Cylinder Head Gasket -- Installation |

| 1. INSTALL CYLINDER HEAD GASKET |

Place a new cylinder head gasket on the cylinder block surface with the Lot No. stamp facing upward.

- NOTICE:

- Remove any oil from the contact surface.

- Be careful of the installation direction.

|

| 2. INSTALL CYLINDER HEAD SUB-ASSEMBLY |

Place the cylinder head on the cylinder head gasket.

- NOTICE:

- Place the cylinder head gently in order to avoid damaging the cylinder head gasket.

Install the cylinder head bolts.

- NOTICE:

- The cylinder head bolts are tightened in 2 successive steps.

Apply a light coat of engine oil to the threads and under the heads of the cylinder head set bolts.

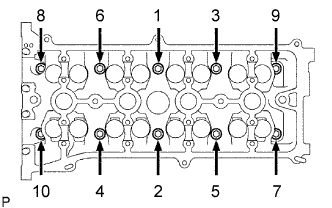

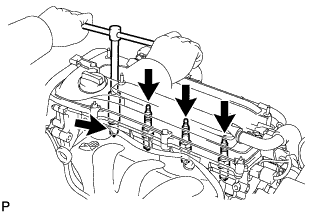

Using several steps, uniformly install and tighten the 10 cylinder head set bolts and plate washers with a 10 mm bi-hexagon wrench in the order shown in the illustration.

- Torque:

- 70 N*m{714 kgf*cm, 52 ft.*lbf}

Mark the front of the cylinder head bolts with paint.

|

Further tighten the cylinder head bolts 90° as shown in the illustration.

Check that the paint mark is now at a 90° angle to the front.

| 3. INSTALL NO. 1 CAMSHAFT BEARING |

Clean the installation surfaces and the inner and outer surfaces of the bearing.

- NOTICE:

- Keep the installation surfaces and the back surfaces of the bearing free of engine oil.

Align the claws and install No. 1 camshaft bearing onto No. 1 camshaft bearing cap.

|

| 4. INSTALL NO. 2 CAMSHAFT BEARING |

Clean the installation surfaces and the inner and outer surfaces of the bearing.

- NOTICE:

- Keep the installation surfaces and the back surfaces of the bearing free of engine oil.

Install the No. 2 camshaft bearing onto the cylinder head.

|

| 5. INSTALL CAMSHAFT |

Apply a light coat of engine oil to the journal portion.

Examine the front marks and numbers, and check that the order is as shown in the illustration. Then install the bearing caps into the cylinder head.

|

Apply a light coat of engine oil to the threads and under the heads of the bearing cap bolts.

Using several steps, uniformly tighten the 10 bearing cap bolts in the sequence shown in the illustration.

- Torque:

- No. 1 Bearing cap:

- 30 N*m{301 kgf*cm, 22 ft.*lbf}

- No. 3 Bearing cap:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

|

| 6. INSTALL NO. 2 CAMSHAFT |

Apply a light coat of engine oil to the journal portion of the No. 2 camshaft.

Examine the front marks and numbers, and check that the order is as shown in the illustration. Then install the bearing caps onto the cylinder head.

|

Apply a light coat of engine oil to the threads and under the heads of the bearing cap bolts.

Using several steps, uniformly tighten the 10 bearing cap bolts in the sequence shown in the illustration.

- Torque:

- No. 2 Bearing cap:

- 30 N*m{301 kgf*cm, 22 ft.*lbf}

- No. 3 Bearing cap:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

|

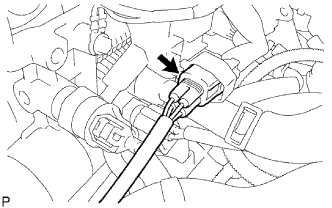

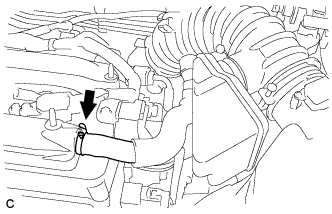

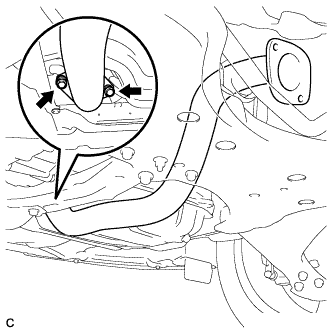

| 7. CONNECT INLET HEATER WATER HOSE |

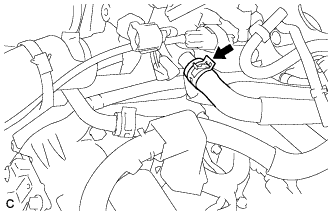

Connect the inlet heater water hose with the clamp.

|

| 8. CONNECT OUTLET HEATER WATER HOSE |

Connect the outlet heater water hose with the clamp.

|

| 9. CONNECT NO. 1 RADIATOR HOSE |

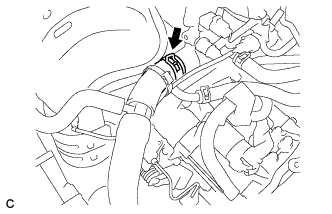

Connect the No. 1 radiator hose with the clamp.

|

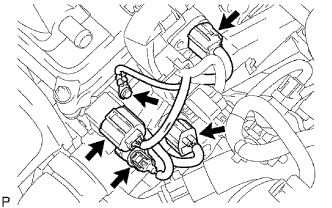

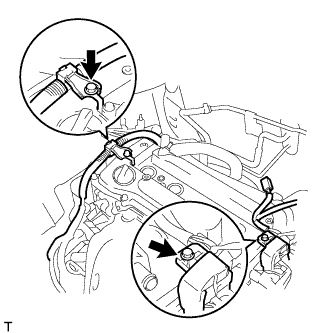

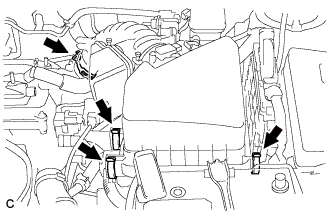

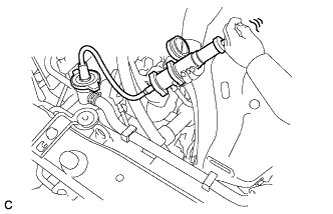

| 10. CONNECT ENGINE WIRE |

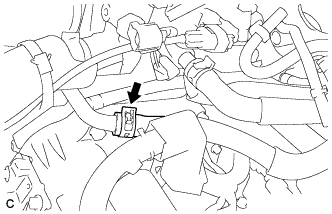

Connect the ground cable with the bolt.

