Compressor (For Sedan) -- Installation |

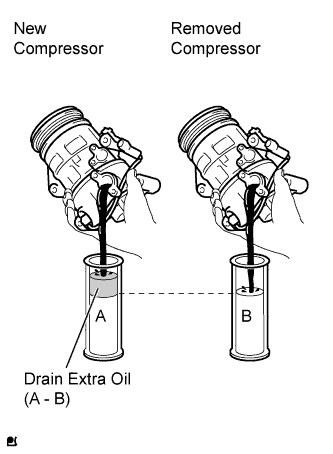

| 1. ADJUST COMPRESSOR OIL |

|

When replacing the compressor with a new one, gradually discharge the refrigerant gas from the service valve. Then drain the following amount of oil from the new compressor before installation, so that the amount of oil contained in it is the same as that in the compressor to be replaced.

- HINT:

- New compressors are filled with sufficient oil for the whole cycle. Therefore, it is necessary to drain residual oil from the condenser and cooling unit.

- Standard:

- (The amount of oil inside a new compressor: 90 (+15) cc (3.0 (+0.51) fl.oz.)) - (The amount of oil remaining in the removed compressor) = The amount of oil to be removed when replacing the compressor

- NOTICE:

- When checking the compressor oil level, observe the precautions for cooler removal/installation.

- If a new compressor is installed without removing the amount of oil remaining in the pipes of the vehicle, the amount of oil becomes too large. This prevents heat exchange in the refrigerant cycle and causes refrigeration failure.

- If the amount of oil remaining in the removed compressor is too small, check for oil leakage.

- Use ND-OIL8 compressor oil.

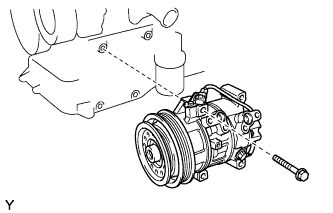

| 2. INSTALL COMPRESSOR AND PULLEY |

|

Provisionally tighten the compressor with the bolt.

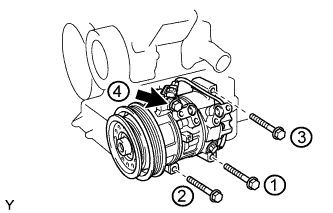

Tighten the compressor with the 4 bolts.

- Torque:

- 25 N*m{255 kgf*cm, 18 ft.*lbf}

- NOTICE:

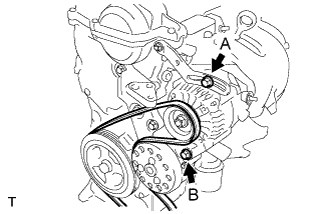

- Tighten the bolts in the sequence shown in the illustration to install the compressor.

|

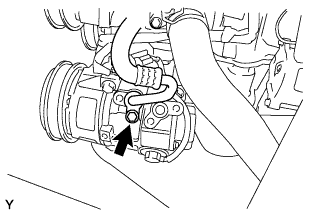

Connect the connector.

| 3. INSTALL NO. 1 COOLER REFRIGERANT DISCHARGE HOSE |

|

Remove the attached vinyl tape from the hose.

Apply sufficient compressor oil (ND-OIL8) to a new O-ring and the fitting surface of the compressor.

- Compressor oil:

- ND-OIL8 or the equivalent

Install the O-ring onto the discharge hose.

Install the discharge hose onto the compressor with the bolt.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

| 4. INSTALL NO. 1 COOLER REFRIGERANT SUCTION HOSE |

|

Remove the attached vinyl tape from the hose.

Apply sufficient compressor oil (ND-OIL8) to a new O-ring and the fitting surface of the compressor.

- Compressor oil:

- ND-OIL8 or the equivalent

Install the O-ring onto the suction hose.

Install the suction hose onto the compressor with the bolt.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

| 5. INSTALL FAN & GENERATOR V BELT |

Provisionally install the fan and generator V belt onto each pulley.

