Engine Unit (W/O Dpf) -- Reassembly |

- NOTICE:

- When replacing the injectors (including shuffling the injectors between the cylinders), common rail or cylinder head, it is necessary to replace the injection pipes with new ones.

- When replacing the fuel supply pump, common rail, cylinder block, cylinder head, cylinder head gasket or timing gear case, it is necessary to replace the fuel inlet pipe with a new one.

- After removing the injection pipes, clean them with a brush and compressed air.

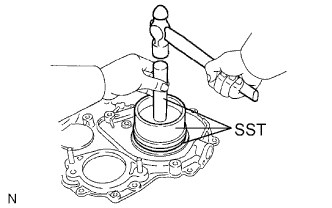

| 1. INSTALL REAR CRANKSHAFT OIL SEAL |

Using SST and a hammer, tap in a new oil seal until its surface is flush with the rear engine oil seal retainer edge.

- SST

- 09518-36030

09950-70010(09951-07100)

- NOTICE:

- Keep the lip free from foreign matter.

- Do not tap the oil seal at an angle.

|

Apply MP grease to the lip of the oil seal.

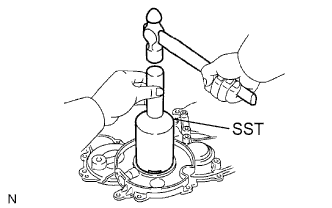

| 2. INSTALL SUPPLY PUMP OIL SEAL |

Using SST and a hammer, tap in a new oil seal until its surface is flush with the timing gear cover edge.

- SST

- 09223-15020

09502-12010

09950-70010(09951-07100)

- NOTICE:

- Keep the lip free from foreign matter.

- Do not tap the oil seal at an angle.

|

Apply MP grease to the lip of the oil seal.

| 3. INSTALL FRONT CRANKSHAFT OIL SEAL |

Using SST and a hammer, tap in a new oil seal until its surface is flush with the timing gear cover edge.

- SST

- 09214-76011

- NOTICE:

- Keep the lip free from foreign matter.

- Do not tap the oil seal at an angle.

|

Apply MP grease to the lip of the oil seal.

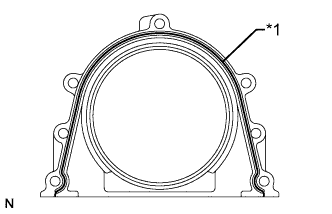

| 4. INSTALL REAR ENGINE OIL SEAL RETAINER |

Remove any old seal packing (FIPG material) from the oil pan and cylinder block.

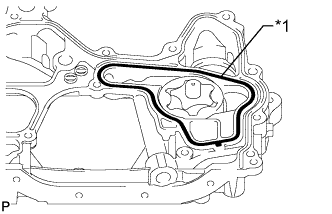

Apply seal packing to the places shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 4 mm (0.157 in.)

Text in Illustration *1 Seal Packing - NOTICE:

- After applying seal packing, install the rear engine oil seal retainer within 3 minutes and tighten the bolts within 15 minutes.

|

Install the rear engine oil seal retainer with the 5 bolts. Alternately tighten the 5 bolts in several passes.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

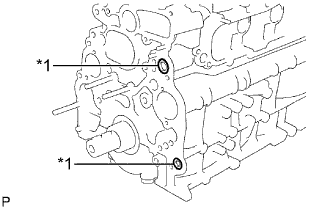

| 5. INSTALL TIMING GEAR CASE ASSEMBLY |

Install 2 new O-rings to the cylinder block.

Text in Illustration *1 New O-Ring

|

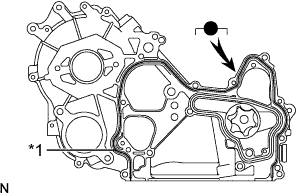

Install a new gasket to the groove of the timing gear case.

Text in Illustration *1 New Gasket

|

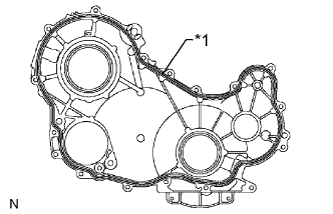

Remove any old seal packing (FIPG material).

Apply seal packing to the timing gear case as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 4 mm (0.157 in.)

Text in Illustration *1 Seal Packing - NOTICE:

- After applying seal packing, install the timing gear case assembly within 3 minutes and tighten the bolts within 15 minutes.

|

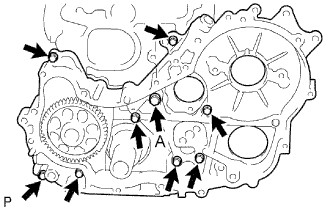

Install the timing gear case with the union bolt and 8 bolts.

