Oil Pump -- Inspection |

| 1. INSPECT OIL JET |

Check the oil jet for damage or clogging.

If necessary, repair the cylinder block.

|

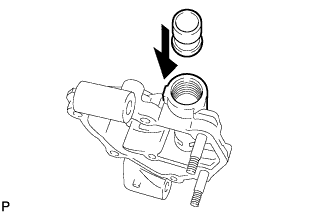

| 2. INSPECT OIL PUMP RELIEF VALVE |

Check the relief valve.

Coat the valve with engine oil, and then check that the valve falls smoothly into the valve hole by its own weight.

If it does not, replace the relief valve.

If necessary, replace the oil pump assembly.

|

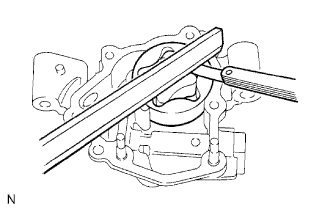

| 3. INSPECT OIL PUMP ROTOR |

Check the side clearance.

Using a feeler gauge and precision straightedge, measure the clearance between the rotors and precision straightedge.

- Standard clearance:

- 0.030 to 0.085 mm (0.00118 to 0.00335 in.)

- Maximum clearance:

- 0.160 mm (0.00630 in.)

Check the tip clearance.

Using a feeler gauge, measure the clearance between the drive and driven rotor tips.

- Standard clearance:

- 0.080 to 0.160 mm (0.00315 to 0.00630 in.)

- Maximum clearance:

- 0.35 mm (0.0138 in.)

|

Check the body clearance.

Using a feeler gauge, measure the clearance between the driven rotor and pump body.

- Standard clearance:

- 0.100 to 0.170 mm (0.00394 to 0.00669 in.)

- Maximum clearance:

- 0.325 mm (0.0128 in.)

|

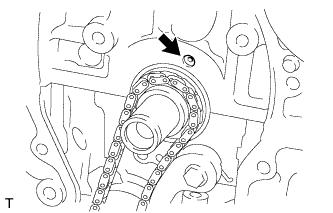

| 4. INSPECT NO. 2 CHAIN SUB-ASSEMBLY |

Pull the chain with a force of 140 N (14.3 kgf, 31.5 lbf) as shown in the illustration.

|

Using a vernier caliper, measure the length of 15 links.

- Maximum chain elongation:

- 102.2 mm (4.024 in.)

- NOTICE:

- Perform the measurement at 3 random places. Use the average of the measurements.

| 5. INSPECT CHAIN TENSIONER PLATE |

Measure the chain tensioner plate wear.

- Maximum wear:

- 0.5 mm (0.0197 in.)

If the wear is greater than the maximum, replace the chain tensioner plate.

|