- NOTICE:

- Make sure that there is no foreign matter or liquid, such as oil, on the belt and pulleys.

- Make sure that the V belt is securely fitted into the rib grooves of the pulley.

| 6. ADJUST FAN & GENERATOR V BELT |

Insert an adjusting bar between the engine mounting bracket and generator assembly. Pull the adjusting bar toward the vehicle front to adjust the generator V belt tension (YARIS_NCP93 RM000001DCH00ZX_01_0001.html).

Text in Illustration *a OK *b NG - NOTICE:

- Do not insert the adjusting bar between the camshaft timing oil control valve assembly and generator assembly. It could damage the camshaft timing oil control valve assembly.

|

First tighten bolt A, then tighten bolt B.

- Torque:

- 19 N*m{189 kgf*cm, 14 ft.*lbf} for bolt A

- 54 N*m{551 kgf*cm, 40 ft.*lbf} for bolt B

|

| 7. INSPECT FAN & GENERATOR V BELT |

|

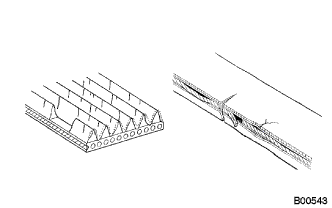

Check the belt for wear, cracks or other signs of damage.

If any of the following defects is found, replace the V-ribbed belt.- HINT:

- The belt is cracked.

- The belt is worn out to the extent that the wires are exposed.

- The belt has chunks missing from the ribbed groves.

Check that the belt fits properly in the ribbed grooves.

Text in Illustration *a CORRECT *b INCORRECT - HINT:

- Check with your hand, to confirm that the belt has not slipped out of the grooves on the bottom to the pulley. If it has slipped out, replace the V-ribbed belt. Install a new V-ribbed belt correctly.

|

Inspect the V belt deflection and tension.

Text in Illustration *A w/o Air Conditioner *B w/ Air Conditioner - Deflection:

Item Specified Condition New belt 8.0 to 9.0 mm (0.31 to 0.35 in) Used belt 12.5 to 13.5 mm (0.49 to 0.53 in)

- Tension:

Item Specified Condition New belt 700 to 800 N (71 to 82 kg, 157 to 180 lb) Used belt 300 to 400 N (31 to 41 kg, 67 to 90 lb)

- HINT:

- When inspecting the V belt deflection, apply 98 N (10 kgf) tensile force to it.

- Perform the V belt inspection and adjustment while the engine is cold.

- V-ribbed belt tension and deflection should be checked immediately after installation of a new belt, and after cranking the engine when inspecting a used belt.

- Check the V belt deflection at the point between the specified pulleys where the deflection is greatest.

- When installing a new belt, set its tension to the intermediate value of the specification.

- When inspecting a belt which has been used for over 5 minutes, apply the Used Belt specifications.

- When reinstalling a belt which has been used for over 5 minutes, adjust its deflection and tension to the intermediate values of each Used Belt specification.

- V-ribbed belt tension and deflection should be checked after 2 revolutions of engine cranking.

- When using a belt tension gauge, confirm its accuracy by using a master gauge first.

|

| 8. INSTALL ENGINE UNDER COVER RH |

| 9. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 10. CHARGE REFRIGERANT |

- NOTICE:

- Charge refrigerant in accordance with equipment manual.

