Manual Transmission Unit Disassembly

Drivetrain. Hilux. Tgn26, 36 Kun25, 26, 35, 36 Ggn25

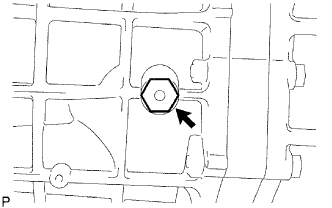

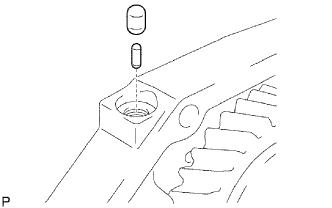

REMOVE FILLER PLUG

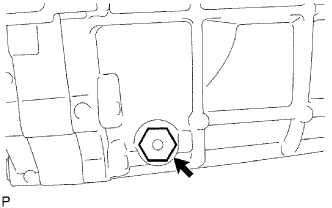

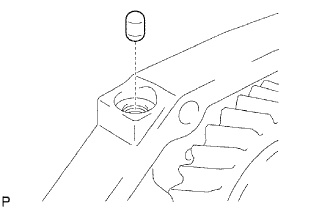

REMOVE DRAIN PLUG

REMOVE CLUTCH RELEASE FORK BOOT

REMOVE CLUTCH RELEASE BEARING ASSEMBLY

REMOVE RELEASE FORK SUPPORT

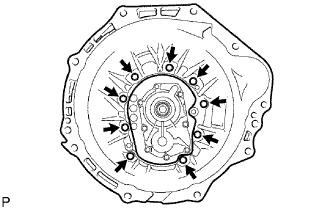

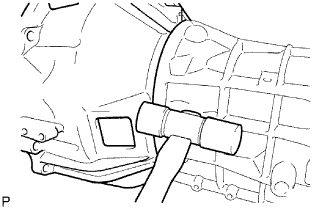

REMOVE CLUTCH HOUSING

REMOVE BACK-UP LIGHT SWITCH ASSEMBLY

REMOVE RESTRICT PIN

REMOVE CONTROL SHIFT LEVER RETAINER

REMOVE TRANSFER CONTROL SHIFT LEVER RETAINER

REMOVE SHIFT AND SELECT LEVER SHAFT

REMOVE TRANSFER ADAPTER

REMOVE OIL RECEIVER PIPE

REMOVE REVERSE RESTRICT PIN

REMOVE TRANSFER ADAPTER OIL SEAL

REMOVE FRONT BEARING RETAINER

REMOVE TRANSMISSION FRONT BEARING RETAINER OIL SEAL

REMOVE FRONT BEARING SHAFT SNAP RING

REMOVE NO. 1 COUNTER GEAR FRONT BEARING SNAP RING

REMOVE MANUAL TRANSMISSION CASE

REMOVE TRANSMISSION MAGNET

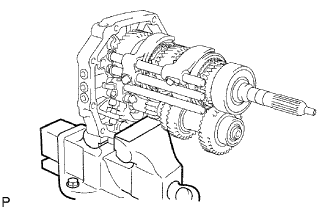

SECURE INTERMEDIATE PLATE

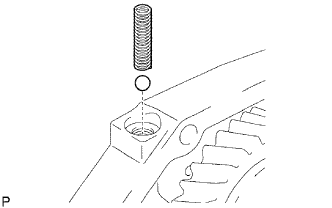

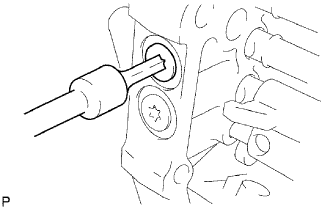

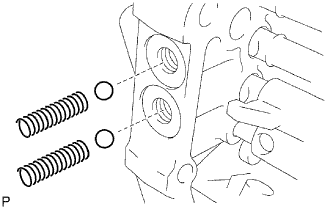

REMOVE NO. 1 SHIFT DETENT BALL SPRING SEAT

REMOVE NO. 2 SHIFT FORK SHAFT

REMOVE NO. 1 SHIFT FORK SHAFT

REMOVE NO. 3 SHIFT FORK SHAFT

REMOVE NO. 4 SHIFT FORK SHAFT

REMOVE REVERSE SHIFT FORK

REMOVE REVERSE SHIFT ARM BRACKET

REMOVE OUTPUT SHAFT BEARING SHAFT SNAP RING

REMOVE OUTPUT SHAFT REAR BEARING

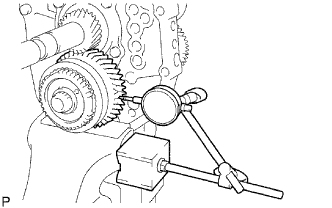

INSPECT COUNTER 5TH GEAR THRUST CLEARANCE

INSPECT COUNTER 5TH GEAR RADIAL CLEARANCE

REMOVE COUNTER GEAR REAR SHAFT SNAP RING

REMOVE NO. 3 TRANSMISSION HUB SLEEVE