- Torque:

- for union bolt (A):

- 16 N*m{163 kgf*cm, 12 ft.*lbf}

- for bolt:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

|

| 6. INSTALL OIL STRAINER SUB-ASSEMBLY |

Install a new gasket and the oil strainer with the 2 bolts and 2 nuts.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

| 7. INSTALL OIL PAN SUB-ASSEMBLY |

|

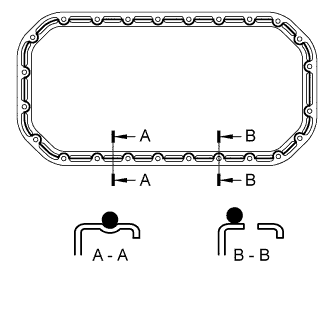

Remove any old seal packing (FIPG material).

Apply seal packing to the oil pan as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal packing diameter:

- 4 mm (0.157 in.)

- NOTICE:

- After applying seal packing, install the oil pan within 3 minutes and tighten the bolts and nuts within 15 minutes.

Install the oil pan with the 22 bolts and 2 nuts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

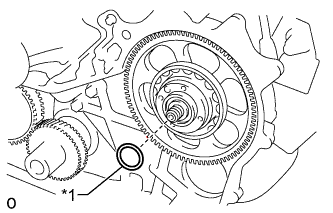

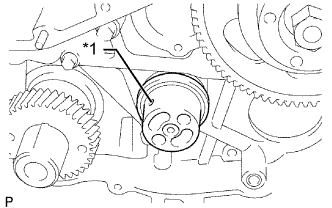

| 8. INSTALL INJECTION GEAR |

Install a new O-ring and the fuel supply pump with the 2 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Temporarily install the injection gear with the nut.

- HINT:

- Fit the key (protrusion) of the fuel supply pump into the key slot of the injection gear.

Install a new O-ring to the injection gear.

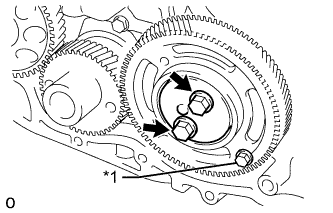

Text in Illustration *1 New O-Ring

|

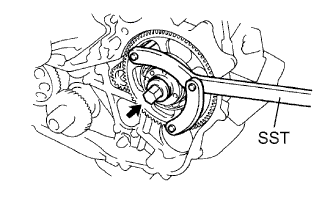

Install the injection gear set nut.

|

Using SST, tighten the set nut.

- SST

- 09960-10010(09962-01000,09963-01000)

- Torque:

- 64 N*m{650 kgf*cm, 47 ft.*lbf}

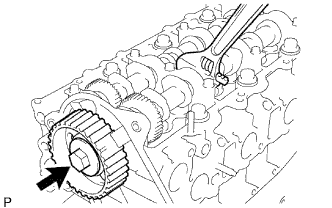

| 9. INSTALL CRANKSHAFT TIMING GEAR |

Position the crankshaft timing gear with the "1" timing marks facing forward.

|

Align the key groove of the crankshaft timing gear with the set key on the crankshaft.

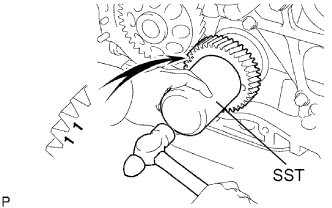

Using SST and a hammer, tap on the timing gear to install it.

- SST

- 09223-00010

| 10. INSTALL NO. 1 IDLE GEAR SHAFT |

Apply a coat of engine oil to the No. 1 idle gear shaft.

Text in Illustration *1 Engine Oil

|

Install the gear shaft as shown in the illustration.

Text in Illustration *1 Oil Hole

|

| 11. INSTALL NO. 2 IDLE SUB GEAR |

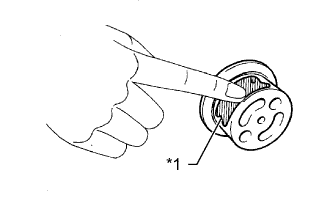

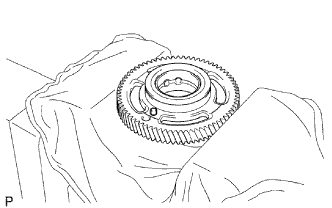

Using a cloth or equivalent, mount the No. 1 idle gear in a vise as shown in the illustration.

- NOTICE:

- Be careful not to damage the gear.

|

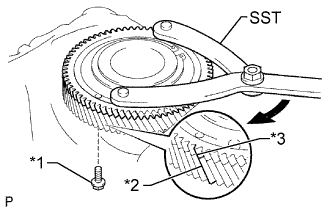

Install the gear spring.

Text in Illustration *1 Wave Washer *2 No. 2 Idle Sub Gear *3 Gear Spring *4 Pin

|

Install the No. 2 idle sub gear.