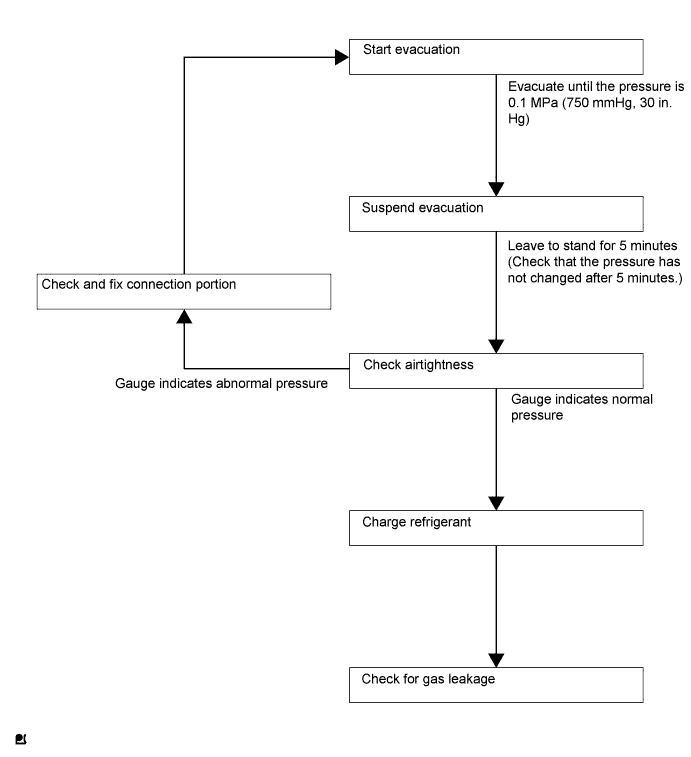

Perform vacuum purging using a vacuum pump.

Charge refrigerant HFC-134a (R134a).

- SST

- 09985-20010(09985-02010,09985-02050,09985-02060,09985-02070,09985-02080,09985-02090,09985-02110,09985-02130,09985-02140,09985-02150)

- Standard:

- 330 to 390g (11.64 to 13.76oz.)

- NOTICE:

- Do not start the engine before charging it with refrigerant as the cooler compressor doesn't work properly without sufficient refrigerant. This could cause the compressor to overheat.

- HINT:

- The relationship between refrigerant charge amount and pressure is as follows.

- High Charge Range:

If refrigerant is overcharged, pressure rises on the high-pressure side. High-pressure cut off frequently occurs. This causes insufficient cooling performance and also insufficient compressor lubrication. - Low Charge Range:

Shortage of refrigerant causes insufficient cooling performance and low circulation of refrigerant oil, which shortens compressor life. Operation with insufficient coolant raises refrigerant temperature and causes heat deterioration of rubber seals and hoses. Cracking and thus refrigerant leakage may occur.

Install the caps onto the service valves on the refrigerant line.

| 11. WARM UP ENGINE |

- NOTICE:

- Warm up the engine at less than 2,000 rpm for 1 minute or more after charging it with refrigerant.

| 12. CHECK FOR REFRIGERANT LEAK |

After recharging the refrigerant gas, check for refrigerant gas leakage using a halogen leak detector.

Perform the operation as follows:

- Stop the engine.

- Secure good ventilation (the halogen leak detector may react to volatile gases other than refrigerant, such as evaporated gasoline or exhaust gas).

- Repeat the test 2 or 3 times.

- Make sure that some refrigerant remains in the refrigeration system.

When compressor is off: approximately 392 to 588 kPa (4 to 6 kgf*cm2, 57 to 85 psi)

- HINT:

- It is impossible for the above pressure to be maintained if there is leakage.

- Stop the engine.

Using the halogen leak detector, check the refrigerant line, especially the connection points, for leakage.

|

Bring the halogen leak detector close to the drain hose before performing the test.

- HINT:

- After the blower motor has stopped, leave the cooling unit for at least 15 minutes.

- Place the halogen leak detector sensor under the drain hose.

- When bringing the halogen leak detector close to the drain hose, make sure that the halogen leak detector does not react to the volatile gases.

|

If a gas leak is not detected from the drain hose, remove the blower motor from the cooling unit. Insert the halogen leak detector sensor into the unit and perform the test.

Disconnect the pressure switch connector and leave it for approximately 20 minutes. Bring the halogen leak detector close to the pressure switch and perform the test.