REMOVE SPARK PLUG

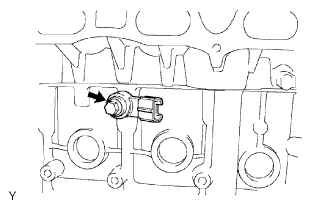

REMOVE ENGINE OIL PRESSURE SWITCH ASSEMBLY

REMOVE KNOCK SENSOR

REMOVE ENGINE COOLANT TEMPERATURE SENSOR

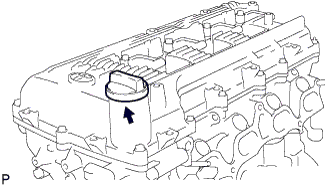

REMOVE OIL FILLER CAP SUB-ASSEMBLY

REMOVE PCV VALVE SUB-ASSEMBLY

REMOVE CAMSHAFT POSITION SENSOR

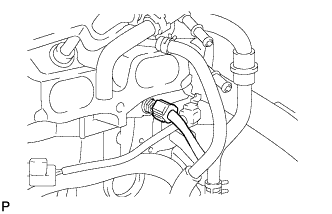

REMOVE CRANKSHAFT POSITION SENSOR

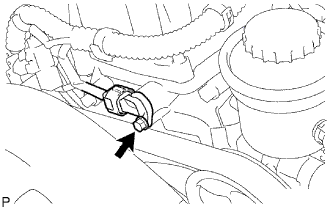

REMOVE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

REMOVE WATER INLET

REMOVE THERMOSTAT

REMOVE CRANKSHAFT PULLEY

REMOVE NO. 2 OIL PAN SUB-ASSEMBLY

REMOVE OIL STRAINER SUB-ASSEMBLY

REMOVE OIL PAN SUB-ASSEMBLY

REMOVE OIL PAN STUD BOLT

REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

REMOVE TIMING CHAIN COVER SUB-ASSEMBLY

REMOVE ENGINE WATER PUMP ASSEMBLY

REMOVE FRONT CRANKSHAFT OIL SEAL

REMOVE OIL PUMP RELIEF VALVE

SET NO. 1 CYLINDER TO TDC/COMPRESSION

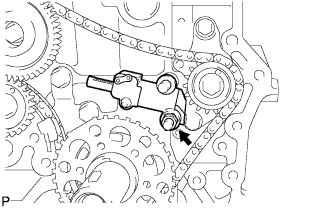

REMOVE TIMING CHAIN GUIDE

REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

REMOVE CHAIN TENSIONER SLIPPER

REMOVE NO. 1 CHAIN VIBRATION DAMPER

REMOVE CHAIN SUB-ASSEMBLY

REMOVE CRANKSHAFT TIMING SPROCKET

REMOVE CAMSHAFT BEARING CAP

REMOVE CAMSHAFT

REMOVE NO. 2 CAMSHAFT

REMOVE NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY

REMOVE CAMSHAFT TIMING SPROCKET

INSPECT CAMSHAFT TIMING GEAR ASSEMBLY

REMOVE CAMSHAFT TIMING GEAR ASSEMBLY

REMOVE CYLINDER HEAD SUB-ASSEMBLY

REMOVE CYLINDER HEAD GASKET

REMOVE NO. 2 CHAIN VIBRATION DAMPER

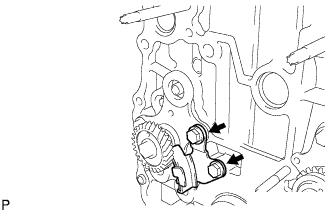

REMOVE NO. 3 CHAIN VIBRATION DAMPER

REMOVE NO. 2 CHAIN TENSIONER ASSEMBLY

REMOVE NO. 2 CHAIN SUB-ASSEMBLY

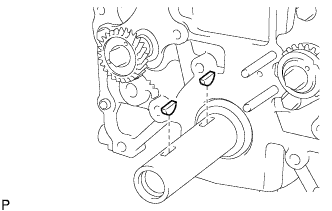

REMOVE NO. 4 CHAIN VIBRATION DAMPER

REMOVE CRANKSHAFT PULLEY SET KEY

REMOVE OIL FILTER SUB-ASSEMBLY

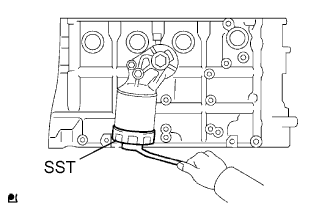

REMOVE OIL FILTER UNION

REMOVE OIL FILTER BRACKET SUB-ASSEMBLY