- HINT:

- Align the pins on the gears with the spring ends.

Install the wave washer.

Using snap ring pliers, install the snap ring.

Using SST, align the holes of the No. 1 idle gear and No. 2 idle sub gear by turning the No. 2 idle sub gear clockwise and temporarily install a service bolt.

- SST

- 09960-10010(09962-01000,09963-00700)

Text in Illustration *1 Service Bolt *2 No. 1 Idle Gear *3 No. 2 Idle Sub Gear

Turn

|

Align the gear teeth of the No. 1 idle gear and No. 2 idle sub gear and tighten the service bolt.

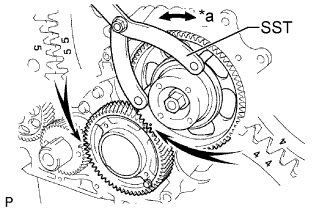

| 12. INSTALL NO. 1 IDLE GEAR |

Align the "4" and "5" timing marks of the idle gear and crankshaft timing gear.

Text in Illustration *a Turn

|

Using SST, turn the injection gear and align the "4" timing marks of the idle gear and injection gear, and then mesh the gears.

- SST

- 09960-10010(09962-01000,09963-00700)

Position the idle gear thrust plate with the protrusion facing forward.

Text in Illustration *1 Service Bolt

|

Align the bolt holes and install the idle gear thrust plate with the 2 bolts.

- Torque:

- 50 N*m{510 kgf*cm, 37 ft.*lbf}

Remove the service bolt.

| 13. INSTALL NO. 1 CRANKSHAFT POSITION SENSOR PLATE |

Align the key groove of the No. 1 crankshaft position sensor plate with the set key.

Install the No. 1 crankshaft position sensor plate with the cupped side facing outward.

| 14. INSTALL TIMING GEAR COVER |

Remove any old seal packing (FIPG material).

Apply seal packing to the timing gear cover as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 4 mm (0.157 in.)

Text in Illustration *1 Seal Packing - NOTICE:

- After applying seal packing, install the timing gear cover within 3 minutes and tighten the bolts within 15 minutes.

|

Install a new O-ring to the timing gear case.

Install the timing gear cover with the 14 bolts and 2 nuts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Remove the screw plug and gasket.

|

Pour approximately 50 cc (3.05 cu. in.) of engine oil into the oil pump.

Install a new gasket and the screw plug.

- Torque:

- 42 N*m{423 kgf*cm, 31 ft.*lbf}

Install the No. 1 vacuum transmitting pipe with the bolt.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

| 15. INSTALL WATER PUMP ASSEMBLY |

Install a new gasket and the water pump with the 5 bolts and 2 nuts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

| 16. INSTALL CYLINDER HEAD GASKET |

Check the piston protrusions for each cylinder.

Clean the cylinder block with solvent.

Set the piston of the cylinder to be measured to slightly before TDC.

Text in Illustration *1 Measuring Tip *2 Protrusion Place a dial indicator on the cylinder block, and position the measuring tip as shown in the illustration.

Set the dial indicator at 0 mm (0 in.)

- HINT:

- Make sure that the measuring tip is square to the cylinder block gasket surface and piston head when taking the measurements.

|

Find where the piston head protrudes most by slowly turning the crankshaft clockwise and counterclockwise.

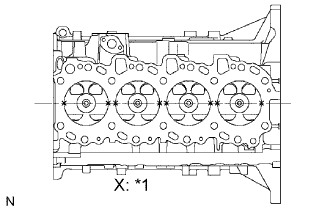

Measure the piston protrusion of each cylinder at the 2 points shown in the illustration.

Text in Illustration *1 Measuring Point

|

For the piston protrusion value of each cylinder, use the average of the 2 measurements of each cylinder.

- Standard piston protrusion:

- 0.005 to 0.255 mm (0.000197 to 0.0100 in.)

- HINT:

- When installing the piston and connecting rod assembly, if the protrusion is not as specified, remove the piston and connecting rod assembly and reinstall them.

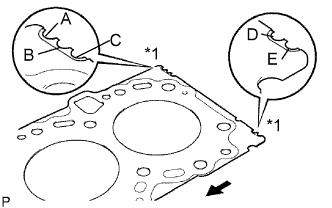

Select a new cylinder head gasket.

Text in Illustration *1 Cutout Mark - HINT:

- New cylinder head gaskets are available in 5 sizes, and are marked A, B, C, D or E.

- New Cylinder Head Gasket Thickness:

Mark Specified Condition A 0.80 to 0.90 mm (0.0315 to 0.0354 in.) B 0.85 to 0.95 mm (0.0335 to 0.0374 in.) C 0.90 to 1.00 mm (0.0354 to 0.0394 in.) D 0.95 to 1.05 mm (0.0374 to 0.0413 in.) E 1.00 to 1.10 mm (0.0394 to 0.0433 in.)