- Torque:

- 8.4 N*m{86 kgf*cm, 74 in.*lbf}

|

Connect the camshaft position sensor connector.

Connect the engine coolant temperature sensor connector.

Connect the engine oil pressure switch connector.

Connect the radio setting condenser connector.

Connect the heater water inlet hose.

| 11. INSTALL NO. 2 CHAIN SUB-ASSEMBLY |

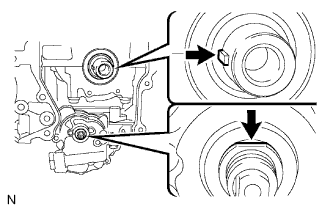

Set the crankshaft key in the left horizontal position.

|

Turn the cutout of the drive shaft so that it faces upward.

|

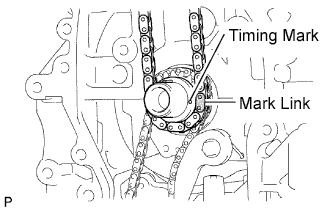

Align the yellow mark links with the timing marks of each gear as shown in the illustration.

Install the sprockets onto the crankshaft and oil pump shaft with the chain placed on the gears.

Temporarily tighten the oil pump drive shaft sprocket with the nut.

Insert the damper spring into the adjusting hole, and then install the chain tensioner plate with the bolt.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

|

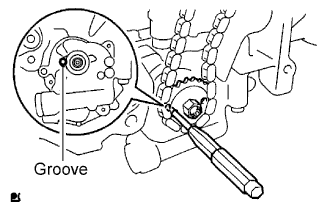

Align the adjusting hole on the oil pump drive shaft sprocket with the groove on the oil pump.

|

Insert a 4 mm diameter bar into the adjusting hole on the oil pump drive shaft gear to lock the gear in position, and then tighten the nut.

- Torque:

- 30 N*m{301 kgf*cm, 22 ft.*lbf}

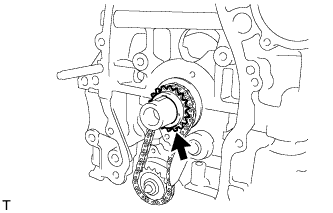

| 12. INSTALL CRANKSHAFT TIMING GEAR OR SPROCKET |

Install the crankshaft timing gear or sprocket to the crankshaft.

|

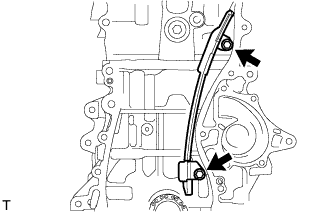

| 13. INSTALL NO. 1 CHAIN VIBRATION DAMPER |

Install the No. 1 chain vibration damper with the 2 bolts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

|

| 14. INSTALL CHAIN SUB-ASSEMBLY |

Set the No. 1 cylinder to TDC/compression.

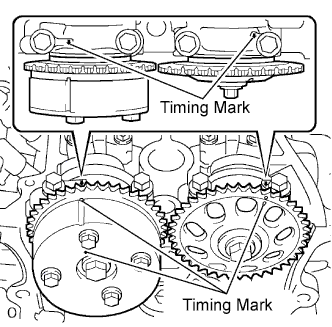

Turn the camshafts with a wrench (using the hexagonal lobe) to align the timing marks on the camshaft timing gear with the timing marks located on the No. 1 and No. 2 bearing caps as shown in the illustration.

Using the crankshaft pulley bolt, turn the crankshaft to position the key on the crankshaft upward.

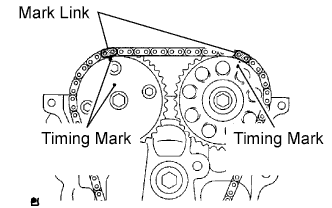

Install the chain onto the crankshaft timing sprocket with the gold or orange mark link aligned with the timing mark on the crankshaft.

|

Using SST and a hammer, tap in the crankshaft timing sprocket.

- SST

- 09309-37010

|

Align the gold or yellow links with the timing marks located on the camshaft timing gear and sprocket, then install the chain.

|

| 15. INSTALL CHAIN TENSIONER SLIPPER |

Install the chain tensioner slipper with the bolt.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

|

| 16. INSTALL TIMING CHAIN GUIDE |

Install the timing chain guide with the bolt.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

|

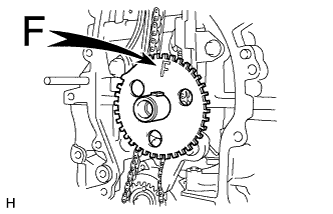

| 17. INSTALL NO. 1 CRANKSHAFT POSITION SENSOR PLATE |

Install the sensor plate with the "F" mark facing forward.

|

| 18. INSTALL TIMING CHAIN OR BELT COVER SUB-ASSEMBLY |

Remove any old packing material and be careful not to drop any oil on the contact surfaces of the timing chain cover, cylinder head and cylinder block.

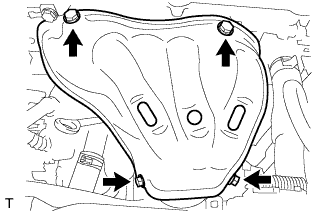

Apply seal packing (Diameter 4.0 to 4.5 mm (0.157 to 0.177 in.)) as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

- Remove any oil from the contact surfaces.

