Input Shaft -- Reassembly |

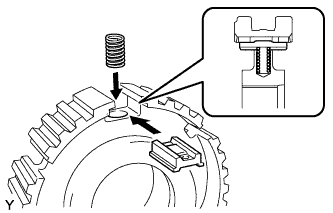

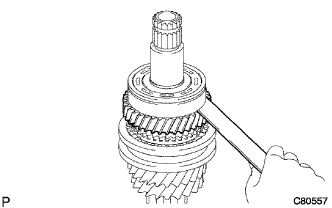

| 1. INSTALL NO. 2 TRANSMISSION HUB SLEEVE |

|

Coat the No. 2 transmission hub sleeve with gear oil.

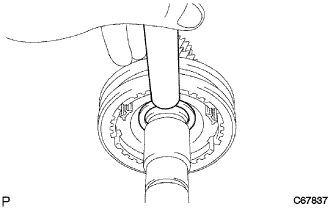

Install the 3 synchromesh shifting key springs and 3 synchromesh shifting keys to the No. 2 transmission clutch hub.

Install the No. 2 transmission clutch hub onto the No. 2 transmission hub sleeve.

- NOTICE:

- Position the No. 2 transmission hub sleeve and No. 2 transmission clutch hub correctly as shown in the illustration.

|

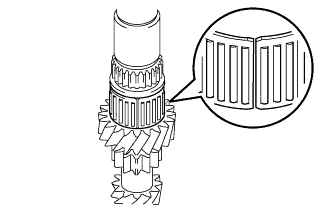

| 2. INSTALL 3RD GEAR NEEDLE ROLLER BEARING |

Coat the 3rd gear needle roller bearing with gear oil and install it onto the input shaft.

|

| 3. INSTALL 3RD GEAR |

Coat the 3rd gear with gear oil and install it onto the input shaft.

|

| 4. INSTALL 3RD GEAR SYNCHRONIZER RING |

Coat the 3rd gear synchronizer ring with gear oil and install it onto the 3rd gear.

|

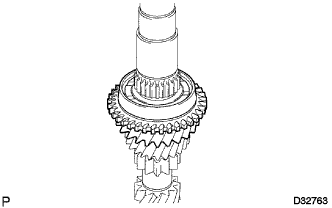

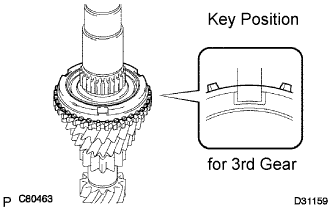

| 5. INSTALL NO. 2 TRANSMISSION CLUTCH HUB |

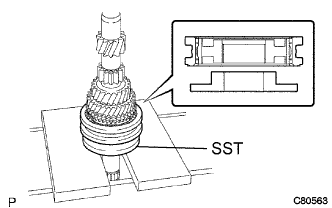

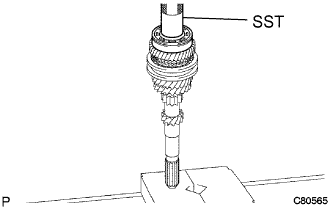

Using SST and a press, install the No. 2 transmission clutch hub onto the input shaft.

- SST

- 09316-60011(09316-00021)

- NOTICE:

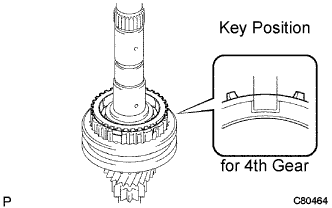

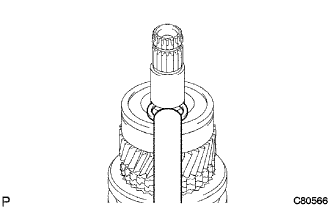

- Fit the synchromesh shifting keys into the grooves of the synchronizer ring correctly.

|

Select a snap ring that will allow minimal axial play.