REMOVE NO. 1 TAPER SCREW PLUG

REMOVE REAR ENGINE OIL SEAL RETAINER

REMOVE REAR CRANKSHAFT OIL SEAL

REMOVE VALVE STEM CAP

REMOVE VALVE LASH ADJUSTER ASSEMBLY

REMOVE OIL CONTROL VALVE FILTER

Engine Unit -- Disassembly |

Using a 16 mm plug wrench, remove the 4 spark plugs.

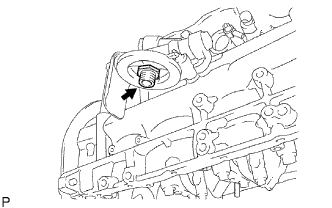

| 2. REMOVE ENGINE OIL PRESSURE SWITCH ASSEMBLY |

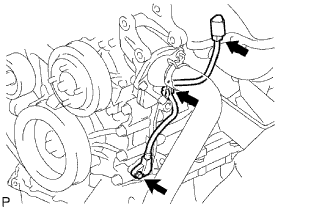

Disconnect the engine oil pressure switch connector.

Using a 24 mm deep socket wrench, remove the engine oil pressure switch.

Disconnect the sensor connector.

Remove the bolt and sensor.

| 4. REMOVE ENGINE COOLANT TEMPERATURE SENSOR |

Disconnect the sensor connector.

Remove the sensor.

Remove the gasket from the sensor.

| 5. REMOVE OIL FILLER CAP SUB-ASSEMBLY |

Remove the oil filler cap.

Remove the gasket from the oil filler cap.

| 6. REMOVE PCV VALVE SUB-ASSEMBLY |

Loosen the hose clamp and disconnect the PCV hose from the PCV valve sub-assembly.

Remove the PCV valve sub-assembly.

| 7. REMOVE CAMSHAFT POSITION SENSOR |

Disconnect the sensor connector.

Remove the bolt and sensor.

| 8. REMOVE CRANKSHAFT POSITION SENSOR |

Disconnect the sensor connector.

Disconnect the connector from the connector bracket.

Detach the harness clamp.

Remove the bolt and sensor.

| 9. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY |

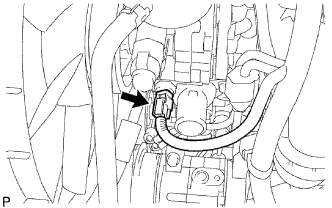

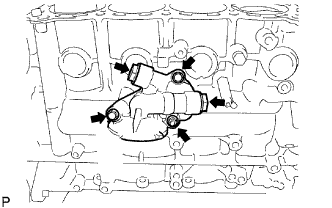

Disconnect the oil control valve connector.

Remove the bolt and oil control valve.

Remove the O-ring from the oil control valve.

| 10. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY |

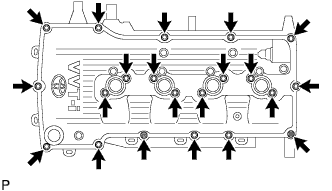

Remove the 19 bolts, 2 nuts, cylinder head cover and 2 gaskets.

Disconnect the power steering pump connector.

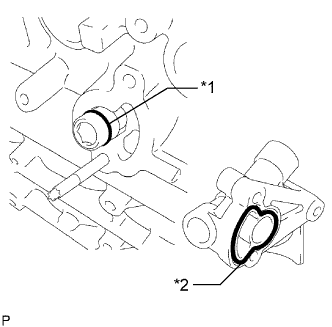

Remove the 2 nuts, bolt and water inlet.