- Install the chain cover within 3 minutes of applying seal packing.

- Do not add engine oil for at least 2 hours after installing the chain cover.

|

Apply a continuous bead of seal packing as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

- Remove any oil from the contact surface.

- Install the chain cover within 3 minutes of applying seal packing.

- Do not add engine oil for at least 2 hours after installing the chain cover.

Apply adhesive to the threads of the bolt A.

- Seal packing:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Temporarily install the timing chain cover with the 12 bolts and 2 nuts.

- Bolt length:

Item Length Bolt A 30 mm (1.18 in.) length for 10 mm head Bolt B 30 mm (1.18 in.) length for 12 mm head Bolt C 40 mm (1.57 in.) length for 14 mm head

|

Temporarily install the engine transverse engine engine mounting bracket with the 3 bolts.

|

Fully tighten the timing chain cover with the 15 bolts and 2 nuts as shown in the illustration.

- Torque:

- Bolt A:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

- Bolt B:

- 25 N*m{255 kgf*cm, 18 ft.*lbf}

- Bolt C:

- 55 N*m{561 kgf*cm, 41 ft.*lbf}

- Nut:

- 11 N*m{112 kgf*cm, 8 ft.*lbf}

Using an E10 "TORX" socket, install the stud bolt for the V-ribbed belt tensioner.

- Torque:

- 22 N*m{220 kgf*cm, 16 ft.*lbf}

|

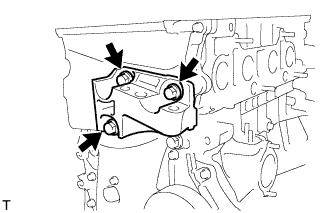

| 19. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY |

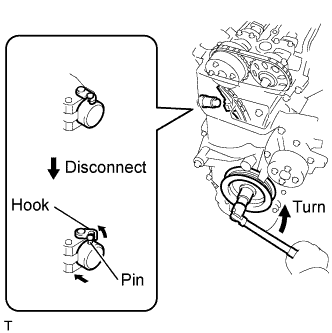

Release the ratchet pawl, then fully push in the plunger and set the hook to the pin so that the plunger is in the position shown in the illustration.

|

Install a new gasket and the chain tensioner with the 2 nuts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

- NOTICE:

- When installing the chain tensioner, set the hook again if the hook releases the plunger.

|

| 20. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY |

Temporarily install the V-ribbed belt tensioner assembly with the nut.

|

Slightly push down on the V-ribbed belt tensioner assembly at part (A) to align the holes of the engine and tensioner as shown in the illustration, and temporarily install the bolt .

Tighten the bolt and nut to install the V-ribbed belt tensioner.

- Torque:

- 60 N*m{612 kgf*cm, 44 ft.*lbf}

- NOTICE:

- When replacing the V-ribbed belt tensioner with a new one, do not pull out the pin.

- The pin will be removed in a later step.

|

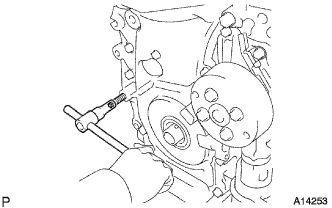

| 21. INSTALL CRANKSHAFT PULLEY |

Using SST, secure the pulley in place and tighten the bolt.

- SST

- 09213-54015(91651-60855)

09330-00021

- Torque:

- 180 N*m{1835 kgf*cm, 133 ft.*lbf}

|

Turn the crankshaft counterclockwise, then disconnect the hook from the pin.

|

Turn the crankshaft clockwise, then check that the plunger is extended.

|

| 22. INSTALL OIL PAN SUB-ASSEMBLY |

Remove any old packing material and be careful not to drop any oil on the contact surfaces of the cylinder block and oil pan.

Apply a continuous bead of seal packing (diameter 4.0 to 4.5 mm (0.158 to 0.177 in.)) as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

- Remove any oil from the contact surfaces.

- Install the oil pan within 3 minutes of applying seal packing.

- Do not add engine oil for at least 2 hours after installing the oil pan.

|

Install the oil pan onto the cylinder block.

Uniformly tighten the 12 bolts and 2 nuts in the sequence shown in the illustration.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

|

Place a wooden block between a floor jack and the engine, then support the engine using the floor jack.

|

Remove the chain block and sling device.

Remove the 2 bolts and engine hangers.

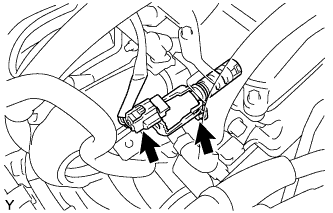

| 23. INSTALL CRANK POSITION SENSOR |

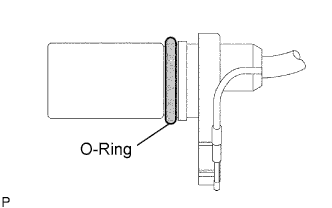

Apply a light coat of engine oil to the O-ring on the crank position sensor.

|

Install the crank position sensor with the bolt.

- Torque:

- 9.0 N*m{90 kgf*cm, 80 in.*lbf}

- NOTICE:

- Do not twist the O-ring.

|

Install the wire harness and crank position sensor connector clamp.

Connect the crank position sensor connector.

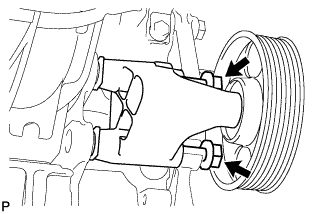

| 24. INSTALL IDLER PULLEY SUB-ASSEMBLY |

Install the idler pulley sub-assembly with the 2 bolts.

