Front Drive Shaft Assembly -- Installation |

- HINT:

- Use the same procedure for the RH and LH sides.

- The procedure listed below is for the LH side.

| 1. INSTALL FRONT DRIVE SHAFT HOLE SNAP RING |

Install a new hole snap ring.

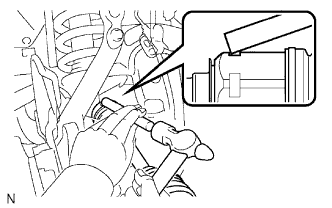

| 2. INSTALL FRONT DRIVE SHAFT ASSEMBLY LH |

|

Coat the splines of the inboard joint with differential oil.

Align the splines and tap in the drive shaft with a brass bar and hammer.

- HINT:

- Whether or not the inboard joint shaft is in contact with the pinion shaft can be determined from the sound and feeling when tapping in the shaft.

- NOTICE:

- Make sure that the snap ring opening is facing downwards when installing the drive shaft.

- Be careful not to damage the oil seal, boot or dust cover.

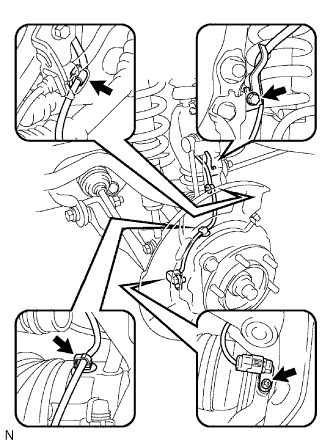

| 3. CONNECT FRONT SPEED SENSOR (w/ ABS) |

|

Install the speed sensor with the bolt.

- Torque:

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

Connect the 2 clamps.

Install the speed sensor wire harness to the steering knuckle with the bolt.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf}

| 4. CONNECT FRONT LOWER SUSPENSION ARM ASSEMBLY LH |

|

Connect the suspension arm with the 2 bolts.

- Torque:

- 160 N*m{1632 kgf*cm, 118 ft.*lbf}

| 5. CONNECT TIE ROD END SUB-ASSEMBLY LH |

Connect the tie rod end to the steering knuckle arm with the nut.

- Torque:

- 91 N*m{928 kgf*cm, 67 ft.*lbf}

Install a new cotter pin.

- NOTICE:

- If the holes for the cotter pin are not aligned, tighten the nut an additional 60°.

| 6. INSTALL FRONT AXLE SHAFT NUT |

|

Clean the threaded parts on the drive shaft and axle shaft nut using a non-residue solvent.

Install the shaft nut.

- Torque:

- 235 N*m{2396 kgf*cm, 173 ft.*lbf}

Install the adjusting cap and a new cotter pin.

- NOTICE:

- If the holes for the cotter pin are not aligned, tighten the nut an additional 60°.

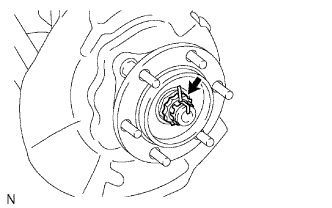

| 7. INSTALL FRONT AXLE HUB GREASE CAP |

Install a new grease cap to the axle hub.

| 8. INSTALL FRONT WHEEL |

- Torque:

- 105 N*m{1071 kgf*cm, 77 ft.*lbf}

| 9. ADD DIFFERENTIAL OIL |

Add differential oil so that the oil level is within 5 mm (0 to 0.196 in.) from the bottom lip of the differential filler plug hole.

Text in Illustration *a 0 to 5 mm (0 to 0.196 in.) - NOTICE:

- After changing the oil, drive the vehicle, and then check the oil level again.

- Too much or too little oil will lead to differential problems.

- Recommended Viscosity:

Item Temperature Viscosity Front Differential (w/ A.D.D.) SAE 75W-90 Front Differential (w/o A.D.D.)

Rear DifferentialAbove -18°C (0°F) SAE 90 Below -18°C (0°F) SAE 80W-90 or SAE 80W

- Differential Oil Type:

Item Oil type Front Differential

Rear DifferentialHypoid gear oil API GL-5 or equivalent Rear Differential (for LSD) Hypoid gear oil LSD API GL-5 or equivalent

- Standard Front Differential Oil Capacity:

Item Capacity w/o A.D.D. 1.40 to 1.50 liters (1.48 to 1.58 US qts., 1.23 to 1.32 Imp. qts.) w/ A.D.D. 1.60 to 1.70 liters (1.69 to 1.79 US qts., 1.41 to 1.49 Imp. qts.)

- Standard Rear Differential Oil Capacity:

Item Capacity for LSD

4WD and Pre-runner

for DANA Made3.30 to 3.40 liters (3.49 to 3.59 US qts., 2.91 to 2.99 Imp. qts.)

|

Check for oil leakage when the oil level is low.

Install a new gasket and the differential filler plug.

- Torque:

- for front differential:

- 39 N*m{400 kgf*cm, 29 ft.*lbf}

- for rear differential:

- 49 N*m{500 kgf*cm, 36 ft.*lbf}

| 10. INSTALL NO. 2 ENGINE UNDER COVER |

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

| 11. INSTALL NO. 1 ENGINE UNDER COVER |

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

| 12. CHECK ABS SPEED SENSOR SIGNAL (w/ ABS) |

w/ VSC:

(HILUX_TGN26 RM000000XHT091X.html)

w/o VSC:

(HILUX_TGN26 RM000000XHT0BEX.html)