Select the largest piston protrusion value from the measurements made. Then select a new appropriate gasket according to the table below.

- Gasket Size:

Item Specified Condition Piston protrusion 0.005 to 0.054 mm (0.000197 to 0.00213 in.) 0.055 to 0.104 mm (0.00217 to 0.00409 in.) 0.105 to 0.154 mm (0.00413 to 0.00606 in.) 0.155 to 0.204 mm (0.00610 to 0.00803 in.) 0.205 to 0.255 mm (0.00807 to 0.0100 in.) Gasket to be used A B C D E

|

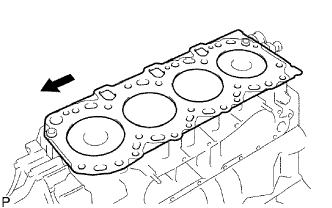

Place the cylinder head gasket on the cylinder block.

Text in Illustration

Front - NOTICE:

- Make sure the gasket is installed facing the proper direction.

|

| 17. INSTALL CYLINDER HEAD SUB-ASSEMBLY |

- HINT:

- The cylinder head bolts are tightened in 3 progressive steps.

- If any bolt is broken or deformed, replace it.

Place the cylinder head on the cylinder head gasket.

Apply a light coat of engine oil to the threads and under the heads of the cylinder head bolts.

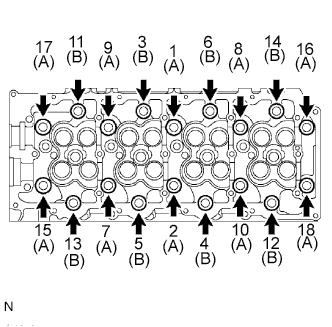

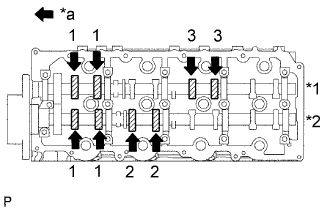

Install the 18 cylinder head bolts and 18 washers and uniformly tighten the bolts in several passes in the sequence shown in the illustration.

- Torque:

- 85 N*m{867 kgf*cm, 63 ft.*lbf}

If any of the cylinder head bolts does not meet the torque specification, replace it.Standard Bolt Length Item Specified Condition A 110 mm (4.33 in.) B 167 mm (6.57 in.)

|

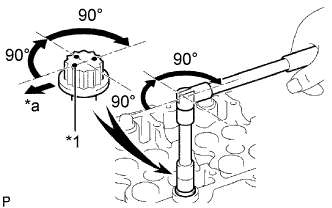

Mark the front of each cylinder head bolt with paint.

Text in Illustration *1 Paint Mark *a Front

|

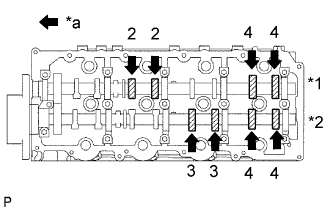

Further tighten the cylinder head bolts by 90° in the sequence shown in the illustration above.

Finally, tighten the cylinder head bolts by an additional 90°.

Check that the paint marks are now facing rearward.

| 18. INSTALL VALVE LIFTER |

Install the valve lifters.

Check that each valve lifter rotates smoothly by hand.

| 19. INSTALL CAMSHAFT |

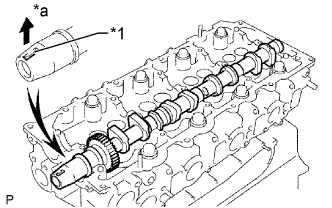

Using the crankshaft pulley bolt, set the No. 1 cylinder to 90° BTDC/compression.

Text in Illustration *1 Key - HINT:

- Set the No. 1 cylinder to 90° BTDC/compression to prevent the top of the piston from hitting against the valve head.

|

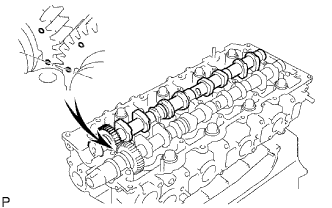

Install the camshafts.

Apply engine oil to the thrust portion of the camshaft.

Place the camshaft on the cylinder head with the key groove facing upward.

Text in Illustration *1 Key Groove *a Upward Align the timing marks (1-dot marks) of the camshaft drive and driven main gears and set the No. 2 camshaft in place.

|

Remove any old seal packing (FIPG material) from the camshaft bearing cap.

Apply seal packing to the specified areas shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 4 mm (0.157 in.)

Text in Illustration *1 Seal Packing *2 Oil Passage - NOTICE:

- Do not allow seal packing to contact the oil passage of the bearing cap.