Remove the gasket from the timing chain cover.

Remove the thermostat from the timing chain cover.

Remove the gasket from the thermostat.

| 13. REMOVE CRANKSHAFT PULLEY |

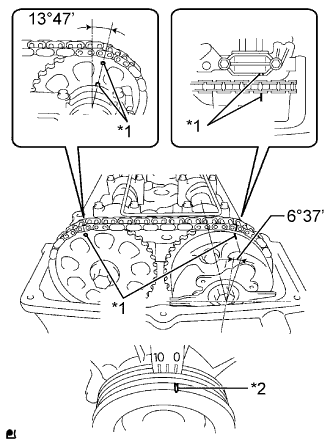

Turn the crankshaft pulley, and align its groove with timing mark 0 of the timing chain cover.

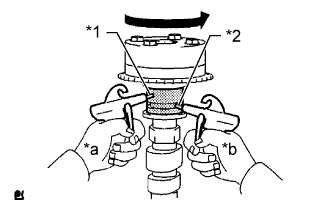

Text in Illustration*1

| Timing Mark

|

*2

| Groove

|

Check that the timing marks of the camshaft timing gear and sprocket are aligned with the timing marks of the No. 1 bearing cap, as shown in the illustration.

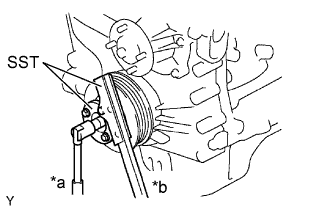

Using SST, loosen the pulley bolt.

- SST

- 09213-54015(91651-60855)

09330-00021

Text in Illustration*a

| Loosen

|

*b

| Hold

|

Using SST, remove the pulley bolt and pulley.

- SST

- 09950-50013(09951-05010,09952-05010,09953-05010,09954-05021)

Text in Illustration*a

| Loosen

|

*b

| Hold

|

| 14. REMOVE NO. 2 OIL PAN SUB-ASSEMBLY |

Remove the drain plug and gasket.

Remove the 20 bolts and 2 nuts.

Insert the blade of an oil pan seal cutter between the oil pans. Cut through the applied sealer and remove the No. 2 oil pan.

- NOTICE:

- Be careful not to damage the contact surfaces of the oil pans.

| 15. REMOVE OIL STRAINER SUB-ASSEMBLY |

Remove the bolt, 2 nuts, oil strainer and gasket.

| 16. REMOVE OIL PAN SUB-ASSEMBLY |

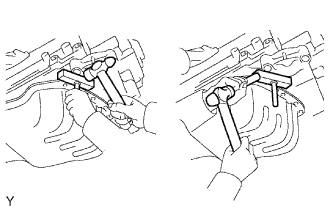

Remove the 16 bolts and 2 nuts.

Remove the oil pan by prying between the oil pan and cylinder block with a screwdriver.

Text in Illustration*1

| Protective Tape

|

- NOTICE:

- Be careful not to damage the contact surfaces of the cylinder block and oil pan.

- HINT:

- Tape the screwdriver tip before use.

Remove the O-ring.

| 17. REMOVE OIL PAN STUD BOLT |

- NOTICE:

- If a stud bolt is deformed or its threads are damaged, replace it.

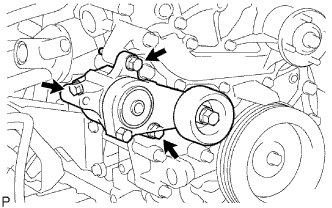

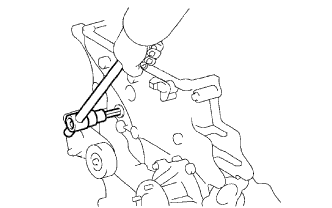

| 18. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY |

Remove the 3 bolts and tensioner.