REMOVE COUNTER 5TH GEAR

REMOVE NO. 5 GEAR SPLINE PIECE

REMOVE NO. 3 SYNCHRONIZER RING

REMOVE COUNTER 5TH GEAR BEARING

REMOVE NO. 3 TRANSMISSION HUB SLEEVE

REMOVE 5TH GEAR THRUST WASHER

REMOVE 5TH GEAR THRUST WASHER PIN

REMOVE REAR BEARING RETAINER

REMOVE REVERSE IDLER GEAR

REMOVE COUNTER SHAFT CENTER BEARING

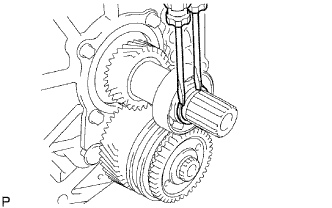

REMOVE COUNTER GEAR

REMOVE INPUT SHAFT ASSEMBLY

REMOVE OUTPUT SHAFT BEARING SHAFT SNAP RING

REMOVE OUTPUT SHAFT ASSEMBLY

INSPECT NO. 3 SYNCHRONIZER RING

INSPECT NO. 3 TRANSMISSION HUB SLEEVE

INSPECT COUNTER 5TH GEAR

INSPECT REVERSE IDLER GEAR SUB-ASSEMBLY

INSPECT REVERSE IDLER GEAR RADIAL CLEARANCE

Manual Transmission Unit -- Disassembly |

Remove the filler plug and gasket from the transmission case.

Remove the drain plug and gasket from the transmission case.

| 3. REMOVE CLUTCH RELEASE FORK BOOT |

| 4. REMOVE CLUTCH RELEASE BEARING ASSEMBLY |

Remove the clutch release bearing assembly together with the clutch release fork sub-assembly from the clutch housing.

Remove the clutch release fork sub-assembly from the clutch release bearing assembly.

Remove the release bearing hub clip from the clutch release bearing assembly.

| 5. REMOVE RELEASE FORK SUPPORT |

Remove the release fork support from the manual transmission unit.

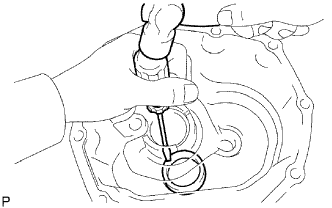

Remove the 9 bolts.

Using a plastic-faced hammer, tap off the clutch housing from the transmission case.

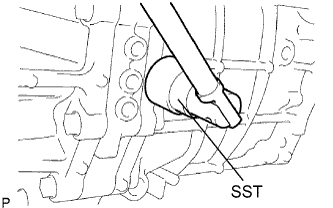

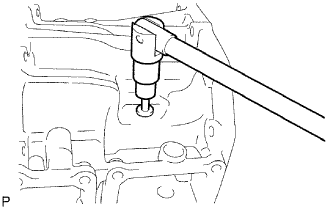

| 7. REMOVE BACK-UP LIGHT SWITCH ASSEMBLY |

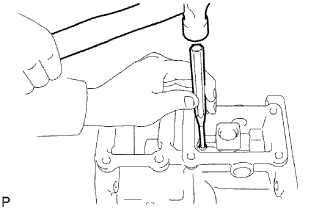

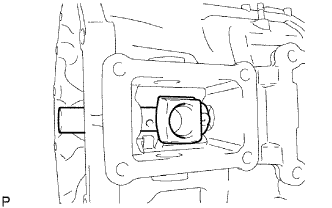

Using SST, remove the back-up light switch and gasket from the transmission case.