- After applying seal packing, install the camshaft bearing caps within 3 minutes and tighten the bolts within 15 minutes.

- Do not start the engine for at least 2 hours after installation.

|

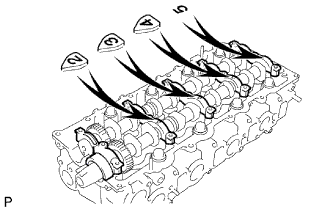

Install the 5 bearing caps to their proper locations.

|

Apply a light coat of engine oil to the threads and under the heads of the bearing cap bolts.

|

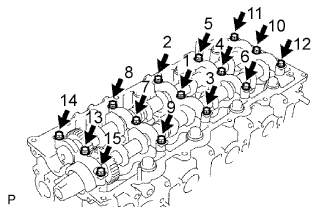

Install and uniformly tighten the 15 bearing cap bolts in several passes in the sequence shown in the illustration.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

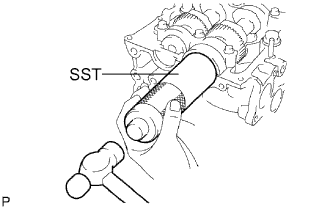

Install a new camshaft oil seal.

Apply MP grease to the lip of a new oil seal.

Using SST and a hammer, tap in the oil seal until its surface is flush with the surfaces of the camshaft bearing cap and cylinder head.

- SST

- 09608-06041

|

| 20. INSTALL CYLINDER BLOCK INSULATOR |

Install the cylinder block insulator to the cylinder head.

| 21. INSTALL NO. 2 TIMING BELT COVER |

Apply seal packing (FIPG) to the specified areas shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Text in Illustration *1 Seal Packing - NOTICE:

- After applying FIPG, install the No. 2 timing belt cover within 3 minutes and tighten its bolts and nut within 15 minutes.

|

Clean the bolts and their holes.

Apply adhesive to 2 or 3 threads at the end of each of the 4 bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Install the No. 2 timing belt cover with the 4 bolts and nut.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 22. INSTALL CAMSHAFT TIMING PULLEY |

Install the camshaft timing pulley.

|

Tighten the bolt of the camshaft timing pulley while holding the camshaft with a wrench.

- Torque:

- 98 N*m{1000 kgf*cm, 72 ft.*lbf}

| 23. INSPECT VALVE CLEARANCE |

Check only the valves indicated.

Using a feeler gauge, measure the clearance between the valve lifter and camshaft.

- Standard Valve Clearance (Cold):

Item Specified Condition Intake 0.2 to 0.3 mm (0.00787 to 0.0118 in.) Exhaust 0.35 to 0.45 mm (0.0138 to 0.0177 in.)

Write down any valve clearance measurements that are not within the specified range. These measurements will be used later to determine the size of the adjustment lifter to be installed.Text in Illustration *1 Exhaust *2 Intake *a Front

|

Turn the crankshaft 360° to set the No. 4 cylinder to TDC/compression.

Check only the valves indicated.

Using a feeler gauge, measure the clearance between the valve lifter and camshaft.

- Standard Valve Clearance (Cold):

Item Specified Condition Intake 0.2 to 0.3 mm (0.00787 to 0.0118 in.) Exhaust 0.35 to 0.45 mm (0.0138 to 0.0177 in.)

Write down any valve clearance measurements that are not within the specified range. These measurements will be used later to determine the size of the adjustment lifter to be installed.Text in Illustration *1 Exhaust *2 Intake *a Front

|

| 24. ADJUST VALVE CLEARANCE |

Remove the camshafts (HILUX_TGN26 RM00000147H02GX.html).

Remove the valve lifters.

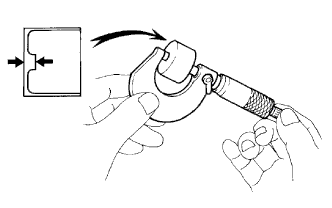

Using a micrometer, measure the thickness of the removed lifter.

|

Calculate the thickness of a new lifter so that the valve clearance is within the specified range.

A B C New lifter thickness Used lifter thickness Measured valve clearance - New lifter thickness:

- Intake: A = B + (C - 0.25 mm (0.00984 in.))

- Exhaust: A = B + (C - 0.40 mm (0.0157 in.))

Select a new lifter with a thickness as close as possible to the calculated values.

- HINT:

- Valve lifters are available in 35 sizes in increments of 0.02 mm (0.000787 in.), from 5.06 mm (0.199 in.) to 5.74 mm (0.226 in.).

