine coolant is low, check for leaks and add "TOYOTA Super Long Life Coolant (SLLC)" or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite and non-borate coolant with long-life hybrid organic acid technology to the FULL line.- NOTICE:

- Do not substitute plain water for engine coolant.

| 142. INSPECT ENGINE IDLE SPEED |

- NOTICE:

- Turn all the electrical systems and the A/C off.

- When checking the idle speed, move the shift lever to neutral.

- HINT:

- For more information about the GTS, refer to its operator's manual.

- If an GTS is not available, use a tachometer tester probe as a substitute.

When using the GTS:

Warm up the engine.

Connect the GTS to the DLC3.

Enter the following menus:

Powertrain / Engine / Data List / Engine Speed.- HINT:

- Refer to the GTS operator's manual for help selecting the Data List.

Inspect the engine idle speed.

- Standard Idle Speed:

Item Specified Condition for Automatic Transmission 550 to 750 rpm for Manual Transmission 500 to 600 rpm

Disconnect the GTS from the DLC3.

When not using the GTS:

Warm up and stop the engine.

Connect a tester probe of a tachometer to terminal 9 (TAC) of the DLC3 with SST.

- SST

- 09843-18040

Text in Illustration *a Front view of DLC3 Inspect the engine idle speed.

- Standard Idle Speed:

Item Specified Condition for Automatic Transmission 550 to 750 rpm for Manual Transmission 500 to 600 rpm

Disconnect the tester probe from terminal 9 (TAC) of the DLC3.

| 143. INSPECT MAXIMUM ENGINE SPEED |

Start the engine.

Fully depress the accelerator pedal.

Check the maximum engine speed.

- Maximum engine speed:

- 4700 to 4900 rpm

| 144. INSTALL UPPER RADIATOR SUPPORT SEAL |

Install the upper radiator support seal with the 7 clips.

| 145. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY (w/ Intercooler) |

Install the engine cover with the 2 nuts.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

|

| 146. PERFORM CRANK TIME COMPENSATION RESET FUNCTION |