- SST

- 09817-16011

Remove the 2 restrict pins from the transfer adapter.

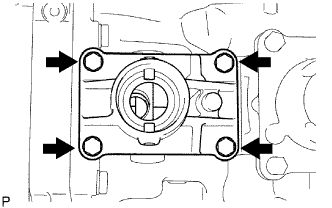

| 9. REMOVE CONTROL SHIFT LEVER RETAINER |

Remove the 4 bolts.

Remove the control shift lever retainer.

Remove the oil deflector.

| 10. REMOVE TRANSFER CONTROL SHIFT LEVER RETAINER |

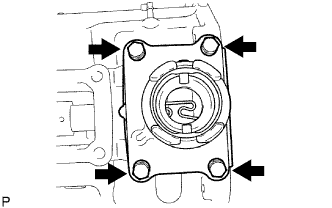

Remove the 4 bolts.

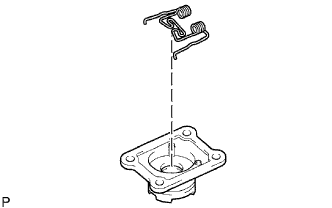

Remove the shift lever retainer from the transfer adapter.

Remove the select return spring from the shift lever retainer.

| 11. REMOVE SHIFT AND SELECT LEVER SHAFT |

Using a 5 mm pin punch and a hammer, tap out the slotted spring pin from the shift lever housing.

Remove the shift and select lever shaft and shift lever housing from the transfer adapter.

| 12. REMOVE TRANSFER ADAPTER |

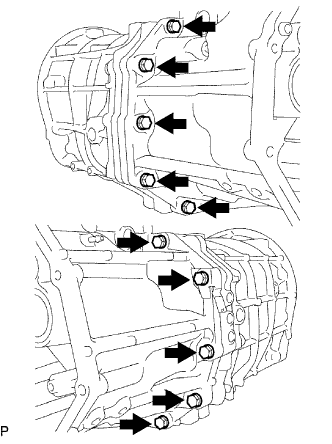

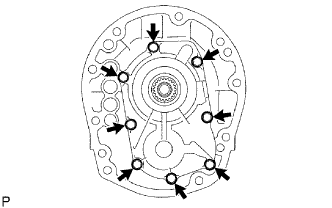

Remove the 10 bolts.

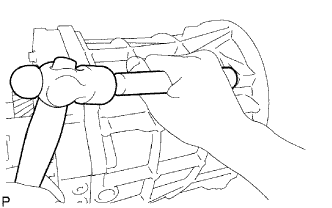

Using a brass bar and a hammer, tap out the transfer adapter from the transmission case.

| 13. REMOVE OIL RECEIVER PIPE |

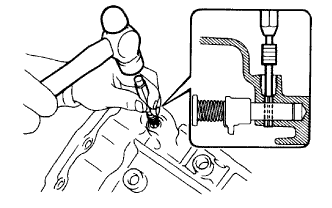

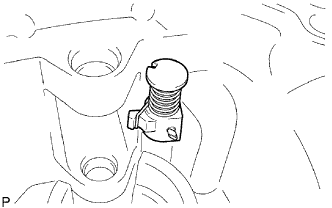

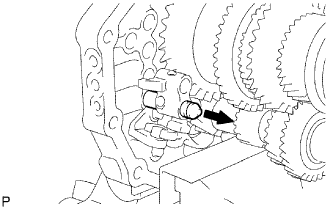

| 14. REMOVE REVERSE RESTRICT PIN |

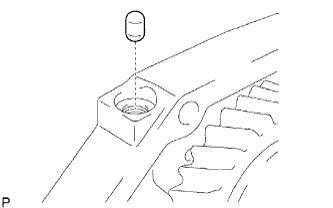

Using a T40 ''TORX'' socket wrench, remove the plug.