- Standard clearance:

- 0.1 mm (0.00394 in.) or less

- Snap Ring Thickness:

Mark Thickness

mm (in.)Mark Thickness

mm (in.)0 2.30 (0.0906) 3 2.48 (0.0976) 1 2.36 (0.0929) 4 2.54 (0.1000) 2 2.42 (0.0953) 5 2.60 (0.1024)

|

Using a brass bar and a hammer, install the snap ring onto the input shaft.

| 6. INSTALL 4TH GEAR SYNCHRONIZER RING |

Coat the 4th gear synchronizer ring with gear oil and install it onto the No. 2 transmission clutch hub.

|

| 7. INSTALL 4TH GEAR NEEDLE ROLLER BEARING |

Coat the 4th gear needle roller bearing and 4th gear bearing spacer with gear oil and install them onto the No. 2 transmission clutch hub.

|

| 8. INSTALL 4TH GEAR |

Coat the 4th gear with gear oil and install it onto the input shaft.

|

| 9. INSTALL INPUT SHAFT REAR RADIAL BALL BEARING |

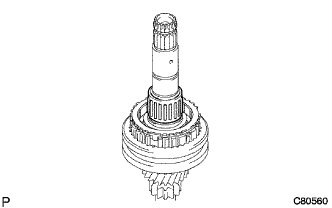

Using SST and a press, install the input shaft rear radial ball bearing onto the input shaft.

- SST

- 09608-04031

|

Select a snap ring that will allow minimum axial play.

- Standard clearance:

- 0.1 mm (0.00394 in.) or less

- Snap Ring Thickness:

Mark Thickness

mm (in.)Mark Thickness

mm (in.)A 2.29 (0.0901) D 2.47 (0.0972) B 2.35 (0.0925) E 2.53 (0.0996) C 2.41 (0.0948) F 2.59 (0.1019)

|

Using a brass bar and a hammer, install the snap ring onto the input shaft.

- NOTICE:

- Do not damage the journal surface of the snap ring.

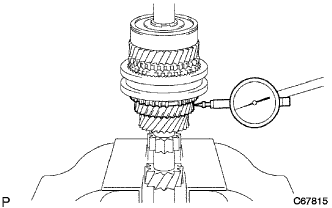

| 10. INSPECT 3RD GEAR RADIAL CLEARANCE |

Using a dial indicator, measure the 3rd gear radial clearance.

- Standard clearance:

- NSK made bearing:

- 0.015 to 0.056 mm (0.000591 to 0.00220 in.)

- JTEKT made bearing:

- 0.015 to 0.058 mm (0.000591 to 0.00228 in.)

- Maximum clearance:

- NSK made bearing:

- 0.056 mm (0.00220 in.)

- JTEKT made bearing:

- 0.058 mm (0.00228 in.)

|

| 11. INSPECT 4TH GEAR RADIAL CLEARANCE |

Using a dial indicator, measure the 4th gear radial clearance between the gear and shaft.

- Standard clearance:

- NSK made bearing:

- 0.009 to 0.050 mm (0.000354 to 0.00197 in.)

- JTEKT made bearing:

- 0.009 to 0.050 mm (0.000354 to 0.00197 in.)

- Maximum clearance:

- NSK made bearing:

- 0.050 mm (0.00197 in.)

- JTEKT made bearing:

- 0.050 mm (0.00197 in.)

|

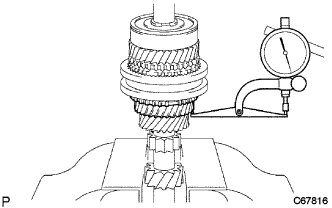

| 12. INSPECT 3RD GEAR THRUST CLEARANCE |

Using a dial indicator, measure the 3rd gear thrust clearance.

- Standard clearance:

- 0.10 to 0.35 mm (0.00394 to 0.0138 in.)

- Maximum clearance:

- 0.35 mm (0.0138 in.)

|

| 13. INSPECT 4TH GEAR THRUST CLEARANCE |

Using a feeler gauge, measure the 4th gear thrust clearance.

- Standard clearance:

- 0.10 to 0.55 mm (0.00394 to 0.0217 in.)

- Maximum clearance:

- 0.55 mm (0.0217 in.)

|