- Torque:

- 50 N*m{510 kgf*cm, 37 ft.*lbf}

|

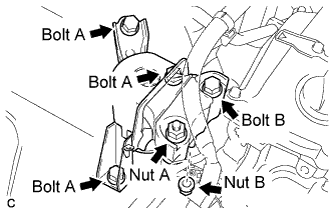

| 25. INSTALL ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH |

Install the engine mounting insulator sub-assembly RH with the 4 bolts and 2 nuts.

- Torque:

- Bolt A:

- 52 N*m{530 kgf*cm, 38 ft.*lbf}

- Bolt B:

- 95 N*m{969 kgf*cm, 70 ft.*lbf}

- Nut A:

- 95 N*m{969 kgf*cm, 70 ft.*lbf}

- Nut B:

- 52 N*m{530 kgf*cm, 38 ft.*lbf}

|

| 26. INSTALL EXHAUST MANIFOLD CONVERTER SUB-ASSEMBLY |

Install a new gasket onto the cylinder head sub-assembly.

Temporarily tighten the exhaust manifold converter sub-assembly with the 5 nuts.

Tighten the 5 nuts in the sequence shown in the illustration.

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

|

Connect the air fuel ratio sensor connector.

|

| 27. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

Install the No. 1 exhaust manifold heat insulator with the 4 bolts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

|

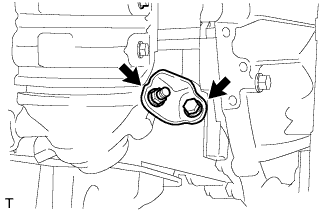

| 28. INSTALL NO. 2 MANIFOLD STAY |

Install the No. 2 manifold stay with the bolt and nut.

- Torque:

- 44 N*m{449 kgf*cm, 33 ft.*lbf}

|

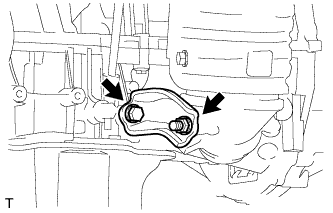

| 29. INSTALL MANIFOLD STAY |

Install the manifold stay with the bolt and nut.

- Torque:

- 44 N*m{449 kgf*cm, 33 ft.*lbf}

|

| 30. INSTALL NO. 1 INTAKE MANIFOLD INSULATOR |

Install the No. 1 intake manifold insulator onto the cylinder block.

|

| 31. INSTALL INTAKE MANIFOLD |

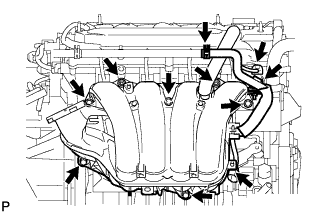

Install a new gasket into the intake manifold.

|

Install the intake manifold with the 5 bolts and 2 nuts.

- Torque:

- 30 N*m{306 kgf*cm, 22 ft.*lbf}

|

Fit the union to connector tube hose into the vacuum hose clamp.

Install the wire harness clamp.

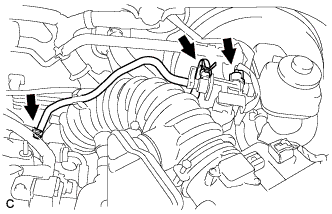

Connect the camshaft timing oil control valve connector.

Connect the union to connector tube hose to the No. 2 hose to hose tube.

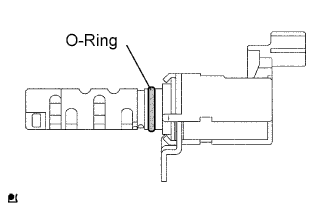

| 32. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY |

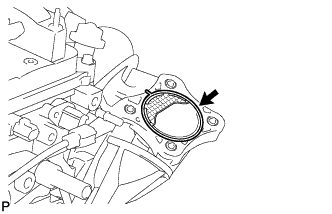

Apply a light coat of engine oil to a new O-ring and install it onto the camshaft timing oil control valve assembly.

|

Install the camshaft timing oil control valve assembly with the bolt.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

|

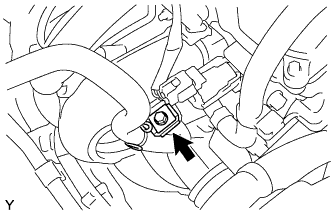

Connect the camshaft timing oil control valve connector.

Install the vacuum hose clamp with the bolt.

|

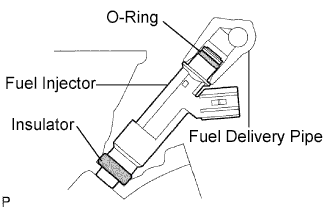

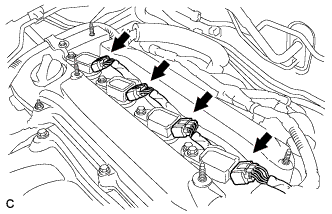

| 33. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY |

Install 4 new insulators to the cylinder head.

|

Install the 2 delivery pipe spacers onto the cylinder head.

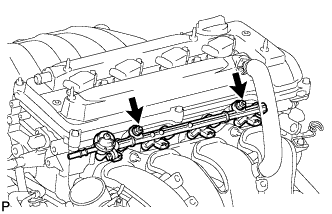

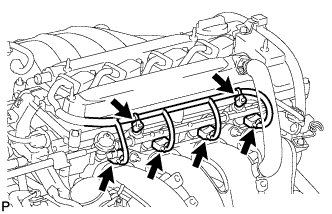

Install the fuel delivery pipe together with the 4 fuel injectors, then temporarily tighten the 2 bolts.

- NOTICE:

- Be careful not to drop the fuel injectors when installing the fuel delivery pipe.

|

Check that the fuel injector rotates smoothly.

If the fuel injector does not rotate smoothly, replace the O-ring.

Tighten the 2 bolts to the specified torque.

