Generator (For Hatchback) -- Reassembly |

| 1. INSTALL GENERATOR ROTOR ASSEMBLY |

|

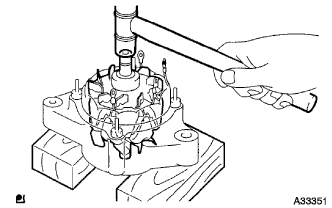

Place the generator rotor assembly on the generator drive end frame assembly.

Using a plastic hammer, install the generator rotor assembly to the generator drive end frame assembly.

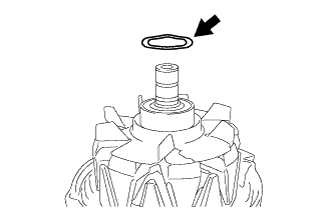

Install a new generator washer on the generator rotor assembly.

|

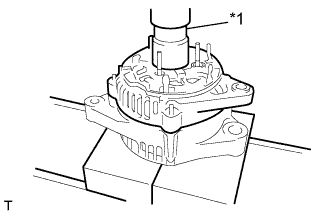

Using a 30 mm/12 pt socket wrench and press, slowly press in the generator rectifier end frame.

Text in Illustration *1 30 mm/ 12 pt Socket Wrench

|

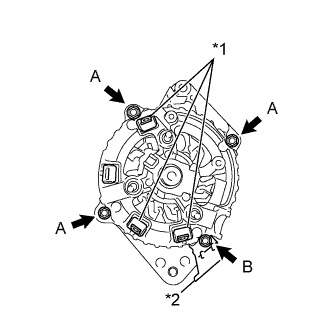

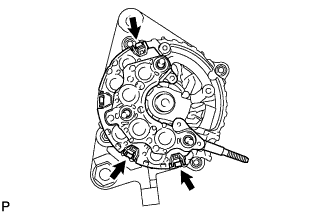

Install the 3 nuts A.

- Torque:

- 4.5 N*m{46 kgf*cm, 40 in.*lbf}

|

Install the 3 terminal insulators onto the generator rectifier end frame.

Install the cord clip with the nut B.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

Text in Illustration *1 Terminal Insulator *2 Cord Clip

| 2. INSTALL GENERATOR HOLDER WITH RECTIFIER |

|

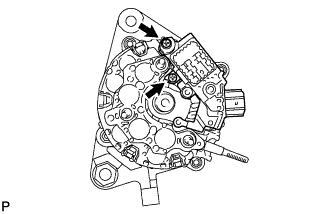

Install the generator holder with rectifier with the 3 screws.

- Torque:

- 2.0 N*m{20 kgf*cm, 18 in.*lbf}

| 3. INSTALL GENERATOR REGULATOR ASSEMBLY |

|

Install the generator regulator assembly with the 2 screws.

- Torque:

- 2.0 N*m{20 kgf*cm, 18 in.*lbf}

| 4. INSTALL GENERATOR BRUSH HOLDER ASSEMBLY |

|

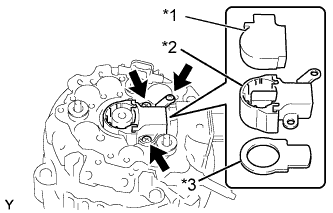

Install the generator plate seal.

Install the generator brush holder assembly with the 3 screws.

- Torque:

- 2.0 N*m{20 kgf*cm, 18 in.*lbf}

Install the generator brush cover onto the generator brush holder assembly.

Text in Illustration *1 Generator Brush Cover *2 Generator Brush Holder Assembly *3 Generator Plate Seal

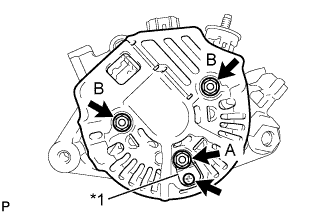

Install the generator rear end cover with the 2 nuts B.

- Torque:

- Nut B:

- 4.4 N*m{45 kgf*cm, 39 in.*lbf}

|

Install the rectifier plate with the nut A and screw.

- Torque:

- Nut A:

- 4.4 N*m{45 kgf*cm, 39 in.*lbf}

- Screw:

- 3.9 N*m{40 kgf*cm, 35 in.*lbf}

Text in Illustration *1 Rectifier Plate

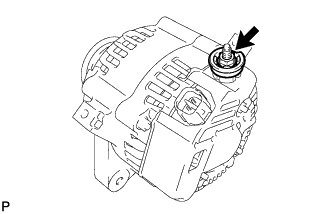

| 5. INSTALL GENERATOR TERMINAL INSULATOR |

Install the generator terminal insulator with the nut.

- Torque:

- 4.1 N*m{42 kgf*cm, 36 in.*lbf}

|

| 6. INSTALL GENERATOR PULLEY |

|

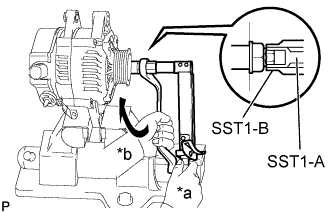

Clamp the generator housing stay in a vise tightly.

Install the generator pulley onto the generator rotor shaft by tightening the generator pulley nut by hand.

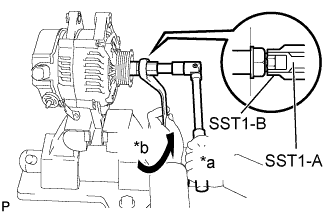

Hold SST1-A with a torque wrench, and tighten SST1-B clockwise to the specified torque.

- SST

- 09820-63011(09820-06010,09820-06021)

- Torque:

- 64 N*m{653 kgf*cm, 47 ft.*lbf}

Text in Illustration *a Hold *b Turn - NOTICE:

- Check that SST is securely fitted onto the generator rotor shaft.

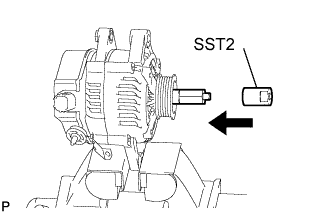

Insert SST2, and engage SST2 to the pulley nut.

|

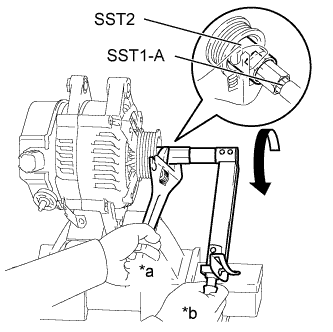

Tighten the generator pulley nut by turning SST1-A in the direction shown in the illustration.

Text in Illustration *a Hold *b Turn - Torque:

- 133 N*m{1356 kgf*cm, 98 ft.*lbf}

- HINT:

- Hold the adjustable wrench against the vise and tighten the nut securely.

|

Remove SST 2 from the generator assembly.

Hold SST1-A, turn SST1-B, and remove SST1-A and SST1-B from the generator assembly.

Text in Illustration *a Hold *b Turn

|

Turn the generator pulley, and check that the generator pulley moves smoothly.

Remove the generator assembly from a vise.