Cylinder Block -- Inspection |

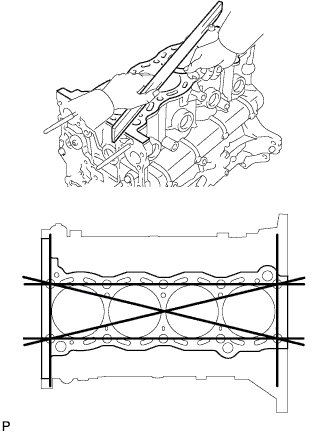

| 1. INSPECT CYLINDER BLOCK FOR WARPAGE |

Using a precision straightedge and feeler gauge, measure the warpage of the surface that contacts the cylinder head gasket.

- Maximum warpage:

- 0.05 mm (0.00197 in.)

|

Visually check the cylinders for vertical scratches.

If deep scratches are present, rebore all 4 cylinders. If necessary, replace the cylinder block.

| 2. INSPECT CYLINDER BORE |

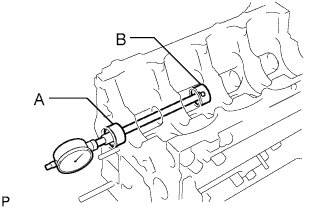

Using a cylinder gauge, measure the cylinder bore diameter at position A in the thrust and axial directions.

- Standard diameter:

- 94.990 to 95.003 mm (3.7398 to 3.7403 in.)

- Maximum difference in diameter:

- 0.2 mm (0.00787 in.)

- Measurement position:

- 70 mm (2.76 in.)

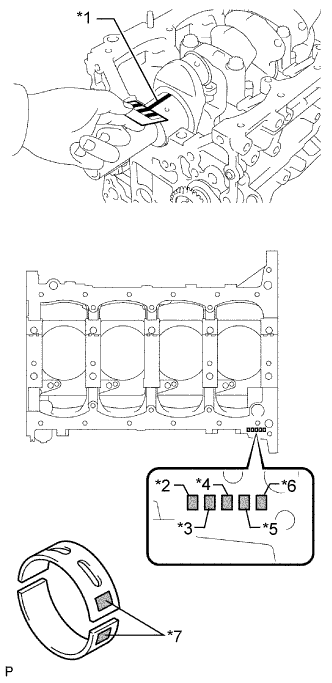

If the diameter is more than the maximum, rebore all 4 cylinders. If necessary, replace the cylinder block.Text in Illustration *1 Thrust Direction *2 Axial Direction *3 Measurement Position

Front

|

Inspect the cylinder ridge.

If the wear is less than 0.2 mm (0.00787 in.), using a ridge reamer, grind the top of the cylinder.Text in Illustration *1 Ridge Reamer

|

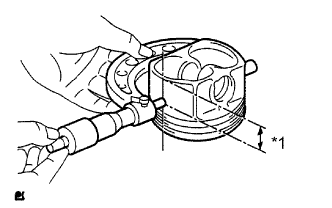

| 3. INSPECT PISTON DIAMETER |

Using a micrometer, measure the piston diameter at right angles to the piston center line where the distance from the piston end is as specified.

- Distance:

- 13.8 mm (0.543 in.)

- Standard diameter:

- 94.940 to 94.966 mm (3.7378 to 3.7384 in.)

Text in Illustration *1 Distance

|

| 4. INSPECT PISTON OIL CLEARANCE |

Measure the cylinder bore diameter in the thrust direction.

Subtract the piston diameter measurement from the cylinder bore diameter measurement.

- Standard oil clearance:

- 0.024 to 0.063 mm (0.000945 to 0.00248 in.)

| 5. INSPECT RING GROOVE CLEARANCE |

Using a feeler gauge, measure the clearance between a new piston ring and the wall of the ring groove.

- Standard Ring Groove Clearance:

Item Specified Condition No. 1 compression ring 0.020 to 0.070 mm (0.000787 to 0.00276 in.) No. 2 compression ring 0.020 to 0.060 mm (0.000787 to 0.00236 in.) Oil ring 0.020 to 0.060 mm (0.000787 to 0.00236 in.)

| 6. INSPECT PISTON RING END GAP |

Insert the piston ring into the cylinder bore.

Using a piston, push the piston ring a little beyond the bottom of the ring travel, 110 mm (4.33 in.) from the top of the cylinder block.

Using a feeler gauge, measure the end gap.

- Standard End Gap:

Item Specified Condition No. 1 compression ring 0.26 to 0.31 mm (0.0102 to 0.0122 in.) No. 2 compression ring 0.59 to 0.71 mm (0.0232 to 0.0280 in.) Oil ring 0.10 to 0.30 mm (0.00394 to 0.0118 in.)

