DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK HARNESS AND CONNECTOR (INTEGRATION RELAY - BATTERY)

INSPECT INTEGRATION RELAY (EFI MAIN NO.1 RELAY AND IG2 MAIN NO.1 RELAY)

CHECK HARNESS AND CONNECTOR (+B, +B2 AND MREL CIRCUIT)

CHECK HARNESS AND CONNECTOR (ECM - BODY GROUND)

INSPECT ECM (IGSW VOLTAGE)

CHECK HARNESS AND CONNECTOR (INTEGRATION RELAY - ECM, INTEGRATION RELAY - BODY GROUND)

CHECK IF VEHICLE IS EQUIPPED WITH ENTRY AND START SYSTEM

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - ENGINE ROOM RELAY BLOCK

CHECK ENTRY AND START SYSTEM (POWER SOURCE MODE DOES NOT CHANGE)

CHECK HARNESS AND CONNECTOR (IGNITION SWITCH - ENGINE ROOM RELAY BLOCK)

INSPECT IGNITION SWITCH ASSEMBLY

SFI SYSTEM - ECM Power Source Circuit |

DESCRIPTION

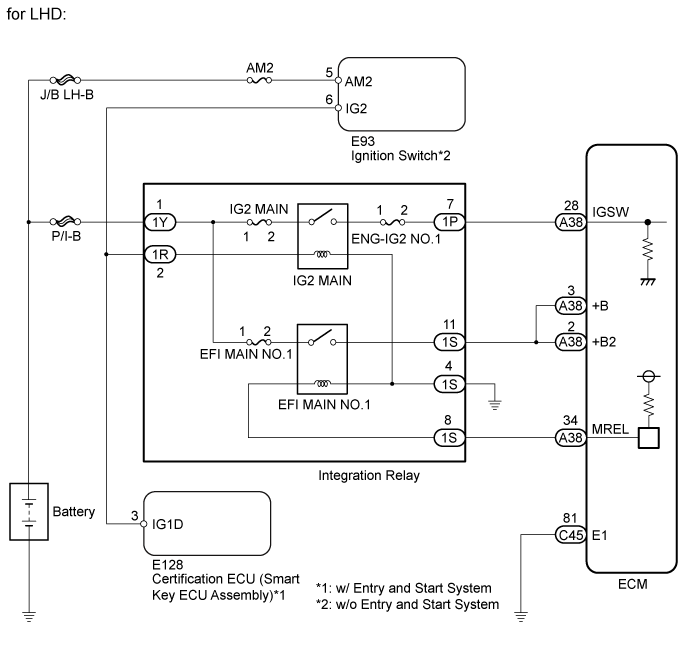

When the ignition switch is turned to ON, battery voltage is applied to the IGSW of the ECM. The output signal from the MREL terminal of the ECM causes a current to flow to the coil, closing the contacts of the integration relay (EFI relay) and supplying power to either terminal +B or +B2 of the ECM.

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

| 1.CHECK HARNESS AND CONNECTOR (INTEGRATION RELAY - BATTERY) |

Remove the integration relay from the engine room relay block.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

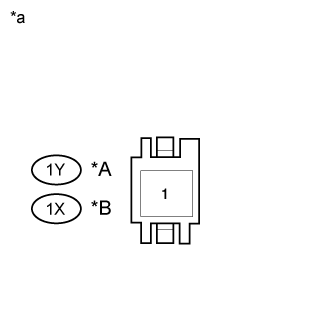

for LHD:Tester Connection

| Condition

| Specified Condition

|

1Y-1 - Body ground

| Always

| 11 to 14 V

|

for RHD:Tester Connection

| Condition

| Specified Condition

|

1X-1 - Body ground

| Always

| 11 to 14 V

|

Text in Illustration*A

| for LHD:

|

*B

| for RHD:

|

*a

| Front view of wire harness connector (to Integration Relay)

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 2.INSPECT INTEGRATION RELAY (EFI MAIN NO.1 RELAY AND IG2 MAIN NO.1 RELAY) |

Inspect the integration relay (Click here).

| | REPLACE INTEGRATION RELAY |

|

|

| 3.CHECK HARNESS AND CONNECTOR (+B, +B2 AND MREL CIRCUIT) |

Check the harness and the connectors between the integration relay and the ECM.