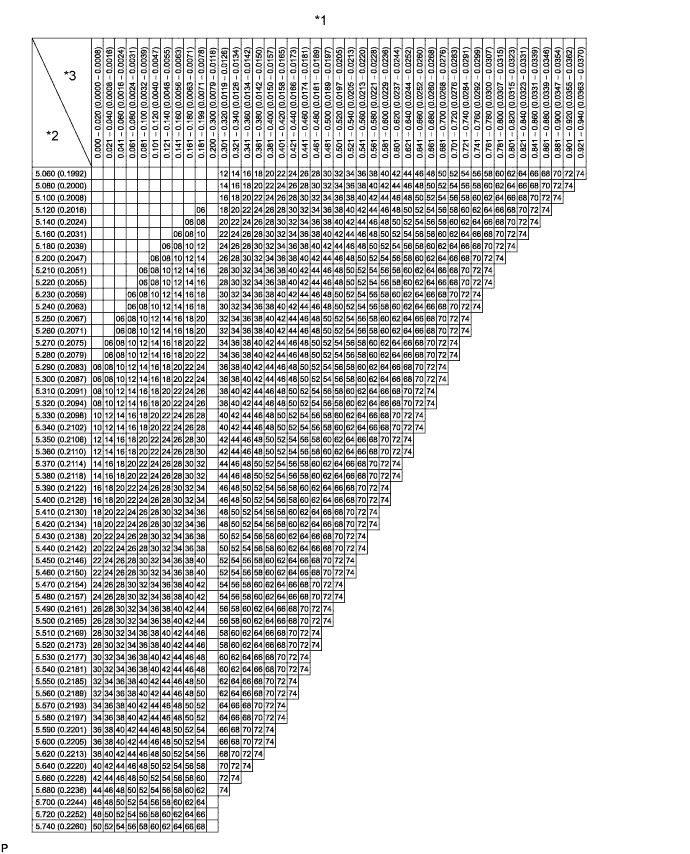

Text in Illustration *1 Valve Lifter Selection Chart (Intake) *2 Installed lifter thickness mm (in.) *3 Measured clearance mm (in.) - - - Standard intake valve clearance (Cold):

- 0.2 to 0.3 mm (0.00787 to 0.0118 in.)

- EXAMPLE:

- A 5.25 mm (0.207 in.) lifter is installed, and the measured clearance is 0.4 mm (0.0157 in.). Replace the 5.25 mm (0.207 in.) lifter with a No. 40 lifter.

- New Lifter Thickness:

Lifter No. Specified Condition Lifter No. Specified Condition Lifter No. Specified Condition 06 5.06 mm (0.1992 in.) 30 5.30 mm (0.2087 in.) 54 5.54 mm (0.2181 in.) 08 5.08 mm (0.2000 in.) 32 5.32 mm (0.2094 in.) 56 5.56 mm (0.2189 in.) 10 5.10 mm (0.2008 in.) 34 5.34 mm (0.2102 in.) 58 5.58 mm (0.2197 in.) 12 5.12 mm (0.2016 in.) 36 5.36 mm (0.2110 in.) 60 5.60 mm (0.2205 in.) 14 5.14 mm (0.2024 in.) 38 5.38 mm (0.2118 in.) 62 5.62 mm (0.2213 in.) 16 5.16 mm (0.2031 in.) 40 5.40 mm (0.2126 in.) 64 5.64 mm (0.2220 in.) 18 5.18 mm (0.2039 in.) 42 5.42 mm (0.2134 in.) 66 5.66 mm (0.2228 in.) 20 5.20 mm (0.2047 in.) 44 5.44 mm (0.2142 in.) 68 5.68 mm (0.2236 in.) 22 5.22 mm (0.2055 in.) 46 5.46 mm (0.2150 in.) 70 5.70 mm (0.2244 in.) 24 5.24 mm (0.2063 in.) 48 5.48 mm (0.2157 in.) 72 5.72 mm (0.2252 in.) 26 5.26 mm (0.2071 in.) 50 5.50 mm (0.2165 in.) 74 5.74 mm (0.2260 in.) 28 5.28 mm (0.2079 in.) 52 5.52 mm (0.2173 in.) - -

Text in Illustration *1 Valve Lifter Selection Chart (Exhaust) *2 Installed lifter thickness mm (in.) *3 Measured clearance mm (in.) - - - Standard exhaust valve clearance (Cold):

- 0.35 to 0.45 mm (0.0138 to 0.0177 in.)

- EXAMPLE:

- A 5.34 mm (0.210 in.) lifter is installed, and the measured clearance is 0.48 mm (0.0189 in.). Replace the 5.34 mm (0.210 in.) lifter with a No. 42 lifter.