Using a 5 mm pin punch and a hammer, tap out the restrict slotted pin.

Remove the restrict pin.

| 15. REMOVE TRANSFER ADAPTER OIL SEAL |

Using a screwdriver and hammer, tap out the oil seal from the transfer adapter.

| 16. REMOVE FRONT BEARING RETAINER |

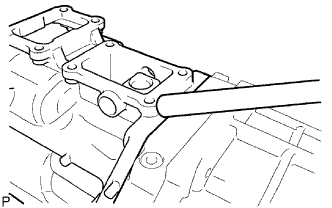

Remove the 8 bolts.

Using a brass bar and hammer, tap off the retainer from the transmission case.

| 17. REMOVE TRANSMISSION FRONT BEARING RETAINER OIL SEAL |

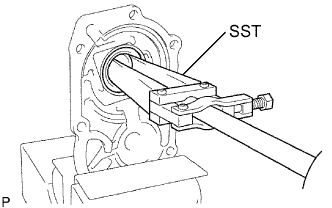

Fix the front bearing retainer in a vise.

Using SST, tap out the oil seal.

- SST

- 09308-00010

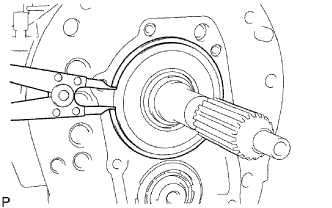

| 18. REMOVE FRONT BEARING SHAFT SNAP RING |

Using a snap ring expander, remove the snap ring from the transmission case.

| 19. REMOVE NO. 1 COUNTER GEAR FRONT BEARING SNAP RING |

Using a snap ring expander, remove the snap ring from the transmission case.

| 20. REMOVE MANUAL TRANSMISSION CASE |

Using a brass bar and hammer, tap off the transmission case from the intermediate plate.

| 21. REMOVE TRANSMISSION MAGNET |

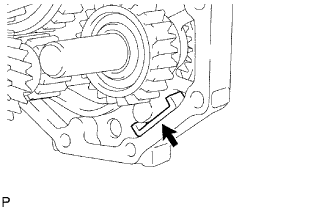

Remove the magnet from the intermediate plate.

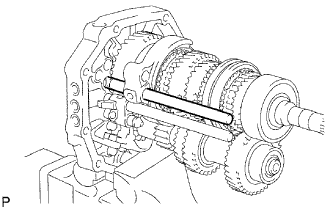

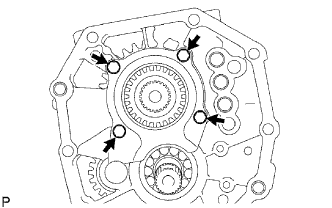

| 22. SECURE INTERMEDIATE PLATE |

Secure the intermediate plate in a vise between aluminum plates.

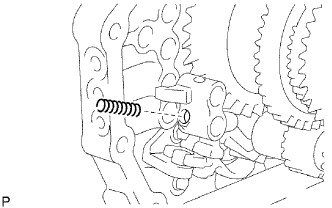

| 23. REMOVE NO. 1 SHIFT DETENT BALL SPRING SEAT |

Using a T40 ''TORX'' socket wrench, remove the spring seat from the intermediate plate.

Using a magnet hand, remove the compression spring and detent ball from the intermediate plate.

Using a T40 ''TORX'' socket wrench, remove the 2 spring seats from the intermediate plate.

Using a magnet hand, remove the 2 compression springs and 2 detent balls from the intermediate plate.

| 24. REMOVE NO. 2 SHIFT FORK SHAFT |

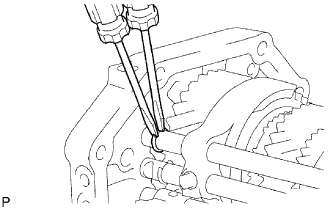

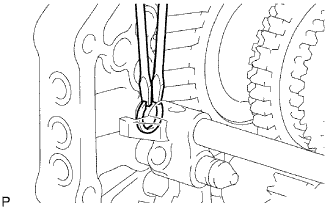

Using 2 screwdrivers and a hammer, tap off the snap ring from the No. 2 shift fork shaft.

