Engine Unit -- Disassembly |

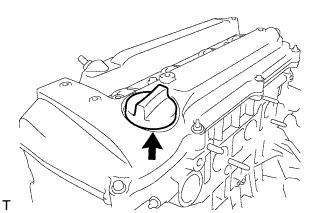

| 1. REMOVE OIL FILLER CAP SUB-ASSEMBLY |

Remove the oil filler cap from the cylinder head cover.

|

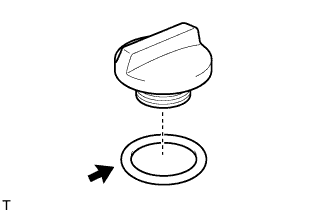

| 2. REMOVE OIL FILLER CAP GASKET |

Remove the oil filler cap gasket from the oil filler cap.

|

| 3. REMOVE VENTILATION VALVE SUB-ASSEMBLY |

Using a 22 mm deep socket wrench, remove the ventilation valve from the cylinder head cover.

|

| 4. REMOVE SPARK PLUG |

Remove the 4 spark plugs.

|

| 5. REMOVE OIL FILTER SUB-ASSEMBLY |

Using SST, remove the oil filter.

- SST

- 09228-06501

| 6. REMOVE OIL FILTER UNION |

Using a 12 mm socket hexagon wrench, remove the oil filter union.

|

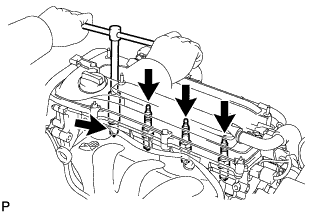

| 7. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY |

Remove the 8 bolts and 2 nuts, and remove the cylinder head cover.

|

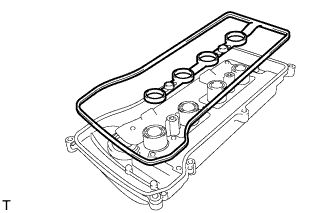

| 8. REMOVE CYLINDER HEAD COVER GASKET |

Remove cylinder head cover gasket from the cylinder head cover.

|

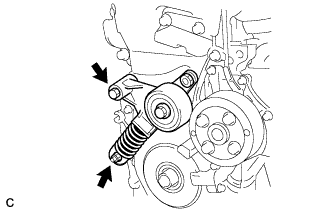

| 9. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY |

Lift the engine upward.

- NOTICE:

- Do not lift the engine more than necessary.

Remove the bolt, nut and V-ribbed belt tensioner assembly.

|

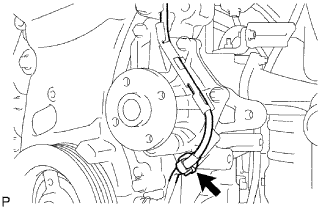

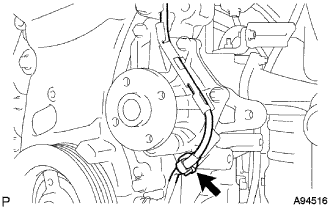

| 10. REMOVE CRANKSHAFT POSITION SENSOR |

Remove the wire harness clamp.

|

Separate the wire harness from the wire harness clamp bracket.

Remove the 2 bolts and sensor.

|

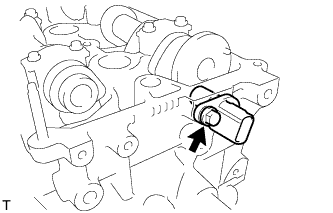

| 11. REMOVE CAMSHAFT POSITION SENSOR |

Remove the bolt and camshaft position sensor.

|

| 12. SET NO. 1 CYLINDER TO TDC/COMPRESSION |

Turn the crankshaft pulley until the groove and the timing mark "0" on the timing chain cover are aligned.

|

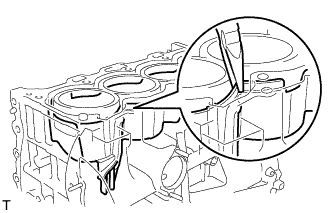

Check that each timing mark on the camshaft timing gear and sprocket is aligned with the timing marks located on the No. 1 and No. 2 bearing caps as shown in the illustration.

If not, turn the crankshaft 1 revolution (360°) to align the timing marks as above.

| 13. REMOVE CRANKSHAFT PULLEY |

Using SST, hold the crankshaft pulley in place and loosen the pulley bolt.

- SST

- 09213-54015(91651-60855)

09330-00021

|

Using SST, remove the crankshaft pulley.