- Torque:

- 20 N*m{205 kgf*cm, 15 ft.*lbf}

|

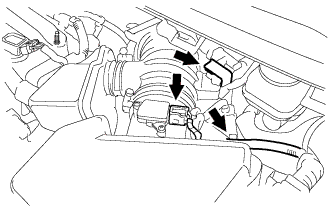

Connect the 4 fuel injector connectors.

|

Install the 2 wire harness clamps.

| 34. CONNECT FUEL MAIN TUBE |

Connect the fuel main tube.

Push the fuel tube connector until it makes a "click" sound.

Install the fuel pipe clamp.

Install the fuel tube to the fuel hose clamp.

| 35. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE |

Apply a light coat of engine oil to a new O-ring and install it onto the engine oil level dipstick guide.

Install the engine oil level dipstick guide with the bolt.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

|

| 36. INSTALL ENGINE OIL LEVEL DIPSTICK |

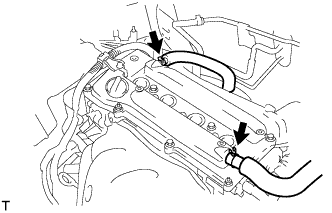

| 37. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY |

Remove any old packing material from the contact surface.

Apply seal packing to the 2 locations shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

- Remove any oil from the contact surface.

- Install the oil pan within 3 minutes of applying seal packing.

- Do not add engine oil for at least 2 hours after installing the oil pan.

|

Install the cylinder head cover gasket and sub-assembly with the 8 bolts and 2 nuts.

- Torque:

- Bolt A:

- 11 N*m{112 kgf*cm, 8 ft.*lbf}

- Bolt B:

- 14 N*m{143 kgf*cm, 10 ft.*lbf}

- Nut:

- 11 N*m{112 kgf*cm, 8 ft.*lbf}

|

Install the 2 engine wire harness brackets with the 2 bolts.

- Torque:

- 8.4 N*m{86 kgf*cm, 74 in.*lbf}

|

Connect the 2 ventilation hoses to the cylinder head cover.

|

| 38. INSTALL SPARK PLUG |

Install the 4 spark plugs.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

|

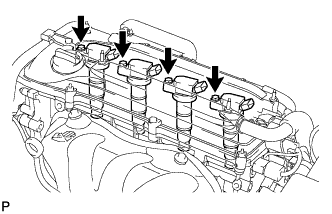

| 39. INSTALL IGNITION COIL ASSEMBLY |

Install the 4 ignition coils with the 4 bolts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

|

Connect the 4 ignition coil connectors.

|

| 40. INSTALL THROTTLE BODY ASSEMBLY |

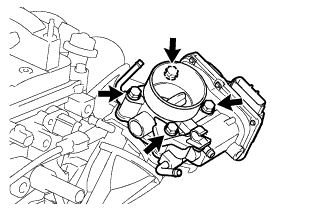

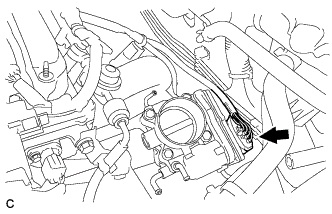

Install a new gasket onto the intake manifold.

|

Install the throttle body assembly with the 4 bolts.

- Torque:

- 30 N*m{306 kgf*cm, 22 ft.*lbf}

|

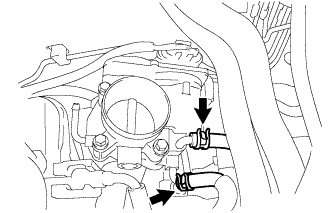

Connect the throttle body connector.

|

Connect the 2 water by-pass hoses.

|

| 41. INSTALL AIR CLEANER CAP SUB-ASSEMBLY WITH HOSE |

Install the air cleaner cap sub-assembly with hose and lock the 3 clamps.

|

Tighten the air cleaner hose clamp.

Connect the ventilation hose.

|

Connect the 2 vacuum hoses and No. 1 vacuum switching valve connector.

|

Connect the 2 wire harness clamps and the mass air flow meter connector.

|

| 42. INSTALL RADIATOR RESERVE TANK ASSEMBLY |

Install the radiator reserve tank assembly with the 3 bolts.

- Torque:

- 7.0 N*m{71 kgf*cm, 62 in.*lbf}

|

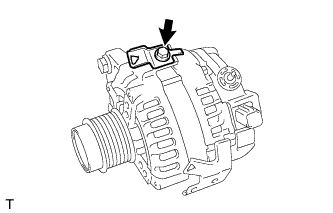

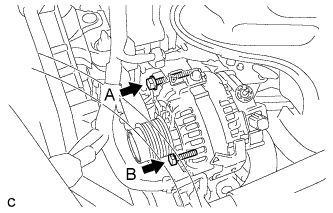

| 43. INSTALL GENERATOR ASSEMBLY |

Install the wire harness clamp bracket with the bolt.

|

Install the generator assembly with the 2 bolts.

- Torque:

- Bolt A:

- 52 N*m{530 kgf*cm, 38 ft.*lbf}

- Bolt B:

- 21 N*m{215 kgf*cm, 16 ft.*lbf}

|

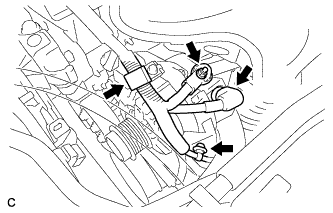

Install the wire harness to terminal B with the nut.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

|

Attach the clamp and connect the generator connector to the generator.

Install the 2 wire harness clamps.

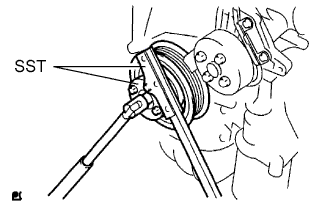

| 44. INSTALL V-RIBBED BELT |

When reusing the V-ribbed belt tensioner:

Install the V-ribbed belt (COROLLA_ZRE142 RM000001R3D013X_01_0001.html).

When replacing the V-ribbed belt tensioner with a new one:

Using SST, slowly turn the V-ribbed belt tensioner clockwise.