- NOTICE:

- Use a cloth to prevent the snap ring from flying off.

Remove the bolt from the No. 2 shift fork.

Remove the No. 2 shift fork shaft from the intermediate plate.

Remove the No. 2 shift fork from the No. 2 transmission hub sleeve.

Using a magnet hand, remove the No. 1 shift interlock roller and shift interlock pin from the intermediate plate.

| 25. REMOVE NO. 1 SHIFT FORK SHAFT |

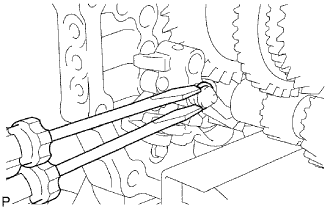

Using 2 screwdrivers and a hammer, tap off the snap ring from the No. 1 shift fork shaft.

- NOTICE:

- Use a cloth to prevent the snap ring from flying off.

Remove the shift fork set bolt from the No. 1 shift fork.

Remove the No. 1 shift fork shaft from the intermediate plate.

Remove the No. 1 shift fork from the reverse gear.

Using a magnet hand, remove the No. 1 shift interlock roller from the intermediate plate.

| 26. REMOVE NO. 3 SHIFT FORK SHAFT |

Using a 5 mm pin punch and hammer, tap out the shift fork set slotted spring pin from the No. 3 shift fork.

Using 2 screwdrivers and a hammer, tap off the snap ring from the shift fork shaft.

- NOTICE:

- Use a cloth to prevent the snap ring from flying off.

Remove the No. 3 shift fork and No. 3 shift fork shaft from the intermediate plate.

Using a magnet hand, remove the No. 1 shift interlock roller from the intermediate plate.

Using a magnet hand, remove the reverse shift fork ball from the reverse shift fork.

| 27. REMOVE NO. 4 SHIFT FORK SHAFT |

Using 2 screwdrivers and a hammer, tap off the snap ring from the No. 4 shift fork shaft.

- NOTICE:

- Use a cloth to prevent the snap ring from flying off.

Remove the No. 4 shift fork shaft from the intermediate plate.

- NOTICE:

- Cover the hole with a cloth to prevent the reverse shift fork ball from popping out.

Using a magnet hand, remove the reverse shift fork return compression spring from the reverse shift fork.

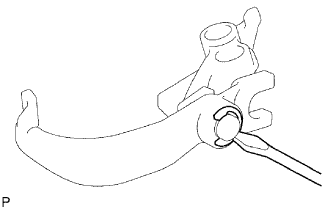

| 28. REMOVE REVERSE SHIFT FORK |

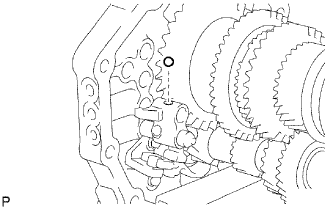

Remove the reverse shift fork with the reverse shift arm from the intermediate plate.

Using a screwdriver, pry out the E-ring and reverse shift fork from the reverse shift arm.

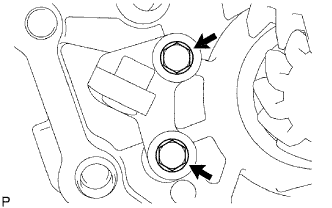

| 29. REMOVE REVERSE SHIFT ARM BRACKET |

Remove the 2 bolts and reverse shift arm bracket from the intermediate plate.

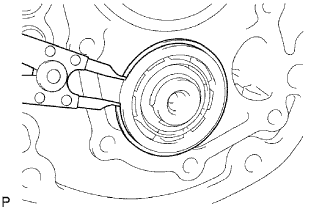

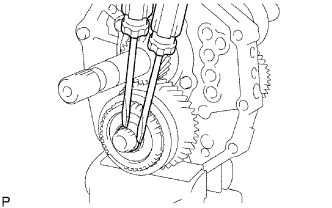

| 30. REMOVE OUTPUT SHAFT BEARING SHAFT SNAP RING |

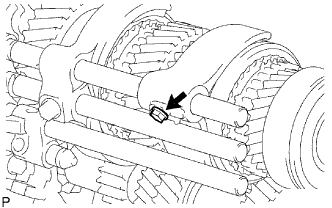

Using 2 screwdrivers and a hammer, tap off the shaft snap ring from the output shaft.

