Engine Hybrid System. Corolla. Zre142 Aze141

2Zr-Fe Cooling. Corolla. Zre142 Aze141

Radiator -- On-Vehicle Inspection |

| 1. CHECK RESERVE TANK CAP |

Measure the valve opening pressure.

If there are water stains or foreign matter on rubber seal 1, 2 or 3, clean the part(s) with water and finger scouring.

Check that rubber seals 1, 2 and 3 are not deformed, cracked or swollen.

Check that rubber seals 3 and 4 are not stuck together.

Apply engine coolant to rubber seals 2 and 3 before using a radiator cap tester.

When using the cap tester, tilt it upwards 30° or more.

Pump the cap tester several times, and check the maximum pressure*1.

- Pumping speed:

- 1 pump per second

- HINT:

- *1: Even if the cap cannot maintain the maximum pressure, it is not defective.

- Judgment Criteria:

Item Specified Condition Standard value

(for brand-new cap)74 to 103 kPa (0.8 to 1.1 kgf/cm2, 10.7 to 15 psi) Minimum standard value

(for used cap)59 kPa (0.6 kgf/cm2, 8.6 psi)

|

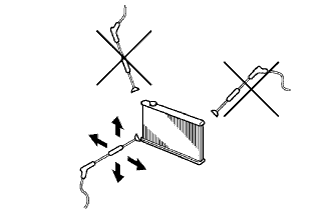

| 2. INSPECT FINS FOR BLOCKAGE |

If the fins are clogged, wash them with water or a steam cleaner and dry them with compressed air.

- NOTICE:

- To avoid damaging the fins, the injection direction should be at right angles to the radiator core surface.

- Use it foe core perpendicularly.

- If the steam cleaner is too close to the radiator core, there is a possibility of damaging the fins, so keep the following injection distances.

- Standard Injection Distance:

Injection Pressure Specified Condition 2942 to 4903 kPa

(30 to 50 kgf/cm2, 427 to 711 psi)300 mm (11.81 in.) 4903 to 7845 kPa

(50 to 80 kgf/cm2, 711 to 1138 psi)500 mm (19.69 in.)

- If the fins are bent, straighten them with a screwdriver or pliers.

- Do not expose electronic components to water.

|