- SST

- 09216-42010(09216-04010)

Pull out the pin from the V-ribbed belt tensioner being compressed in a clockwise direction.

Slowly return the V-ribbed belt tensioner.

- NOTICE:

- Make sure that SST and other tools are set to the tensioner securely.

- When compressing the V-ribbed belt tensioner, slowly turn the tensioner.

Install the V-ribbed belt (COROLLA_ZRE142 RM000001R3D013X_01_0001.html).

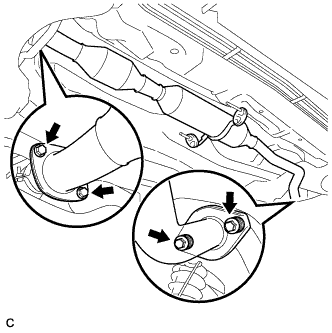

| 45. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

Using a vernier caliper, measure the free length of the compression springs.

Minimum 41.5 mm (1.63 in.) - HINT:

- If the free length is less than the minimum, replace the compression spring.

|

Remove the remains of exhaust manifold converter with wire brash.

Fully insert a new gasket to the exhaust manifold.

- NOTICE:

- Be sure to install the gasket in the correct direction.

- Do not reuse the gasket.

- Do not damage the gasket.

|

Install the front exhaust pipe assembly with the 2 bolts and 2 compression springs.

- Torque:

- 43 N*m{440 kgf*cm, 32 ft.*lbf}

|

Connect the heated oxygen sensor connector.

| 46. INSTALL CENTER EXHAUST PIPE ASSEMBLY |

Using a vernier caliper, measure the free length of the compression springs.

Minimum 38.5 mm (1.52 in.) - HINT:

- If the free length is less than the minimum, replace the compression spring.

|

Fully insert a new gasket to the center exhaust pipe assembly.

- NOTICE:

- Be sure to install the gasket in the correct direction.

- Do not reuse the gasket.

- Do not damage the gasket.

|

Install a new gasket to the front exhaust pipe assembly.

Connect the center exhaust pipe assembly to the 2 exhaust pipe supports.

Install the center exhaust pipe assembly with the 4 bolts and 2 compression springs.

- Torque:

- 43 N*m{440 kgf*cm, 32 ft.*lbf}

|

| 47. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 48. ADD ENGINE OIL |

Add fresh engine oil and install the oil filler cap.

Engine Oil Oil Grade Oil Viscosity (SAE) - ILSAC multigrade engine oil

- 0W-20

- 5W-20

Capacity Item Standard Condition Drain and refill with oil filter change 3.8 liters (4.0 US qts, 3.3 Imp. qts) Drain and refill without oil filter change 3.6 liters (3.8 US qts, 3.2 Imp. qts) Dry fill 4.5 liters (4.8 US qts, 4.0 Imp. qts) - ILSAC multigrade engine oil

| 49. ADD ENGINE COOLANT |

Tighten the lower radiator drain cock plug.

Tighten the cylinder block drain cock plug.

- Torque:

- 13 N*m{130 kgf*cm, 9 ft.*lbf}

Loosen the upper radiator drain cock plug.

Slowly fill the radiator with TOYOTA Super Long Life Coolant (SLLC).

- Standard Capacity:

Item Capacity Engine coolant 5.7 liters (6.0 US qts, 5.0 lmp. qts)

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

- Contact your TOYOTA dealer for further details.

- NOTICE:

- Never use water as a substitute for engine coolant.

Squeeze the inlet and outlet radiator hoses several times by hand, and then check the level of the coolant.

If the coolant level is low, add coolant.

Tighten the upper radiator drain cock plug.

Slowly pour coolant into the radiator reservoir tank until it reaches the FULL line.

Install the radiator cap sub-assembly and reservoir tank cap.

Start the engine and warm it up.

Bleed air from the cooling system.

- NOTICE:

- Before starting the engine, turn the A/C switch off.

- Adjust the air conditioning temperature setting to MAX (HOT).

- Adjust the air conditioning blower setting to LO.

Warm up the engine until the thermostat opens. While the thermostat is open, allow the coolant to circulate for several minutes.

- HINT:

- Thermostat opening timing can be determined by squeezing the inlet radiator hose, and sensing vibrations when the engine coolant starts to flow inside the hose.

- CAUTION:

- When squeezing the radiator hoses:

- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the radiator fan.

Stop the engine, and wait until the engine coolant cools down.

Add engine coolant to the FULL line on the radiator reservoir.

| 50. INSPECT FOR FUEL LEAK |

Check fuel pump operation.

Connect the Techstream to the DLC3.

Turn the ignition switch to ON and turn the Techstream on.

- NOTICE:

- Do not start the engine.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump / Speed.

Check for pressure in the fuel inlet tube from the fuel line. Check that sounds of fuel flowing from the fuel tank can be heard. If no sounds can be heard, check the integration relay, fuel pump, ECM and wiring connectors.

Check for fuel leaks.

There is no fuel leakage after performing maintenance anywhere on the fuel system. If there is a fuel leak, repair or replace parts as necessary.

Turn the ignition switch off.

Disconnect the Techstream from the DLC3.

| 51. INSPECT FOR COOLANT LEAK |

|

- CAUTION:

- To avoid the danger of being burned, do not remove the radiator cap sub-assembly while the engine and radiator assembly are still hot. Thermal expansion will cause hot engine coolant and steam to blow out from the radiator assembly.

Fill the radiator assembly with engine coolant, then attach a radiator cap tester.

Pump the tester to 118 kPa (1.2 kgf/cm2, 17.1 psi), then check that the pressure does not drop.

If the pressure drops, check the hoses, radiator assembly and water pump assembly for leakage. If there are no signs or traces of external engine coolant leakage, check the heater core, cylinder block and head.

| 52. INSPECT FOR OIL LEAK |

| 53. INSPECT FOR EXHAUST GAS LEAK |

| 54. INSPECT IGNITION TIMING |

- NOTICE:

- Turn all the electrical systems and the A/C off.

