Condenser (For Sedan) -- Installation |

| 1. INSTALL CONDENSER |

|

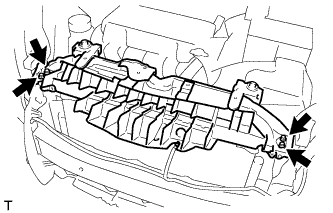

Engage the 2 claws and install the condenser into the vehicle.

- NOTICE:

- Do not damage the condenser or radiator when installing the condenser.

- HINT:

- If a new condenser is installed, add compressor oil to the condenser as follows.

- Compressor oil:

- ND-OIL8 or the equivalent. Add 40 cc (1.35 fl. oz.)

| 2. INSTALL LIQUID TUBE SUB-ASSEMBLY A |

|

Remove the attached vinyl tape from the pipe and the connecting part of the cooler condenser.

Apply sufficient compressor oil to a new O-ring and the fitting surface of the pipe joint.

- Compressor oil:

- ND-OIL8 or the equivalent

Install the O-ring onto the liquid tube.

Install the liquid tube onto the cooler condenser with the bolt.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 3. INSTALL NO. 1 COOLER REFRIGERANT DISCHARGE HOSE |

|

Remove the attached vinyl tape from the hose and the connecting part of the cooler condenser.

Apply sufficient compressor oil to a new O-ring and the fitting surface of the hose joint.

- Compressor oil:

- ND-OIL8 or the equivalent

Install the O-ring onto the discharge hose.

Install the discharge hose onto the cooler condenser with the bolt.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 4. INSTALL RADIATOR SUPPORT SUB-ASSEMBLY UPPER |

|

Install the radiator support sub-assembly upper with the 4 bolts.

- Torque:

- 5.5 N*m{56 kgf*cm, 49 in.*lbf}

Connect the horn assembly connector.

| 5. INSTALL HOOD LOCK ASSEMBLY (w/ Theft Deterrent System) |

|

Temporarily install the hood lock assembly with the 3 bolts.

Connect the engine hood courtesy switch connector.

Connect the hood lock control cable assembly to the 2 clamps.

|

| 6. INSTALL HOOD LOCK ASSEMBLY (w/o Theft Deterrent System) |

|

Temporarily install the hood lock assembly with the 3 bolts.

Connect the hood lock control cable assembly to the 2 clamps.

|

| 7. INSTALL NO. 1 COOLER COVER |

|

Insert the 2 pins of No. 1 cooler cover into the radiator support LWR.

Install No. 1 cooler cover with the 2 clips.

| 8. INSTALL FRONT BUMPER COVER |

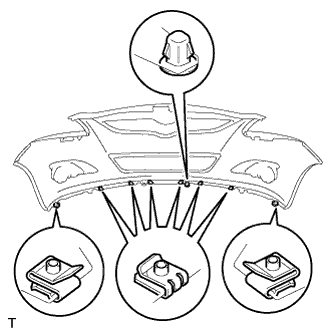

Install the 2 clips, screw grommet and the 6 spring nuts.

|

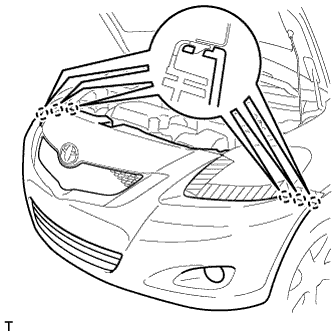

Engage the 6 claws and install the front bumper cover.

|

Connect the connectors.

- HINT:

- If the vehicle is equipped with fog lights, connect the connector.

Install the 6 clips.

|

Install the 2 screw grommets.

Tighten the 9 bolts and the 7 screws.

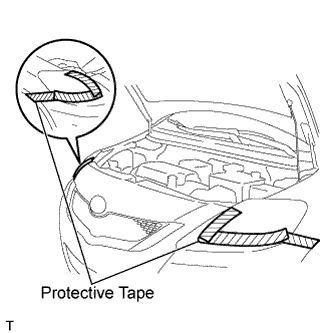

Remove the protective tape.

|

| 9. INSTALL FRONT SPOILER COVER |

Install the front spoiler cover with the 2 screws and the 10 bolts.

|

| 10. ADJUST HOOD LOCK ASSEMBLY |

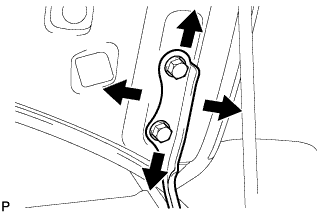

Loosen the hood side hinge bolts.

|

Move the hood to adjust the clearance to within the standard range.

Tighten the hood side hinge bolts after the adjustment.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

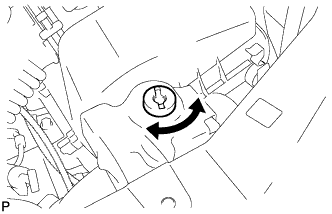

Adjust the height of the hood front end by turning the cushion rubber.

