Engine Hybrid System. Yaris. Ncp93, 131

1Nz-Fe Engine Mechanical. Yaris. Ncp93, 131

Drive Belt (For Sedan) -- On-Vehicle Inspection |

| 1. INSPECT FAN AND GENERATOR V BELT |

|

Check the belt for wear, cracks or other signs of damage.

If any of the following defects is found, replace the V-ribbed belt.- HINT:

- The belt is cracked.

- The belt is worn out to the extent that the wires are exposed.

- The belt has chunks missing from the ribbed groves.

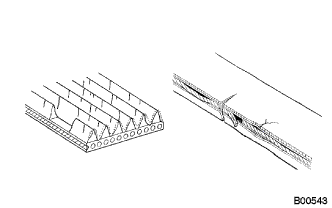

Check that the belt fits properly in the ribbed grooves.

Text in Illustration *a CORRECT *b INCORRECT - HINT:

- Check with your hand, to confirm that the belt has not slipped out of the grooves on the bottom to the pulley. If it has slipped out, replace the V-ribbed belt. Install a new V-ribbed belt correctly.

|

Inspect the V belt deflection and tension.

Text in Illustration *A w/o Air Conditioner *B w/ Air Conditioner - Deflection:

Item Specified Condition New belt 8.0 to 9.0 mm (0.31 to 0.35 in) Used belt 12.5 to 13.5 mm (0.49 to 0.53 in)

- Tension:

Item Specified Condition New belt 700 to 800 N (71 to 82 kg, 157 to 180 lb) Used belt 300 to 400 N (31 to 41 kg, 67 to 90 lb)

- HINT:

- When inspecting the V belt deflection, apply 98 N (10 kgf) tensile force to it.

- Perform the V belt inspection and adjustment while the engine is cold.

- V-ribbed belt tension and deflection should be checked immediately after installation of a new belt, and after cranking the engine when inspecting a used belt.

- Check the V belt deflection at the point between the specified pulleys where the deflection is greatest.

- When installing a new belt, set its tension to the intermediate value of the specification.

- When inspecting a belt which has been used for over 5 minutes, apply the Used Belt specifications.

- When reinstalling a belt which has been used for over 5 minutes, adjust its deflection and tension to the intermediate values of each Used Belt specification.

- V-ribbed belt tension and deflection should be checked after 2 revolutions of engine cranking.

- When using a belt tension gauge, confirm its accuracy by using a master gauge first.

|