Rear Differential Carrier Oil Seal Replacement

Drivetrain. Hilux. Tgn26, 36 Kun25, 26, 35, 36 Ggn25

REMOVE REAR PROPELLER SHAFT ASSEMBLY

REMOVE REAR DRIVE PINION NUT

REMOVE REAR DRIVE PINION COMPANION FLANGE SUB-ASSEMBLY WITH DUST DEFLECTOR

REMOVE REAR DIFFERENTIAL CARRIER OIL SEAL

REMOVE REAR DIFFERENTIAL DRIVE PINION OIL SLINGER

REMOVE REAR DRIVE PINION FRONT TAPERED ROLLER BEARING

REMOVE DIFFERENTIAL OIL STORAGE RING

REMOVE REAR DIFFERENTIAL DRIVE PINION BEARING SPACER

INSTALL REAR DIFFERENTIAL DRIVE PINION BEARING SPACER

INSTALL DIFFERENTIAL OIL STORAGE RING

INSTALL REAR DRIVE PINION FRONT TAPERED ROLLER BEARING

INSTALL REAR DIFFERENTIAL DRIVE PINION OIL SLINGER

INSTALL REAR DIFFERENTIAL CARRIER OIL SEAL

INSTALL REAR DRIVE PINION COMPANION FLANGE SUB-ASSEMBLY WITH DUST DEFLECTOR

INSPECT DIFFERENTIAL DRIVE PINION PRELOAD

INSPECT TOTAL PRELOAD

STAKE DRIVE PINION NUT

INSTALL REAR PROPELLER SHAFT ASSEMBLY

ADD DIFFERENTIAL OIL

Rear Differential Carrier Oil Seal -- Replacement |

| 1. REMOVE REAR PROPELLER SHAFT ASSEMBLY |

(HILUX_TGN26 RM000000ZZ301QX.html)

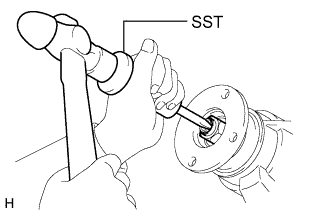

| 2. REMOVE REAR DRIVE PINION NUT |

Using SST and a hammer, loosen the staked part of the nut.

- SST

- 09930-00010(09931-00010,09931-00020)

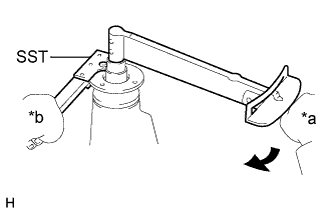

Using SST to hold the companion flange in place, remove the nut.

- SST

- 09330-00021(09330-00030)

Text in Illustration*a

| Turn

|

*b

| Hold

|

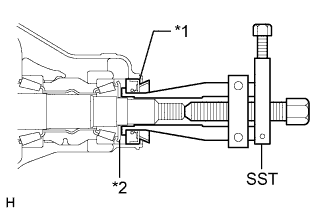

| 3. REMOVE REAR DRIVE PINION COMPANION FLANGE SUB-ASSEMBLY WITH DUST DEFLECTOR |

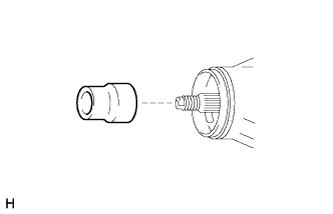

Using SST, remove the companion flange with dust deflector.

- SST

- 09950-30012(09951-03010,09953-03010,09954-03010,09955-03030,09956-03040)

- NOTICE:

- Before using SST (center bolt), apply hypoid gear oil to its threads and tip.

| 4. REMOVE REAR DIFFERENTIAL CARRIER OIL SEAL |

Using SST, remove the oil seal.

- SST

- 09308-10010

Text in Illustration*1

| Oil Seal

|

*2

| Oil Slinger

|

| 5. REMOVE REAR DIFFERENTIAL DRIVE PINION OIL SLINGER |

Remove the oil slinger from the drive pinion.

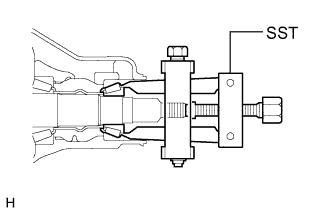

| 6. REMOVE REAR DRIVE PINION FRONT TAPERED ROLLER BEARING |

Using SST, remove the roller bearing (inner).

- SST

- 09556-22010

Using SST, tap out the roller bearing (outer).

- SST

- 09308-00010

| 7. REMOVE DIFFERENTIAL OIL STORAGE RING |

Using a screwdriver and hammer, tap out the oil storage ring.

| 8. REMOVE REAR DIFFERENTIAL DRIVE PINION BEARING SPACER |

Remove the bearing spacer from the drive pinion.

| 9. INSTALL REAR DIFFERENTIAL DRIVE PINION BEARING SPACER |

Install a new bearing spacer.

- HINT:

- Make sure the spacer is installed correctly.

| 10. INSTALL DIFFERENTIAL OIL STORAGE RING |

Using a brass bar and hammer, tap in a new oil storage ring.

- NOTICE:

- Be careful not to damage the oil storage ring.

| 11. INSTALL REAR DRIVE PINION FRONT TAPERED ROLLER BEARING |

Using SST and a hammer, tap in the roller bearing (outer).