- New Lifter Thickness:

Lifter No. Specified Condition Lifter No. Specified Condition Lifter No. Specified Condition 06 5.06 mm (0.1992 in.) 30 5.30 mm (0.2087 in.) 54 5.54 mm (0.2181 in.) 08 5.08 mm (0.2000 in.) 32 5.32 mm (0.2094 in.) 56 5.56 mm (0.2189 in.) 10 5.10 mm (0.2008 in.) 34 5.34 mm (0.2102 in.) 58 5.58 mm (0.2197 in.) 12 5.12 mm (0.2016 in.) 36 5.36 mm (0.2110 in.) 60 5.60 mm (0.2205 in.) 14 5.14 mm (0.2024 in.) 38 5.38 mm (0.2118 in.) 62 5.62 mm (0.2213 in.) 16 5.16 mm (0.2031 in.) 40 5.40 mm (0.2126 in.) 64 5.64 mm (0.2220 in.) 18 5.18 mm (0.2039 in.) 42 5.42 mm (0.2134 in.) 66 5.66 mm (0.2228 in.) 20 5.20 mm (0.2047 in.) 44 5.44 mm (0.2142 in.) 68 5.68 mm (0.2236 in.) 22 5.22 mm (0.2055 in.) 46 5.46 mm (0.2150 in.) 70 5.70 mm (0.2244 in.) 24 5.24 mm (0.2063 in.) 48 5.48 mm (0.2157 in.) 72 5.72 mm (0.2252 in.) 26 5.26 mm (0.2071 in.) 50 5.50 mm (0.2165 in.) 74 5.74 mm (0.2260 in.) 28 5.28 mm (0.2079 in.) 52 5.52 mm (0.2173 in.) - -

Install the selected valve lifters.

Install the camshafts (HILUX_TGN26 RM00000147D02TX.html).

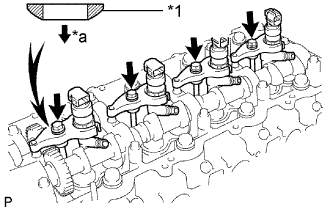

| 25. INSTALL INJECTOR ASSEMBLY |

- NOTICE:

- Be sure to install each injector, No. 1 nozzle holder clamp, washer and bolt in its original position.

Install 4 new injection nozzle seats to the cylinder head.

|

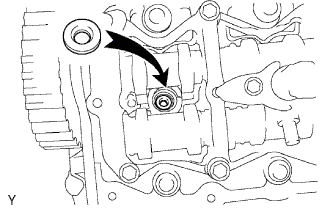

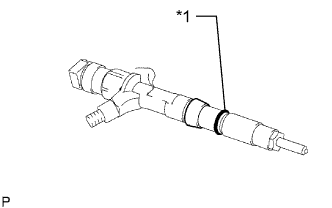

Apply a small amount of clean engine oil to 4 new O-rings.

Install an O-ring to each injector as shown in the illustration.

Text in Illustration *1 New O-Ring

|

Insert the 4 injectors into the cylinder head.

- NOTICE:

- Insert the injector until it touches the injection nozzle seat surface.

- After installing the injector to the cylinder head, the O-ring may prevent the injector from fully seating. If so, pull out the injector and reinstall it.

- Always return an injector to the same place it was removed from.

For an injector that has been replaced with a new injector, register the injector compensation code.

- w/ EGR Cooler: (HILUX_TGN26 RM0000012XK043X_02_0003.html)

- w/o EGR Cooler: (HILUX_TGN26 RM0000012XK03ZX_02_0003.html)

- w/ EGR Cooler: (HILUX_TGN26 RM0000012XK043X_02_0003.html)

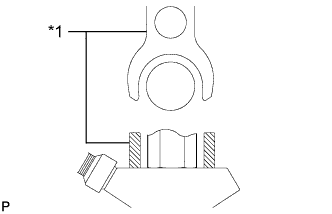

Temporarily install 4 new washers and the 4 No. 1 nozzle holder clamps with the 4 bolts.

Text in Illustration *1 Washer *a Downward - NOTICE:

- The fork portion of the nozzle holder clamp must be set on the injector.

- Before tightening the bolts, check that the No. 1 nozzle holder clamps are set properly.

- To fasten the clamp bolts, first tighten them by hand until they cannot be turned further. Then, tighten the bolts to the specified torque in a following step.

- When tightening the bolts, pay attention so as not to tilt the bolt or clamp.

- Do not reuse the washer.

- If the nozzle leakage pipe is accidentally tightened beyond the torque specification, it must be replaced.

Text in Illustration *1 No. 1 Nozzle Holder Clamp - HINT:

- Apply a small amount of engine oil to the threads and under the heads of the clamp bolts.

|

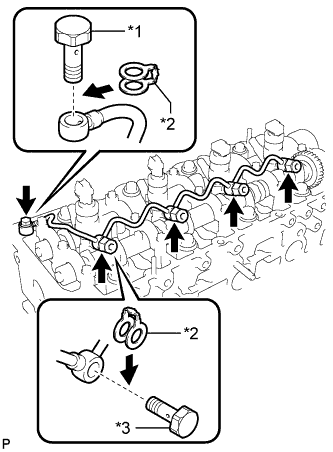

Temporarily install the 4 injection pipes with the union nuts.

