Smart Key System (For Entry Function) Driver Side Door Entry Lock And Unlock Functions Do Not Operate

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK POWER DOOR LOCK OPERATION

READ VALUE USING TECHSTREAM

CHECK WAVE ENVIRONMENT

PERFORM KEY DIAGNOSTIC MODE INSPECTION

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU - DOOR ELECTRICAL KEY OSCILLATOR)

CHECK HARNESS AND CONNECTOR (DOOR ELECTRICAL KEY OSCILLATOR - FRONT DOOR OUTSIDE HANDLE)

CHECK HARNESS AND CONNECTOR (DOOR ELECTRICAL KEY OSCILLATOR - BATTERY AND BODY GROUND)

REPLACE DOOR ELECTRICAL KEY OSCILLATOR

CHECK DOOR ELECTRICAL KEY OSCILLATOR (OPERATION)

SMART KEY SYSTEM (for Entry Function) - Driver Side Door Entry Lock and Unlock Functions do not Operate |

DESCRIPTION

When the driver door entry lock and unlock functions do not operate, one of the following may be malfunctioning: 1) power door lock control system, 2) driver side door electrical key oscillator, or 3) certification ECU (smart key ECU assembly).

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.CHECK POWER DOOR LOCK OPERATION |

When the master switch assembly's door control switch is operated, check that the doors unlock and lock according to switch operation (COROLLA_ZRE142 RM000001333049X.html).

- OK:

- Door locks operate normally.

| 2.READ VALUE USING TECHSTREAM |

Connect the Techstream to the DLC3

Turn the engine switch on (IG).

Turn the Techstream on.

Enter the following menus: Body Electrical / Smart Key / Data List.

Read the Data List according to the display on the Techstream.

Smart Key (Certification ECU (Smart Key ECU Assembly))Tester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

D-Door Touch Sensor

| Driver side door touch sensor/ON or OFF

| ON: Sensor is touched

OFF: Sensor is not touched

| -

|

D-Door Trigger SW

| Driver side door lock switch/ON or OFF

| ON: Switch is touched

OFF: Switch is not touched

| -

|

- OK:

- On the Techstream screen, each item changes between ON and OFF according to the chart above.

Bring the electrical key transmitter near the driver door outside handle, and perform a driver door entry lock and unlock operation check.

- NOTICE:

- If the key is brought within 0.2 m (0.656 ft.) of the door handle, communication is not possible.

- HINT:

- When the electrical key transmitter is brought near the driver door outside handle, the possibility of wave interference decreases, and it can be determined if wave interference is causing the problem symptom.

- If the operation is normal, the possibility of wave interference is high. Also, added vehicle components may cause wave interference. If installed, remove them and perform the operation check.

- OK:

- Entry functions operate normally.

| OK |

|

|

|

| AFFECTED BY WAVE INTERFERENCE |

|

| 4.PERFORM KEY DIAGNOSTIC MODE INSPECTION |

Diagnostic mode inspection

Connect the Techstream to the DLC3.

Turn the engine switch on (IG).

Turn the Techstream on.

Enter the following menus: Body Electrical / Smart Key / Utility / Communication Check (Key Diag Mode) / Overhead + Driver Side.

When the electrical key transmitter is in the position shown in the illustration, check that the wireless door lock buzzer sounds.

- HINT:

- If the buzzer sounds, it can be determined that the driver seat outside transmitter is operating normally.

- OK:

- Wireless door lock buzzer sounds.

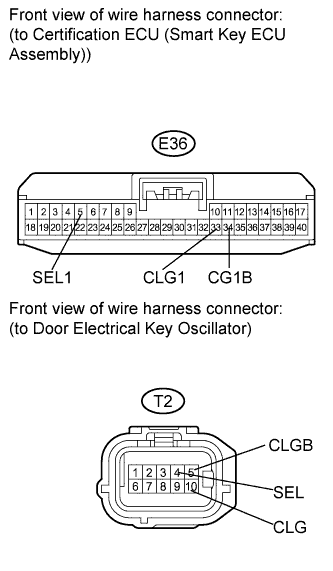

| 5.CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU - DOOR ELECTRICAL KEY OSCILLATOR) |

Disconnect the certification ECU (smart key ECU assembly) connector.

Disconnect the door electrical key oscillator connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

E36-5 (SEL1) - T2-4 (SEL)

| Always

| Below 1 Ω

|

E36-33 (CLG1) - T2-10 (CLG)

| Always

| Below 1 Ω

|

E36-34 (CG1B) - T2-5 (CLGB)

| Always

| Below 1 Ω

|

E36-5 (SEL1) - Body ground

| Always

| 10 kΩ or higher

|

E36-33 (CLG1) - Body ground

| Always

| 10 kΩ or higher

|

E36-34 (CG1B) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

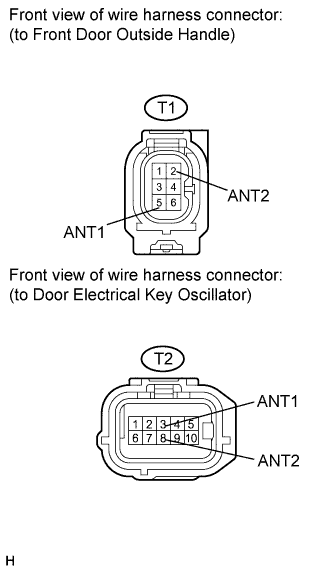

| 6.CHECK HARNESS AND CONNECTOR (DOOR ELECTRICAL KEY OSCILLATOR - FRONT DOOR OUTSIDE HANDLE) |

Disconnect the front door outside handle connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

T1-2 (ANT2) - T2-8 (ANT2)

| Always

| Below 1 Ω

|

T1-5 (ANT1) - T2-3 (ANT1)

| Always

| Below 1 Ω

|

T1-2 (ANT2) - Body ground

| Always

| 10 kΩ or higher

|

T1-5 (ANT1) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

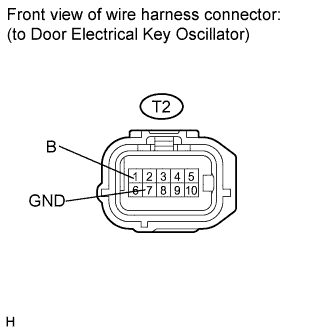

| 7.CHECK HARNESS AND CONNECTOR (DOOR ELECTRICAL KEY OSCILLATOR - BATTERY AND BODY GROUND) |

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Condition

| Specified Condition

|

T2-1 (B) - T2-7 (GND)

| Always

| 11 to 14 V

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 8.REPLACE DOOR ELECTRICAL KEY OSCILLATOR |

Replace the door electrical key oscillator (COROLLA_ZRE142 RM0000011QF0BCX.html).

| 9.CHECK DOOR ELECTRICAL KEY OSCILLATOR (OPERATION) |

Check that the entry functions operate normally.

- OK:

- Entry functions operate normally.

| OK |

|

|

|

| END (DOOR ELECTRICAL KEY OSCILLATOR IS DEFECTIVE) |

|