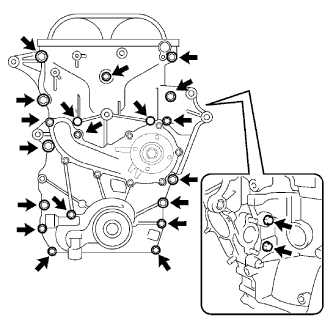

| 19. REMOVE TIMING CHAIN COVER SUB-ASSEMBLY |

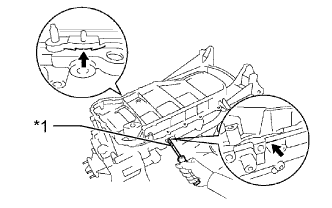

Remove the 19 bolts and 2 nuts shown in the illustration.

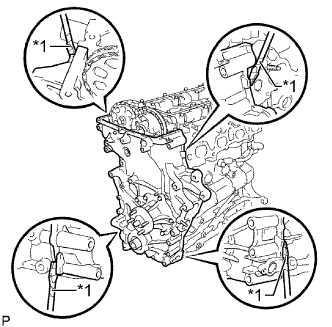

Remove the timing chain cover by prying between the timing chain cover and cylinder head or cylinder block with a screwdriver.

Text in Illustration*1

| Protective Tape

|

- NOTICE:

- Be careful not to damage the contact surfaces of the cylinder head, cylinder block and timing chain cover.

- HINT:

- Tape the screwdriver tip before use.

Remove the 3 O-rings.

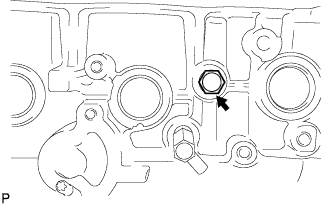

Using a 10 mm socket hexagon wrench, remove the timing gear case plug.

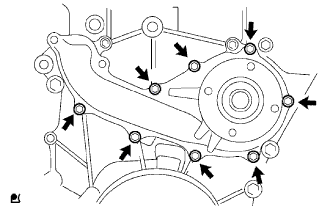

| 20. REMOVE ENGINE WATER PUMP ASSEMBLY |

Remove the 8 bolts, engine water pump and gasket.

| 21. REMOVE FRONT CRANKSHAFT OIL SEAL |

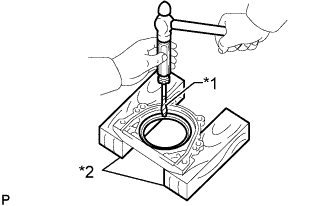

Place the timing chain cover on wooden blocks.

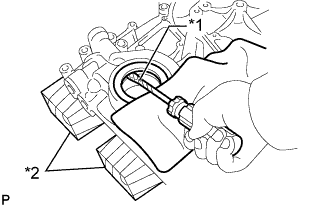

Text in Illustration*1

| Protective Tape

|

*2

| Wooden Block

|

Using a screwdriver pry out the front crankshaft oil seal.

- HINT:

- Tape the screwdriver tip before use.

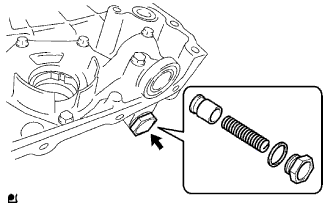

| 22. REMOVE OIL PUMP RELIEF VALVE |

Using a 27 mm socket wrench, remove the plug and gasket.

Remove the valve spring and relief valve.

| 23. SET NO. 1 CYLINDER TO TDC/COMPRESSION |

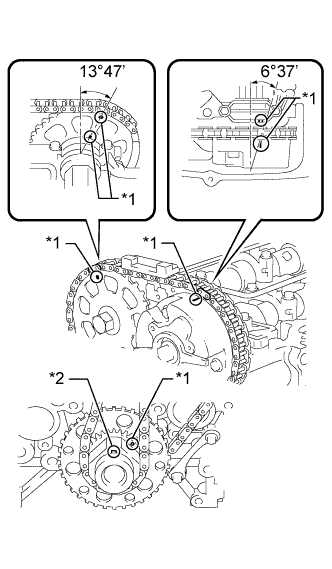

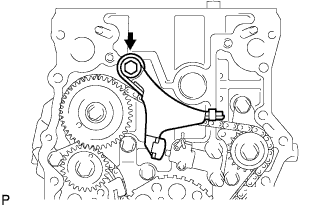

Temporarily install the crankshaft pulley bolt.