- HINT:

- To position the injectors, loosely tighten the union nuts.

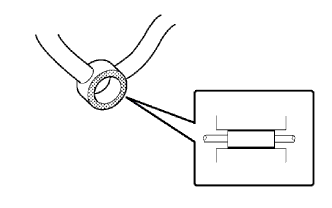

Check the nozzle leakage pipe. Check that there are no scratches or dents on the 5 union seal surfaces.

If scratches or dents are present, replace the nozzle leakage pipe.

|

Set the nozzle leakage pipe and 5 new gaskets in place.

Text in Illustration *1 Union Bolt *2 New Gasket *3 Injector Hollow Screw

|

Apply a small amount of oil to the 4 injector hollow screws and union bolt.

Temporarily install the nozzle leakage pipe with the 4 injector hollow screws and union bolt.

Tighten the 4 holder clamp bolts.

- Torque:

- 22 N*m{220 kgf*cm, 16 ft.*lbf}

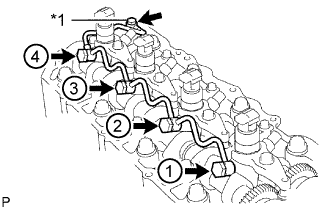

Remove the 4 injection pipes.

Tighten the 4 injector hollow screws in order from 1 to 4.

- Torque:

- 16 N*m{163 kgf*cm, 12 ft.*lbf}

Text in Illustration *1 Union Bolt - NOTICE:

- If an injector hollow screw is accidentally tightened beyond the torque specification, it must be replaced.

|

Tighten the union bolt.

- Torque:

- 13 N*m{127 kgf*cm, 9 ft.*lbf}

- NOTICE:

- If the union bolt is accidentally tightened beyond the torque specification, it must be replaced.

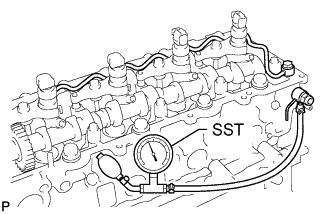

| 26. INSPECT FOR FUEL LEAK |

Check that there are no leaks from the nozzle leakage pipe connection.

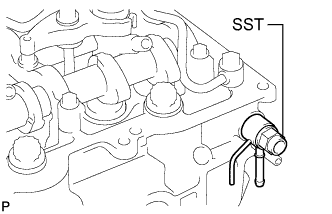

Install the gasket and No. 2 nozzle leakage pipe to the cylinder head with SST (check valve).

- Part No.:

- 23762-27010 (No. 2 nozzle leakage pipe)

- SST

- 09280-00010

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Apply a small amount of soapy water (or other fluid for detecting fuel leakage) on the nozzle leakage pipe connection.

Install SST (turbocharger pressure gauge) to the fuel return side of the leakage pipe and maintain 100 kPa (1.0 kgf/cm2, 15 psi) of pressure for 60 seconds to check that no bubbles form.

- SST

- 09992-00242

- NOTICE:

- Before checking for leakage, be sure to remove the ball and spring in the check valve.

After checking for fuel leaks, wipe off the soapy water from the leakage pipe connection.

Remove SST, the No. 2 nozzle leakage pipe and gasket.

- NOTICE:

- Never reinstall the disassembled check valve to the engine.

|

| 27. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY |

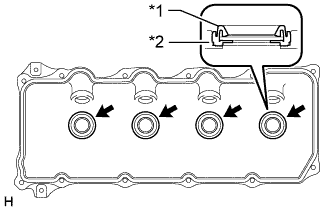

Install 4 new No. 3 cylinder head cover gaskets to the cylinder head cover in the directions shown in the illustration.

Text in Illustration *1 No. 3 Cylinder Head Cover Gasket *2 Cylinder Head Cover - NOTICE:

- Do not install the No. 3 cylinder head cover gaskets at an angle.

- Check that there is no foreign matter at the installation location of the No. 3 cylinder head cover gaskets.

|

Remove any old seal packing (FIPG material) from the cylinder head.

Apply seal packing to the specific areas shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Text in Illustration

Seal Packing - NOTICE:

- Remove any oil from the contact surface.

- Install the head cover within 3 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after installing the seal packing.

|

Install a new cylinder head cover gasket and the cylinder head cover with the 10 bolts and 2 nuts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

Install 4 new nozzle holder seals.

Connect the ventilation hose.

w/ EGR Cooler:

Connect the 4 injector connectors and install the 3 bolts.- Torque:

- 13 N*m{127 kgf*cm, 9 ft.*lbf}

w/o EGR Cooler:

Connect the 4 injector connectors.

| 28. INSTALL OIL FILLER CAP SUB-ASSEMBLY |