- Maximum End Gap:

Item Specified Condition No. 1 compression ring 0.90 mm (0.0354 in.) No. 2 compression ring 1.36 mm (0.0535 in.) Oil ring 0.75 mm (0.0295 in.)

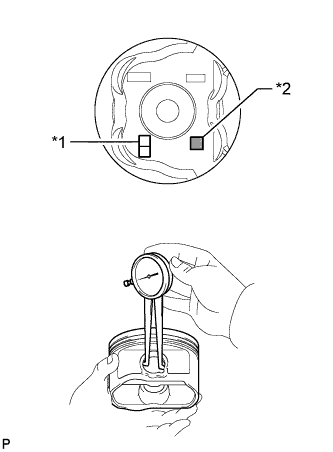

| 7. INSPECT PISTON PIN OIL CLEARANCE |

Using a caliper gauge, measure the inside diameter of the piston pin hole.

- Standard Piston Pin Hole Inside Diameter:

Item Specified Condition A 22.001 to 22.004 mm (0.86618 to 0.86630 in.) B 22.005 to 22.007 mm (0.86634 to 0.86642 in.) C 22.008 to 22.010 mm (0.86645 to 0.86653 in.)

If the diameter is not as specified, replace the piston with pin.Text in Illustration *1 Front Mark *2 Piston Pin Hole Inside Diameter Mark

|

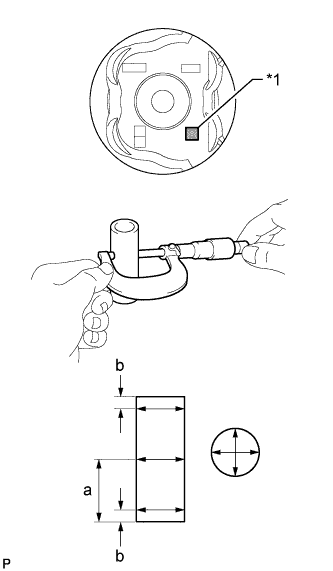

Using a micrometer, measure the piston pin diameter.

- Measurement Position:

Measurement Position Piston Pin Position a 28 mm (1.10 in.) b 5 mm (0.197 in.)

- Standard Piston Pin Diameter:

Item Specified Condition A 21.997 to 22.000 mm (0.86602 to 0.86614 in.) B 22.001 to 22.003 mm (0.86618 to 0.86626 in.) C 22.004 to 22.006 mm (0.86630 to 0.86638 in.)

If the diameter is not as specified, replace the piston with pin.Text in Illustration *1 Piston Pin Hole Inside Diameter Mark

|

Subtract the piston pin diameter measurement from the piston pin hole diameter measurement.

- Standard oil clearance:

- 0.001 to 0.007 mm (0.0000394 to 0.000276 in.)

- Maximum oil clearance:

- 0.010 mm (0.000394 in.)

Using a caliper gauge, measure the inside diameter of the connecting rod bush.

- Standard Bush Inside Diameter:

Item Specified Condition A 22.005 to 22.008 mm (0.86634 to 0.86645 in.) B 22.009 to 22.011 mm (0.86649 to 0.86657 in.) C 22.012 to 22.014 mm (0.86661 to 0.86669 in.)

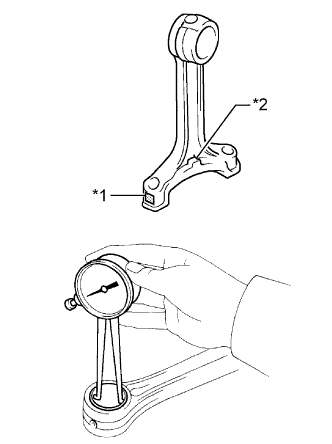

If the diameter is not as specified, replace the connecting rod small end bush.Text in Illustration *1 Connecting Rod Bush Inside Diameter Mark *2 Front Mark

|

Subtract the piston pin diameter measurement from the bush inside diameter measurement.

- Standard oil clearance:

- 0.005 to 0.011 mm (0.000197 to 0.000433 in.)

- Maximum oil clearance:

- 0.025 mm (0.000984 in.)

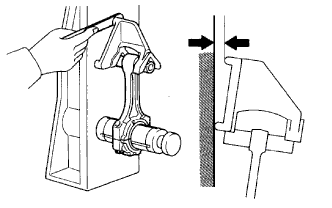

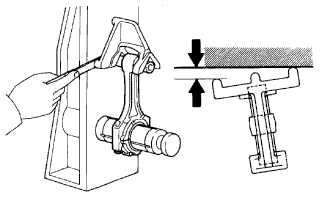

| 8. INSPECT CONNECTING ROD SUB-ASSEMBLY |

Using a rod aligner and feeler gauge, check the connecting rod alignment.

