Starter (For 1.6 Kw Type) -- Inspection |

| 1. INSPECT STARTER ASSEMBLY |

- CAUTION:

- As a large electric current passes through the cable during this inspection, a thick cable must be used. Otherwise, the cable may become hot and cause injury.

- NOTICE:

- These tests must be performed within 3 to 5 seconds to prevent the coil from burning out.

Mount the starter in a vise between aluminum plates.

Perform a pull-in test.

Remove the nut and disconnect the lead wire from terminal C.

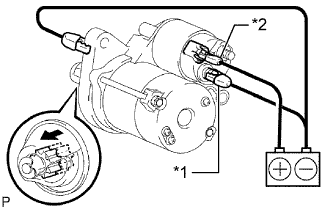

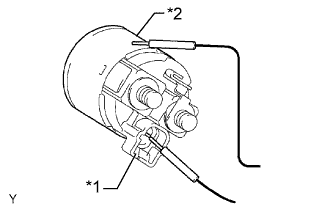

Connect the battery to the starter as shown in the illustration. Check that the clutch pinion gear moves outward.

If the clutch pinion gear does not move, replace the repair service starter kit.Text in Illustration *1 Terminal C *2 Terminal 50

Moves outward

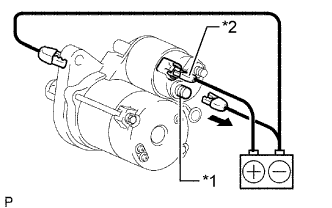

Perform a holding test.

Disconnect the negative (-) terminal lead from terminal C with the condition specified in the pull-in test above being maintained. Check that the pinion gear remains out.

If the clutch pinion gear moves inward, replace repair service starter kit.Text in Illustration *1 Terminal C *2 Terminal 50

Disconnect

|

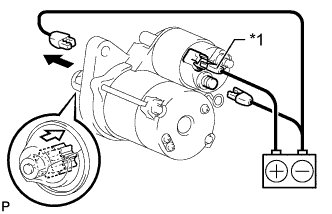

Inspect clutch pinion gear return.

Disconnect the negative (-) terminal lead from the starter body. Check that the clutch pinion gear returns inward.

If the clutch pinion gear does not return inward, replace the repair service starter kit.Text in Illustration *1 Terminal 50

Disconnect

Returns inward

|

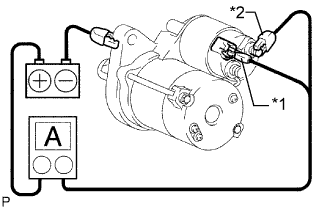

Perform an operation test without load.

Connect the lead wire to terminal C.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Connect the battery and an ammeter to the starter as shown in the illustration.

Text in Illustration *1 Terminal 50 *2 Terminal 30 Check that the starter rotates smoothly and steadily while the pinion gear is moving out. Then measure the current.

- Standard current:

- 90 A or less at 11.5 V

|

| 2. INSPECT STARTER ARMATURE ASSEMBLY |

Check the commutator for dirt and/or burns on the surface.

If the surface is dirty or burnt, correct it with sandpaper (No. 400) or a lathe.

If necessary, replace the starter armature assembly.

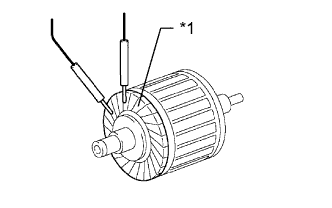

Inspect the commutator for an open circuit.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition Segment - Segment Always Below 1 Ω

If the result is not as specified, replace the starter armature assembly.Text in Illustration *1 Segment

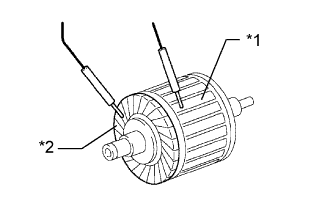

Inspect the commutator for a short circuit.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition Segment - Coil core Always 10 kΩ or higher

If the result is not as specified, replace the starter armature assembly.Text in Illustration *1 Coil Core *2 Segment

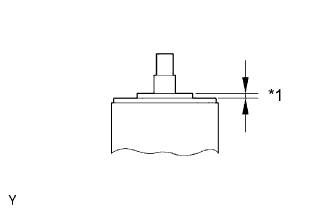

Using a vernier caliper, measure the protrusion length.

- Standard length:

- 3.1 mm (0.122 in.)

- Maximum length:

- 3.8 mm (0.150 in.)

If the length is more than the maximum, replace the starter armature assembly.Text in Illustration *1 Length

|

| 3. INSPECT STARTER COMMUTATOR END FRAME ASSEMBLY |

Check the brush length.

Using a vernier caliper, measure the brush length.

- Standard exposed length:

- 9.0 mm (0.354 in.)

- Minimum exposed length:

- 4.0 mm (0.157 in.)

If the length is less than the minimum, replace the starter commutator end frame assembly.Text in Illustration *1 Length

|

Check the resistance.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition Positive (+) brush - Negative (-) brush Always 10 kΩ or higher

|

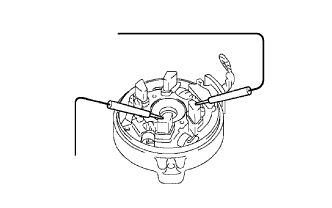

| 4. INSPECT STARTER CENTER BEARING CLUTCH SUB-ASSEMBLY |

Check the gear teeth on the planetary gears, and the internal gear and pinion gear of the starter center bearing clutch for wear or damage.

If any of the gears is damaged, replace the center bearing clutch sub-assembly.

Check the starter center bearing clutch pinion gear.

Hold the starter center bearing clutch, rotate the pinion gear clockwise and check that pinion gear turns freely. Try to rotate the pinion gear counterclockwise and check that it locks.

If the result is not as specified, replace the starter center bearing clutch sub-assembly.Text in Illustration

Free

Lock

|

| 5. INSPECT REPAIR SERVICE STARTER KIT |

Check the plunger.

Push in the plunger and check that it returns quickly to its original position.

If the result is not as specified, replace the repair service starter kit.

|

Check the resistance.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition Terminal 50 - Terminal C Always Below 1 Ω

If the result is not as specified, replace the repair service starter kit.Text in Illustration *1 Terminal C *2 Terminal 50 Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition Terminal 50 - Repair service starter kit body Always Below 2 Ω

If the result is not as specified, replace the repair service starter kit.Text in Illustration *1 Terminal 50 *2 Repair Service Starter Kit Body

|