| 31. REMOVE OUTPUT SHAFT REAR BEARING |

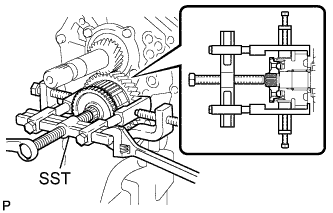

Using SST, remove the rear bearing and output shaft spacer from the output shaft.

- SST

- 09950-40011(09951-04010,09952-04010,09953-04020,09954-04010,09955-04051,09957-04010,09958-04011)

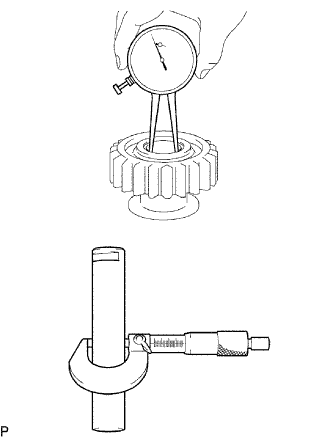

| 32. INSPECT COUNTER 5TH GEAR THRUST CLEARANCE |

Using a feeler gauge, measure the thrust clearance.

- Standard clearance:

- 0.10 to 0.35 mm (0.00394 to 0.0137 in.)

If the clearance is not as specified, replace the counter 5th gear.

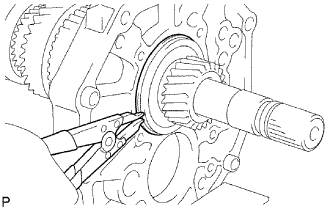

| 33. INSPECT COUNTER 5TH GEAR RADIAL CLEARANCE |

Using a dial indicator, measure the radial clearance.

- Standard clearance:

- 0.015 to 0.068 mm (0.00591 to 0.00267 in.)

If the clearance is not as specified, replace the counter 5th gear bearing with a new one.

| 34. REMOVE COUNTER GEAR REAR SHAFT SNAP RING |

Using 2 screwdrivers and a hammer, tap off the snap ring from the counter gear.

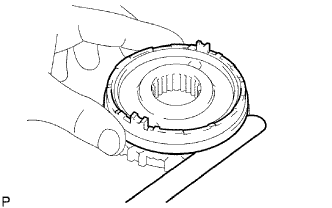

| 35. REMOVE NO. 3 TRANSMISSION HUB SLEEVE |

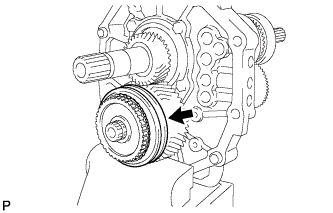

Remove the No. 3 transmission hub sleeve from the counter 5th gear.

| 36. REMOVE COUNTER 5TH GEAR |

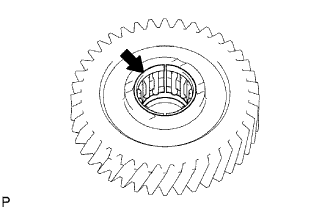

Using SST, remove the counter 5th gear together with the 2 No. 3 synchromesh shifting keys, 2 No. 3 synchromesh shifting key springs, No. 3 synchronizer ring and No. 5 gear spline piece from the counter gear.

- SST

- 09950-40011(09951-04020,09952-04010,09953-04020,09954-04010,09955-04021,09957-04010,09958-04011)

| 37. REMOVE NO. 5 GEAR SPLINE PIECE |

Remove the No. 5 gear spline piece from the counter 5th gear.

| 38. REMOVE NO. 3 SYNCHRONIZER RING |

Remove the synchronizer ring from the counter 5th gear.

| 39. REMOVE COUNTER 5TH GEAR BEARING |

Remove the bearing from the counter 5th gear.

| 40. REMOVE NO. 3 TRANSMISSION HUB SLEEVE |

Using a snap ring expander, remove the snap ring.