Check for bend.

- Maximum bend:

- 0.03 mm (0.00118 in.) per 100 mm (3.94 in.)

Check for twist.

- Maximum twist:

- 0.15 mm (0.00591 in.) per 100 mm (3.94 in.)

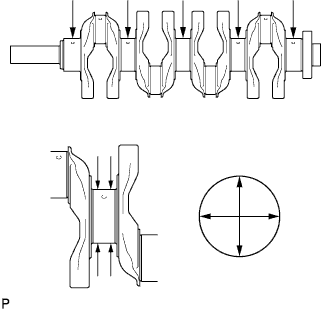

| 9. INSPECT CRANKSHAFT |

Inspect the circle runout.

Place the crankshaft on V-blocks.

Using a dial indicator, measure the circle runout at the center journal.

- Maximum circle runout:

- 0.03 mm (0.00118 in.)

Inspect the main journals.

Using a micrometer, measure the diameter of each main journal.

- Standard Journal Diameter:

Item Specified Condition No. 3 journal 59.981 to 59.994 mm (2.361 to 2.362 in.) Except No. 3 journal 59.987 to 60.000 mm (2.3617 to 2.3622 in.)

Check each main journal for taper and out-of- round as shown in the illustration.

- Maximum taper and out-of-round:

- 0.005 mm (0.000197 in.)

Inspect the crank pins.

Using a micrometer, measure the diameter of each crank pin.

- Standard diameter:

- 52.989 to 53.002 mm (2.086 to 2.087 in.)

Check each crank pin for taper and out-of-round as shown in the illustration.

- Maximum taper and out-of-round:

- 0.003 mm (0.000118 in.)

| 10. INSPECT CRANKSHAFT OIL CLEARANCE |

- HINT:

- Keep the lower bearings and crankshaft bearing caps together.

- Arrange the thrust washers in the correct order.

- Keep the upper crankshaft bearings and upper thrust washers together with the cylinder block.

Clean each main journal and bearing.

Check each main journal and bearing for pitting and scratches.

If the journal or bearing is damaged, replace the bearing.

Install the crankshaft bearings and upper crankshaft thrust washers.

Place the crankshaft on the cylinder block.

Lay a strip of Plastigage across each journal.

Text in Illustration *1 Plastigage

|

Install the 5 crankshaft bearing caps with the 10 bolts (HILUX_TGN26 RM00000125B044X_02_0060.html).

- NOTICE:

- Do not turn the crankshaft.

Remove the 10 bolts and 5 crankshaft bearing caps (HILUX_TGN26 RM00000125A04MX_04_0135.html).

Measure the Plastigage at its widest point.

- Standard Oil Clearance:

Item Specified Condition No. 3 journal 0.030 to 0.055 mm (0.00118 to 0.00217 in.) Other journals 0.024 to 0.049 mm (0.000945 to 0.00193 in.)

- Maximum oil clearance:

- 0.10 mm (0.00394 in.)

If the oil clearance is more than the maximum, replace the crankshaft bearing.Text in Illustration *1 Plastigage *2 No. 1 Journal *3 No. 2 Journal *4 No. 3 Journal *5 No. 4 Journal *6 No. 5 Journal *7 Mark 1, 2 or 3

If replacing the cylinder block, measure the bearing standard clearance.

If replacing a bearing, first check the number on the cylinder block for the journal of the bearing. Then replace the bearing with one that has the same number. The standard thickness of each bearing is indicated by a 1, 2 or 3 mark on its surface.- Standard Cylinder Block Main Journal Bore Diameter:

Item Specified Condition Mark 1 64.004 to 64.010 mm (2.51984 to 2.52007 in.) Mark 2 64.011 to 64.016 mm (2.52011 to 2.52031 in.) Mark 3 64.017 to 64.022 mm (2.52035 to 2.52055 in.)

- Standard Bearing Center Wall Thickness:

Item Specified Condition Mark 1 1.987 to 1.990 mm (0.07823 to 0.07835 in.) Mark 2 1.991 to 1.993 mm (0.07839 to 0.07846 in.) Mark 3 1.994 to 1.996 mm (0.07850 to 0.07858 in.)

|

Completely remove the Plastigage.

| 11. INSPECT NO. 1 BALANCE SHAFT |

Inspect the diameter of the journals.

Using a micrometer, measure the diameter of the balance shaft main journals.

- Standard Main Journal Diameter:

Item Specified Condition A 37.969 to 37.985 mm (1.49 to 1.50 in.) B 37.449 to 37.465 mm (1.474 to 1.475 in.)

Inspect the diameter of the bearings.

Using a cylinder gauge, measure the inside diameter of the balance shaft bearings.