- SST

- 09316-60011(09316-00011,09316-00021)

Install the roller bearing (inner).

| 12. INSTALL REAR DIFFERENTIAL DRIVE PINION OIL SLINGER |

Install the oil slinger to the drive pinion.

| 13. INSTALL REAR DIFFERENTIAL CARRIER OIL SEAL |

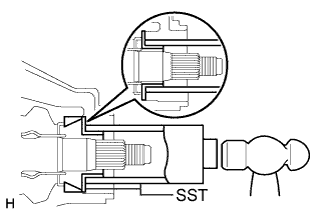

Using SST and a hammer, tap in a new oil seal.

- SST

- 09554-30011

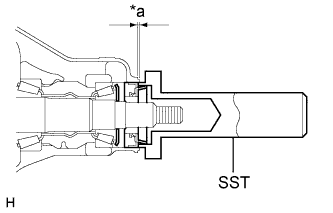

Text in Illustration*a

| Oil Seal Depth

|

- Standard oil seal depth:

- 0 +/-0.3mm (0 +/-0.0118in.)

Apply MP grease to the lip of the oil seal.

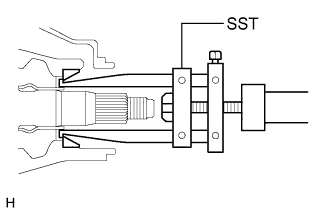

| 14. INSTALL REAR DRIVE PINION COMPANION FLANGE SUB-ASSEMBLY WITH DUST DEFLECTOR |

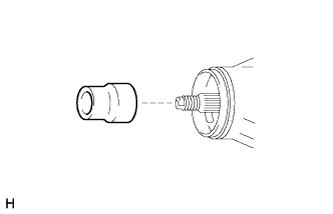

Using SST, install the companion flange with dust deflector.

- SST

- 09950-30012(09951-03010,09953-03010,09954-03010,09955-03030,09956-03040)

- NOTICE:

- Before using SST (center bolt), apply hypoid gear oil to its threads and tip.

Apply hypoid gear oil LSD to drive pinion thread and nut seat face.

Using SST to hold the companion flange in place, install a new nut.

- SST

- 09330-00021(09330-00030)

Text in Illustration*a

| Turn

|

*b

| Hold

|

- Torque:

- 370 N*m{3773 kgf*cm, 273 ft.*lbf}or less

| 15. INSPECT DIFFERENTIAL DRIVE PINION PRELOAD |

Using a torque wrench, measure the preload.

- Standard Preload (Starting Torque):

Item

| Specified Condition

|

New bearing

| 1.1 to 1.6 N*m (12 to 16 kgf*cm, 10 to 14 in.*lbf)

|

Reused bearing

| 0.6 to 0.8 N*m (7 to 8 kgf*cm, 6 to 7 in.*lbf)

|

- If the result is not as specified, adjust the preload.

| 16. INSPECT TOTAL PRELOAD |

Using a torque wrench, measure the preload with the teeth of the drive pinion and ring gear in contact.

- Standard Total Preload:

Bearing

| Specified Condition

|

New

| 0.4 to 0.5 N*m (4 to 6 kgf*cm, 4 to 5 in.*lbf) + drive pinion preload

|

Reused

| 0.4 to 0.5 N*m (4 to 6 kgf*cm, 4 to 5 in.*lbf) + drive pinion preload

|

If the result is not as specified, adjust the preload.

| 17. STAKE DRIVE PINION NUT |

Using a chisel and hammer, stake the nut.

| 18. INSTALL REAR PROPELLER SHAFT ASSEMBLY |

(HILUX_TGN26 RM000000ZZ101RX.html)

|

Add differential oil so that the oil level is within 5 mm (0 to 0.196 in.) from the bottom lip of the differential filler plug hole.

Text in Illustration*a

| 0 to 5 mm (0 to 0.196 in.)

|

- NOTICE:

- After changing the oil, drive the vehicle, and then check the oil level again.

- Too much or too little oil will lead to differential problems.

If necessary, fill the differential carrier with hypoid gear oil.

- Recommended Viscosity:

Item

| Temperature

| Viscosity

|

Front Differential (w/ A.D.D.)

| SAE 75W-90

|

Front Differential (w/o A.D.D.)

Rear Differential

| Above -18°C (0°F)

| SAE 90

|

Below -18°C (0°F)

| SAE 80W-90 or SAE 80W

|

- Differential Oil Type:

Item

| Oil type

|

Front Differential

Rear Differential

| Hypoid gear oil API GL-5 or equivalent

|

Rear Differential (for LSD)

| Hypoid gear oil LSD API GL-5 or equivalent

|

- Standard Front Differential Oil Capacity:

Item

| Capacity

|

w/o A.D.D.

| 1.40 to 1.50 liters (1.48 to 1.58 US qts., 1.23 to 1.32 Imp. qts.)

|

w/ A.D.D.

| 1.60 to 1.70 liters (1.69 to 1.79 US qts., 1.41 to 1.49 Imp. qts.)

|

- Standard Rear Differential Oil Capacity:

Item

| Capacity

|

for LSD

4WD and Pre-runner

for DANA Made

| 3.30 to 3.40 liters (3.49 to 3.59 US qts., 2.91 to 2.99 Imp. qts.)

|

Check for oil leakage when the oil level is low.

Install a new gasket and the differential filler plug.

- Torque:

- for front differential:

- 39 N*m{400 kgf*cm, 29 ft.*lbf}

- for rear differential:

- 49 N*m{500 kgf*cm, 36 ft.*lbf}