Transmission. Camry. Acv40 Gsv40

Clutch. Camry. Acv40 Gsv40

Clutch Unit -- Inspection |

| 1. INSPECT CLUTCH DISC ASSEMBLY |

Using vernier calipers, measure the rivet head depth.

- Minimum rivet depth:

- 0.3 mm (0.012 in.)

|

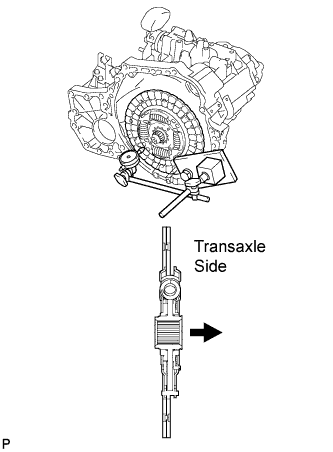

Install the clutch disc assembly to the transaxle assembly.

- NOTICE:

- Take care not to insert the clutch disc assembly in the wrong direction.

|

Using a dial indicator with a roller instrument, measure the clutch disc assembly runout.

- Maximum runout:

- 0.8 mm (0.031 in.)

| 2. INSPECT CLUTCH COVER ASSEMBLY |

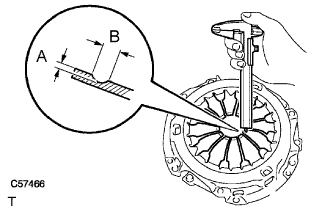

Using vernier calipers, inspect the diaphragm spring for depth and width of wear.

- Maximum:

- A (Depth):

- 0.5 mm (0.020 in.)

- B (Width):

- 6.0 mm (0.236 in.)

|

| 3. INSPECT FLYWHEEL SUB-ASSEMBLY |

Using a dial indicator, measure the flywheel runout.

- Maximum runout:

- 0.1 mm (0.004 in.)

|

| 4. INSPECT CLUTCH RELEASE BEARING ASSEMBLY |

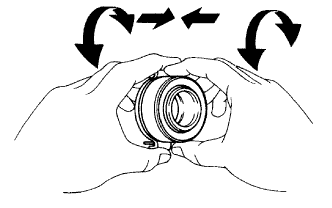

Check that the bearing moves smoothly without abnormal resistance by turning the sliding parts of the bearing (contact surfaces with the clutch cover) while applying force in the axial direction.

|

Inspect the bearing for damage or wear. If necessary, replace the release bearing assembly.

| 5. INSPECT AND ADJUST CLUTCH COVER ASSEMBLY |

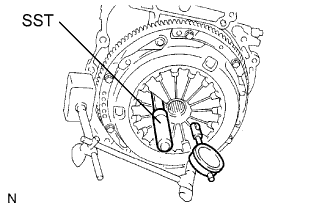

Using a dial indicator with a roller instrument, check the diaphragm spring tip alignment.

- Maximum variation:

- 0.5 mm (0.020 in.)

- SST

- 09333-00013

|