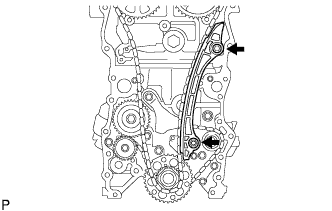

Rotate the crankshaft clockwise so that the timing marks on the crankshaft timing gear and camshaft timing gears are as shown in the illustration.

Text in Illustration*1

| Timing Mark

|

*2

| Key

|

- HINT:

- If the timing marks do not align, rotate the crankshaft clockwise again and align the timing marks.

Remove the crankshaft pulley bolt.

| 24. REMOVE TIMING CHAIN GUIDE |

Remove the 2 bolts, chain guide and O-ring.

Text in Illustration*1

| O-Ring

|

| 25. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY |

- NOTICE:

- When the chain tensioner is removed, do not rotate the crankshaft.

- When the chain is removed and the camshaft needs to be rotated, rotate the crankshaft 90° to the right.

Move the stopper plate upward to release the lock and push the plunger deep into the tensioner.

Text in Illustration*1

| Plunger

|

*2

| Stopper Plate

|

*3

| Hexagon Wrench

|

Move the stopper plate downward to set the lock and insert a hexagon wrench into the stopper plate hole.

Remove the bolt, nut, chain tensioner and gasket.

| 26. REMOVE CHAIN TENSIONER SLIPPER |

Remove the bolt and tensioner slipper.

| 27. REMOVE NO. 1 CHAIN VIBRATION DAMPER |

Remove the 2 bolts and vibration damper.

| 28. REMOVE CHAIN SUB-ASSEMBLY |

| 29. REMOVE CRANKSHAFT TIMING SPROCKET |

Remove the crankshaft timing sprocket from the crankshaft.

| 30. REMOVE CAMSHAFT BEARING CAP |

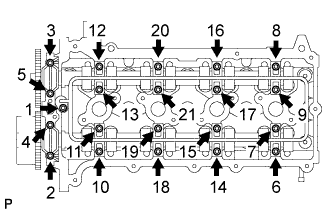

Uniformly loosen and remove the 21 bearing cap bolts in the sequence shown in the illustration.

- NOTICE:

- Uniformly loosen the bolts while keeping the camshafts level.

Remove the oil delivery pipe and O-ring from the bearing caps.

Remove the 9 bearing caps.

- HINT:

- Arrange the removed parts in the correct order.

| 32. REMOVE NO. 2 CAMSHAFT |

| 33. REMOVE NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY |

Remove the 16 valve rocker arms from the cylinder head.

- HINT:

- Arrange the removed parts in the correct order.

| 34. REMOVE CAMSHAFT TIMING SPROCKET |

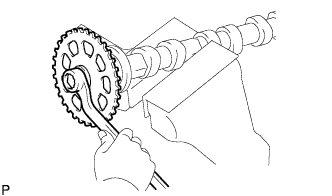

Mount the camshaft in a vise and remove the sprocket bolt and camshaft timing sprocket.

- NOTICE:

- Do not damage the camshaft.

| 35. INSPECT CAMSHAFT TIMING GEAR ASSEMBLY |

Check the lock of the camshaft timing gear.

Mount the camshaft in a vise and confirm that the camshaft timing gear is locked.

Text in Illustration*1

| Retard Side Path

|

*2

| Advance Side Path

|

*a

| Open

|

*b

| Close

|

| Rubber Piece

|

| Vinyl Tape

|

- NOTICE:

- Do not damage the camshaft.

