Meter / Gauge System (For Hatchback) Fuel Receiver Gauge Malfunction

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CONFIRM DTC OUTPUT

PERFORM ACTIVE TEST USING TECHSTREAM (FUEL METER OPERATION)

INSPECT FUEL SENDER GAUGE ASSEMBLY

CHECK FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY

CHECK HARNESS AND CONNECTOR (COMBINATION METER ASSEMBLY - FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY)

METER / GAUGE SYSTEM (for Hatchback) - Fuel Receiver Gauge Malfunction |

DESCRIPTION

- The combination meter assembly controls the fuel receiver gauge in accordance with the resistance of the fuel sender gauge, which varies depending on the amount of fuel remaining in the fuel tank.

WIRING DIAGRAM

Refer to DTC B1500 (YARIS_NCP93 RM000002S2T04ZX_02.html).

INSPECTION PROCEDURE

Check DTC (YARIS_NCP93 RM000001Q7700YX.html).

ResultResult

| Proceed to

|

DTC B1500 is not output

| A

|

DTC B1500 is output

| B

|

| 2.PERFORM ACTIVE TEST USING TECHSTREAM (FUEL METER OPERATION) |

Connect the Techstream to the DLC3.

Turn the ignition switch to ON.

Turn the Techstream on.

Enter the following menus: Body Electrical / Combination Meter / Active Test.

According to the display on the Techstream, perform the Active Test.

Combination MeterTester Display

| Test part

| Control Range

| Diagnostic Note

|

Fuel Meter Operation

| Fuel gauge

| EMPTY / 1/2 / FULL

| Vehicle is stopped and the engine idling

|

- OK:

- Fuel receiver gauge indication is normal.

| 3.INSPECT FUEL SENDER GAUGE ASSEMBLY |

Remove the fuel sender gauge assembly (YARIS_NCP93 RM000000SL805GX.html).

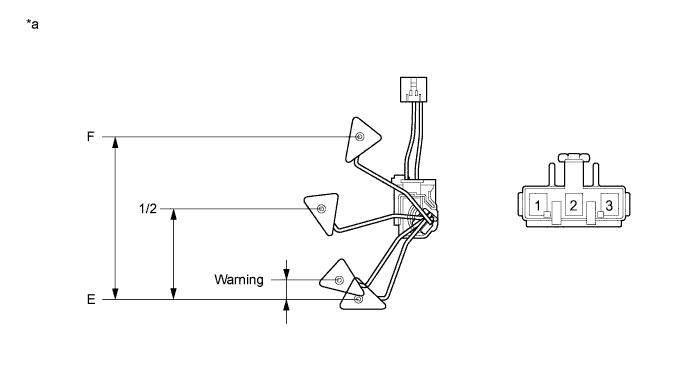

Text in Illustration*a

| Component without harness connected

(Fuel Sender Gauge Assembly)

| -

| -

|

Check that the float moves smoothly between F and E.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Float Level

| Float Position (mm (in.))

| Specified Condition

|

1 - 2

| F

| 142 to 152 (5.591 to 5.984)

| 13.5 to 16.5 Ω

|

1/2

| 71.1 to 76.1 (2.799 to 2.996)

| 208.3 Ω

|

Warning

| 5.9 to 10.9 (0.232 to 0.429)

| 365.2 Ω

|

E

| 0 (0)

| 405.5 to 414.5 Ω

|

Reinstall the fuel sender gauge assembly.

| 4.CHECK FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY |

Remove the fuel suction with pump and gauge tube assembly (YARIS_NCP93 RM000004NLO00FX_01_0009.html).

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

A-2 (FS) - B-2

| Always

| Below 1 Ω

|

A-3 (FE) - B-1

| Always

| Below 1 Ω

|

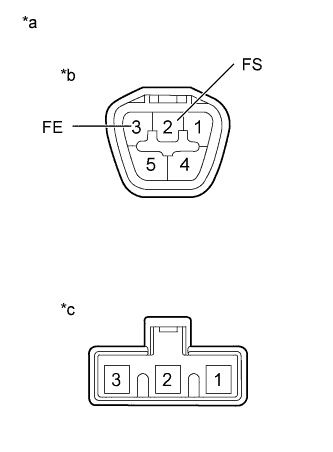

Text in Illustration*a

| Component without harness connected

(Fuel Suction with Pump and Gauge Tube Assembly)

|

*b

| Connector A

|

*c

| Connector B

|

Reinstall the fuel suction plate sub-assembly.

| 5.CHECK HARNESS AND CONNECTOR (COMBINATION METER ASSEMBLY - FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY) |

Disconnect the D100 combination meter assembly connector.

Disconnect the J71 fuel suction with pump and gauge tube assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

D100-16 (L) - J71-2 (FS)

| Always

| Below 1 Ω

|

D100-16 (L) - Body ground

| Always

| 10 kΩ or higher

|

J71-3 (FE) - Body ground

| Always

| Below 1 Ω

|

Reconnect the fuel suction with pump and gauge tube assembly connector.

Reconnect the combination meter assembly connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|