- SST

- 09950-50013(09951-05010,09952-05010,09953-05020,09954-05021)

09950-40011(09957-04010)

- HINT:

- If necessary, remove the pulley and pulley bolt using SST.

|

| 14. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY |

Remove the bolt and camshaft timing oil control valve from the cylinder head.

- NOTICE:

- The camshaft timing oil control valve may be damaged when loosening the cylinder head bolts if the it is not removed.

|

Remove the O-ring from the camshaft timing oil control valve.

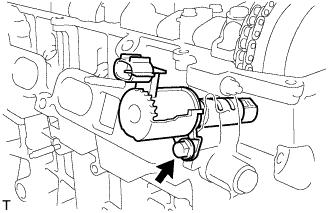

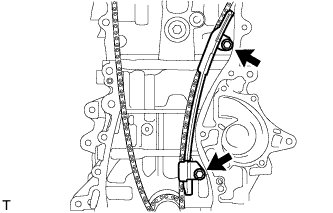

| 15. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY |

Remove the 2 nuts, No. 1 chain tensioner assembly and gasket.

- NOTICE:

- Do not turn the crankshaft without the No. 1 chain tensioner assembly.

|

| 16. REMOVE WATER PUMP PULLEY |

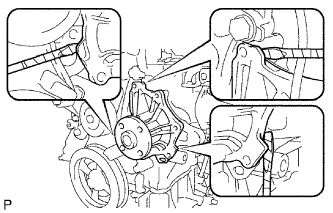

Using SST, remove the 4 bolts and water pump pulley.

- SST

- 09960-10010(09962-01000,09963-00700)

|

| 17. REMOVE WATER PUMP ASSEMBLY |

Remove the clamp of the crankshaft position sensor from the water pump.

|

Disconnect the wire of the crankshaft position sensor from the clamp bracket.

Remove the 4 bolts, 2 nuts and clamp bracket.

|

Using a screwdriver, pry between the water pump and cylinder block, and then remove the water pump.

- HINT:

- Tape the screwdriver tip before use.

- NOTICE:

- Be careful not to damage the contact surfaces of the water pump and cylinder block.

|

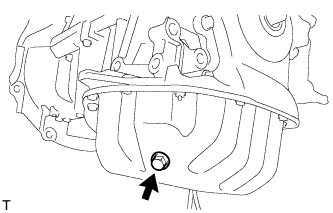

| 18. REMOVE OIL PAN DRAIN PLUG |

Remove the oil pan drain plug from the oil pan.

|

| 19. REMOVE OIL PAN SUB-ASSEMBLY |

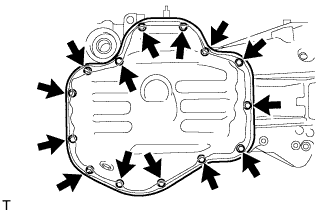

Remove the 12 bolts and 2 nuts.

|

Insert the blade of oil pan seal cutter between the crankcase, chain cover and oil pan, then cut through the applied sealer and remove the oil pan.

- NOTICE:

- Be careful not to damage the contact surfaces of the crankcase, chain cover and oil pan.

|

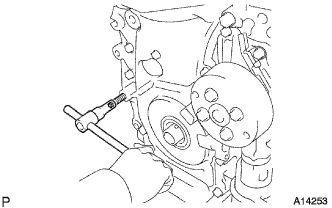

| 20. REMOVE TIMING CHAIN OR BELT COVER SUB-ASSEMBLY |

Remove the 3 bolts and transverse engine engine mounting bracket.

|

Using an E10 "TORX" socket, remove the stud bolt for the V-ribbed belt tensioner.

|

Remove the 12 bolts and 2 nuts.

|

Remove the timing chain cover by prying the portions between the timing chain cover, cylinder head and cylinder block with a screwdriver.

- NOTICE:

- Be careful not to damage the contact surfaces of the timing chain cover, cylinder head and cylinder block.

- HINT:

- Tape the screwdriver tip before use.

|

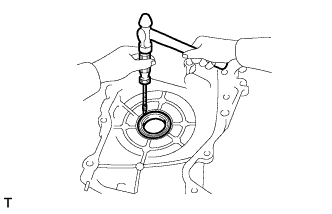

| 21. REMOVE FRONT CRANKSHAFT OIL SEAL |

Place the timing chain cover on wooden blocks.

|

Using a screwdriver, pry out the oil seal.

- NOTICE:

- Do not damage the surface of the oil seal press fit hole.

- HINT:

- Tape the screwdriver tip before use.

| 22. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR PLATE |

Remove the No. 1 crankshaft position sensor plate.

|

| 23. REMOVE TIMING CHAIN GUIDE |

Remove the bolt and timing chain guide.