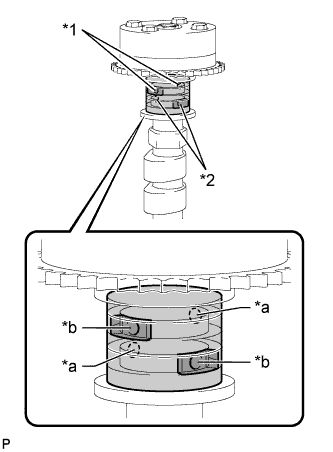

Release the lock pin.

Cover the 4 oil paths of the cam journal with vinyl tape as shown in the illustration.

- HINT:

- 2 advance side paths are provided in the groove of the camshaft. Plug one of the paths with a rubber piece.

Break through the tape over the advance side path, and then break through the tape over the retard side path on the opposite side from the hole over the advance side path as shown in the illustration.

Apply compressed air at approximately 200 kPa (2.0 kgf/cm2, 28 psi) to the two paths accessible through the holes in the tape.

Text in Illustration*1

| Retard Side Path

|

*2

| Advance Side Path

|

- CAUTION:

- Some oil splashing will occur. Cover the paths with a piece of cloth.

Check that the camshaft timing gear revolves in the advance direction when reducing the air pressure applied to the retard side path.

- OK:

- Gear rotates in the advance direction.

Text in Illustration*1

| Retard Side Path

|

*2

| Advance Side Path

|

*a

| Decompress

|

*b

| Hold Pressure

|

- HINT:

- This operation releases the lock pin which holds the timing gear in the most retarded position.

When the camshaft timing gear reaches the most advanced position, release the air pressure from the retard side path and advance side path in that order.

- NOTICE:

- Do not release the air pressure from the advance side path first. The gear may abruptly shift in the retard direction and break the lock pin.

Check for smooth rotation.

Rotate the camshaft timing gear within its movable range several times, but do not turn it to the most retarded position. Check that the gear rotates smoothly.

- CAUTION:

- Do not use air pressure to perform the smooth operation check.

Check the lock in the most retarded position.

Confirm that the camshaft timing gear becomes locked at the most retarded position.

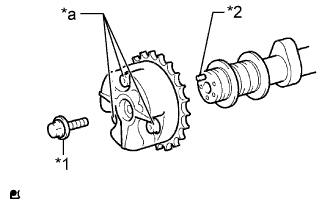

| 36. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY |

Remove the flange bolt of the camshaft timing gear.

Text in Illustration*1

| Flange Bolt

|

*2

| Straight Pin

|

*a

| Do Not Remove

|

- NOTICE:

- Be sure not to remove the other 3 bolts.

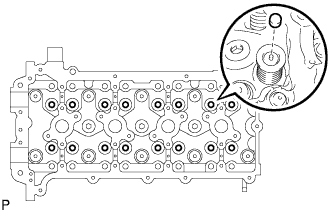

| 37. REMOVE CYLINDER HEAD SUB-ASSEMBLY |

Uniformly loosen the 10 bolts in the sequence shown in the illustration. Remove the 10 cylinder head bolts and plate washers.

- NOTICE:

- Be careful not to drop the washers into the cylinder head.

- Head warpage or cracking could result from removing the bolts in the wrong order.

| 38. REMOVE CYLINDER HEAD GASKET |

Remove the cylinder head gasket from the cylinder block.

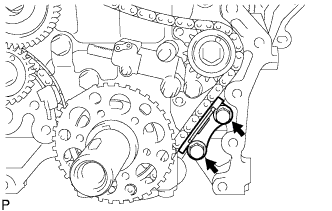

| 39. REMOVE NO. 2 CHAIN VIBRATION DAMPER |

Move the stopper plate downward to release the lock and push the plunger deep into the No. 2 chain tensioner.

Text in Illustration*1

| Plunger

|

*2

| Stopper Plate

|

Move the stopper plate upward to set the lock and insert a hexagon wrench into the stopper plate hole.