- HINT:

- The cushion rubber can be raised and lowered by turning it.

|

Adjust the hood lock.

Loosen the 3 bolts.

Adjust the hood lock position so that the striker can enter it smoothly.

Tighten the 3 bolts after the adjustment.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

|

| 11. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

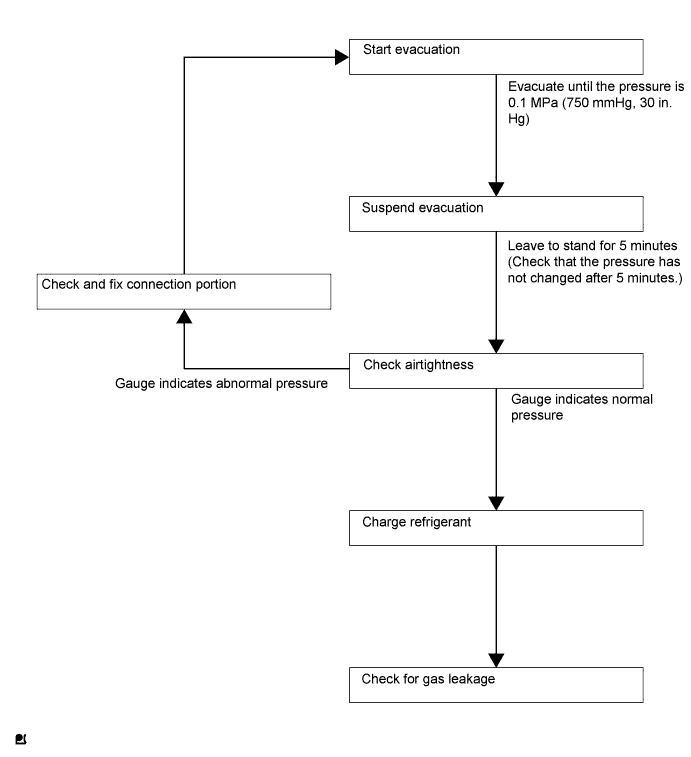

| 12. CHARGE REFRIGERANT |

- NOTICE:

- Charge refrigerant in accordance with equipment manual.

Perform vacuum purging using a vacuum pump.

Charge refrigerant HFC-134a (R134a).

- SST

- 09985-20010(09985-02010,09985-02050,09985-02060,09985-02070,09985-02080,09985-02090,09985-02110,09985-02130,09985-02140,09985-02150)

- Standard:

- 330 to 390g (11.64 to 13.76oz.)

- NOTICE:

- Do not start the engine before charging it with refrigerant as the cooler compressor doesn't work properly without sufficient refrigerant. This could cause the compressor to overheat.

- HINT:

- The relationship between refrigerant charge amount and pressure is as follows.

- High Charge Range:

If refrigerant is overcharged, pressure rises on the high-pressure side. High-pressure cut off frequently occurs. This causes insufficient cooling performance and also insufficient compressor lubrication. - Low Charge Range:

Shortage of refrigerant causes insufficient cooling performance and low circulation of refrigerant oil, which shortens compressor life. Operation with insufficient coolant raises refrigerant temperature and causes heat deterioration of rubber seals and hoses. Cracking and thus refrigerant leakage may occur.

Install the caps onto the service valves on the refrigerant line.

| 13. WARM UP ENGINE |

- NOTICE:

- Warm up the engine at less than 2,000 rpm for 1 minute or more after charging it with refrigerant.

| 14. CHECK FOR REFRIGERANT LEAK |

After recharging the refrigerant gas, check for refrigerant gas leakage using a halogen leak detector.

Perform the operation as follows:

- Stop the engine.

- Secure good ventilation (the halogen leak detector may react to volatile gases other than refrigerant, such as evaporated gasoline or exhaust gas).

- Repeat the test 2 or 3 times.

- Make sure that some refrigerant remains in the refrigeration system.

When compressor is off: approximately 392 to 588 kPa (4 to 6 kgf*cm2, 57 to 85 psi)

- HINT:

- It is impossible for the above pressure to be maintained if there is leakage.

- Stop the engine.

Using the halogen leak detector, check the refrigerant line, especially the connection points, for leakage.

|

Bring the halogen leak detector close to the drain hose before performing the test.

- HINT:

- After the blower motor has stopped, leave the cooling unit for at least 15 minutes.

- Place the halogen leak detector sensor under the drain hose.

- When bringing the halogen leak detector close to the drain hose, make sure that the halogen leak detector does not react to the volatile gases.

|

If a gas leak is not detected from the drain hose, remove the blower motor from the cooling unit. Insert the halogen leak detector sensor into the unit and perform the test.

Disconnect the pressure switch connector and leave it for approximately 20 minutes. Bring the halogen leak detector close to the pressure switch and perform the test.