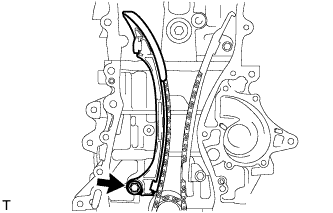

|

| 24. REMOVE CHAIN TENSIONER SLIPPER |

Remove the bolt and chain tensioner slipper.

|

| 25. REMOVE NO. 1 CHAIN VIBRATION DAMPER |

Remove the 2 bolts and No. 1 chain vibration damper.

|

| 26. REMOVE CHAIN SUB-ASSEMBLY |

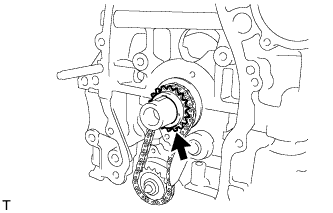

| 27. REMOVE CRANKSHAFT TIMING GEAR OR SPROCKET |

Remove the crankshaft timing gear or sprocket from the crankshaft.

|

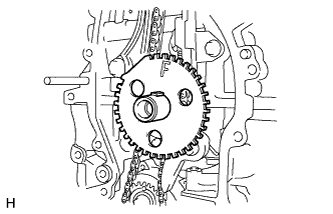

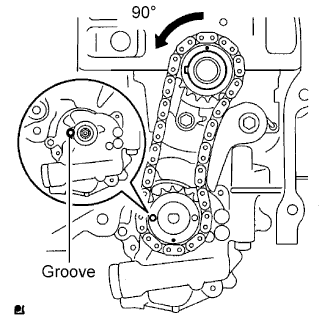

| 28. REMOVE NO. 2 CHAIN SUB-ASSEMBLY |

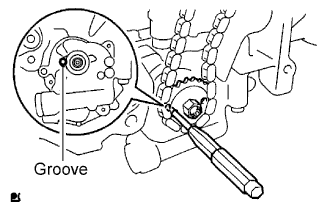

Turn the crankshaft 90° counterclockwise to align the adjusting hole on the oil pump drive shaft sprocket with the groove on the oil pump.

|

Insert a 4 mm diameter bar into the adjusting hole of the oil pump drive shaft sprocket to lock the gear in position, and then remove the nut.

|

Remove the bolt, chain tensioner plate and spring.

|

Remove the oil pump drive sprocket, oil pump drive shaft sprocket and No. 2 chain.

| 29. REMOVE KEYS |

Remove the 2 pulley set keys from the crankshaft.

|

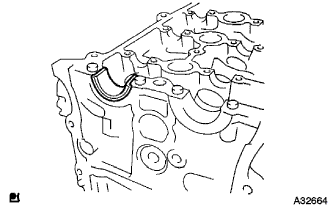

| 30. REMOVE NO. 2 CAMSHAFT |

Using several steps, uniformly loosen and remove the 10 bearing cap bolts in the sequence shown in the illustration.

- NOTICE:

- Uniformly loosen the bolts while keeping the camshaft level.

- HINT:

- Arrange the removed parts in the correct order.

|

Remove the 5 bearing caps.

Remove the No. 2 camshaft.

| 31. REMOVE CAMSHAFT |

Using several steps, uniformly loosen and remove the 10 bearing cap bolts in the sequence shown in the illustration.

- NOTICE:

- Uniformly loosen the bolts while keeping the camshaft level.

- HINT:

- Arrange the removed parts in the correct order.

|

Remove the 5 bearing caps.

Remove the camshaft.

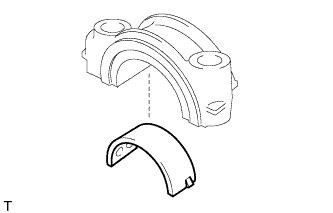

| 32. REMOVE NO. 1 CAMSHAFT BEARING |

Remove the camshaft bearing from the No. 1 camshaft bearing cap.

|

| 33. REMOVE NO. 2 CAMSHAFT BEARING |

Remove the No. 2 camshaft bearing from the cylinder head.

|

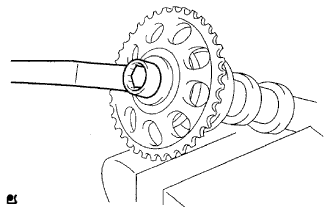

| 34. REMOVE CAMSHAFT TIMING GEAR OR SPROCKET |

Clamp the camshaft in a vise.

- NOTICE:

- Do not overtighten the vise.

- Do not damage the camshaft.

|

Remove the bolt and camshaft timing gear or sprocket.

| 35. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY |

Clamp the camshaft in a vise, and make sure that the camshaft timing gear assembly does not rotate.

|

Cover all the oil path with vinyl tape except the advance side path shown in the illustration.

