Emission Control System -- On-Vehicle Inspection |

| 1. CHECK FUEL CUT RPM |

Increase the engine speed to at least 3500 rpm.

Use a sound scope to check for injector operation noise.

Check that when the throttle lever is released, injector operation noise stops momentarily and then resumes.

- Standard:

Item Specified Condition Fuel cut off rpm 2500 rpm Fuel return rpm 1200 rpm

| 2. VISUALLY CHECK HOSES, CONNECTORS AND GASKETS |

Check that there are no cracks, leaks or damage.

- NOTICE:

- Detachment or other problems with the engine oil dipstick, filler cap, PCV hose and other components may cause the engine to run improperly.

- Air suction caused by disconnections, looseness or cracks in the parts of the air induction system between the throttle body and cylinder head will cause engine failure or engine malfunctions.

If the result is not as specified, replace parts as necessary.

| 3. CHECK HOSES AND CONNECTORS |

Visually check for loose connections, sharp bends or damage.

| 4. CHECK FUEL TANK ASSEMBLY |

Visually check for deformation, cracks or fuel leakage.

| 5. CHECK PURGE VSV |

Connect the intelligent tester to the DLC3.

Remove the V-bank cover (HILUX_TGN26 RM000000VWO02AX_01_0015.html).

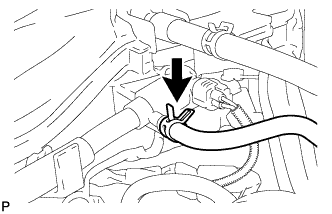

Disconnect the hose (connected to the canister) from the purge VSV.

|

Start the engine and turn the tester main switch on.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the VSV for EVAP Control.

- Standard:

Tester Operation Specified Condition EVAP VSV: OFF Purge VSV has no suction EVAP VSV: ON Purge VSV has suction

Connect the hose (connected to the canister) to the purge VSV.

Install the V-bank cover (HILUX_TGN26 RM000000VWL02HX_01_0020.html).