- When checking the ignition timing, move the shift lever to neutral.

Warm up and stop the engine.

When using the Techstream:

Connect the Techstream to the DLC3.

Turn the ignition switch to ON.

Turn the Techstream on.

Enter the following menus: Power Train / Engine and ECT / Data List / IGN Advance

Start the engine.

According to the display on the Techstream, read the Data List.

- Standard ignition timing:

- 5 to 15° BTDC at idle

Check that the ignition timing advances immediately when the engine speed is increased.

Turn the ignition switch off.

Disconnect the Techstream from the DLC3.

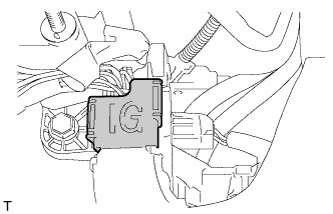

When not using the Techstream:

Remove the No. 1 engine cover sub-assembly (COROLLA_ZRE142 RM000001BC301CX_01_0101.html).

Open the ignition cover located to the right of the No. 4 ignition coil.

Pull the wire harness out from the IG cover.

Connect the timing light to the wire harness.

- NOTICE:

- Use a timing light that detects the primary signal.

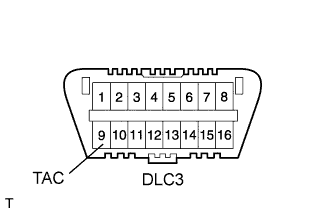

Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

- SST

- 09843-18040

Allow the engine to idle and check the ignition timing.

- Standard ignition timing:

- 8 to 12° BTDC at idle

- HINT:

- Run the engine at 1000 to 1300 rpm for 5 seconds, then check that the engine speed returns to idle speed.

Disconnect SST from terminals 13 (TC) and 4 (CG) of the DLC3.

Allow the engine to idle and check the ignition timing.

- Standard ignition timing:

- 5 to 15° BTDC at idle

Check that the ignition timing advances immediately when the engine speed is increased.

Turn the ignition switch off.

Remove the timing light.

Close the IG cover.

Install the No. 1 engine cover sub-assembly (COROLLA_ZRE142 RM000001BC101CX_01_0268.html).

| 55. INSPECT ENGINE IDLING SPEED |

- NOTICE:

- Turn all the electrical systems and the A/C off.

- When checking the idle speed, move the shift lever to P or neutral.

Warm up and stop the engine.

When using the Techstream:

Connect the Techstream to the DLC3.

Turn the ignition switch to ON.

Turn the Techstream on.

Enter the following menus: Power Train / Engine and ECT / Data List / Engine Speed

Start the engine.

According to the display on the Techstream, read the Data List.

- Standard idle speed:

- 600 to 700 rpm

Turn the ignition switch off.

Disconnect the Techstream from the DLC3.

When not using the Techstream:

Turn off all the accessories and air conditioning.

Move the shift lever to P or neutral.

Connect SST to 9 (TAC) of the DLC3 terminal, and then connect a tachometer to SST.

- SST

- 09843-18030

Start the engine.

Check the idle speed with the cooling fan off.

- Standard idle speed:

- 600 to 700 rpm

Turn the ignition switch off.

Remove the tachometer and disconnect SST from the DLC3.

| 56. INSPECT COMPRESSION |

Warm up and stop the engine.

Remove the 4 ignition coils and spark plugs (COROLLA_ZRE142 RM000001QVM03MX.html).

Disconnect the 4 fuel injector connectors.

Insert the compression gauge into the spark plug hole.

|

Fully open the throttle.

While cranking the engine, measure the compression pressure.

- Standard compression pressure:

- 1300 kPa (13.3 kgf/cm2, 189 psi)

- Minimum compression pressure:

- 1000 kPa (10.0 kgf/cm2, 145 psi)

- Standard difference between each cylinder:

- 100 kPa (1.0 kgf/cm2, 15 psi) or less

- NOTICE:

- Always use a fully-charged battery to obtain an engine speed of 250 rpm or more.

- Check the other cylinders in the same way.

- This measurement must be done as quickly as possible.

- HINT:

- If adding oil increases the compression, the piston rings and/or cylinder bore may be worn or damaged.

- If pressure stays low, a valve may be stuck or seated improperly, or there may be leakage in the gasket.

Connect the 4 fuel injector connectors.

Install the 4 spark plugs and ignition coils (COROLLA_ZRE142 RM000001QVK03PX.html).

| 57. INSPECT CO/HC |

- HINT:

- This check determines whether or not the idle CO/HC complies with local regulations.

Start and warm up the engine.

Run the engine at 2500 rpm for approximately 180 seconds.

Insert the CO/HC meter testing probe at least 40 cm (1.3 ft.) into the tailpipe while idling.

Inspect the CO/HC concentration during idle at 2500 rpm.

If the CO/HC concentration does not comply with local regulations, troubleshoot in the order given below.Check the A/F sensor and heated oxygen sensor operation.

See the table below for possible causes, then inspect the applicable parts and repair them if necessary.

CO HC Problem Possible Cause Normal High Rough idle 1. Faulty ignition:

- Incorrect timing

- Plugs are contaminated, shorted, or gaps are defective

2. Incorrect valve clearance

3. Leaks in intake and exhaust valve

4. Leaks in cylindersLow High Rough idle

(Fluctuating HC reading)1. Vacuum leakage:

- Ventilation hoses

- Intake manifold

- Throttle body

- Brake booster line

2. Lean mixture causing misfireHigh High Rough idle

(Black smoke from exhaust)1. Restricted air filter

2. Plugged PCV valve

3. Faulty EFI system:

- Faulty pressure regulator

- Faulty engine coolant temperature sensor

- Faulty mass air flow meter

- Faulty ECM

- Faulty injectors

- Faulty throttle body

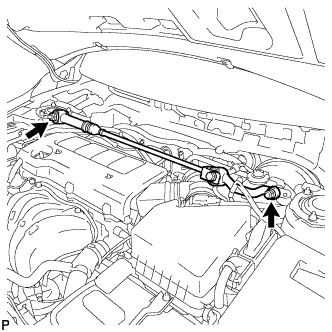

| 58. INSTALL SUSPENSION TOWER DAMPER ASSEMBLY (w/ Front Strut Bar) |

Fully tighten the 2 nuts.