Remove the No. 3 transmission hub sleeve, No. 3 synchromesh shifting key spring and 2 No. 3 synchromesh shifting keys from the counter 5th gear.

| 41. REMOVE 5TH GEAR THRUST WASHER |

Remove the thrust washer from the counter gear.

| 42. REMOVE 5TH GEAR THRUST WASHER PIN |

Remove the thrust washer pin from the counter gear.

| 43. REMOVE REAR BEARING RETAINER |

Remove the 4 bolts and bearing retainer from the intermediate plate.

| 44. REMOVE REVERSE IDLER GEAR |

Pull out the reverse idler gear shaft from the rear side and remove the reverse idler gear from the intermediate plate.

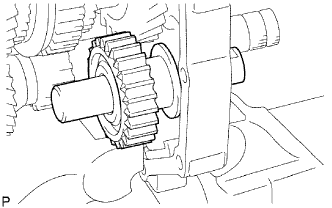

| 45. REMOVE COUNTER SHAFT CENTER BEARING |

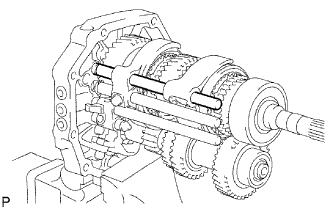

Using a snap ring expander, remove the snap ring.

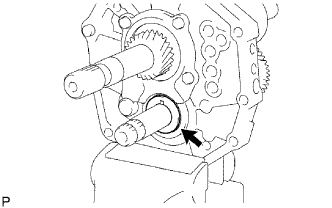

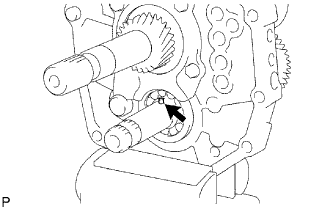

Using SST, remove the center bearing from the intermediate plate.

- SST

- 09950-40011(09951-04010,09952-04010,09953-04020,09954-04010,09955-04011,09957-04010,09958-04011)

- HINT:

- Remove the bearing while tapping the tip of the counter gear so that the counter gear does not hit the side wall of the output shaft gear by being pushed forward.

Remove the counter gear from the intermediate plate.

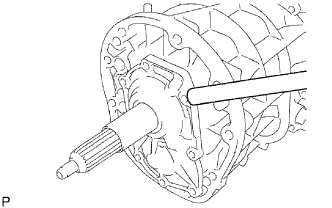

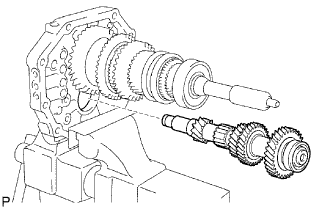

| 47. REMOVE INPUT SHAFT ASSEMBLY |

Remove the input shaft and No. 2 synchronizer ring from the output shaft.

- NOTICE:

- Do not drop the input shaft bearing or No. 2 synchronizer ring.

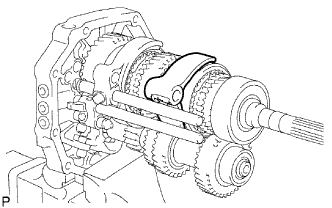

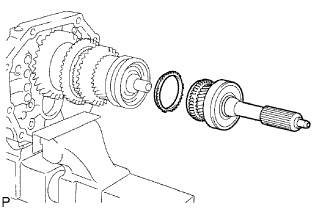

| 48. REMOVE OUTPUT SHAFT BEARING SHAFT SNAP RING |

Using a snap ring expander, remove the snap ring from the output shaft.

| 49. REMOVE OUTPUT SHAFT ASSEMBLY |

Using a plastic-faced hammer, remove the output shaft by tapping the intermediate plate.

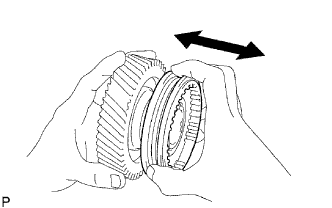

| 50. INSPECT NO. 3 SYNCHRONIZER RING |

Apply gear oil to the cone part of the No. 5 gear spline piece, and check that it does not turn in either direction while pushing the No. 3 synchronizer ring against the No. 5 gear spline piece.