Remove the integration relay from the engine room relay block.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

for LHDTester Connection

| Condition

| Specified Condition

|

A38-34 (MREL) - 1S-8

| Always

| Below 1 Ω

|

A38-3 (+B) - 1S-11

| Always

| Below 1 Ω

|

A38-2 (+B2) - 1S-11

| Always

| Below 1 Ω

|

A38-34 (MREL) or 1S-8 - Body ground

| Always

| 10 kΩ or higher

|

A38-3 (+B) or 1S-11 - Body ground

| Always

| 10 kΩ or higher

|

A38-2 (+B2) or 1S-11 - Body ground

| Always

| 10 kΩ or higher

|

for RHDTester Connection

| Condition

| Specified Condition

|

A52-34 (MREL) - 1S-8

| Always

| Below 1 Ω

|

A52-3 (+B) - 1S-11

| Always

| Below 1 Ω

|

A52-2 (+B2) - 1S-11

| Always

| Below 1 Ω

|

A52-34 (MREL) or 1S-8 - Body ground

| Always

| 10 kΩ or higher

|

A52-3 (+B) or 1S-11 - Body ground

| Always

| 10 kΩ or higher

|

A52-2 (+B2) or 1S-11 - Body ground

| Always

| 10 kΩ or higher

|

Check the harness and connectors between the integration relay and body ground.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

1S-4 - Body ground

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 4.CHECK HARNESS AND CONNECTOR (ECM - BODY GROUND) |

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

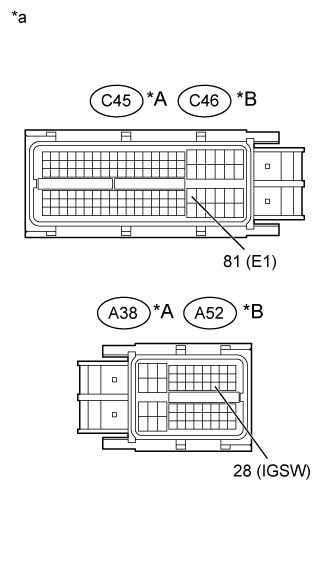

for LHDTester Connection

| Condition

| Specified Condition

|

C45-81 (E1) - Body ground

| Always

| Below 1 Ω

|

for RHDTester Connection

| Condition

| Specified Condition

|

C46-81 (E1) - Body ground

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 5.INSPECT ECM (IGSW VOLTAGE) |

Disconnect the ECM connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

for LHDTester Connection

| Switch Condition

| Specified Condition

|

A38-28 (IGSW) - C45-81 (E1)

| Ignition switch ON

| 11 to 14 V

|

for RHDTester Connection

| Switch Condition

| Specified Condition

|

A52-28 (IGSW) - C46-81 (E1)

| Ignition switch ON

| 11 to 14 V

|

Text in Illustration*A

| for LHD

|

*B

| for RHD

|

*a

| Front view of wire harness connector (to ECM)

|

| 6.CHECK HARNESS AND CONNECTOR (INTEGRATION RELAY - ECM, INTEGRATION RELAY - BODY GROUND) |

Remove the integration relay from the engine room relay block.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

for LHDTester Connection

| Condition

| Specified Condition

|

1P-7 - A38-28 (IGSW)

| Always

| Below 1 Ω

|

1P-7 or A38-28 (IGSW) - Body ground

| Always

| 10 kΩ or higher

|

for RHDTester Connection

| Condition

| Specified Condition

|

1P-7 - A52-28 (IGSW)

| Always

| Below 1 Ω

|

1P-7 or A52-28 (IGSW) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 7.CHECK IF VEHICLE IS EQUIPPED WITH ENTRY AND START SYSTEM |

ResultResult

| Proceed to

|

w/ Entry and Start System

| A

|

w/o Entry and Start System

| B

|

| 8.CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - ENGINE ROOM RELAY BLOCK |

Remove the integration relay from the engine room relay block.

Disconnect the certification ECU (smart key ECU assembly) connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

E128-3 (IG1D) - 1R-2

| Always

| Below 1 Ω

|

1S-4 - Body ground

| Always

| Below 1 Ω

|

E2-11 (IG2D) or 1R-2 - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 9.CHECK ENTRY AND START SYSTEM (POWER SOURCE MODE DOES NOT CHANGE) |

Check the entry and start system (Click here).

| 10.CHECK HARNESS AND CONNECTOR (IGNITION SWITCH - ENGINE ROOM RELAY BLOCK) |

Remove the integration relay from the engine room relay block.

Disconnect the ignition switch connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

E93-6 (IG2) - 1R-2

| Always

| Below 1 Ω

|

1S-4 - Body ground

| Always

| Below 1 Ω

|

E93-6 (IG2) or 1R-2 - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 11.INSPECT IGNITION SWITCH ASSEMBLY |

Inspect the ignition switch assembly (Click here).

| OK |

|

|

|

| REPAIR OR REPLACE HARNESS OR CONNECTOR (IGNITION SWITCH - BATTERY) |

|