- Torque:

- 52 N*m{530 kgf*cm, 38 ft.*lbf}

|

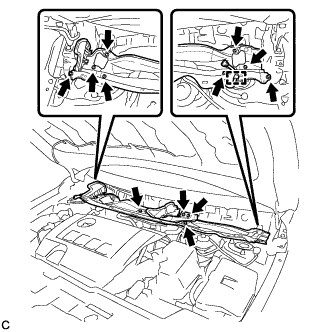

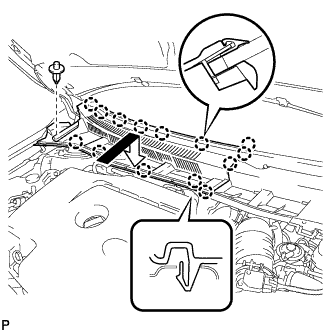

| 59. INSTALL OUTER COWL TOP PANEL |

Install the outer cowl top panel with the 12 bolts.

- Torque:

- 8.8 N*m{90 kgf*cm, 78 in.*lbf}

|

Engage the clamp.

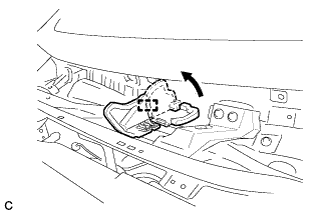

Bend the water guard plate RH as shown in the illustration and engage the clamp.

|

| 60. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY |

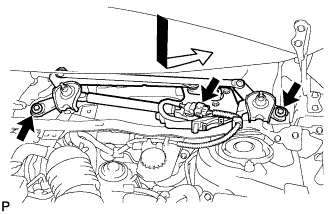

Install the windshield wiper motor and link assembly with the 2 bolts.

- Torque:

- 5.5 N*m{56 kgf*cm, 49 in.*lbf}

|

Connect the connector.

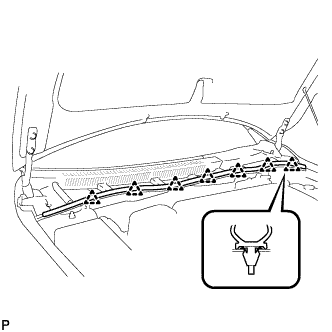

| 61. INSTALL COWL TOP VENTILATOR LOUVER LH |

Engage the clip and 8 claws to install the cowl top ventilator louver LH.

|

| 62. INSTALL CENTER NO. 1 COWL TOP VENTILATOR LOUVER |

Engage the clip and 14 claws to install the center No. 1 cowl top ventilator louver.

|

| 63. INSTALL HOOD TO COWL TOP SEAL |

Engage the 7 clips to install the hood to cowl top seal.

|

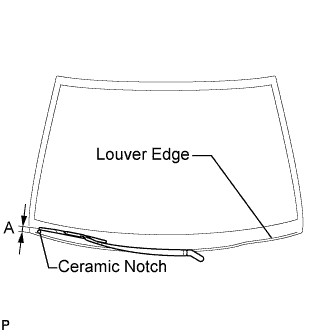

| 64. INSTALL FRONT WIPER ARM AND BLADE ASSEMBLY LH |

Operate the front wipers and stop the windshield wiper motor at the automatic stop position.

Clean the wiper arm serrations.

|

When reinstalling:

Clean the wiper pivot serrations with a wire brush.

Install the front wiper arm and blade assembly LH with the nut to the position shown in the illustration.

- Torque:

- 26 N*m{265 kgf*cm, 19 ft.*lbf}

- HINT:

- Hold the arm hinge by hand while fastening the nut.

Area Measurement A 31.5 to 46.5 mm (1.24 to 1.83 in.)

|

Operate the front wipers while spraying washer fluid on the windshield glass. Make sure that the front wipers function properly and the wipers do not come into contact with the vehicle body.

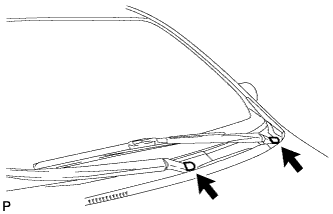

| 65. INSTALL FRONT WIPER ARM AND BLADE ASSEMBLY RH |

Operate the wiper and stop the windshield wiper motor at the automatic stop position.

Clean the wiper arm serrations.

|

When reinstalling:

Clean the wiper pivot serrations with a wire brush.

Install the front wiper arm and blade assembly RH with the nut to the position shown in the illustration.

- Torque:

- 26 N*m{265 kgf*cm, 19 ft.*lbf}

- HINT:

- Hold the arm hinge by hand while fastening the nut.

Area Measurement A 27.5 to 42.5 mm (1.08 to 1.67 in.)

|

| 66. INSTALL FRONT WIPER ARM HEAD CAP |

Install the 2 front wiper arm head caps.

|

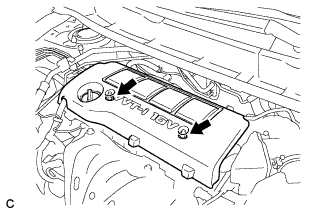

| 67. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY |

Install the No. 1 engine cover sub-assembly with the 2 nuts.

|

| 68. INSTALL ENGINE UNDER COVER LH |

| 69. INSTALL ENGINE UNDER COVER RH |

| 70. INSTALL FRONT WHEEL RH |

- Torque:

- 103 N*m{1050 kgf*cm, 76 ft.*lbf}