- Standard Bearing Inside Diameter:

Item Specified Condition A 38.025 to 38.045 mm (1.497 to 1.498 in.) B 37.525 to 37.545 mm (1.477 to 1.478 in.)

Inspect the oil clearance.

Subtract the balance shaft main journal diameter measurement from the balance shaft bearing inside diameter measurement.

- Standard Oil Clearance:

Item Specified Condition A 0.040 to 0.076 mm (0.00157 to 0.00299 in.) B 0.060 to 0.096 mm (0.00236 to 0.00378 in.)

- Maximum oil clearance:

- 0.15 mm (0.00591 in.)

| 12. INSPECT NO. 2 BALANCE SHAFT |

Inspect the diameter of the journals.

Using a micrometer, measure the diameter of the balance shaft main journals.

- Standard Main Journal Diameter:

Item Specified Condition A 37.969 to 37.985 mm (1.49 to 1.50 in.) B 37.449 to 37.465 mm (1.474 to 1.475 in.)

Inspect the diameter of the bearings.

Using a cylinder gauge, measure the inside diameter of the balance shaft bearings.

- Standard Bearing Inside Diameter:

Item Specified Condition A 38.025 to 38.045 mm (1.497 to 1.498 in.) B 37.525 to 37.545 mm (1.477 to 1.478 in.)

Inspect the oil clearance.

Subtract the balance shaft main journal diameter measurement from the balance shaft bearing inside diameter measurement.

- Standard Oil Clearance:

Item Specified Condition A 0.040 to 0.076 mm (0.00157 to 0.00299 in.) B 0.060 to 0.096 mm (0.00236 to 0.00378 in.)

- Maximum oil clearance:

- 0.15 mm (0.00591 in.)

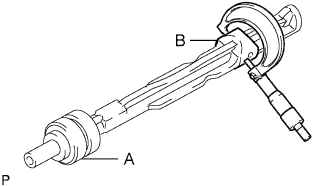

| 13. INSPECT NO. 1 OIL NOZZLE SUB-ASSEMBLY |

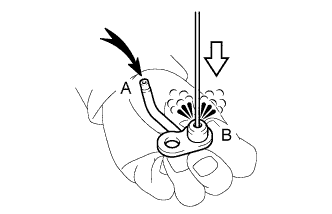

Push the check valve with a pin to check if it is stuck.

If the check valve is stuck, replace the No. 1 oil nozzle.Text in Illustration

Push

|

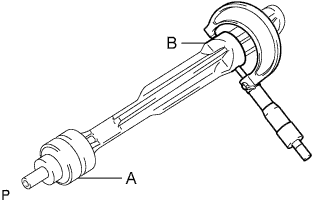

Push the check valve with a pin to check if it moves smoothly.

If the check valve does not move smoothly, clean or replace the No. 1 oil nozzle.

Blow air into A. Check that air does not leak from B.

If air leaks, clean or replace the No. 1 oil nozzle.Text in Illustration

Air

|

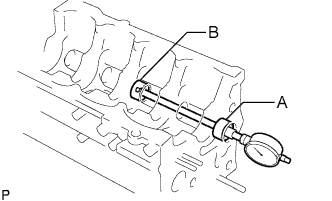

Push the check valve while blowing air into A. Check that air passes through B.

If air does not pass through B, clean or replace the No. 1 oil nozzle.Text in Illustration

Air

Push

|

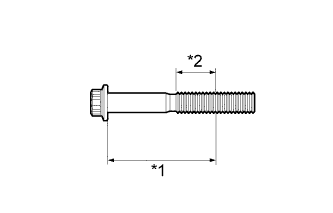

| 14. INSPECT CRANKSHAFT BEARING CAP SET BOLT |

Using a vernier caliper, measure the diameter of the most elongated threads in the measuring area.

- Distance:

- 64 mm (2.52 in.)

- Standard diameter:

- 10.76 to 10.97 mm (0.424 to 0.432 in.)

- Minimum diameter:

- 10.66 mm (0.420 in.)

If the diameter is less than the minimum, replace the crankshaft bearing cap bolt.Text in Illustration *1 Distance *2 Measuring Area

|

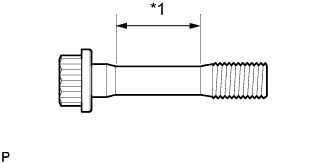

| 15. INSPECT CONNECTING ROD BOLT |

Using a vernier caliper, measure the tension portion diameter of the bolt.

- Standard diameter:

- 7.2 to 7.3 mm (0.283 to 0.287 in.)

- Minimum diameter:

- 7.0 mm (0.276 in.)

If the diameter is less than the minimum, replace the connecting rod bolt.Text in Illustration *1 Tension Portion

|