Manual Transaxle Unit (For Hatchback) -- Inspection |

| 1. INSPECT NO. 3 SYNCHRONIZER RING |

|

Check for wear and damage.

Coat the 5th gear cone with gear oil.

Turn the No. 3 synchronizer ring in one direction while pushing it against the 5th gear cone.

Check that the ring locks.

If the No. 3 synchronizer ring does not lock, replace the No. 3 synchronizer ring.

Using a feeler gauge, measure the clearance between the No. 3 synchronizer ring back and the gear spline end.

- Minimum clearance:

- 0.75 mm (0.0295 in.)

|

| 2. INSPECT NO. 3 TRANSMISSION HUB SLEEVE |

|

Check the sliding condition between No. 3 transmission hub sleeve and No. 3 transmission clutch hub.

Check that the edges of the No. 3 transmission hub sleeve spline gear are not worn down.

Using a vernier caliper, measure the width of the No. 3 transmission hub sleeve groove (A) and the thickness of the claw part on the No. 3 gear shift fork (B), and calculate the clearance.

Text in Illustration *a Clearance = (A - B) - Standard clearance (A - B):

- 0.3 to 0.5 mm (0.0118 to 0.00197 in.)

|

| 3. INSPECT 5TH GEAR |

|

Using a caliper gauge, measure the inside diameter of the 5th gear.

- Standard inside diameter:

- 29.915 to 29.931 mm (1.1778 to 1.1784 in.)

- Maximum inside diameter:

- 29.931 mm (1.1784 in.)

| 4. INSPECT REVERSE IDLER GEAR SUB-ASSEMBLY |

|

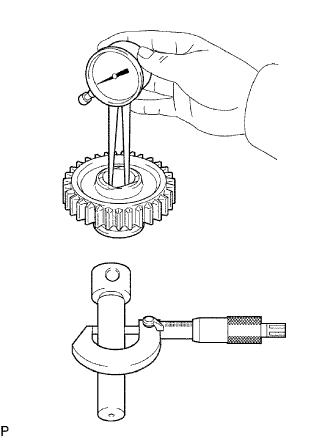

Using a caliper gauge, inspect the reverse idle gear sub-assembly.

- Standard inside diameter:

- 18.040 to 18.058 mm (0.710 to 0.711 in.)

- Maximum inside diameter:

- 18.058 mm (0.711 in.)

Using a micrometer, inspect the reverse idler gear shaft as shown in the illustration.

- Standard outer diameter:

- 17.966 to 17.984 mm (0.707 to 0.708 in.)

- Minimum outer diameter:

- 17.966 mm (0.707 in.)