DESCRIPTION

MONITOR DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

INSPECT AIR FUEL RATIO SENSOR (HEATER RESISTANCE)

CHECK TERMINAL VOLTAGE (AIR FUEL RATIO SENSOR HEATER VOLTAGE)

CHECK HARNESS AND CONNECTOR (AIR FUEL RATIO SENSOR - ECM)

REPLACE ECM

CHECK HARNESS AND CONNECTOR (INTEGRATION RELAY - A/F SENSOR, BODY GROUND)

INSPECT INTEGRATION RELAY (EFI MAIN NO.2, A/F)

REPLACE AIR FUEL RATIO SENSOR

REPLACE INTEGRATION RELAY

REPAIR OR REPLACE HARNESS OR CONNECTOR

CHECK ECM POWER SOURCE CIRCUIT

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

DTC P0031 Oxygen (A/F) Sensor Heater Control Circuit Low (Bank 1 Sensor 1) |

DTC P0032 Oxygen (A/F) Sensor Heater Control Circuit High (Bank 1 Sensor 1) |

DTC P0051 Oxygen (A/F) Sensor Heater Control Circuit Low (Bank 2 Sensor 1) |

DTC P0052 Oxygen (A/F) Sensor Heater Control Circuit High (Bank 2 Sensor 1) |

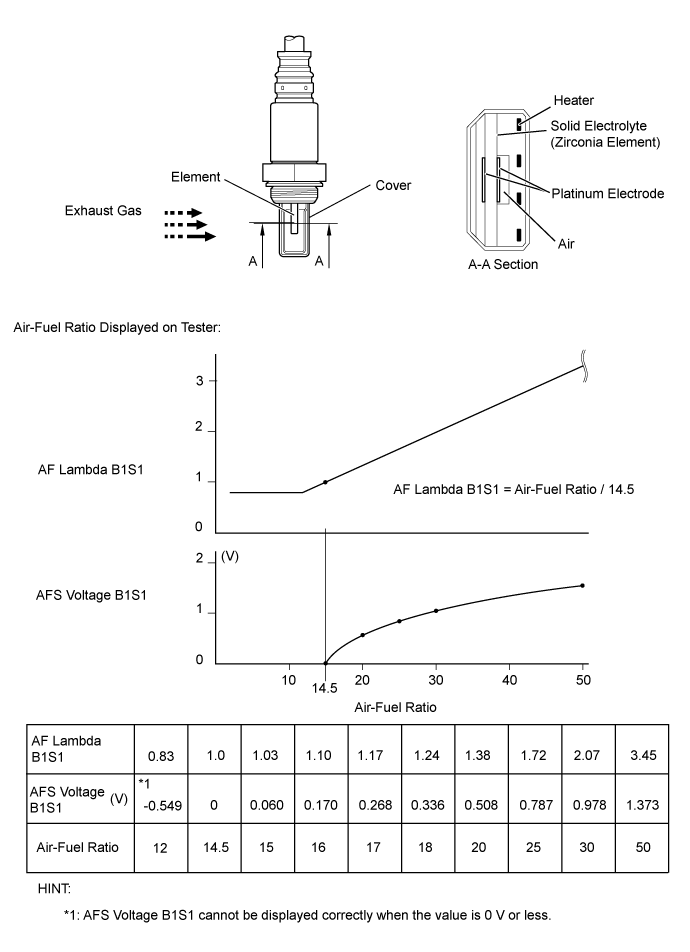

DESCRIPTION

- HINT:

- For more information on the air fuel ratio sensor and Diesel Particulate Filter (DPF), refer to the following procedures (Click here).

- These DTCs are related to the air fuel ratio sensor, although the titles say oxygen sensor.

The air fuel ratio sensor outputs a voltage* that is proportional to the air-fuel ratio. The air fuel ratio sensor output voltage is used to control the A/F mixture.The air fuel ratio sensor is located after the Diesel Particulate Filter (DPF) catalytic converter. This sensor has been developed based on the structure and technology of the air fuel ratio sensor that is used for gasoline engines. The cover for the sensor electrode has been modified to suit its application in a diesel engine. This change allows the sensor to function effectively in this DPF type diesel engine, and it also avoids problems with sensor temperature and particulate matter (PM).In order to reduce PM, the ECM adjusts the air-fuel ratio to a value slightly richer than that which would otherwise be used (note that this mixture is still leaner than the stoichiometric air fuel ratio). The ECM controls these adjustments on signals from the air fuel ratio sensor.When the ECM performs PM forced regeneration (cleaning) by adding fuel using the exhaust fuel addition injector assembly, the air fuel ratio sensor feedback is used to ensure that an appropriate air fuel ratio is maintained.*: This voltage change occurs only inside the ECM. It is not possible to measure this voltage at the sensor. The GTS can be used to monitor this voltage.- HINT:

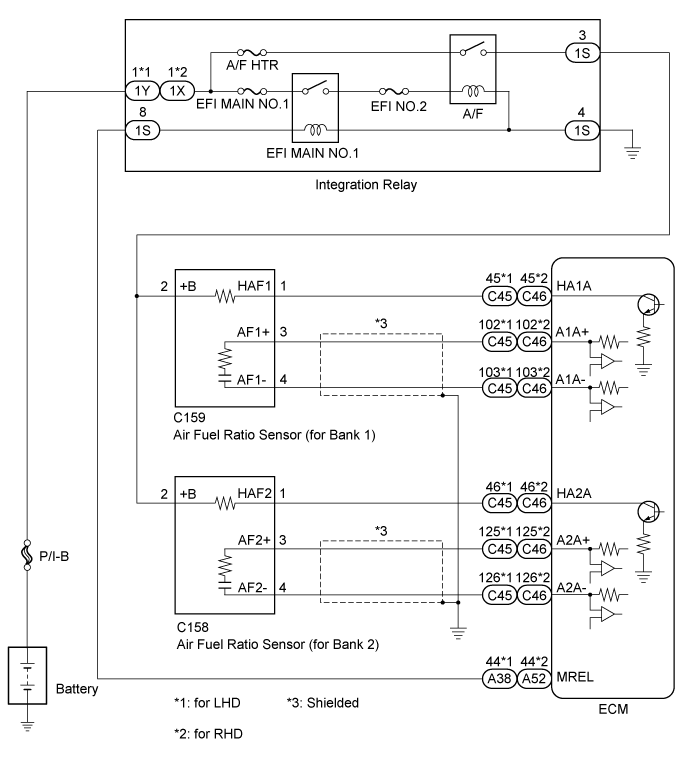

- The ECM provides a pulse width modulated control circuit to adjust current through the heater. The air fuel ratio sensor heater circuit uses a relay on the +B side of the circuit.

P0031 (Bank 1), P0051 (Bank 2)DTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

- Drive the vehicle at 50 km/h (30 mph) or more for a total of 300 seconds or more.

- Check that "Exhaust Temperature B1S1" displays 200°C (392°F) or higher using the GTS.

| Air fuel ratio sensor heater current is 0.8 A or less when the heater operates for 4 seconds.

(1 trip detection logic)

| - Open in air fuel ratio sensor heater circuit

- air fuel ratio sensor heater

- A/F relay

- ECM

|

P0032 (Bank 1), P0052 (Bank 2)DTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

Ignition switch ON for 5 seconds

| Either condition is met (1 trip detection logic):

- Air fuel ratio sensor heater current reaches the high limit (overcurrent is detected even though the air fuel ratio sensor heater is off)

- Air fuel ratio sensor heater current is 0.8 A or more when the heater does not operate for 4 seconds.

| - Short in air fuel ratio sensor heater circuit

- Air fuel ratio sensor heater

- ECM

|

Related Data ListDTC No.

| Data List

|

P0031

P0032

| - AFS Voltage B1S1

- AF Lambda B1S1

- Exhaust Temperature B1S1

|

P0052

P0053

| - AFS Voltage B2S1

- AF Lambda B2S1

- Exhaust Temperature B2S1

|

MONITOR DESCRIPTION

The inner surface of the air fuel ratio sensor element is exposed to outside air. The outer surface of the sensor element is exposed to exhaust gases. The sensor element is made of platinum coated zirconia and includes an integrated heating element. The zirconia element generates a small voltage when there is a large difference in the oxygen concentrations of the exhaust and the outside air. The platinum coating amplifies the voltage generation. When heated, the sensor becomes very efficient. If the temperature of the exhaust is low, without supplemental heating, the sensor will not generate useful voltage signals. The ECM controls the heating by using a duty-cycle to regulate the average current in the heater element. If the heater current is out of the normal range, the output signals of the sensor are inaccurate and the ECM cannot regulate the air-fuel ratio properly. When the heater current is out of the normal operating range, the ECM interprets this as a malfunction and stores a DTC.

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses of circuits related to this system before performing the following inspection procedure.

- After replacing the ECM, the new ECM needs registration (Click here) and initialization (Click here).

- After replacing the fuel supply pump assembly, the ECM needs initialization (Click here).