Remove the bolt and chain vibration damper.

| 40. REMOVE NO. 3 CHAIN VIBRATION DAMPER |

Remove the 2 bolts and chain vibration damper.

| 41. REMOVE NO. 2 CHAIN TENSIONER ASSEMBLY |

Remove the hexagon wrench from the tensioner assembly.

Remove the nut and chain tensioner assembly.

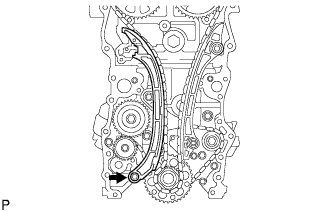

| 42. REMOVE NO. 2 CHAIN SUB-ASSEMBLY |

Remove the bolt, balance shaft drive gear shaft and balance shaft drive gear.

Remove the No. 2 crankshaft timing sprocket and chain.

| 43. REMOVE NO. 4 CHAIN VIBRATION DAMPER |

Remove the 2 bolts and vibration damper.

| 44. REMOVE CRANKSHAFT PULLEY SET KEY |

Remove the 2 pulley set keys from the crankshaft.

| 45. REMOVE OIL FILTER SUB-ASSEMBLY |

Using SST, remove the oil filter.

- SST

- 09228-07501

| 46. REMOVE OIL FILTER UNION |

Using a 27 mm socket wrench, remove the oil filter union.

| 47. REMOVE OIL FILTER BRACKET SUB-ASSEMBLY |

Remove the 2 bolts and nut from the oil filter bracket.

Remove the 2 screw plugs and 2 gaskets from the oil filter bracket.

Remove the oil filter bracket gasket and O-ring.

Text in Illustration*1

| O-Ring

|

*2

| Oil Filter Bracket Gasket

|

Using a hexagon wrench, remove the oil filter bracket union.

| 48. REMOVE NO. 1 TAPER SCREW PLUG |

Remove the taper screw plug from the cylinder block.

| 49. REMOVE REAR ENGINE OIL SEAL RETAINER |

Remove the 6 bolts.

Using a screwdriver, pry off the oil seal retainer.

Text in Illustration*1

| Protective Tape

|

- HINT:

- Tape the screwdriver tip before use.

| 50. REMOVE REAR CRANKSHAFT OIL SEAL |

Place the oil seal retainer on wooden blocks.

Text in Illustration*1

| Protective Tape

|

*2

| Wooden Blocks

|

Using a screwdriver and hammer, tap out the oil seal.

- HINT:

- Tape the screwdriver tip before use.

| 51. REMOVE VALVE STEM CAP |

Remove the 16 valve stem caps from the cylinder head.

- HINT:

- Arrange the removed parts in the correct order.

| 52. REMOVE VALVE LASH ADJUSTER ASSEMBLY |

- NOTICE:

- Keep the lash adjuster free from dirt and foreign objects.

- Only use clean engine oil.

Place the lash adjuster into a container full of new engine oil.

Text in Illustration*1

| Tapered Part

|

*2

| Plunger

|

*3

| Low Pressure Chamber

|

*4

| Check Ball

|

*5

| High Pressure Chamber

|

*a

| CORRECT

|

*b

| INCORRECT

|

Insert the tip of SST into the lash adjuster plunger and use the tip to press down on the check ball inside the plunger.

- SST

- 09276-75010

Squeeze SST and the lash adjuster together to move the plunger up and down 5 to 6 times.

Check the movement of the plunger and bleed air.

- OK:

- Plunger moves up and down.

- NOTICE:

- When bleeding high-pressure air from the compression chamber, make sure that the tip of SST is actually pressing the check ball as shown in the illustration. If the check ball is not pressed, air will not bleed.

After bleeding the air, remove SST. Then try to quickly and firmly press the plunger with your fingers.

- OK:

- Plunger can be pressed 3 times.

If the plunger can still be compressed after pressing it 3 times, replace the valve lash adjuster with a new one.

| 53. REMOVE OIL CONTROL VALVE FILTER |

Using an 8 mm hexagon wrench, remove the screw plug.

Remove the oil control valve filter and gasket.