Apply air pressure of 150 kPa (1.5 kgf/cm2, 22 psi) to the oil path, then turn the camshaft timing gear assembly to the advance direction (counterclockwise) by hand.

- CAUTION:

- Cover the paths with a piece of cloth to avoid oil splashes.

- HINT:

- Depending on the air pressure, the camshaft timing gear assembly may turn to the advance side without applying force by hand. Also, if the pressure is difficult to apply because of air leakage from a path, the lock pin may be difficult to release.

|

Remove the flange bolt of the camshaft timing gear.

- NOTICE:

- Be sure not to remove the other 4 bolts.

- When reusing the camshaft timing gear, release the straight pin lock first, then install the gear.

|

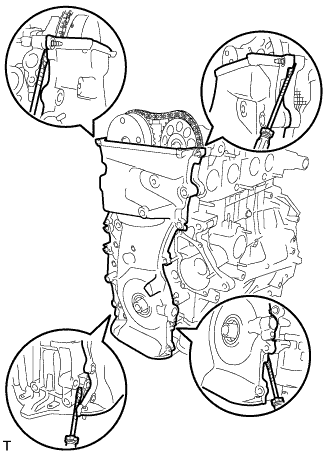

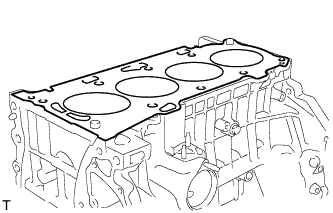

| 36. REMOVE CYLINDER HEAD SUB-ASSEMBLY |

In several steps, uniformly loosen and remove the 10 cylinder head bolts and 10 plate washers with a 10 mm bi-hexagon wrench in the sequence shown in the illustration.

- NOTICE:

- Head warpage or cracking could result from removing the bolts in the wrong order.

|

Using a screwdriver with its tip wrapped with tape, pry between the cylinder head and cylinder block, and remove the cylinder head.

- NOTICE:

- Be careful not to damage the contact surfaces between the cylinder head and cylinder block.

|

| 37. REMOVE CYLINDER HEAD GASKET |

|

| 38. REMOVE CYLINDER BLOCK WATER JACKET SPACER |

Using needle nose pliers, remove the cylinder block water jacket spacer from the water jacket.

- NOTICE:

- Before turning the cylinder block upside down, make sure that the water jacket spacer is removed, as it will fall out.

|

| 39. REMOVE CYLINDER BLOCK WATER DRAIN COCK SUB-ASSEMBLY |

Remove the water drain cock from the stiffening crankcase.

|

Remove the water drain cock plug from the water drain cock.

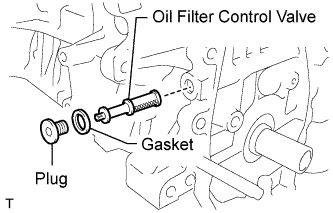

| 40. REMOVE OIL CONTROL VALVE FILTER |

Using a 8mm socket hexagon wrench, remove the plug, gasket and oil control valve filter.

|

| 41. REMOVE NO. 1 TAPER HEAD SCREW PLUG |

Remove the No. 1 taper head screw plug.

|

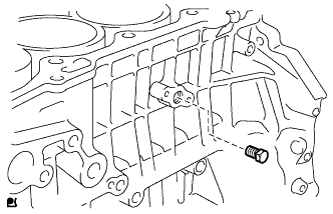

| 42. REMOVE OIL PUMP ASSEMBLY |

Remove the 3 bolts, oil pump and gasket.

|

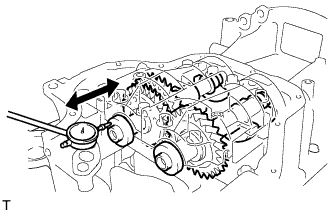

| 43. INSPECT BALANCESHAFT THRUST CLEARANCE |

Install the balanceshafts (COROLLA_ZRE142 RM00000224800UX.html).

Using a dial indicator, measure the thrust clearance while moving the balanceshaft back and forth.

- Standard thrust clearance:

- 0.05 to 0.09 mm (0.0020 to 0.0035 in.)

- Maximum thrust clearance:

- 0.09 mm (0.0035 in.)

|

| 44. INSPECT BALANCESHAFT OIL CLEARANCE |

Clean each bearing and journal.

Check each bearing and journal for pitting and scratches.

If a bearing or journal is damaged, replace the bearings. If necessary, replace the balanceshaft.