- After replacing an injector assembly, the ECM needs registration (Click here).

- HINT:

- Read freeze frame data using the GTS. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

| 1.INSPECT AIR FUEL RATIO SENSOR (HEATER RESISTANCE) |

Inspect the air fuel ratio sensor (for bank 1 or bank 2) (Click here).

| 2.CHECK TERMINAL VOLTAGE (AIR FUEL RATIO SENSOR HEATER VOLTAGE) |

Disconnect the air fuel ratio sensor connector.

Turn the ignition switch to ON.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

C159-2 (+B) - Body ground

| Ignition switch ON

| 11 to 14 V

|

C158-2 (+B) - Body ground

| Ignition switch ON

| 11 to 14 V

|

Text in Illustration*A

| for Bank 1

|

*B

| for Bank 2

|

*a

| Front view of wire harness connector

(to Air Fuel Ratio Sensor)

|

| 3.CHECK HARNESS AND CONNECTOR (AIR FUEL RATIO SENSOR - ECM) |

Disconnect the air fuel ratio sensor connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

for LHDTester Connection

| Condition

| Specified Condition

|

C159-1 (HAF1) - C45-45 (HA1A)

| Always

| Below 1 Ω

|

C158-1 (HAF2) - C45-46 (HA2A)

| Always

| Below 1 Ω

|

C159-1 (HAF1) or C45-45 (HA1A) - Body ground

| Always

| 10 kΩ or higher

|

C158-1 (HAF2) or C45-46 (HA2A) - Body ground

| Always

| 10 kΩ or higher

|

for RHDTester Connection

| Condition

| Specified Condition

|

C159-1 (HAF1) - C46-45 (HA1A)

| Always

| Below 1 Ω

|

C158-1 (HAF2) - C46-46 (HA2A)

| Always

| Below 1 Ω

|

C159-1 (HAF1) or C46-45 (HA1A) - Body ground

| Always

| 10 kΩ or higher

|

C158-1 (HAF2) or C46-46 (HA2A) - Body ground

| Always

| 10 kΩ or higher

|

Replace the ECM (Click here).

| 5.CHECK HARNESS AND CONNECTOR (INTEGRATION RELAY - A/F SENSOR, BODY GROUND) |

Disconnect the air fuel ratio sensor connector.

Remove the integration relay from the engine room relay block and junction block assembly.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

C159-2 (+B) - 1S-3

| Always

| Below 1 Ω

|

C158-2 (+B) - 1S-3

| Always

| Below 1 Ω

|

C159-2 (+B) or 1S-3 - Body ground

| Always

| 10 kΩ or higher

|

C158-2 (+B) or 1S-3 - Body ground

| Always

| 10 kΩ or higher

|

| 6.INSPECT INTEGRATION RELAY (EFI MAIN NO.2, A/F) |

Inspect the integration relay (EFI MAIN NO.2, A/F) (Click here).

| 7.REPLACE AIR FUEL RATIO SENSOR |

When DTC P0031 or P0032 is output:- Replace the air fuel ratio sensor (for bank 1) (Click here).

When DTC P0051 or P0052 is output:- Replace the air fuel ratio sensor (for bank 2) (Click here).

| 8.REPLACE INTEGRATION RELAY |

Replace the integration relay (EFI MAIN NO.2, A/F).

| 9.REPAIR OR REPLACE HARNESS OR CONNECTOR |

Repair or replace harness or connector.

| 10.CHECK ECM POWER SOURCE CIRCUIT |

Check the ECM power source circuit (Click here).

| 11.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Connect the GTS to the DLC3.

Clear the DTCs (Click here).

Turn the ignition switch off for 30 seconds or more.

Turn the ignition switch to ON.

Turn the GTS on.

Drive the vehicle at 50 km/h (30 mph) or more for a total of 300 seconds or more.

- HINT:

- "Exhaust Temperature B1S1" and "Exhaust Temperature B2S1" on the GTS screen should be 200°C (392°F) or higher.

Confirm that the DTC is not output again.

- HINT:

- Perform the following procedure using the GTS to determine whether or not the DTC judgment has been carried out.

Enter the following menus: Engine and ECT / Utility / All Readiness.

Input DTC P0031, P0032, P0052 or P0053.

Check that STATUS is NORMAL.

- HINT:

- If STATUS is NORMAL, DTC judgment is complete and the system is determined to be normal.

- If STATUS is INCOMPLETE or N/A, DTC judgment is incomplete. Drive the vehicle at 50 km/h (30 mph) or more for a total of 300 seconds or more again.