Text in Illustration*a

| Locks

|

If it can turn, replace the No. 3 synchronizer ring.

Push the No. 3 synchronizer ring against the cone part of the No. 5 gear spline piece. Measure the clearance between the No. 3 synchronizer ring and No. 5 gear spline piece.

- Standard clearance:

- 0.68 to 1.32 mm (0.0268 to 0.0519 in.)

If the clearance is not as specified, replace the No. 3 synchronizer ring with a new one.

| 51. INSPECT NO. 3 TRANSMISSION HUB SLEEVE |

Check the sliding condition between the counter shaft 5th gear and No. 3 transmission hub sleeve.

Check the spline gear of the No. 3 transmission hub sleeve for wear.

If there are any defects, replace the No. 3 transmission hub sleeve.

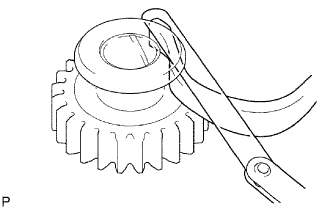

Using a vernier caliper, measure the No. 3 transmission hub sleeve groove and the thickness of the claw part of the No. 3 shift fork to calculate the clearance.

- Standard clearance:

- 0.26 to 0.84 mm (0.0102 to 0.0330 in.)

If the clearance is not as specified, replace the No. 3 transmission hub sleeve and No. 3 shift fork with new ones.

| 52. INSPECT COUNTER 5TH GEAR |

Using a cylinder gauge, measure the inside diameter of the counter 5th gear.

- Standard inside diameter:

- 38.015 to 38.040 mm (1.4967 to 1.4976 in.)

- Maximum inside diameter:

- 38.040 mm (1.4976 in.)

If the inside diameter is more than the maximum, replace the counter shaft 5th gear with a new one.

| 53. INSPECT REVERSE IDLER GEAR SUB-ASSEMBLY |

Using a caliper gauge, measure the inside diameter of the reverse idler gear.

- Standard inside diameter:

- 24.040 to 24.061 mm (0.9465 to 0.9472 in.)

- Maximum inside diameter:

- 24.061 mm (0.9472 in.)

If the inside diameter is more than the maximum, replace the reverse idler gear with a new one.

Using a micrometer, measure the diameter of the sliding part of the reverse idler gear on the reverse idler gear shaft.

- Standard diameter:

- 23.979 to 24.000 mm (0.9441 to 0.9448 in.)

- Minimum diameter:

- 23.979 mm (0.9441 in.)

If the diameter is less than the minimum, replace the reverse idler gear shaft.

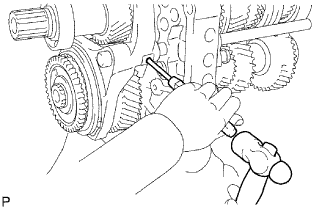

Using a feeler gauge, measure the thrust clearance of the shoe part between the reverse idler gear and reverse shift arm.

- Standard clearance:

- 0.05 to 0.35 mm (0.0020 to 0.0138 in.)

If the clearance is not as specified, replace the reverse idler gear and reverse shift arm.

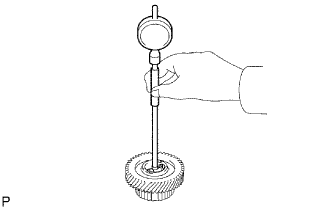

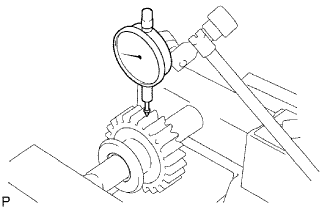

| 54. INSPECT REVERSE IDLER GEAR RADIAL CLEARANCE |

Install the reverse idler gear to the reverse idler gear shaft, and clamp it in a vise.

Using a dial indicator, measure the radial clearance.

- Standard clearance:

- 0.040 to 0.082 mm (0.00158 to 0.00322 in.)

If the clearance is not as specified, replace the reverse idler gear.