Place the No. 1 and No. 2 balanceshafts onto the crankcase.

Lay a strip of Plastigage across each journal.

|

Install the balanceshaft housing (COROLLA_ZRE142 RM00000224800UX.html).

- NOTICE:

- Do not turn the balanceshafts.

Remove the balanceshafts (COROLLA_ZRE142 RM00000224700UX.html).

Measure the Plastigage at its widest point.

- Standard oil clearance:

- 0.022 to 0.049 mm (0.0009 to 0.0019 in.)

- Maximum oil clearance:

- 0.049 mm (0.0019 in.)

- NOTICE:

- Remove the Plastigage completely after the measurement.

|

If replacing a bearing, select a new one with the same number.

- Standard Balanceshaft Housing Journal Bore Diameter:

Item Specified Condition Mark 1 26.000 to 26.006 mm (1.0236 to 1.0239 in.) Mark 2 26.007 to 26.012 mm (1.0239 to 1.0241 in.) Mark 3 26.013 to 26.018 mm (1.0241 to 1.0243 in.)

- Standard Bearing Center Wall Thickness:

Item Specified Condition Mark 1 1.486 to 1.489 mm (0.05850 to 0.05862 in.) Mark 2 1.490 to 1.492 mm (0.05866 to 0.05874 in.) Mark 3 1.493 to 1.495 mm (0.0588 to 0.0589 in.)

- Standard balanceshaft journal diameter:

- 22.985 to 23.000 mm (0.9049 to 0.9055 in.)

|

Inspect the balanceshaft housing bolts.

Using a vernier caliper, measure the length of the bolts from the seat to the end.

- Standard bolt length:

- 58.3 to 59.7 mm (2.295 to 2.350 in.)

- Maximum bolt length:

- 60.3 mm (2.374 in.)

| 45. REMOVE NO. 1 AND NO. 2 BALANCESHAFTS |

Remove the No. 1 and No. 2 balanceshafts.

|

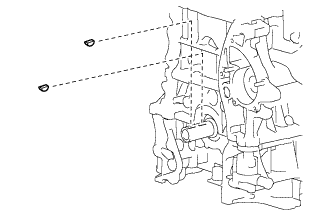

| 46. REMOVE NO. 1 BALANCESHAFT BEARING |

Remove the 8 No. 1 balanceshaft bearings shown in the illustration.

|

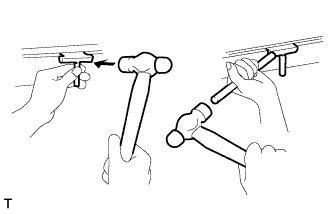

| 47. REMOVE REAR CRANKSHAFT OIL SEAL |

Using a knife, cut off the lip of the oil seal.

|

Using a screwdriver, pry out the oil seal.

- NOTICE:

- After removing, check the crankshaft for damage. If damaged, smooth the surface with 400-grit sandpaper.

- HINT:

- Tape the screwdriver tip before use.

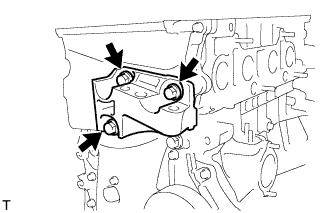

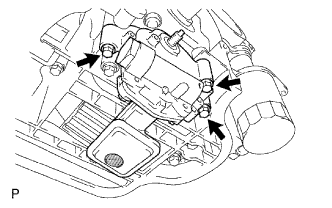

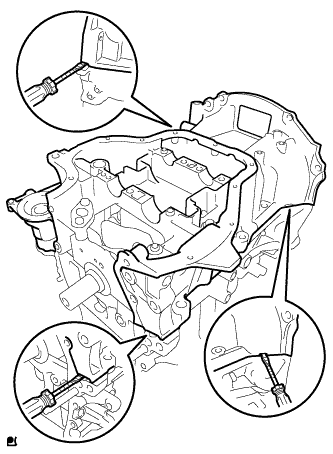

| 48. REMOVE STIFFENING CRANKCASE ASSEMBLY |

Uniformly loosen and remove the 11 bolts in the sequence shown in the illustration.

|

Using a screwdriver with its tip wrapped with protective tape, remove the crankcase by prying between the crankcase and cylinder block.

- NOTICE:

- Be careful not to damage the contact surfaces between the crankcase and cylinder block.

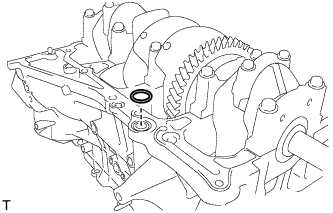

|

Remove the O-ring from the cylinder block.

|